Professional Documents

Culture Documents

SRI CO2 Manual

Uploaded by

ChhomCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRI CO2 Manual

Uploaded by

ChhomCopyright:

Available Formats

CO2 EXTINGUISHING SYSTEM

TABLE OF CONTENT

DESCRIPTION PAGE

1.0 INTRODUCTION 3

1.1 DESCRIPTION 3

1.2 GENERAL AND SAFETY HAZARDS 3

1.3 SYSTEM COMPONENTS 5

1.4 HIGH PRESSURE SYSTEMS 5

2.0 DESIGN 6

2.1 TOTAL FLOODING SYSTEM 6

2.1.1 EXAMPLES OF HAZARDS 6

2.1.2 TYPE OF FIRES 6

2.1.3 WHERE CO2 IS NOT EFFECTIVE 6

2.2 CO2 REQUIREMENTS FOR SURFACE FIRES 7

2.2.1 VOLUME FACTOR 7

2.2.2 FLAMMABLE MATERIALS 7

2.3 INTERCONNECTED VOLUMES 8

2.3.1 SPECIAL CONDITIONS 8

2.4 OPENINGS THAT CAN NOT BE CLOSED 8

2.4.1 LIMITATIONS OF OPENINGS THAT CAN NOT BE CLOSED 8

2.5 CO2 REQUIREMENTS FOR DEEP SEATED FIRES 10

2.5.1 OPENINGS 10

2.5.2 FORCED VENTILATION 11

2.6 DISTRIBUTION SYSTEMS 13

GENERAL 13

2.6.1 RATES OF APPLICATION 13

2.6.2 NOZZLES DISTRIBUTION 13

2.6.3 PIPE SELECTION 13

2.6.4 PIPE SIZE ESTIMATES 14

2.6.5 STORAGE CYLINDERS LOCATION 14

2.6.6 DISTRIBUTION VALVES 14

2.6.7 ALARMS 15

2.6.8 DETECTION 15

-1-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

3.0 INSTALLATION

3.1 GENERAL 16

3.2 DISTRIBUTION PIPING AND FITTINGS 16

3.2.1 PIPING – GENERAL 16

3.2.2 PIPE 16

3.2.3 PIPE JOINING 19

3.2.4 CLEANING 19

3.2.5 TREADS 19

3.2.6 INSTALLATION 19

3.3 DISCHARGE NOZZLE 19

3.4 PILOT HOSE (PRESSURE ACTUATION LINES) 19

3.5 FLEXIBLE DISCHARGE HOSE C/W CHECK VALVE 19

3.6 CO2 CYLINDER 20

3.7 LEVER OPERATED CONTROL HEAD 20

3.8 PILOT CYLINDER AND MOUNTING BRACKET 20

3.9 PRESSURE SWITCH 21

3.10 MANUAL PULL STATION 21

3.11 POST INSTALLATION CHECK OUT 21

4.0 COMMISSIONING 23

5.0 OPERATION 25

5.1 GENERAL 25

5.2 OPERATING PROCEDURES 25

5.2.1 AUTOMATIC OPERATION 25

5.2.2 MANUAL PULL STATION OR REMOTE MANUAL OPERATION 25

5.2.3 LOCAL MANUAL OPERATION 25

5.3 POST FIRE OPERATION 26

5.4 CYLINDER RECHARGE 26

6.0 MAINTENANCE 27

7.0 TECHNICAL DATA AND DRAWINGS 28

1.0 INTRODUCTION

-2-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

1.1 DESCRIPTION

This type of system consists of high pressure cylinders containing carbon dioxide

(CO2) agent under pressure, connected to fixed piping and nozzles or hoses. The

systems are used for Total Flooding of a volume with carbon dioxide, such as a

flammable liquid storage room, or for Local Application, such as on a Work Bench.

Since carbon dioxide is electrically non-conductive, it is frequently used for protection

of electrical equipment. Being a gaseous fire extinguishing system makes CO2

suitable for fires in electrical equipment, electronic equipment, and flammable liquids.

