Professional Documents

Culture Documents

Disassembly and Assembly General Assembly

Uploaded by

ale ale0 ratings0% found this document useful (0 votes)

14 views1 pageThe document provides instructions for disassembling and assembling a general assembly. It describes tightening the main cap mounting bolts in three steps, either using a tool G or manually, to specified torques. It also notes to check that the crankshaft rotates smoothly after assembly and measure the end play to ensure it is within standards.

Original Description:

Original Title

torques wa470

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides instructions for disassembling and assembling a general assembly. It describes tightening the main cap mounting bolts in three steps, either using a tool G or manually, to specified torques. It also notes to check that the crankshaft rotates smoothly after assembly and measure the end play to ensure it is within standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageDisassembly and Assembly General Assembly

Uploaded by

ale aleThe document provides instructions for disassembling and assembling a general assembly. It describes tightening the main cap mounting bolts in three steps, either using a tool G or manually, to specified torques. It also notes to check that the crankshaft rotates smoothly after assembly and measure the end play to ensure it is within standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

DISASSEMBLY AND ASSEMBLY GENERAL ASSEMBLY

•When using tool G to tighten the main cap

mounting bolts

3 Main cap mounting bolt

1st step: Tighten to

98.1 ± 9.8 Nm {10.0 ± 1.0 kgm}

2nd step:Tighten again to

196.1 ± 4.9 Nm {20.0 ± 0.5 kgm}

3rd step: 90° +30°

0

i) Tighten mounting bolts to second stage

with torque wrench or tool G.

ii) With tool G set to mounting bolt, install

tube and clip to tool G, then set clip to

engine block.

iii) Set scale angle of tool G to 90°, then

tighten until scale reads 0°.

• When not using tool G

3 Main cap mounting bolt

1st step: Tighten to

98.1 ± 9.8 Nm {10.0 ± 1.0 kgm}

2nd step:Tighten again to

196.1 ± 4.9 Nm {20.0 ± 0.5 kgm}

3rd step: Mark bolt and cap with felt-tip pen,

then tighten bolt 90° +30°

0

• With the above procedure, use a torque

wrench to tighten the mounting bolts.

11) After tightening the bolts, rotate the crank-

shaft and check that it rotates smoothly.

12) Measure end play of the crankshaft with dial

gauge . If it is outside the standard value,

take actions according to the maintenance

standard.

★ End play: 0.14 – 0.315 mm

13-56 125-3 SERIES

1

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Specifications Culender Head 3512 CatDocument16 pagesSpecifications Culender Head 3512 CatAngel Theran Pardo75% (4)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Timing Manual Galant ST v6!24!1998 2005 PDFDocument8 pagesTiming Manual Galant ST v6!24!1998 2005 PDFArya RamadhanNo ratings yet

- Tugas Diferensial PDFDocument3 pagesTugas Diferensial PDFBgas StwnNo ratings yet

- Motor 4D56 Series PDFDocument45 pagesMotor 4D56 Series PDFMario RogersNo ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- CoroMill 425 92023Document41 pagesCoroMill 425 92023Nelson SanchezNo ratings yet

- Spect Torque Cat 320DDocument5 pagesSpect Torque Cat 320DlilikNo ratings yet

- Procedure For Backlash Adjusting On Slewing Ring To PitchDocument3 pagesProcedure For Backlash Adjusting On Slewing Ring To PitchVasanth KumarNo ratings yet

- Group 10 TransmissionDocument54 pagesGroup 10 TransmissionDado OgameNo ratings yet

- 1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Document11 pages1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Marco100% (3)

- Hg-Tqj100 Adjustable One Way T O R Q U E H I N G E Installation InstructionsDocument1 pageHg-Tqj100 Adjustable One Way T O R Q U E H I N G E Installation InstructionsSarinNo ratings yet

- (Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocument170 pages(Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIAngelo RuedaNo ratings yet

- Industrial Series HDX ModelsDocument3 pagesIndustrial Series HDX Modelskuhn403825No ratings yet

- Piaggio Hiper ProDocument30 pagesPiaggio Hiper PropanandriyNo ratings yet

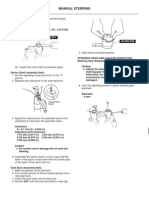

- Manual Steering: Adjusting ShimDocument1 pageManual Steering: Adjusting Shimpavel35No ratings yet

- Clutch: Click On The Applicable Bookmark To Selected The Required Model YearDocument7 pagesClutch: Click On The Applicable Bookmark To Selected The Required Model YearhafizinnaimNo ratings yet

- 03.0-310 Checking and Tightening Connecting Rod BoltsDocument2 pages03.0-310 Checking and Tightening Connecting Rod BoltsSchmiernippel OskarNo ratings yet

- VDL Service ManualDocument13 pagesVDL Service ManualSergio Martín BrionesNo ratings yet

- Group 3 Tests and Adjustments Group 3 Tests and AdjustmentsDocument15 pagesGroup 3 Tests and Adjustments Group 3 Tests and AdjustmentsGlaitonNo ratings yet

- Motor5 Suzuki VL800Document10 pagesMotor5 Suzuki VL800Crisan SorinNo ratings yet

- DR 6 Spec 2Document24 pagesDR 6 Spec 2kaswade Brian100% (1)

