Professional Documents

Culture Documents

GLPM Mi 10991790en

Uploaded by

Anton LyakhovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GLPM Mi 10991790en

Uploaded by

Anton LyakhovCopyright:

Available Formats

ü ü

SELL TECH WORK CUST USER

* 1 0 9 9 1 7 9 0 EN *

English ORIGINAL INSTRUCTIONS

MI GREENLIFT GLT

INSTALLATION

MANUAL

GREEN LIFT SYSTEM

GLT Σ WITH PERMANENT MAGNETS

FOR SYSTEMS:

q GLT Σ (GLPM MRL 1:1)

q GLT Σ (GLPM MRL 2:1)

SYSTEM N° INSTALLER

GMV SPA UNI EN ISO 9001 2.00

FLUID DYNAMIC EQUIPMENTS Certified Company

AND LIFT COMPONENTS

ENG

ENG SYSTEMS GLT Σ - GLPM

2 / 36 INSTALLATION MANUAL

INDEX

0 GENERAL INFORMATIONS 5

0.1 INTRODUCTION 5

0.1.1 DEFINITIONS 5

0.1.2 MAIN STANDARDS OF REFERENCE 5

0.1.1 TERMS AND SYMBOLS USED 6

0.1.2 DOCUMENTS RELATED WITH INSTALLATION 6

0.2 SAFETY PRECAUTION DURING INSTALLATION 6

0.3 PRELIMINARY OPERATIONS 7

0.3.1 INSTALLATION PROCEDURES 7

0.3.2 DIMENSIONS CONFORMITY 7

0.3.3 MATERIALS OFF LOADING AND STORAGE 7

0.3.1 TOOLING 7

0.3.2 SCAFFOLDING 7

1 WELL MATERIAL 8

1.1 ANCHORING 8

1.1.1 PLUMBING 8

1.1.2 BRACKETS 8

1.1.2.1 FIXING WITH ANCHORS 9

1.1.2.2 FIXING WITH HALFEN 9

1.1.2.3 FIXING IN WALL 9

1.1.2.4 OTHER FIXINGS 9

1.2 BOLTS, SCREWS AND ANCHORS 10

1.2.1 ANCHORS AND HALFEN 10

1.2.2 TIGHTENING TORQUES 10

1.2.3 TIGHTENING TORQUES FOR OTHER SYSTEMS BOLTS 10

1.3 GUIDE RAILS 11

2 SLING 12

2.1 SLINGS MRL 1:1 12

2.1.1 FRAME FOR MACHINE, COUNTERWEIGHT AND ACCESSORIES 13

2.2 SLINGS MRL 2:1 14

2.2.1 FRAME FOR MACHINE, COUNTERWEIGHT AND ACCESSORIES 15

2.3 SHOES ADJUSTMENT 16

2.4 SLING LIFTING AND PEDESTAL INSTALLATION 16

2.4.1 PEDESTAL LENGTH 17

2.5 LOAD WEIGHTING DEVICE AND CAR BOTTOM 17

2.6 DRIVING LEVERS OF THE SAFETY DEVICES 18

2.7 WEIGHTS OF THE MAIN COMPONENTS 18

3 TRACTION MACHINE AND ROPES 19

3.1 T RACTION MACHINE 19

3.1.1 ROPES LAYING 19

3.2 ROPES 19

3.2.1 ROPING OF THE SYSTEM 1:1 19

3.2.2 ROPING OF THE SYSTEM 2:1 20

3.2.3 TENSIONING OF THE SYSTEM 22

3.3 FINAL OPERATIONS ON THE SLING 22

3.3.1 POSITION OF THE FINAL LIMIT SWITCH 22

3.4 SPEED GOVERNOR 23

3.5 CHECKS 23

3.5.1 CHECKS FOR STNDARD SYSTEMS 23

4 CAR AND DOOR OPERATOR 24

5 LANDING DOORS 24

6 ELECTRICAL MATERIAL 24

6.1 WELL AND MACHINERY ROOM 24

6.1.1 INSTALLATION OF THE CONTROL PANEL OUTSIDE THE WELL 24

6.1.2 WELL ELECTRICAL LINES 24

6.1.2.1 TRUNKS 24

6.1.2.2 FLEXIBLE CABLES 25

6.1.2.3 CONNECTION CABLES 25

6.1.2.4 ELECTRICAL CONNECTIONS 25

6.2 T RACTION MACHINE 25

6.3 SLING AND ROPES 26

6.3.1 FINAL LIMIT ELECTRICAL SWITCH 26

6.3.2 SAFETY ELECTRICAL SWITCH (SAFETY GEAR/RELEASING ROPES) 26

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 3 / 36

6.3.3 SAFETY ELECTRICAL SWITCHES (SPEED GOVERNOR) 26

6.3.4 ELECTRICAL SWITCHES AND WELL INFO 27

6.4 CAR AND DOOR OPERATOR 27

6.4.1 CAR OPERATING PANEL 27

6.4.2 COLLEGAMENTI SU TETTO CABINA 27

6.4.3 DOOR OPERATOR AND DOOR SWITCH 27

6.5 LANDING DOORS 27

6.5.1 PUSH-BUTTON PANELS 27

6.5.2 SAFETY SWITCHES 27

6.6 ACCESSORIES 28

6.6.1 CONNECTION OF THE WELL LIGHTING 28

6.6.1.1 W ELL LIGHTING 28

6.7 DEVICES 28

6.7.1 SAFETY SWITCHES OF THE DEVICES 28

7 DEVICES AND PROCEDURES FOR GLPM SYSTEM 29

7.1 DEVICES FOR MRL 29

7.1.1 WORKING AREA IN WELL 29

7.1.1.1 U PPER CAR STOP MECHANICAL DEVICE (UCSMD) 29

7.1.1.2 RIGHT POSITION OF THE DEVICE 29

7.1.2 LOCK DEVICE FOR DOOR OPERATOR AND DOORS 2AT 31

7.1.2.1 LOCK DEVICE - DOOR OPERATOR 2AT 31

7.1.2.2 LOCK DEVICE - LANDING DOOR 2AT 32

7.1.3 OTHER DEVICES 32

7.1.3.1 UNLOCKING TRIANGLE WITH ELETRICAL SAFETY SWITCH 32

7.2 NOTICES, MARKINGS AND OPERATING INSTRUCTION 32

8 EXAMINATIONS AND TESTS 33

9 FINAL OPERATIONS 33

9.1 ADVICES 33

9.2 FINAL OPERATIONS 33

REV

25.05.2018 2.00 update to EN81-20

DT GG DT AM

All rights reserved.

ENG Any kind of reproduction, even partial, of this document is forbidden without written permission from GMV Spa

GMV Spa reserves the right to alter the product or this document, partially or entirely without any prior notice in the event of any

technical, construction or production improvements.

The drawings, descriptions and technical characteristics given in this document are purely for indication purposes.

For any data that is not given in this document, reference should be made to the documentation attached to each component.

To guarantee the constant safety of the product, only original parts or spares should be used, unless they are approved by GMV

Spa beforehand.

GMV Spa accepts no responsibility in the event the instructions given herein are not adhered to.

