Professional Documents

Culture Documents

EHS Risk Assessment - 3. Pole Erection

Uploaded by

shamshu12386%(7)86% found this document useful (7 votes)

3K views4 pagesThis risk assessment document evaluates hazards associated with pole erection activities. Key risks include:

1) Slip and fall of poles or workers during pole shifting and transportation, with possible leg/arm injuries or being hit by poles. Controls include proper securing of poles, use of flags and channels during movement.

2) Falling during pole lifting, with potential for serious injuries. Controls are use of ladders and securing poles with ropes and channels during erection.

3) Breaking of ropes securing poles, with risk of serious injuries if poles fall. Controls are barricading of work areas, supervision, and keeping people and animals away from poles.

Original Description:

Original Title

EHS Risk Assessment- 3. Pole Erection

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis risk assessment document evaluates hazards associated with pole erection activities. Key risks include:

1) Slip and fall of poles or workers during pole shifting and transportation, with possible leg/arm injuries or being hit by poles. Controls include proper securing of poles, use of flags and channels during movement.

2) Falling during pole lifting, with potential for serious injuries. Controls are use of ladders and securing poles with ropes and channels during erection.

3) Breaking of ropes securing poles, with risk of serious injuries if poles fall. Controls are barricading of work areas, supervision, and keeping people and animals away from poles.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

86%(7)86% found this document useful (7 votes)

3K views4 pagesEHS Risk Assessment - 3. Pole Erection

Uploaded by

shamshu123This risk assessment document evaluates hazards associated with pole erection activities. Key risks include:

1) Slip and fall of poles or workers during pole shifting and transportation, with possible leg/arm injuries or being hit by poles. Controls include proper securing of poles, use of flags and channels during movement.

2) Falling during pole lifting, with potential for serious injuries. Controls are use of ladders and securing poles with ropes and channels during erection.

3) Breaking of ropes securing poles, with risk of serious injuries if poles fall. Controls are barricading of work areas, supervision, and keeping people and animals away from poles.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

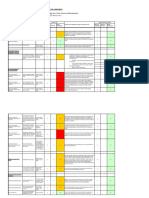

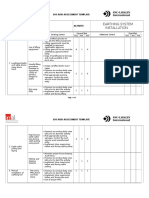

EHS RISK ASSESSMENT

Name Of Activity: Pole Erection Date: 2/04/2016

Hazard

evolving Possible Risk / Hierarchy

Hazard / Residual

Sl Normal / Outcome Probability Severity Impact Existing Control Measures Control of

Activity Environment Risk / Action By

No Abnormal / Rating Rating Level Risk E/ S/

Aspect Impact

Emergency EC/ AC/

Situation PPE

1 Pole

Erection

11manpower shall be

deployed for pole

erection(8.5mts).

Manual pole shifting

Mechanism Must be used.

Pole shall not be dragged by

tractor.

If pole shifting is being done

by tractor &

Trolley, pole & workmen

shall not be transported in

the same vehicle. Site

Shifting of Slip & Fall of Abnormal Leg/Arm Pole shall be properly tied Engineer &

1.1 pole at Pole 3 3 M AC L

Injury/ Hit with the trolley to prevent Site

location Pole damage by pole any slip of pole from tractor Supervisor

while transportation.

Red Flag shall be tied with

the project part of pole

during transportation.

Pole shall not be dashed

from trolley to ground.

Channel or sufficient man

power shall be used for

unloading the pole from

trolley.

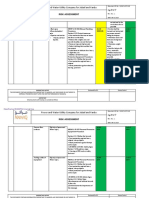

1.2 Lifting of Site

Pole A MS pipe/Bamboo ladder of AC Engineer &

2 mts & 4Mtr height should Site

be provided for initial Supervisor

3 4 M supporting of pole erection.

Ensure that bamboo ladder

tense with slings at top & AC

bottom corner to ensure the L

stability of runners & ladder.

Tie the pole by PP rope at

the height of 6 mtr from the

bottom. Pole shall be

supported by 25mm dia (25

Meter length) PP Rope from

4 corners (Guy rope

S

arrangement).

.Avoid children to come near

the work place

Check the condition of PP

Abnormal Serious rope.

Slip & Fall Injury on MS channel (ISMC-150 of 2

either mtr length) shall be placed in

human, the pole pit (opposite to the

animals or pole base).

equipment. Nobody shall stand on the

pole end as dead weight.

All the area shall be

Abnormal Serious barricaded with safety cone

Injury & safety caution tape before

start of pole erection where

residential area available or EC

road crossing. Site

Breaking of Ensure that no one shall Engineer &

3 4 M

pole come in the vicinity of pole Site

(to avoid accident in case of Supervisor

breaking of guy rope). AC L

Must avoid children/animals

near the workplace.

Must ensure the full time

supervision during work.

PP ropes shall be removed

from the pole top by using EC Site

Removing Slip & Fall L

Abnormal Serious the FRP Ladder/ Pole Engineer &

the rope (during 3 3 M

1.3 Injury climbing paddle. Site

from Pole Climbing)

Direct climbing must be Supervisor

prohibited.