Where the hazard being protected is enclosed in a room, total flooding systems are

provided. Where there is no enclosing room for the hazard, local application systems

serve best. Since a total flooding system extinguishes fires by smothering within a

fixed volume, the volume of the room being protected must be closed at the time of

discharge. Any doors or dampers in the room must be self-closing or close

automatically in the event of system operation.

1.2 GENERAL AND SAFETY HAZARDS

Carbon Dioxide is present in the atmosphere at an average concentration of about

0.03 percent by volume. It is also a normal end product of human and animal

metabolism. Carbon Dioxide influences certain vital functions in a number of

important ways, including control of respiration, dilation, and constriction of the

vascular system – particularly the cerebrum – and the pH of body fluids. The

concentration of carbon dioxide in the air governs the rate at which carbon dioxide is

released from the lungs and thus affects the concentration of carbon dioxide in the

blood and tissues. An increasing concentration in the air can, therefore, become

dangerous due to a reduction in the rate of release of carbon dioxide from the lungs

and decreased oxygen intake. Further details of carbon dioxide exposure can be

obtained from DHHS (NIOSH) Publication No. 76-194. Personnel safety

considerations are covered in Section 4.3. Table A provides information on acute

health effects of high concentration of carbon dioxide.

Although carbon dioxide has been a commercial product for years – familiar in its

solid form as “dry ice”, used as a refrigerant, or its gaseous form for carbonating

beverages – this agent is not without hazards. Carbon dioxide extinguishes fires by

creating an oxygen deficiency. For people in this atmosphere, this limitation of

oxygen can be lethal. When carbon dioxide discharges, it creates a refrigerating

effect, which can condense water vapor in the area, producing a fog, which reduces

visibility. In addition, the rush of carbon dioxide through the nozzles creates a shrill

noise, which can be frightening. The movement of carbon dioxide through the system

under pressure while changing state from a liquid to a gas creates static electricity.

For these reasons, pre-discharge alarms are usually required for evacuation of all

occupants prior to carbon dioxide discharge.

Carbon dioxide is heavier than air and will settle into low spaces. Once actuated, all

the carbon dioxide supply in the containers, which were activated, will be discharged.

The system must be recharged after every use.

-3-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Table A – Acute Health Effects of High Concentration of Carbon Dioxide (with Increasing

Exposure Levels of Carbon Dioxide)

Concentration

of Carbon

Dioxide in Air

(%) Time Effects

__________________________________________________________________________________________

2 Several hours Headache, dyspnea upon mild

exertion

__________________________________________________________________________________________

3 1 Hour Dilation of cerebral blood vessels,

increased pulmonary ventilation,

and increased oxygen delivery to the

tissues

__________________________________________________________________________________________

4 -5 Within a few Mild headache, sweating, and

minutes and dyspnea at rest

__________________________________________________________________________________________

6 1- 2 minutes Hearing and visual disturbances

<16 minutes Headache and dyspnea

Several hours Tremors

__________________________________________________________________________________________

7-10 Few minutes Unconsciousness or near

unconsciousness

1.5 minutes - Headache, increased heart rate,

1 hour shortness of breath, dizziness,

sweating, rapid breathing

__________________________________________________________________________________________

10-15 1+ minute Dizziness, drowsiness, severe

muscle twitching, and

unconsciousness

__________________________________________________________________________________________

17-30 <1 minute Loss of controlled and purposeful

activity, unconsciousness,

convulsions, coma, and death

__________________________________________________________________________________________

Source: EPA 430-R-00-002, “Carbon Dioxide as a Fire Suppressant: Examining the Risks,” February 2000.

-4-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

1.3 SYSTEM COMPONENTS

A carbon dioxide high pressure total flooding system, the most common type,

consists of fire detectors, manual releases, wiring, conduit, control panel, cylinder,

solenoid or electrical control head, discharge control valve, discharge nozzles,

extinguishing agent under pressure, and piping.