Information and support :

FLUID DYNAMIC EQUIPMENTS UNI EN ISO 9001

AND LIFT COMPONENTS CERTIFIED COMPANY

GMV SPA

VIA DON GNOCCHI, 10 - 20016 PERO - MILANO (ITALY) - TEL. +39 02 33930.1 - FAX +39 02 3390379 - E-MAIL: INFO@GMV.IT

VIA PER BIANDRATE, 110/112 – 28100 NOVARA (ITALY) – TEL. +39 0321 677 611 – FAX +39 0321 677690 - E-MAIL: INFO@GMV.IT

Please visit www.gmv.it to check for

any updated versions of this document or further information about GMV products

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

4 / 36 INSTALLATION MANUAL

MAIN DATA OF THE SYSTEM

P K

GMV PK N° SYSTEM REF.

S/N OF THE CONTROL PANEL

SYSTEM TYPE

GLT Σ ™ MRL ™ 1:1 ™ 2:1

WELL TYPE

REDUCED REDUCED REDUCED PIT

STD

™ EN81-20 ™ HEADROOM ™ PIT ™ AND HEADROOM

TR EN81-21 FR EN81-21 TFR EN81-21

MANOEUVRE

AUTOMATIC PUSH BUTTON (APB) HOLD TO RUN (SOLO HLDM)

™ ™

DOWN COLLECTIVE FULL COLLECTIVE

™ ™

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 5 / 36

0 GENERAL INFORMATIONS

0.1 INTRODUCTION

0.1.1 DEFINITIONS

The definitions are used in this manual as indicated in the following standards and regulations

EN81-20 e EN81-50 Safety regulations for the construction and installation of lifts

UNI EN ISO 14798 Lifts (elevators), escalators and mobile walkways

– Risks assessment and reduction methodology

UNI EN ISO 7010 Graphic symbols: Safety signs and colours

EN12016 e EN12015 Electromagnetic compatibility

CEI EN 61439-1 Low voltage switchgear and control gear assemblies (LV control panels)

0.1.2 MAIN STANDARDS OF REFERENCE

For anything that is not expressly given in this manual, reference should be made to the local standards and

regulations in force, observing in particular:

Directive 2006/42/CE Machine Directive – in relation to machines, and amending Directive 95/16/CE (recast)

Directive 2014/33/UE Lifts Directive - on the harmonisation of the laws of the Member States relating to lifts and safety

components for lifts

Directive 2014/35/CE Low Voltage Directive – on the harmonisation of the laws of the Member States relating to the

making available on the market of electrical equipment designed for use within certain voltage limits

Directive 2004/108/CE Electromagnetic Compatibility Directive (EMC) – approximation of laws in member States

regarding electromagnetic compatibility, and repealing Directive 89/336/CEE

Safety regulations for the construction and installation of lifts

Rules EN-81 complete series Refer to the complete series and, in particular to:

EN 81-20 Safety rules for the construction and installation of lifts – Lift for the transport of persons and

goods - Part 20: Passengers and goods passenger lifts

EN 81-50 Safety rules for the construction and installation of lifts – Examinations and tests - Part 50: Design

rules, calculations, examinations and tests of lift components

EN 81-41 Safety regulations for the construction and installation of lifts

– Special lifts for the transport of persons and goods

– Part 41: Vertical lifting platforms for use by persons with impaired mobility

EN 81-58 Safety regulations for the construction and installation of lifts – Examinations and tests

– Part 58: Landing door fire resistance test

EN 81-70 Safety regulations for the construction and installation of lifts

– Particular applications for lifts for the transport of persons and goods

- Part 70: Accessibility to lifts for persons, including persons with disabilities

CEI EN 60439-1 Low voltage switchgear and control gear assemblies (LV control panels)

Part 1: Type tested assemblies (AS) and partially type tested assemblies (ANS)

EN 12015 Electromagnetic compatibility – Product family standard for lifts, escalators and moving walkways

– Emission

EN 12016 Electromagnetic compatibility – Product family standard for lifts, escalators and moving walkways

– Immunity

EN 12183 Manual wheelchairs: Requirements and test methods

EN 12184 Electrically powered wheelchairs, scooters and their chargers

― Requirements and test methods

UNI EN 12385-3 Steel wire ropes – Safety – Part 3: Information for their use and maintenance

UNI EN 12385-5 Steel wire ropes – Safety – Part 5: Stranded ropes for lifts

UNI EN 13015 Maintenance for lifts and escalators: Rules for maintenance instructions

EN 13411-6+A1 Terminations for steel wire ropes – Safety

– Part 6: Asymmetric wedge sockets

EN 13411-7+A1 Terminations for steel wire ropes – Safety

– Part 7: Asymmetric wedge sockets

UNI EN ISO 7010 Graphic symbols – Safety signs and colours – Registered safety signs

UNI EN ISO 13857 Machine safety – Safety distance to avoid access to dangerous areas with arms or legs

UNI EN ISO 14121-1 Machine safety – Risks assessment – Part 1: Principles

UNI EN ISO 12100 Safety of machinery - General principles for design - Risk assessment and risk reduction

UNI EN ISO 14798 Lifts (elevators), escalators and mobile walkways

– Risks assessment and reduction methodology

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

6 / 36 INSTALLATION MANUAL

0.1.1 TERMS AND SYMBOLS USED

NOTE

Gives information of particular importance.

ATTENTION

A warning that the described operation could cause damage to the system or physical injury, even

serious, if the safety rules are not observed.

NOTE

Correct work. The normal use of the lift is possible

To make installation operations is possible

NOTA

The normal use of the lift is NOT

Wrong work.

possible

To make installation operations is NOT possible

ABBREVIAZIONI

MRL Machine Room Less (Control panel inside well) TR Reduced headroom FR Reduced pit

MRL2 Machine Room Less (Control panel outside well) TFR Reduced headroom and pit

0.1.2 DOCUMENTS RELATED WITH INSTALLATION

This is the documentation to be used for the installation of a complete lift:

>100

>130>150

Vano - Well

Sx I ngombr o Tela i - Fr ames Dx

INSTRUCTION RELATED TO INSTRUCTION RELATED TO

Test at a- H eadr oom

Ingo mbr o tel ai- Fr am esH eight

luce por te- openi ng door s

M ur o-G uida - Wal l- Gui de

Vano - Well

Int er noC abina - I nside Car

LIFT PROJECT DRAWING

Int er noC abi na- I nsi deC ar

Mur o- Gu ida - Wall -G ui de

W INCH AND BRAKE

Dt g- Dbg

V ano - Well

Cor sa - Tr avel

THE SAFETY GEAR

Fo ssa- P it

l ce por te c- l ear ent rance

u

I ngombr o Tela i - Fr ames

Sx Dx

INSTRUCTION RELATED TO

INSTRUCTION RELATED TO INSTRUCTION RELATED TO

DOOR OPERATOR, CAR

SLING AND ROPES THE CAR

AND LANDING DOORS

INSTRUCTION AND INSTRUCTION RELATED TO

DIAGRAMS OF THE SPEED GOVERNOR AND

THIS MANUAL

ELECTRICAL PART AND ADDITIONAL OR

THE CONTROL PANEL OPTIONAL COMPONENTS

All the documentation for a correct and safe installation of the lift, must be stored by the installation responsible.

Please remember that this documentation is considered part of the plant and must be complete, well stored

and unabridged in every part.

In order to maintain the readability, the documentation shouldn’t be damaged and shouldn’t have missing

parts. Moreover, do not tear or deteriorate sheets during consulting.

0.2 SAFETY PRECAUTION DURING INSTALLATION

During installation and maintenance, it is compulsory to observe the applicable national safety standards for

the workplaces

ATTENTION - Before beginning any of the installation operations, ALWAYS check that all the

mechanical and electrical safety devices are, turned on and in perfect working order.