- Group 3 Tests and Adjustments Group 3 Tests and AdjustmentsDocument16 pagesGroup 3 Tests and Adjustments Group 3 Tests and AdjustmentsKadir Koray BozyelNo ratings yet

- Spect Torque Cat 320DDocument8 pagesSpect Torque Cat 320Dlilik100% (2)

- Inplant Training ReportDocument56 pagesInplant Training Reportsankey11286No ratings yet

- Point SheaveDocument2 pagesPoint SheaveGilney FreitasNo ratings yet

- MITICSDocument748 pagesMITICSfersky100% (5)

- Nissan Almera n16 2001 Electronic Repair Manual 200Document1 pageNissan Almera n16 2001 Electronic Repair Manual 200netifig352No ratings yet

- TTR125 150BigBore Update2Document4 pagesTTR125 150BigBore Update2eddielindermannNo ratings yet

- 6-3.presiones de Trabajo.Document16 pages6-3.presiones de Trabajo.Jeison BarradasNo ratings yet

- 1B Engine Mechanical (4JJ1 Without DPD) PDFDocument762 pages1B Engine Mechanical (4JJ1 Without DPD) PDFPatricio ValenciaNo ratings yet

- Onrobot Gripper Datasheet 3FG15 v1.4 ENDocument11 pagesOnrobot Gripper Datasheet 3FG15 v1.4 ENALSAMAD V MNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- 626 e 3 CCB 56164Document2 pages626 e 3 CCB 56164MohamedHussein MohamedHusseinNo ratings yet

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

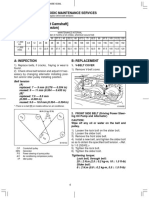

- Drive Belt(s) (Except Camshaft) (Inspect Drive Belt Tension)Document2 pagesDrive Belt(s) (Except Camshaft) (Inspect Drive Belt Tension)Anton FortovNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- Inspection Procedure: 1. Inspect No. 1 Valve Rocker Arm Sub-AssemblyDocument12 pagesInspection Procedure: 1. Inspect No. 1 Valve Rocker Arm Sub-AssemblyDTC CODENo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- FR20 3 Chassis Partie3 enDocument30 pagesFR20 3 Chassis Partie3 enEdmond MarkovitsNo ratings yet

- KGE1000Ti Service ManualDocument41 pagesKGE1000Ti Service Manualmarksmods100% (1)

- Valve Adjustment Procedure - Tier 3Document3 pagesValve Adjustment Procedure - Tier 3ကျော်မျိုး လွင်No ratings yet

- 8920A360 - New Holland 7740 TractorDocument13 pages8920A360 - New Holland 7740 TractorBaytolgaNo ratings yet

- Acoples TramecDocument26 pagesAcoples TramecAndres ValderramaNo ratings yet

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- Manual - Tong XQ2.6Document19 pagesManual - Tong XQ2.6yury1102No ratings yet

- 12M Montagem Freio de ServiçoDocument10 pages12M Montagem Freio de ServiçoPaulo_GleriaNo ratings yet

- Fig. 1: Lab Vane Shear ApparatusDocument2 pagesFig. 1: Lab Vane Shear ApparatusKishanNo ratings yet

- SI1129D Alternator Belt Tension, Methods of CheckingDocument2 pagesSI1129D Alternator Belt Tension, Methods of CheckingNickNo ratings yet

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 pageDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanNo ratings yet

- Perno CulataDocument1 pagePerno Culatasergio conchaNo ratings yet

- Main Control Valve Especificações 320D and 323D ExcavatorsDocument17 pagesMain Control Valve Especificações 320D and 323D Excavatorsdaniel lacerdaNo ratings yet

- Pont DifferentielDocument8 pagesPont DifferentielOthmanNo ratings yet

- Torquímetro MastercoolDocument8 pagesTorquímetro MastercooljokekaNo ratings yet

- Especificaciones de Apriete para Excavadora CAT 320DLDocument6 pagesEspecificaciones de Apriete para Excavadora CAT 320DLAlex JordánNo ratings yet

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainDocument23 pages938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleNo ratings yet

- Velocidad de Cilindros - Boom-Stick-Balde 314C KJADocument5 pagesVelocidad de Cilindros - Boom-Stick-Balde 314C KJAale aleNo ratings yet

- Failure Code (DXA0KA) PC-EPC Sol Open Circuit: SEN01887-02 40 TroubleshootingDocument2 pagesFailure Code (DXA0KA) PC-EPC Sol Open Circuit: SEN01887-02 40 Troubleshootingale aleNo ratings yet

- MT 575B TECHstar CVT Powered by CAT Tier3 (3906118m3)Document447 pagesMT 575B TECHstar CVT Powered by CAT Tier3 (3906118m3)ale aleNo ratings yet

- XH250 Start Up & TrackingDocument53 pagesXH250 Start Up & Trackingale ale100% (1)

- 950F Prueba y Ajuste Transmision Sistema ElectricoDocument38 pages950F Prueba y Ajuste Transmision Sistema Electricoale aleNo ratings yet

- Wb97-5E0 Outrigger Hydraulic Piping (Con Valvula de Alivio)Document2 pagesWb97-5E0 Outrigger Hydraulic Piping (Con Valvula de Alivio)ale aleNo ratings yet