1.4 HIGH PRESSURE SYSTEMS

High pressure cylinders are designed to withstand the pressure created by the

highest expected temperature within the room where they are located. The normal

design is for a pressure of 58.6 Bar of 21oC (850 psi at 70oF). These cylinders must

be treated with care when handled. If a cylinder or its valve leaks or breaks, the

cylinder becomes a projectile, powered by high pressure gas, capable of demolishing

masonry walls. Carbon dioxide high pressure cylinders contain carbon dioxide which

is liquefied by pressure. If the temperature decreases to 0oC (32oF), the pressure

drops to 34.7 Bar (504 psi). For this reason, the contents of the cylinder can be

determined only by weighing the cylinders. The empty cylinder weight (tare weight) is

stamped onto the cylinder body.

Operation of detectors initiates an alarm condition in the control panel. The control

panel sound pre-discharge alarms, operate the building fire alarm system, and do

other routines, but must operate the carbon dioxide cylinder solenoid or electrical

control head. The solenoid or control head, which sits on top the discharge control

valve, upon operation provides a gas escape route through the valve to the

atmosphere. The escape of gas creates an imbalance of pressure in the discharge

control valve. This causes the carbon dioxide gas in the cylinder to raise a piston in

the valve, which uncovers the discharge port to release the gas through the discharge

hose, manifold, distribution piping and final discharge at the nozzle to the

atmosphere.

-5-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

2.0 DESIGN

2.1 Total Flooding System

C02 total flooding systems are based on creating an extinguishing concentration of

C02 within an enclosed space containing the combustible materials, the quantity of

C02 is determined by applying an appropriate factor to the volume being protected.

The efficiency of a total flooding system depends upon maintaining the concentration

for as long as possible, so before total flooding can be considered as a method of

extinguishing, the protected space must be reasonably well enclosed.

A fixed supply of C02 is permanently connected to fixed piping and discharge nozzles

are arranged to discharge C02 into the protected space.

2.1.1 Examples of Hazards

Rooms, vaults, enclosed machines, ovens dust collectors, floor and ceiling

voids and fume extraction ducts.

2.1.2 Types of Fires

Fires that can be extinguished by total flooding methods shall be divided into

the following two categories:

(a) Surface fires involving flammable liquids and gases, and solids.

Surface fires are subject to prompt extinguishment when carbon

dioxide is quickly introduced into the enclosure in a quantity to

overcome leakage and provide an extinguishing concentration for the

particular materials involved.

(b) Deep seated fires involving solids subject to smoldering.

For deep seated fires, the required extinguishing concentration shall

be maintained for a period of time to allow the smoldering to be

extinguished and the material to cool to point at which re-ignition will

not occur when the inert atmosphere is dissipated.

2.1.3 Where C02 is NOT Effective

(a) Materials that contain their own oxygen supply and liberate oxygen

when burning, e.g. cellulose nitrate.

(b) Reactive metals e.g. sodium potassium, magnesium, titanium,

zirconium, uranium and plutonium.

(c) Metal hydrides.

While C02 may not extinguish these fires, it will not react dangerously or

increase the burning rate. C02 will protect adjacent, combustibles and will

also extinguish fires of other materials in which the reactive metals are often

stored.

-6-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Example:

(a) Sodium stored or used under kerosene.

(b) Cellulose nitrate in a solvent.

(c) Magnesium chips covered with heavy oil.

2.2 C02 Requirement for Surface Fires

2.2.1 Volume Factor

The volume factor used to determine the basic quantity of carbon to protect an

enclosure containing a material requiring a design concentration of 34% shall

be in accordance with table 1.

The volume to be used is the gross volume of the enclosure but you are

permitted to deduct permanent, impermeable elements of the building

structure i.e. beams, stanchions, solid stairways and foundations.