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 7 / 36

0.3 PRELIMINARY OPERATIONS

0.3.1 INSTALLATION PROCEDURES

Before the installation please verify the following items:

q Adequate lighting in the lift well.

q Cleaning conditions of the well and the pit waterproofing.

q The electrical equipment must be adequately grounded (otherwise stop the installation until the ground

wire is correctly connected)

q The entrance to the well are closed

q Verify that is possible to introduce the components into the well and also the adequate lifting devices.

q The accesses to the machine room can be safely used in any moment (EN81-20 §5.2.2.5), both in the

prefab machine room and in the machine room cabinet.

q The accesses to the machine room should be adequately lighted (EN81-20 §5.2.2). Particularly as

concerns the machine room cabinet, the lighting in the working area, limited by the open swing panels

and by a chain, should comply with EN81-20 §5.2.1.4.2.

q The cabinet can be positioned according to the LIFT PROJECT DRAWING in an environment protected

against bad weather.

q Prepare a material storage area near the well, easily accessible by the installation personnel and

protected against bad weather.

q Verify that all grooves and the holes for the electrical cable are free, accessible and smooth.

q Verify there is an air vent in the lift well.

0.3.2 DIMENSIONS CONFORMITY

Perform the following check before starting the installation of the plant, verify that the measures are

according with the project drawing, particularly pay attention to:

q Width of the well (distance between the side panels). q Dimensions and characteristics of the winch.

q Length of the well (distance between front and rear q Length of the pedestals

panel). q Car frame DBG (distance between guides).

q Depth of the pit. q Distance between well and Machine room.

q Travel height. q Recesses for the landing doors

q Height of the headroom. q Indicate the level of the finished floor, inside

q Verticality of the well. the lift well, at each landing station.

0.3.3 MATERIALS OFF LOADING AND STORAGE

q Using the packing list as reference verify that all materials received are those ordered and are complete.

q Check the condition of all components and materials upon reception at the building yard, to verify if any

damage occurred during transport; immediately inform GMV Spa in case any part is missing or in case of

damage.

q Store the electrical and electronic components in a cool and dry place in their original packages

q If, for any reason, it were not possible to install the plant immediately, periodically check the stored

components to prevent possible damages due to a prolonged storage in bad conditions.

q Check if the documentation related to the plant is enclosed.

q Pay particular attention when off-loading the guide rails

0.3.1 TOOLING

No special tools are required unless expressly provided by component manufacturers supplied by third parties.

In this case, the related features and operating instructions are indicated in the manuals supplied with them.

0.3.2 SCAFFOLDING

Use regular scaffolding for the installation.

The scaffolding must have work landing at each landing station, at least at 0,5 m under the floor level of the

landing station.

ATTENTION

The scaffolding, if entirely or partly composed by metal structures, should be grounded and comply

with the safety standards.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

8 / 36 INSTALLATION MANUAL

1 WELL MATERIAL

NOTE

The oil collecting tray Is NOT supplied with the mechanical part but is inside the

sling packaging.

1.1 ANCHORING

1.1.1 PLUMBING

For a correct plumbing, refer to the following instructions

and to the images

Lower the plumb lines for the doors and for the guide rails

- Verify if the plan and vertical dimensions of the well comply

with the project drawing

- Highlight possible structural differences in the panels

plumbing.

Set the control templates to verify the distance between guides.

1.1.2 BRACKETS

If not contrary to the specific instructions of the materials supplied, for a correct and safe installation of the

brackets please refer to the following procedure:

hef

L do h(min)

df [mm] [mm] [mm]

min

[mm]

M10 90 10 80 60

M12 100 12 95 70

M16 145 16 135 85

DTG = dimension show on layout

DAG = dimension show on layout

Y <= dimension show on layout

G S Pd Ps

T82/A

68,25 10 5/10 = Pd

T82/B

T90/A

75 10 5/10 = Pd

T90/B

T125/B 82 10 5/10 = Pd

Set the brackets on the well panels taking the

plumbing as reference. B C

Drill the wall and install the brackets starting A D

from the bottom with the supplied fixing

material (dowels and bolts). A // B // C // D

Mount the brackets taking as a reference the positions indicated on the project drawing of the plant.

Mount the counter-bracket using the related fixing material.

Se non in contrasto con le istruzioni specifiche del materiale fornito, per una corretta e sicura installazione

delle staffe fare riferimento alla seguente procedura:

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 9 / 36

CTP

ST/1B

T 50

CAR

T 82

T 90

T125

1.1.2.1 FIXING WITH ANCHORS

1.1.2.2 FIXING WITH HALFEN

1.1.2.3 FIXING IN WALL

Make some holes, sufficiently wide to insert the brackets in the wall, in the position, showed on the layout,

where you should fix them.

Install the guides in the correct position as shown on the layout fixing them temporarily to the well or to the scaffolding

Place the brackets in the holes fixing them to the guides using their counter-brackets, paying attention to

leave a distance for adjustment.

Fix the brackets in the wall using pieces of bricks and cement paying attention to do not move the guide from

their position.

When the cement become dry verify that the guides are parallel and in the position shown on layout. If the

guides are not in the needed position move them to the correct placement.

1.1.2.4 OTHER FIXINGS

If you have another type of fixing, please refer to the instructions of the manufacturer.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

10 / 36 INSTALLATION MANUAL

1.2 BOLTS, SCREWS AND ANCHORS

1.2.1 ANCHORS AND HALFEN

Tensile Minimum Min distance

Cut resistance

Type Class strength distance from the

VRk,s [kN]

NRk,p [kN] [mm] edge [mm]

M10 x 90 5.8 9,00 16,65 180 90

M12 x 100 5.8 23,55 26,10 210 105

M16 x 125 5.8 31,00 47,40 255 130

M16 x 50 4.6 31,40 22,60 80 -

1.2.2 TIGHTENING TORQUES

T45/A T82/A T90/A

T125/B

T50/A T82/B T90/B

[Nm] [Nm] [Nm] [Nm]

M10x90 M12x100 M12x100

30 50 50

5.8 5.8 5.8

M12x100 M16x125 M16x125

50 100 100

5.8 5.8 5.8

M16x50 M16x50 M16x50 M16x50

60 60 60 60

4.6 4.6 4.6 4.6

M8 M12 M12

27 92 92

8.8 M12 8.8 8.8

92

M10 8.8 M16 M16

53 232 232

8.8 8.8 8.8

T1 T2 T3 T4

21 36 58 88

(M10) (M12) (M14) (M16)

M8 M12 M12 M16

27 92 92 232

8.8 8.8 8.8 8.8

1.2.3 TIGHTENING TORQUES FOR OTHER SYSTEMS BOLTS

Friction coefficient = 0,15

CLASS M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24

5.8 0,8 1,83 3,62 6,2 15,2 30 52 83 130 179 254 438

8.8 1,21 2,78 5,5 9,5 23 46 79 127 198 283 402 809

CLASS M27 M30 M32 M36 M38 M41 M46 M50 M55 M60 M65 M70

5.8 649 880 1195 1534 1994 2464 3085 4258 5978 7428 8935 10445

8.8 1201 1628 2216 2840 3697 4554 5712 7888 11075 13785 16572 19359

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 11 / 36

1.3 GUIDE RAILS

If not contrary to the specific instructions of the materials supplied, for a correct and safe installation of the

brackets please refer to the following procedure:

ATTENTION

xm

5.0 m

5.0 m

B C

A D

A // B // C // D

1 2 3

Fix the fishplate to the guide-rails Place the collecting oil tray and the Install the guide rails starting

segments, on the side with the beam, on the bottom of the pit or from the bottom of the pit

“male” connection part. on the pre-set cement base and positioning the “male” part

level it using a bubble level, upwards into the groove.

complying with the indications of Connect the guide-rails

the project drawing. segments using the

connection plate

4 5 6

Mount the counter-bracket using Perform the same procedure to Check the distances referring to

the related fixing material install all guide-rails and the project drawing and verify

brackets. the verticality of the guide-rails

in comparison to the plumbing

and the position template.