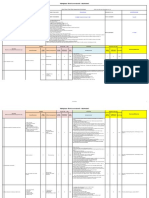

1.4 Pole Fall of Pole 3 5 H Only authorized operator Site

Erection by (Valid DL) shall be allow Engineer &

Tractor operate the crane. AC Site

Ensure prohibition of mobile L

phone use by the crane

Single & operator & Signal man.

Abnormal Multiple Before staring work, crane

Fatality Inspection must be Supervisor

important. EC

Check all the lifting tools &

tackles.

Crane fitness certificate shall AC

be available and Crane hook Site

having hook latch, over load, L Engineer &

Failure of Abnormal Single & 3 5 H over hoist limit switch & Site

Crane Multiple boom limit switch are EC Supervisor

Fatality provided & checked for its

machine function.

Ensure the Tag line to

Site

Single & control the load & instruct

Hit by the L Engineer &

Abnormal Multiple 3 5 H the workmen to keep away EC

pole Site

Fatality from front tire

Supervisor

.

The

movement of Where residential area or

Trespassers / crowed available. There

Vehicle may must be caution required Site

Abnormal Serious Barricaded the area or EC L

Cause Engineer &

injury 2 4 M inform the people about the

danger. (In Site

very few work work associated hazard. Supervisor

location this

problem may

arise).

_____________________

PM Safety Officer

E=Elimination

S=Substitution

EC=Engineering controls

AC=Administrative controls

PPE=Personal Protective Equipment

You might also like

- 007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationDocument5 pages007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationJahan Zaib50% (2)

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq80% (5)

- Risk Assessment For Mobilization Works DCP 3Document4 pagesRisk Assessment For Mobilization Works DCP 3thomas_196382% (11)

- TRA-Installation of Cathodic ProtectionDocument9 pagesTRA-Installation of Cathodic ProtectionGilbert Gill100% (4)

- Risk Assessment Tower CraneDocument3 pagesRisk Assessment Tower CraneChoubi Choubaca91% (11)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- Risk Assessment Concrete Cutting - 02Document6 pagesRisk Assessment Concrete Cutting - 02kapsarc75% (4)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Generator: P16C / BBR84, Bandar Bukit Raja, Klang, Selangor. 4. GeneratorDocument2 pagesGenerator: P16C / BBR84, Bandar Bukit Raja, Klang, Selangor. 4. GeneratorRafee Pie100% (3)

- Risk Assessment Tower Erection WorkDocument4 pagesRisk Assessment Tower Erection WorkMuhammad Umar67% (6)

- Risk Assessment (Electric Works)Document4 pagesRisk Assessment (Electric Works)Raza Muhammad Soomro100% (3)

- Risk Assessment For Demolition WorksDocument5 pagesRisk Assessment For Demolition Worksappu pocom3100% (2)

- Hazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted CraneDocument1 pageHazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted Cranesaravanan .b90% (10)

- Job Safety Analysis (JSA) Stringing WorkDocument4 pagesJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Porta Cabins Shifting Risk AssessmentDocument8 pagesPorta Cabins Shifting Risk AssessmentAsad Raza100% (3)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- Job Safety Analysis For Highmast ErectionDocument8 pagesJob Safety Analysis For Highmast ErectionSantoshkumar Gupta100% (3)

- Risk Assessment All Activities TLT HIRADocument50 pagesRisk Assessment All Activities TLT HIRAvijay100% (2)

- 2 - Pulling CablesDocument5 pages2 - Pulling CablesAhmed KhaledNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- Risk Assessment Relocation Overhead LineDocument5 pagesRisk Assessment Relocation Overhead Lineghada gattouchNo ratings yet

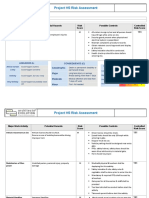

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- 1.4c Drinking Water Cooler Inspection ChecklistDocument1 page1.4c Drinking Water Cooler Inspection ChecklistShafie Zubier100% (3)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- 20 - Roofing WorksDocument2 pages20 - Roofing WorksRafee PieNo ratings yet

- Concrete WorkDocument1 pageConcrete WorkChandruNo ratings yet

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pages(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- Example Risk Assessment For Excavations Updated 21-11-12Document3 pagesExample Risk Assessment For Excavations Updated 21-11-12rishi100% (3)

- 2019 Sitaca - v. - Palomares - Jr.20210424 12 rsvs2dDocument10 pages2019 Sitaca - v. - Palomares - Jr.20210424 12 rsvs2dchan.aNo ratings yet

- Job Safety Analysis Template - BatteryDocument2 pagesJob Safety Analysis Template - Batteryvenkateshbitra63% (8)

- Risk Assessment For Cable Laying and Raceway InstallationDocument15 pagesRisk Assessment For Cable Laying and Raceway Installationmanikandan100% (3)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JSA For Service MaintenanceDocument8 pagesJSA For Service Maintenancemohamed yasinNo ratings yet

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- Risk Analisis Ramming WorksDocument2 pagesRisk Analisis Ramming Worksdefidmsp39No ratings yet