Table 1 – Flooding Factors

Volume of Space Volume Factor Calculated Minimum

M3 Kg C02/m3 Kg

Up to 3.96 1.15 -

3.97 – 14.15 1.07 4.5

14.16 – 45.28 1.01 15.1

45.29 – 127.35 0.90 45.4

127.36 – 1415.0 0.80 113.5

Over 1415.0 0.77 1135.0

Volume Factors above, must ONLY be used for SURFACE FIRES

Example: Room: 6m x 9m x 3m = 162m3

162m3 x 0.80 kg/m3 = 129.6kg

2.2.2 Flammable Materials

The design concentration shall be determined by adding the factor (20

percent) to the minimum effective concentration. In no case shall a

concentration less than 34 percent be used. Table 2 shall be used to

determine the minimum carbon dioxide concentration for the liquids and gases

shown in the table.

For material not given in table 2, the minimum theoretical carbon dioxide

concentration shall be obtained from some recognized source or determined

be test.

-7-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

2.3 Interconnected Volumes

In two or more interconnected volumes where free flow of C02 can occur, the C02

quantity shall be the sum of the quantities calculated for each volume, using its

respective volume factor from Table 1. If one volume requires greater than normal

concentration, the higher concentration shall be used for all interconnected volumes.

2.3.1 Special Conditions

Additional quantities of carbon dioxide shall be provided to compensate for

any special condition that can adversely affect the extinguishing efficiency.

2.4 Openings That Cannot Be Closed

Any openings that cannot be closed at the time of extinguishment shall be

compensated for by the additional of a quantity of carbon dioxide equal to the

anticipated loss at the design concentration during a 1 minute period or

arranged to close automatically before or simultaneously with the start of the

C02 discharge. This can be done by self-closing door devices, fire curtains or

steel shutters.

2.4.1 Limitations of Openings That Cannot Be Closed

The maximum area permitted is the smaller result of the following calculations:

(a) An area in square metres which is numerically equivalent to 10% of the

volume in cubic metres.

(b) 10% of the total area of all sides, top and bottom in square metres.

When these openings exceed this limitation, the system should be designed

by a local application method.

-8-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Table 2 - Minimum Carbon Dioxide Concentration for Extinguishment

======================================================================================

Theoretical Minimum

Minimum CO2 Design CO2

Concentration Concentration

Material (%) (%)

__________________________________________________________________________________________

Acetylene 55 66

Acetone 27* 34

Aviation gas grades 115/145 30 36

Benzol, benzene 31 37

Butadiene 34 41

__________________________________________________________________________________________

Butane 28 34

Butane-I 31 37

Carbon disulfide 60 72

Carbon monoxide 53 64

Coal or natural gas 31* 37

__________________________________________________________________________________________

Cyclopropane 31 37

Diethyl ether 33 40

Dimethyl ether 33 40

Dowtherm 38* 46

Ethane 33 40

__________________________________________________________________________________________

Ethyl alcohol 36 43

Ethyl ether 38* 46

Ethylene 41 49

Ethylene dichloride 21 34

Ethylene oxide 44 53

__________________________________________________________________________________________

Gasoline 28 34

Hexane 29 35

Higher paraffin 28 34

Hydrocarbons Cn H2m + 2m – 5

Hydrogen 62 75

Hydrogen sulfide 30 36

__________________________________________________________________________________________

Isobutane 30* 36

Isobutylene 26 34

Isobutyl formate 26 34

JP-4 30 36

Kerosene 28 34

__________________________________________________________________________________________

Methane 25 34

Methyl acetate 29 35

Methyl alcohol 33 40

Methyl butane-I 30 36

Methyl ethyl ketone 33 40

__________________________________________________________________________________________

Methyl formate 32 39

Pentane 29 35

Propane 30 36

Propylene 30 36

Quench, lube oils 28 34

__________________________________________________________________________________________

Note: The theoretical minimum extinguishing concentration in air for the materials in the table were obtained from a compilation

of Bureau of Mines, Bulletins 503 and 627, Limits of Flammability of Gases and Vapors.