7 Tighten all bolts. Clean the guides and lubricate them.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

12 / 36 INSTALLATION MANUAL

2 SLING

ATTENTION

The following instructions refers to parts subject to modifications not dependent by Gmv Spa,

therefore, for a correct and safe installation ALWAYS refer to the instructions provided by the

manufacturer with the component.

ATTENTION

It is recommended to operators to use ALWAYS, seat belts and appropriate

lifting equipment.

2.1 SLINGS MRL 1:1

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 13 / 36

2.1.1 FRAME FOR MACHINE, COUNTERWEIGHT AND ACCESSORIES

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

14 / 36 INSTALLATION MANUAL

2.2 SLINGS MRL 2:1

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 15 / 36

2.2.1 FRAME FOR MACHINE, COUNTERWEIGHT AND ACCESSORIES

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

16 / 36 INSTALLATION MANUAL

2.3 SHOES ADJUSTMENT

• Loose the nut on the internal side of the upright

• Adjust the position of the shoe, turning the

hexagonal eccentric nut (see image).

• Align the car frame to the guide axis

• Tighten the nut on the internal side of the upright

2.4 SLING LIFTING AND PEDESTAL INSTALLATION

1500 kg

50

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 17 / 36

2.4.1 PEDESTAL LENGTH

The buffer pedestal is supplied in a standard length and you must cut it to obtain the required length.

To obtain the correct cutting length of the pedestals please refer to the project drawing and the following

procedure:

Always verify, on project, the following distances:

Std HF [mm]

F (pit) ? • To obtain the correct length use, as shown in

image, the following formula:

P (floor) 80

H= F-P-220-D-A-8

D (distance buffer / car frame) 50

(H Standard = F-441)

A (buffer) 80+3

P

220

A 8

D F

2.5 LOAD WEIGHTING DEVICE AND CAR BOTTOM

Install the load weighting device following the instruction supplied with it and fix the car bottom.

When the load weighting device is connected and working, remember to calibrate end to set the parameters:

PARAMETER

VALUE TO BE SET

Zero

(Zero definition) kg

Weight of the empty car

(auto detected)

Well-known weight

(Calibration)

Weight, introduced in

the car, superior than

50% of the rated load

and exactly known

Complete Load

(Alarm - Notice)

Rated Load

Overload

(Alarm - System Stop)

Load + 10% with a

minimum of 75 kg

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

18 / 36 INSTALLATION MANUAL

2.6 DRIVING LEVERS OF THE SAFETY DEVICES

Adjust the return springs of the safety gear driving levers as shown in figure

~2

mm

~ 5Kg

M10x60

2.7 WEIGHTS OF THE MAIN COMPONENTS

Floor covering

Dimensions Load Bottom Standard Marble Weight Weight

Model Model

[mm] [kg] [kg] [kg] [kg] [kg] [kg]

800x1200 350 46 40 SG22 163

5 4805 130

1000x1300 480 62 50 SG30 193

1100x1400 630 73 60 6305 146 SG40 238

1400x1500 900 100 10 80

1006 300 SG48 298

1100x2110 1025 110 90

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 19 / 36

3 TRACTION MACHINE AND ROPES

ATTENTION

The following instructions refers to parts subject to modifications not dependent by Gmv Spa,

therefore, for a correct and safe installation ALWAYS refer to the instructions provided by the

manufacturer with the component.

3.1 TRACTION MACHINE

Fix the traction machine over the frame for machine located at the top of the guide rails following the

instructions of the traction machine manual.

3.1.1 ROPES LAYING

• Place the middle of the ropes into the grooves of the traction pulley without connecting the ends to the

wire terminals

• Do not remove any protection device.

3.2 ROPES

3.2.1 ROPING OF THE SYSTEM 1:1

For a correct and safe roping of the system, if not differently indicated in the manual of the supplied sling,

refer to the following procedure:

Pass one of the rope end into the wedge socket termination.

Fix the rope with the supplied clamps.

Hook the wedge socket termination to the fixed connection

element of the sling.

Pass the other end of the rope into the wedge socket termination

and fix it with the clamps.

Hook the second wedge socket termination to the ropes

connection on the counterweight frame without weights.

Repeat the same procedure for all ropes with one of the following

sequences.

The rope terminations shall not make noise during the travel of

the lift.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

20 / 36 INSTALLATION MANUAL

10 6 2 3 7 x

8 4 1 5 9 864213579 9 7 5 3 1 2 4 6 8 10

x9 x10

8 4 1 5 9

10 6 2 3 7

Ctp Arcata

3.2.2 ROPING OF THE SYSTEM 2:1

For a correct and safe roping of the system, refer to the following procedure:

Pass one of the rope end into the wedge socket termination.

Fix the rope with the supplied clamps.

Hook the wedge socket termination to the fixed connection

element on the beam of the frame for machine.

Pass the other end of the rope into the wedge socket termination

and fix it with the clamps.

Hook the wedge socket termination to the other side of the fixed

connection element on the beam of the frame for machine.

Repeat the same procedure for all ropes with one of the following

sequence.

The rope terminations shall not make noise during the travel of

the lift.

3 6 6 3 3 6 6 3

4 4 4 4

2 7 7 2 2 7 7 2

5 5 5 5

1 1 1 8 8 1

1357 7531 1357 7531

246 642 2468 8642

76 78

5 56

34 34

12 12

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 21 / 36

4 4 4 4

3 3 3 10 10 3

5 5 5 5

2 9 9 2 2 9 9 2

6 6 6 6

1 8 8 1 1 8 8 1

7 7 7 7

13579 97531 13579 97531

2468 8642 2 4 6 8 10 10 8 6 4 2

98 9 10

76

54 78

3 56

12 34

12

3

5

150

2

~ 250 mm

~ 250 mm

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

22 / 36 INSTALLATION MANUAL

3.2.3 TENSIONING OF THE SYSTEM

For a correct and safe tensioning of the lift please refer to the following procedure:

• Fix the maintenance keyboard to the car frame upright.

• Position the bottom of the car or a provisory plan on the car frame and fix it with bolts.

• Load the car bottom and the counterweight with at least 200 kg.

• Raise the car frame unwinding the flexible cable.

• Measure the upper extra-travel of the car and adjust the ropes in compliance with this length.

• Move the car to the lowest station and compare the measures with the project drawing.

NOTE NOTE

Asymmetric wedge socket terminations Symmetric wedge socket terminations

UNI EN 13411-6, X Max = 75% Y UNI EN 13411-7, X Max = 40% Y

3.3 FINAL OPERATIONS ON THE SLING

3.3.1 POSITION OF THE FINAL LIMIT SWITCH

max 50mm

EXS

EXS/EXD

ü0

ð

EXD

max 50mm

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 23 / 36

3.4 SPEED GOVERNOR

5 x M6x20

M12x35

M12x30

~ 400

~

M5x20

M5x20

~ 170

3.5 CHECKS

3.5.1 CHECKS FOR STNDARD SYSTEMS

• Verify that the free distance between buffer and sling is the same specified in the project.