- CISM Study NotesDocument4 pagesCISM Study NotesLa Vita Di Lusso44% (9)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- RISK ASSESSMENT - Tower Crane DraftDocument12 pagesRISK ASSESSMENT - Tower Crane Draftloveson70933% (3)

- EHS Risk Assessment - 6. Conductor StringingDocument5 pagesEHS Risk Assessment - 6. Conductor Stringingshamshu12367% (3)

- WMS-02 - Material Unloading & Shifting by Farana & MannuallyDocument5 pagesWMS-02 - Material Unloading & Shifting by Farana & MannuallySufiyan Khedekar100% (2)

- Kingsbridge Armory Request For Proposals 2011 FF 1 11 12Document54 pagesKingsbridge Armory Request For Proposals 2011 FF 1 11 12xoneill7715No ratings yet

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- Job SatisfactionDocument59 pagesJob SatisfactionMahesh Manda100% (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- EHS Risk Assessment - 5. DTR ErectionDocument2 pagesEHS Risk Assessment - 5. DTR Erectionshamshu123No ratings yet

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- PTW JHA Installation of New Control Panel at WWTPDocument2 pagesPTW JHA Installation of New Control Panel at WWTPPHH9834100% (1)

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- Hira of Pier Revision-02Document5 pagesHira of Pier Revision-02Vipin Kumar Parashar100% (1)

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- OperationDocument5 pagesOperationFILE 1131No ratings yet

- Working at HeightDocument4 pagesWorking at HeightFILE 1131No ratings yet

- Object OvhdDocument1 pageObject Ovhdalex.kollosovNo ratings yet

- Hm70 Mobile Chipset BriefDocument4 pagesHm70 Mobile Chipset BriefUmair Latif KhanNo ratings yet

- MC 10136780 9999Document13 pagesMC 10136780 9999henrysaputra168No ratings yet

- DVC-GBW May 2012 NewsletterDocument7 pagesDVC-GBW May 2012 NewsletterValeria KremserNo ratings yet

- AP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Document34 pagesAP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Leah BatillerNo ratings yet

- Torque Follower Setup Rev 1Document7 pagesTorque Follower Setup Rev 1NelsonNo ratings yet

- Simple Chemistry PBL 2.0 During PKPBDocument4 pagesSimple Chemistry PBL 2.0 During PKPBAryanaNo ratings yet

- Las - Ict 7 - Special Programs - Q4 - Week 5&6Document16 pagesLas - Ict 7 - Special Programs - Q4 - Week 5&6George Mar Bien AriolaNo ratings yet

- MD MDCG 2019 14 MDR Codes enDocument23 pagesMD MDCG 2019 14 MDR Codes enLeilNo ratings yet

- LXM23DU07M3X: Product Data SheetDocument10 pagesLXM23DU07M3X: Product Data SheetAshrafNo ratings yet

- AgaSlots SASDocument3 pagesAgaSlots SASManolo GonzalezNo ratings yet

- 2022-The General Court's Decisions On State Aid Law in Times of COVID-19 PandemicDocument24 pages2022-The General Court's Decisions On State Aid Law in Times of COVID-19 Pandemicllord.zhouNo ratings yet

- Land Transfer FormDocument5 pagesLand Transfer FormKarma WangdiNo ratings yet

- Physics Lab - Detailed - Answer KeyDocument6 pagesPhysics Lab - Detailed - Answer KeyJasdeepSinghNo ratings yet

- Fini Twin Start 2 IngleseDocument5 pagesFini Twin Start 2 InglesesebastianNo ratings yet

- Deed of Absolute Sale-CantilangDocument3 pagesDeed of Absolute Sale-CantilangrodneyNo ratings yet

- Marketing 3rd Quarter ReviewerDocument10 pagesMarketing 3rd Quarter ReviewerJohn Cris BuanNo ratings yet

- QuizletDocument2 pagesQuizletJaceNo ratings yet

- Tech Trend Radar 2023 PresentationDocument189 pagesTech Trend Radar 2023 Presentationcb0rgNo ratings yet

- Bluman 5th - Chapter 8 HW Soln For My ClassDocument11 pagesBluman 5th - Chapter 8 HW Soln For My Classbill power100% (1)

- Bug Bounty Course ContentDocument5 pagesBug Bounty Course ContentJdjdjdjdjNo ratings yet

- Effect of Industrial Effluents On StreamsDocument13 pagesEffect of Industrial Effluents On StreamsHarsha OjhaNo ratings yet

- BENGUET A TOUR ITINERARY PROPOSAL-1Document7 pagesBENGUET A TOUR ITINERARY PROPOSAL-1Jupiter MercaderoNo ratings yet

- William Allan Kritsonis, PHDDocument5 pagesWilliam Allan Kritsonis, PHDWilliam Allan Kritsonis, PhDNo ratings yet

- Xc6o Cem Pinout Yr.09Document11 pagesXc6o Cem Pinout Yr.09TomášShishamanNo ratings yet

- DocumentsDocument135 pagesDocumentsupsc.bengalNo ratings yet

- Divya CVDocument3 pagesDivya CVAman mehraNo ratings yet