• Calculated from accepted residual oxygen values.

-9-

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Table 3 – Flooding Factors for Specific Hazards

Design

Concentration

(%) m³ / kg CO2 kg CO2 / m³ Specific Hazards

__________________________________________________________________________________________

50 0.62 1.60 Dry electrical hazards in general (spaces

less than 56.6m³)

50 0.75 1.33 Dry electrical hazards in general (spaces

greater than 56.6m³)

65 0.50 2.00 Record (bulk paper) storage, ducts,

Covered trenches

75 0.38 2.66 Fur storage vaults, dust collectors

__________________________________________________________________________________________

2.5 Carbon Dioxide Requirements for Deep Seated Fires

Basic Quantity

After the design concentration is reached, the concentration shall be maintained for a

substantial period of time, but not less than 20 minutes. Any possible leakage shall be

given special consideration because no allowance is included in the basic flooding

factors.

The design concentration listed in table 2 shall be achieved for the hazards listed.

Flooding factors for others deep-seated fires shall be justified to the satisfaction of the

authority having jurisdiction before use.

Multiply the volume to be protected (cubic metres) by the flooding factor given in table

3 or 4.

Example: Paper documents storage room: Design Concentration: 65%

6m x 6m x 3m high = 108m3

108m3 x 2kg/m3 C02 = 216kg

2.5.1 Openings

Total flooding systems protecting solid materials cannot tolerate the degree of

openings permitted for surface fire protections.

The design concentration must be maintainable over a long period, so low level

openings are not practicable. Small openings at or near the ceiling are ideal

because:

(a) Compensation for losses involves only reasonable quantities of additional

C02.

(b) They allow the escape of hot gases

(c) They prevent pressure increases that can stress the enclosure structure.

Any openings that cannot be closed shall be compensated for by the addition of C02

equal in volume to the expected loss during the extinguishing and holding time.

- 10 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

2.5.2 Forced Ventilation

When forced air ventilation systems are used, they shall, if possible, be shutdown

before, or simultaneously, with the start of the C02 discharge. If this cannot be done,

additional C02 must be applied.

If there is a short run down time but the quantity of air removed is significant,

additional C02 must be applied, the additional C02 must be discharged within the

time specified for the required design concentration.

For calculation purposes the volume of air removed in one minute will be replaced

with C02 at the design concentration being used.

Example: Assume the room has 30m3 of air removed by the ventilation system in

one minutes.

30m3 x 2kg/m3 = 60kg + 216kg (original) = 276 kg

Services such as heating, fuel supplies, paint spraying, conveyors etc. must also be

shutdown before or simultaneously, with the C02 discharge.

- 11 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Table 4 – Flooding Factors applicable for Deep Seated Fires Only.

Design Flooding

Hazard Concentration Factors

(%) (kg/m³)

Electrical equipment

Enclosed rotating equipment

Dry electrical wiring

Electrical insulating materials 50 1.35

Computer Installations

Central processing areas and

Equipment 53 1.50

Data processing

2.25

Tape controlled machinery 68

Stores

Record stores and archives off

2.00

Paper documents 65

Fur storage vaults

75 2.70

Dust collectors

General

Cocoa

Leather

Silk

Wool 63 1.78

Coffee

Cork

Cotton

Peanuts

Rubber

2.70

Soybean 75

- 12 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

2.6 Distribution System

General

The distribution system for applying carbon dioxide to enclosed hazards shall be

designed with due consideration for the material involved and the nature of the

enclosure, because these items can require various discharge times and rates of

application.

2.6.1 Rates of Application

Where advancement of flame is potentially rapid, as in surface fires, the C02

discharge must be comparably fast to minimise damage. For surface fires the design

concentration shall be achieve within 1 minute.

Where the spread of fire is potentially slow, such as deep seated fires in solid

materials, more emphasis is placed on maintaining a fire suppression concentration

for a lengthy period of time to allow time for cooling. The design concentration shall

be achieved within 7 minutes, but the rate shall be not less than that required to

develop a concentration of 30% in 2 minutes.