þ • Verify that the distance between sling shoes is the same specified in the project.

• Verify that the buffers are perfectly perpendicular and corresponding with support points under the

sling.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

24 / 36 INSTALLATION MANUAL

4 CAR AND DOOR OPERATOR

For the installation refer to the instructions of the manual of the supplied car.

If necessary, install panels, roof and cabin doors after the landing doors and the electrical material.

ATTENTION

Do not remove the protection film from the exposed side of angles, uprights, roof, panels and

accessories until specified, since the film preserves their integrity.

ATTENTION

The sill shall be flush.

ATTENTION

Protect the covering floor (for example using a cardboard) to preserve its integrity during the

assembly

5 LANDING DOORS

For the installation refer to the instructions of the manual of the supplied doors

ATTENTION

If the emergency devices (remote push-button) are placed inside the upright verify that the door with

the above devices is installed at the correct floor (normally the lower landing floor).

6 ELECTRICAL MATERIAL

For a correct and safe installation, follow the instructions of the ELECTICAL PART MANUAL and the W IRING

DIAGRAMS, paying attention to the following:

6.1 WELL AND MACHINERY ROOM

6.1.1 INSTALLATION OF THE CONTROL PANEL OUTSIDE THE WELL

ATTENTION

The distance between the upper side of the control panel and the floor level of the machine room

should be minor or equal of 2000mm.

Hang the control panel to the guide rails in the cabinet (MRL), or fix it, in the machine room (MR), with

dowels or bolts provided, following the instructions of the control panel supplied.

6.1.2 WELL ELECTRICAL LINES

Perform the electrical connections complying with the W IRING DIAGRAMS and with the ELECTRICAL PART MANUAL.

6.1.2.1 TRUNKS

Install the trunks for the connection cables as suggested in the following pictures:

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 25 / 36

6.1.2.2 FLEXIBLE CABLES

The flexible cables are used to take all electrical lines from the electrical power unit to the car’s roof, and

must be set and fixed thoroughly to avoid damaging them.

Install the flexible cables as suggested in the following pictures:

ATTENTION

The flexible cables should be fixed (A) to the wall in the upper middle part of the well, in a position

such as they do not touch (B) the car and (C) the pit.

6.1.2.3 CONNECTION CABLES

The connection cables are used to make easier some connections on the car’s roof and in the machine room

and must be set and fixed thoroughly into the trunks to avoid damaging them.

ATTENTION

Do NOT cut the exceeding cables

6.1.2.4 ELECTRICAL CONNECTIONS

The connection operations are extremely easy: the devices are pre-wired at the manufacturer and the

outputs are joined to the connectors.

To perform the connections it is enough to match the connectors with the same initial.

If you need to move the system, following the procedure shown in the installation manual of the control

panel, it necessary to connect at first the power unit and after the main power.

6.2 TRACTION MACHINE

Perform the electrical connections complying

with the ELECTRICAL DIAGRAMS, the CONTROL

PANEL AND ACCESSORIES MANUAL and the

GEARLESS MANUAL.

In particular, if installed, pay attention to the

correct connection of:

- Motor

- Motor protection sensors, thermistors

- Micro switches and brake power

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

26 / 36 INSTALLATION MANUAL

6.3 SLING AND ROPES

6.3.1 FINAL LIMIT ELECTRICAL SWITCH

max 50mm

EXS

EXS/EXD

EXD

max 50mm

6.3.2 SAFETY ELECTRICAL SWITCH (SAFETY GEAR/RELEASING ROPES)

With sling 1:1 With sling 2:1

6.3.3 SAFETY ELECTRICAL SWITCHES (SPEED GOVERNOR)

1. Anti-creeping coil

2. Anti-creeping safety switch

3. Speed governor safety switch

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 27 / 36

6.3.4 ELECTRICAL SWITCHES AND WELL INFO

Install switches and magnets complying with the ELECTRICAL DIAGRAMS and the ELECTRICAL PART MANUAL

Pay attention to the instruction of the

ELECTRICAL PART MANUAL

6.4 CAR AND DOOR OPERATOR

NOTE

Connect the car and the door operator only after the connection of all the other parts.

6.4.1 CAR OPERATING PANEL 6.4.2 COLLEGAMENTI SU TETTO CABINA

Connect the cables to the terminals of the box on the

car roof complying with the CIRCUIT DIAGRAMS

Particularly, pay attention to connect correctly the

Connect the car operating panel (COP)

following terminals:

complying with the ELECTRICAL

- The safety electrical switch

DIAGRAMS

(safety gear/releasing ropes)

- Well sensors

- Car lighting

6.4.3 DOOR OPERATOR AND DOOR SWITCH

Connect the cable to the terminal of the car roof electrical box complying with the ELECTRICAL DIAGRAMS.

6.5 LANDING DOORS

6.5.1 PUSH-BUTTON PANELS

Connect the terminal of the push-button panels

complying with the ELECTRICAL DIAGRAMS.

6.5.2 SAFETY SWITCHES

Connect the safety switches complying with the CIRCUIT

DIAGRAMS.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

28 / 36 INSTALLATION MANUAL

6.6 ACCESSORIES

6.6.1 CONNECTION OF THE WELL LIGHTING

Install the well lighting, referring to the instructions of the MANUAL OF THE ELECTRICAL PART supplied and in

accordance with the requirements of the current regulations with particular reference to the EN 81-20.

6.6.1.1 WELL LIGHTING

ID: Residual current circuit breaker

IM: Thermal magnetic circuit breaker

LC: Car lighting

6.7 DEVICES

To determine the installed devices to refer to chapter § 7and to MANUAL OF THE ELECTRICAL PART

6.7.1 SAFETY SWITCHES OF THE DEVICES

Perform the electrical connections of the safety switches complying with the ELECTRICAL DIAGRAMS.

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 29 / 36

7 DEVICES AND PROCEDURES FOR GLPM SYSTEM

7.1 DEVICES FOR MRL

7.1.1 WORKING AREA IN WELL

The traction machine is placed in the lift well and it is necessary to install the following devices.

7.1.1.1 UPPER CAR STOP MECHANICAL DEVICE (UCSMD)

NOTE

The dimensions in the left side

layout refer to a standard system.

The installation of the car stop

min 2000

mechanical device must always be

carried out in accordance with the

dimensions of the project design.

3500

SBA

min 500

2000

~1150

OFF

T82 T90 T125

1000

12

ON SBA

T82 T125

66.5

T90 80.5

7.1.1.2 RIGHT POSITION OF THE DEVICE

During installation of the mechanical device it is mandatory to respect the rule EN81-20 and follow the

instructions below:

The car mechanical stop device should be installed:

- To prevent uncontrolled or unexpected car movement when machinery is to be maintained or inspected

from the pit, as specified at section 5.2.6.4.4.1 of the rule EN81-20

- To give the possibility to leave the working area safety as specified at section 5.2.6.4.4.2 of rule EN81-

20.

and it must be fixed to the guide, under the traction machine, at a height such that it is granted:

- A free height of at least 2000 mm between the work surface above the car roof and the well ceiling;

- If there is no trap door on the cabin roof, a free distance of 500 mm between the top of the clear

opening of the landing door and the top of the operator on the car roof.

For standard systems, the position corresponds to a height of about 1150 mm above the level of the higher

floor.

The car mechanical stop device, once activated, prevents to move the sling (and the car), blocking the

system.

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

30 / 36 INSTALLATION MANUAL

T2

= =

M 12

100

50

M 12x35

M 12x35

M 12

M 4x30

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 31 / 36

7.1.2 LOCK DEVICE FOR DOOR OPERATOR AND DOORS 2AT

7.1.2.1 LOCK DEVICE - DOOR OPERATOR 2AT

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

32 / 36 INSTALLATION MANUAL

7.1.2.2 LOCK DEVICE - LANDING DOOR 2AT

7.1.3 OTHER DEVICES

To guarantee the required safety standards is necessary to install the following devices:

7.1.3.1 UNLOCKING TRIANGLE WITH ELETRICAL SAFETY SWITCH

The unlocking triangle, through a direct connection,

operate on an electrical safety contact that when you

unlock the door it stop any movement of the lift.

The electrical safety switch should be connected to the

control panel according to the electrical scheme

(SCC01, SCC02 …, SCC12 on S.e.a. scheme,

beginning from the lower floor).

7.2 NOTICES, MARKINGS AND OPERATING INSTRUCTION

ATTENTION

All labels, notices, markings and operative instructions shall be legible and readily understandable. They

shall be placed in a visible position and written in the language of the country where the lift is installed.

This notices shall be installed as shown in the instructions supplied.

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 33 / 36

8 EXAMINATIONS AND TESTS

At the end of the installation it’s necessary to proceed with examinations and tests of the lift.

Carry out the tests indicated in chapter 6 of the EN81-20 standard, referring the instructions of the system

putting on service manual.

9 FINAL OPERATIONS

9.1 ADVICES

Verify that non authorised personnel should not enter into the machine room (always keep it locked)

Verify that all protections are mounted on the power unit (electrical connections covering, tank).

Do not lean on nor sit on the traction machine.

Do not set containers with liquids on the clamp board (danger of short-circuit).

Always inform the responsible of the arrival. Before setting the plant out of work, hang the “out of service”

signs to every landing door.

Do not leave components, parts, tools, oil or grease stains on the floor.

Pay attention to any contact when operating on rotating devices or on devices that remained under tension.

ATTENTION

Never exclude the safety circuits.

Before moving the lift-car, verify the correct operation of the emergency button on the roof.

During the movement tightly support with the post or other parts of the lift-car and in any case not with the

ropes.

Pay particular attention during the upward travel.

At the end of the operations, please verify that all protections have been mounted and lock the machine

room.

9.2 FINAL OPERATIONS

At the end of the installation it is necessary to perform a test of the plant, in compliance with the standards in

force.

• This test is performed by the installer (if qualified by a certified Quality System in compliance with UNI EN

ISO 9000) or by a notified organism according to the Lift Standards

If the test gives a positive result, it is necessary to communicate that the installation has been performed,

indicating:

- The address of the building.

- The speed, the rated load, the travel, the number of stations and the starting type

- Name or name of the company of the installer.

- Copy of the compliance certificate.

- Name of the company in charge of the maintenance of the plant

- Name of the individual in charge of the periodical maintenance interventions on the plant

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

34 / 36 INSTALLATION MANUAL

10991790 EN - 2.00 - 07.12.2018

SYSTEMS GLT Σ - GLPM ENG

INSTALLATION MANUAL 35 / 36

10991790 EN - 2.00 - 07.12.2018

ENG SYSTEMS GLT Σ - GLPM

36 / 36 INSTALLATION MANUAL

FLUID DYNAMIC EQUIPMENTS

AND LIFT COMPONENTS

GMV SPA

VIA DON GNOCCHI, 10 - 20016 PERO – MILANO (ITALY)

TEL. +39 02 33930.1 - FAX +39 02 3390379

STRADA PER BIANDRATE, 110/112 - 28100 NOVARA (ITALY)

TEL. +39 0321 677611 - FAX +39 0321 677690

HTTP://WWW .GMV.IT - E-MAIL: INFO@GMV.IT

FILE: GLPM-MI-10991790EN-200.DOCX - (J2)

10991790 EN - 2.00 - 07.12.2018

You might also like

- MANUAL TUBEFORMER - 1602 - 2012 - 08 - 22 - enDocument44 pagesMANUAL TUBEFORMER - 1602 - 2012 - 08 - 22 - enBulboaca Bogdan100% (7)

- Manual of Induction Furnace For CustomerDocument66 pagesManual of Induction Furnace For CustomerAbdul Basit100% (14)

- Intellisave AX700Document458 pagesIntellisave AX700OMAR GONZALEZ100% (2)

- Practical Power System and Protective Relays CommissioningFrom EverandPractical Power System and Protective Relays CommissioningRating: 4.5 out of 5 stars4.5/5 (10)

- Guide to Operating Your Bavaria 50 Cruiser Sailing YachtDocument42 pagesGuide to Operating Your Bavaria 50 Cruiser Sailing YachtJuan A. Escribano BretonesNo ratings yet

- BKM Z60 80 B III Service Manual PDFDocument54 pagesBKM Z60 80 B III Service Manual PDFKelly VillamilNo ratings yet

- 1, U&M PPC - Draft From DalmecDocument55 pages1, U&M PPC - Draft From Dalmecbách hà100% (2)

- Installation Manual for Liebherr Crane Model BOS 4200-100 LITRONICDocument55 pagesInstallation Manual for Liebherr Crane Model BOS 4200-100 LITRONICLaur Iri100% (2)

- Use Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40F GPL 80FDocument5 pagesUse Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40F GPL 80FAnton LyakhovNo ratings yet

- Use Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40F GPL 80FDocument5 pagesUse Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40F GPL 80FAnton LyakhovNo ratings yet

- Olympian Generator Set Engine FiltersDocument6 pagesOlympian Generator Set Engine FiltersJavier Méndez100% (1)

- Green lift system installation manualDocument56 pagesGreen lift system installation manualDiego Fernandes do NascimentoNo ratings yet

- Pe Mium 02 10991487enDocument96 pagesPe Mium 02 10991487enAnton LyakhovNo ratings yet

- N10P Mium 10991487enDocument92 pagesN10P Mium 10991487enAnton LyakhovNo ratings yet

- Dodo Table of ContentsDocument4 pagesDodo Table of ContentsPiyush KumawatNo ratings yet

- M I, U M: Mium 3100el2Document32 pagesM I, U M: Mium 3100el2Tecnico 1 EmbarbaNo ratings yet

- QSV91G Containerized SpecificationDocument26 pagesQSV91G Containerized SpecificationmackyyoNo ratings yet

- Manuel Instalation 2Document66 pagesManuel Instalation 2prasad100% (1)

- Trimble-GS820 UserGde GM820 ENG Rev2020Aug 57708Document135 pagesTrimble-GS820 UserGde GM820 ENG Rev2020Aug 57708gabri1992No ratings yet

- LS20S 02250115-257Document102 pagesLS20S 02250115-257sledhead47No ratings yet

- (00A) Manual-0660274-Total-GbDocument277 pages(00A) Manual-0660274-Total-Gbtatenda bosopoNo ratings yet

- x3010 A3 MIUM 10991838EN 100Document28 pagesx3010 A3 MIUM 10991838EN 100AbdNo ratings yet