Where the spread of fire may be faster than normal for the type of fire expected, or

where high values, or vital machinery or equipment are involved, rate higher than the

stated minimums may be used.

Where a hazard contains materials that will produce both the surface and deep

seated fires, the rate of application should be at least the minimum required for

surface fires.

2.6.2 Nozzle Distribution

Horns should space approximately 6m apart.

For rooms up to 5m high, install horns at a height of 2.5m and angle of 45o . Average

throws approximately 4m.

For rooms between 5 and 10m high, install at 1/3 height up from floor.

For rooms with high stacking or rooms over 10m high, it may be necessary to install

at 1/3 and 2/3 levels.

2.6.3 Pipe Selection

For the selection of the various grades of pipe and fittings in order to meet the duties

imposed by operating pressures and temperatures, please refer to Section 3.2

Distribution Piping and Fittings.

- 13 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

2.6.4 Pipe Size Estimates

Hydraulic pipe size calculations are accurately determined by using the SRI Fire

Protection C02 Computer Calculation Program. However, for estimating for a

quotation, only a reasonably accurate result is needed and this can be achieved by

using the table below,

Table 5 - Pipe Size Estimates

Flow Rate Estimates Pipe Size

(kg/min) Nominal bore (mm)

Up to 123 20

123 to 177 25

178 to 363 32

364 to 545 40

546 to 1045 50

1045 to 1363 65

2.6.5 Storage Cylinders Location

It is important to get a commitment from the prospective client about the location of

storage containers because this will affect the installation of pipe, detection lines and

cabling, and remote pull controls.

Storage containers should be located as near as possible to the hazard they protect,

but should not be exposed to the fire in a manner that is likely to impair performance.

They should not be exposed to weather conditions or put in a location where they can

be subjected to chemical or other damage. Suitable guards or enclosures should be

provided when necessary.

The general ambient storage temperatures should not exceed the following:

(a) For total flooding systems:

Not greater than 46oC or less than –18oC

(b) For local application systems:

Not greater than 46oC or less than 0oC

NOTE: The minimum storage temperature for local application is higher than that

allowed for total flooding systems because the discharge area limit tests were

carried out at a minimum temperature of 0oC and to operate at lower

temperatures would cause the figures in Table 5 to be incorrectly applied.

2.6.6 Distribution Valves

When the multiple hazards are located reasonable close together they can be

protected with a single bank of containers with the C02 being directed to the hazard

on fire by opening the appropriate distribution valve on a distribution valve manifold.

- 14 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

When using this method it is important to consider the list below:

(a) The amount of C02 is sufficient for the largest hazard.

(b) There is only one supply of agent so it must not be possible for fire to spread

from one zone to another.

(c) Any number of zones can be protected by a single bank of containers but

Insurers’ rules generally limit the number to 5 zones.

(d) A reserve supply of C02 should be considered.

2.6.7 Alarms

System condition indicators should be provided as appropriate to the surroundings.

(a) A total flooding systems should have indicators located outside the entrance

doors to show:

C02 Discharged – red lamp

System in Normal – green lamp

These indications may not always be necessary for local application system.

(b) Additional alarms may be needed to be transmitted to remote locations

including a Central Station, and other system conditions may be required such

as:

Fire – red flashing lamp

System Operated – red steady lamp

Supply Healthy – green lamp

Warning labels are required to be located alongside manual release points, and

located on all entrance doors.

Operating and Maintenance manuals should always be provided.

Audible alarms should be provided as appropriate to the type of system and protected

area.

2.6.8 Detection

Automatic detection systems used with C02 extinguishing systems should comply

with appropriate codes of practice - eg. (NFPA 72 – National Fire Alarm Code)

- 15 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

3.0 INSTALLATION

3.1 GENERAL

This Chapter provides installation instructions covering the main components. Before

installing, refer to the bill of material on the System Layout Drawing to ensure all

required system components are available.