- LS-20S - SullairDocument102 pagesLS-20S - SullairWalter CarmonaNo ratings yet

- Sachal Feasibility Study 50 MW Utility Scale Wind PowerDocument191 pagesSachal Feasibility Study 50 MW Utility Scale Wind PowerArif Mateen AnsariNo ratings yet

- Mk6 Omd Manual Full Ver. Apr 05Document90 pagesMk6 Omd Manual Full Ver. Apr 05Clodoaldo BiassioNo ratings yet

- Continental Manual Rev 062010-05GBDocument32 pagesContinental Manual Rev 062010-05GBwilsonNo ratings yet

- Operation Instruction of AF-type Screw PumpDocument27 pagesOperation Instruction of AF-type Screw PumpNazar KhanNo ratings yet

- CO2 Fire Extinguishing System Design and InstallationDocument28 pagesCO2 Fire Extinguishing System Design and InstallationChhomNo ratings yet

- MG34M302Document161 pagesMG34M302Enrique OlarteNo ratings yet

- Excite User ManualDocument83 pagesExcite User ManualNando MendonçaNo ratings yet

- Hydraulic HLDM-MI-02-10991478ENDocument70 pagesHydraulic HLDM-MI-02-10991478ENnus06No ratings yet

- FC280 DG MG07B202Document96 pagesFC280 DG MG07B202Tedjo KartonoNo ratings yet

- Separtor GT 60Document110 pagesSepartor GT 60Universal solutionsNo ratings yet

- Controller - 6000 - 1.0 GBDocument27 pagesController - 6000 - 1.0 GBbekir.yeni18No ratings yet

- (Yeni) KL 003 HYDRAULIC PRESS BRAKE OPERATING MAINTENANCE AND USING MANUAL 03.07.2012Document66 pages(Yeni) KL 003 HYDRAULIC PRESS BRAKE OPERATING MAINTENANCE AND USING MANUAL 03.07.2012noname1789No ratings yet

- Install and Configure Slurry Density MeterDocument65 pagesInstall and Configure Slurry Density MeterZikriya KarnekarNo ratings yet

- VLT Aqua Drive FC 202Document214 pagesVLT Aqua Drive FC 202Ben FranNo ratings yet

- Vaporizer2 - Synthesizer Plug-In User'S Manual: © 2019, 2020 by Vast Dynamics GBRDocument60 pagesVaporizer2 - Synthesizer Plug-In User'S Manual: © 2019, 2020 by Vast Dynamics GBRMirko SvirkoNo ratings yet

- EVO 6800 ManualDocument261 pagesEVO 6800 ManualNguyễn Hữu NhânNo ratings yet

- 01 31462-01-02-01 - Inst - Manual - Rev2Document120 pages01 31462-01-02-01 - Inst - Manual - Rev2pRADEEP sNo ratings yet

- LAS5000XD ENG Manual 22.12Document84 pagesLAS5000XD ENG Manual 22.12Rafael Porcelles BonilhaNo ratings yet

- Design Guide FCP 106Document66 pagesDesign Guide FCP 106Ivan KurniadiNo ratings yet

- Design Guide: VLT Refrigeration Drive FC 103Document160 pagesDesign Guide: VLT Refrigeration Drive FC 103Khaled MoncerNo ratings yet

- CDS302 CDS 303Document158 pagesCDS302 CDS 303Mr.K ch100% (1)

- Manual DanfossDocument212 pagesManual DanfossEduardo LegorretaNo ratings yet

- GIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerDocument41 pagesGIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerwaqarNo ratings yet

- MaxiRider ManualDocument36 pagesMaxiRider ManualSalam Elec fsuptNo ratings yet

- Manual Redutor Elevacao EurogamaDocument104 pagesManual Redutor Elevacao EurogamaWanderson FIALHONo ratings yet

- R07 HC3D02 MML SPC Ci 0001Document779 pagesR07 HC3D02 MML SPC Ci 0001Muhammad FaheemNo ratings yet

- MM Greenlift: Reen IFT YstemsDocument44 pagesMM Greenlift: Reen IFT YstemsAnton LyakhovNo ratings yet

- Design Guide: VLT Automationdrive FC 301/302Document200 pagesDesign Guide: VLT Automationdrive FC 301/302Damiano ZitoNo ratings yet

- Separtor GT 40Document78 pagesSepartor GT 40Universal solutionsNo ratings yet

- 02 - XZG3834000001 - LS - Generator - LSA 53.2, 54.2 - BA IN WA EK KO - ENDocument38 pages02 - XZG3834000001 - LS - Generator - LSA 53.2, 54.2 - BA IN WA EK KO - ENAM76No ratings yet

- O & M Manual1-TractionDocument203 pagesO & M Manual1-Tractionsatyendrakiet539380% (5)

- G2000 Ambient Oil Mist Detector E2 11 1 EDocument38 pagesG2000 Ambient Oil Mist Detector E2 11 1 Edario100% (1)

- 100953en de Manual Cegardlift Lxly v210Document52 pages100953en de Manual Cegardlift Lxly v210silviuNo ratings yet

- R2ka - 34.20 Rad Ing Manuale 1507.1 - PMDocument76 pagesR2ka - 34.20 Rad Ing Manuale 1507.1 - PMGiedrius ŽiūkasNo ratings yet

- Switch Yard ErectionDocument274 pagesSwitch Yard Erectionkishorebodhale86% (29)

- Motion Control ReportFrom EverandMotion Control ReportRating: 4 out of 5 stars4/5 (1)

- Modern Practice in Servo Design: International Series of Monographs in Electrical EngineeringFrom EverandModern Practice in Servo Design: International Series of Monographs in Electrical EngineeringRating: 5 out of 5 stars5/5 (1)

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Use Manual: Vehicle Lift VL 35 VL 40Document4 pagesUse Manual: Vehicle Lift VL 35 VL 40Anton LyakhovNo ratings yet

- GMV 3100 EL2 Electronic Hydraulic ValveDocument2 pagesGMV 3100 EL2 Electronic Hydraulic ValveAnton LyakhovNo ratings yet

- Serbatoi MIUM 02 10991439EN 001Document24 pagesSerbatoi MIUM 02 10991439EN 001younesNo ratings yet

- Maintenance Manual: Vehicle Lift VL 30 & VL 35Document9 pagesMaintenance Manual: Vehicle Lift VL 30 & VL 35Anton LyakhovNo ratings yet

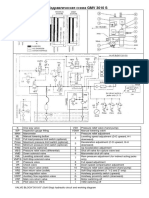

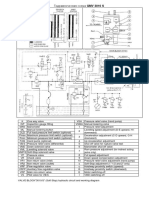

- Гидравлическая схема GMV 3010 S A5Document1 pageГидравлическая схема GMV 3010 S A5Anton LyakhovNo ratings yet

- Hydraulic HLDM-MI-02-10991478ENDocument70 pagesHydraulic HLDM-MI-02-10991478ENnus06No ratings yet

- Maintenance Manual: Vehicle Lift VL 30 & VL 35Document9 pagesMaintenance Manual: Vehicle Lift VL 30 & VL 35Anton LyakhovNo ratings yet

- Hydraulic circuit diagram for GMV 3010 SDocument1 pageHydraulic circuit diagram for GMV 3010 SAnton LyakhovNo ratings yet

- F S H L: Aintenance AnualDocument20 pagesF S H L: Aintenance AnualAnton LyakhovNo ratings yet