All SRI C02 System equipment must be installed to facilitate proper inspection,

testing, manual operation, recharging and any other required maintenance as may be

necessary. Equipment must not be subject to severe weather conditions or

mechanical, chemical or other damage which could render the equipment inoperative.

Equipment must be installed in accordance with NFPA 12 and the Authority Having

Jurisdiction.

3.2 DISTRIBUTION PIPING AND FITTINGS

3.2.1 Piping – General

Refer to the system drawings for location and layout of the Agent

Distribution Piping System. Examine the configuration to ensure the

piping and nozzles do not interfere with objects in the hazard area. Also,

confirm that the discharge pattern from the nozzles will not be obstructed

by objects in the hazard area. Should conflicts occur, make changes

before proceeding with installation.

3.2.2 Pipe

I) All the pipe work sizes shown in the schematic of the installation have

been determined using a computer programme. It is IMPORTANT that

these sizes are used to ensure the correct flow of C02 within the stated

discharge time.

ii) The pipe and fittings materials must conform to the requirements of as

shown in the following tables.

Table 6 - Open Ended Pipe work

Up to & incl. 40mm API 5L B Schedule 40

ASTM A106-77 A or B

Over 40mm up to & incl. ASTM A106-77 A or B Schedule 80

50mm API 5L B

- 16 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

iii) The pipe works MUST BE FIRMLY SUPPORTED because, in the

event of a fire, the discharge will impose a force on the pipe work. If

the piping became dislodged, considerable damage could be caused

and the extinguishing system may not function correctly. Allowance

must be made for expansion and contraction of the pipe work. See

Table 10 for the minimum recommended pipe support spacing.

Table 7 – Hanger Spacing

Pipe size (mm) 15 20 25 32 40 50 80 100 150

Max Spacing (m) 1.5 1.8 2.1 2.4 2.7 3.4 3.7 4.3 5.2

iv) Electrical Clearances

Where exposed electrical conductors are present, clearance no

smaller than those given in Table 7 shall be provided where

practicable, between the electrical conductors and all parts of the C02

System that may be approached during maintenance, where these

clearance distances cannot be achieved, warning notices shall be

provided and a safe system of maintenance work shall be adopted.

Minimum clearance from any point on or about the permanent

equipment where a man may be required to stand (measured from

position of the feet).

Table 8 - Safety Clearance of Pipe work

To the nearest

unscreened

live conductor

in air (section

clearance)

Metres 2.59 2.59 2.74 2.74 2.89 3.05 3.20 3.35 3.50 3.81 4.27 4.57

To the nearest

part not at

earth potential

of an insulator

supporting a

live conductor

(ground

clearance)

Metres 2.44

Max rated

Voltage (XY) 11 15 22 33 44 66 88 110 132 165 220 275

The terms insulator includes all forms of insulating supports, such as

pedestal and suspension insulators, bushings, cable sealing ends and

the insulating supports of certain types of circuit breakers etc.

- 17 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Table 9 – Equivalent Length of Treaded Pipe Fitting

Long Bend &

Pipie Size 90º Elbow 45º Elbow Side Tee Union

Thru Tee

(mm) (m) (m) (m) (m)

(m)

10 0.18 0.4 0.24 0.82 0.09

15 0.24 0.52 0.3 1.04 0.12

20 0.3 0.67 0.42 1.37 0.15

25 0.4 0.85 0.55 1..74 0.18

32 0.52 1.13 0.7 2.29 0.24

40 0.61 1.31 0.82 2.65 0.27

50 0.79 1.67 1.06 3.41 0.37

65 0.95 2.01 1.25 4.08 0.43

80 1.16 2.5 1.55 5.06 0.55

100 1.52 3.26 2.01 6.64 0.73

125 1.92 4.08 2.56 8.35 0.91

150 2.32 4.94 3.08 10 1.07

Table 10 – Equivalent Length of Welded Pipe Fitting

Long Bend &

Pipe Size 90º Elbow 45º Elbow Side Tee Union

Thru Tee

(mm) (m) (m) (m) (m)