- MM Greenlift: Reen IFT YstemsDocument44 pagesMM Greenlift: Reen IFT YstemsAnton LyakhovNo ratings yet

- Mi - Sling: Anuale D NstallazioneDocument26 pagesMi - Sling: Anuale D NstallazioneAnton LyakhovNo ratings yet

- Maintenance Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40FDocument12 pagesMaintenance Manual: Goods / Passenger Lift GPL 25 GPL 40 GPL 40FAnton LyakhovNo ratings yet

- GLF Mi 10991458enDocument24 pagesGLF Mi 10991458enAnton LyakhovNo ratings yet

- MFX Greenlift: Reen IFT YstemsDocument12 pagesMFX Greenlift: Reen IFT YstemsAnton LyakhovNo ratings yet

- GLPM Mi 10991790enDocument36 pagesGLPM Mi 10991790enAnton LyakhovNo ratings yet

- Adjust existing hydraulic lifts to modern safety standardsDocument2 pagesAdjust existing hydraulic lifts to modern safety standardsAnton LyakhovNo ratings yet

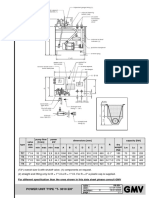

- Power Unit Type "T-3010 En"Document1 pagePower Unit Type "T-3010 En"Anton LyakhovNo ratings yet

- Easykit NGV Ek IngDocument4 pagesEasykit NGV Ek IngAnton LyakhovNo ratings yet

- 136 GMV-PDDocument294 pages136 GMV-PDMatthewNo ratings yet

- GMV Valve 3010 S DVL A3 02 04 2014 Ver D Table 04 008 ENDocument2 pagesGMV Valve 3010 S DVL A3 02 04 2014 Ver D Table 04 008 ENAnton Lyakhov100% (1)

- GMV 3100 EL2 Electronic Hydraulic ValveDocument2 pagesGMV 3100 EL2 Electronic Hydraulic ValveAnton LyakhovNo ratings yet

- Gree Central Air conditioners Installation GuideDocument362 pagesGree Central Air conditioners Installation GuideGuilherme LopesNo ratings yet

- Technical Manuals GMV MRL T MSTK3-GB Rev04 Man UsoInstallaz GMV10 Precablato GBDocument81 pagesTechnical Manuals GMV MRL T MSTK3-GB Rev04 Man UsoInstallaz GMV10 Precablato GBAnonymous Ih1EEENo ratings yet

- GMV-2P - Service ManualDocument245 pagesGMV-2P - Service ManualAvk SanjeevanNo ratings yet

- Mi - Sling: Anuale D NstallazioneDocument26 pagesMi - Sling: Anuale D NstallazioneAnton LyakhovNo ratings yet

- 3010 GMV BlokDocument16 pages3010 GMV Blokdragishabl100% (1)

- F S H L: Aintenance AnualDocument20 pagesF S H L: Aintenance AnualAnton LyakhovNo ratings yet

- Maintenance Manual: Vehicle Lift VL 30 & VL 35Document9 pagesMaintenance Manual: Vehicle Lift VL 30 & VL 35Anton LyakhovNo ratings yet

- Davao & Camiguin: All You Need to Know (40Document2 pagesDavao & Camiguin: All You Need to Know (40Kyla Francine TiglaoNo ratings yet

- Vw Vento Diesel EcmDocument15 pagesVw Vento Diesel EcmDavid AcostaNo ratings yet

- Savage Worlds - Steamscapes - Adv - Rivalry - Chapter 2 (Option A)Document3 pagesSavage Worlds - Steamscapes - Adv - Rivalry - Chapter 2 (Option A)jaklsdhoweNo ratings yet

- Fortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2009 Hyster Company 02/2009Document678 pagesFortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2009 Hyster Company 02/2009José SilvaNo ratings yet

- Job Hazard Analysis (Bridge Crossing)Document4 pagesJob Hazard Analysis (Bridge Crossing)jay RNo ratings yet

- F11 Door Corrosion RemovalDocument5 pagesF11 Door Corrosion RemovalWill RobertsonNo ratings yet

- Golf Mkiv Lista OsiguracaDocument3 pagesGolf Mkiv Lista OsiguracaDusan JovanovicNo ratings yet

- Series: Service & Parts ManualDocument166 pagesSeries: Service & Parts ManualSandra Krzysiek KaduczkaNo ratings yet

- #02.single Part List (Stack)Document32 pages#02.single Part List (Stack)longkhanhckNo ratings yet

- "Cement Concrete Roads": Taken atDocument35 pages"Cement Concrete Roads": Taken atAbhijeet ParasharNo ratings yet

- UntitledDocument163 pagesUntitledDarwin GoldingNo ratings yet

- Invoice # OC - OAK - M112002Document6 pagesInvoice # OC - OAK - M112002Denzel WillingtonNo ratings yet

- Revised GST Process for Physically Disabled CustomersDocument7 pagesRevised GST Process for Physically Disabled CustomersNeeraj SharmaNo ratings yet

- Tractor Engine and Drawbar PerformanceDocument3 pagesTractor Engine and Drawbar PerformancemaureenNo ratings yet

- Branford Road Safety Audit Report: Rt.146Document92 pagesBranford Road Safety Audit Report: Rt.146Ellyn SantiagoNo ratings yet

- Tax InvoiceDocument1 pageTax InvoiceManju nathNo ratings yet

- Understanding Autonomous VehiclesDocument29 pagesUnderstanding Autonomous VehiclesGergely HornyakNo ratings yet

- Fiat Kobelco E16 E18 Evolution Workshop ManualDocument20 pagesFiat Kobelco E16 E18 Evolution Workshop Manualryan100% (52)

- Porsche Werkswagen BrochureDocument3 pagesPorsche Werkswagen BrochureZg ZgNo ratings yet

- Service Manual: Built-In Oven Akp 242 IxDocument5 pagesService Manual: Built-In Oven Akp 242 IxNeoNo ratings yet

- BMW m70 Engine InfoDocument1 pageBMW m70 Engine Infodaniel100% (29)

- Maintenance Instructions for Bogie Petrol Tank WagonsDocument34 pagesMaintenance Instructions for Bogie Petrol Tank WagonsIndian RailwayNo ratings yet

- Transport (IELTS Speaking Part 2-3) : Warm-UpDocument4 pagesTransport (IELTS Speaking Part 2-3) : Warm-UpEleonora LibanoriNo ratings yet

- Operator'S Manual: Pneumatic-Tired WheelsDocument30 pagesOperator'S Manual: Pneumatic-Tired WheelsХелфор УкраинаNo ratings yet

- Vag ToolDocument43 pagesVag ToolSebastian Damian0% (1)

- Naoshima: Honmura Area Miyanoura AreaDocument4 pagesNaoshima: Honmura Area Miyanoura AreaStanley WinaryoNo ratings yet

- Notice Inviting Bid: Signature Not VerifiedDocument1 pageNotice Inviting Bid: Signature Not VerifiedBhavesh Patel100% (1)

- RHVPI Overview Document Chapter 4 The Ministry of Transportation and Friction TestingDocument200 pagesRHVPI Overview Document Chapter 4 The Ministry of Transportation and Friction TestingJohnEMERYNo ratings yet

- Gta San Andreas PC CheatsDocument100 pagesGta San Andreas PC CheatsMaulana Achsan Keliobas57% (7)