(m)

10 0.06 0.21 0.15 0.49 0.09

15 0.09 0.24 0.21 0.64 0.12

20 0.12 0.33 0.27 0.85 0.15

25 0.15 0.43 0.33 1.07 0.18

32 0.21 0.55 0.46 1.4 0.24

40 0.24 0.64 0.52 1.65 0.27

50 0.3 0.85 0.67 2.1 0.37

65 0.36 1 0.82 2.5 0.43

80 1.16 1.25 1 3.1 0.55

100 0.61 1.65 1.34 4.08 0.73

125 0.76 2.04 1.67 5.12 0.91

150 0.91 2.47 2.01 6.16 1.07

- 18 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

3.2.3 Pipe Joining

The method of joining all pipes must be in accordance with the latest

requirements listed in NFPA 12. Acceptable fittings include screwed,

flanges, welded, brazed, flared and compression. Each fitting must be

300 lb. Class. Ordinary cast iron fittings are not acceptable.

3.2.4 Cleaning

All pipe lengths must be reamed, blown clear and swabbed with suitable

solvents to remove burrs, mill varnish and cutting oil before assembly.

3.2.5 Threads

It is recommended that only Teflon tape be used and must be only applied

to male pipe threads. Threads on all pipe and fittings must be tapered

threads conforming to ANSI Specification B-20.1.

3.2.6 Installation

All piping must be installed in accordance with good engineering practice.

The piping system shall be securely supported by hangers or piping

bracket with allowance for expansion and contraction. Refer to ANSI B-

31.1 for bracing requirements.

Class 150 and cast iron fittings must not be used. Fittings used must be a

minimum 300 lb. Class conforming to ASTM A-197 and have a minimum

working pressure of 42 bar (620 PSI). Pressure temperature ratings of the

fitting manufacturer must not be exceeded. Teflon tape must be applied

on male threads only for screwed fittings. See NFPA 12 for further details.

All threaded joints must be in accordance with ANSI B-20.1.

3.3 DISCHARGE NOZZLE

After the system piping has been blown free of debris, install the discharge nozzles in

strict accordance with the system drawings. Orientate the nozzles as shown on

drawings. Make certain that the correct nozzle type(s), and orifice size(s) are

installed in the proper location(s).

3.4 PILOT (LOOP) HOSE (PRESSURE ACTUATION LINES)

Flexible Pilot (Loop) Hose must be ¼”

3.5 FLEXIBLE DISCHARGE HOSE C/W CHECK VALVE

WARNING: ALWAYS CONNECT FLEXIBLE DISCHARGE HOSE INTO

SYSTEM PIPING BEFORE CONNECTING TO SRI CYLINDER

- 19 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

The discharge hose is a heavy duty flexible hose which connects the valve discharge

outlet to the manifold. There is a check valve attached to the discharge hose which

connects to the manifold.

NOTES: The discharge hose must have a smooth bend radius in flexible

loop.

3.6 C02 CYLINDER

The cylinders should be located as close to the protected hazard area as possible.

The assemblies shall be located in a readily accessible location to allow for manual

actuation and ease of inspection, service and maintenance.

The cylinders shall be located in an environment protected from the weather and

where the ambient temperature does not exceed 54oC (130oF) nor fall below 0oC

(32oF). External heating or cooling may be required to maintain this temperature

range. Cylinders must be located and mounted where they will not be subject to

accidental damage or movement. Suitable protection to prevent accidental cylinder

damage or movement must be installed when necessary to prevent accidental

discharge, bodily injury or property damage.

Position cylinders in designated location and secure in place with cylinder bracket

and attaching hardware. Orientate cylinders to that valve outlet is angled towards

discharge piping.

Connect flexible discharge hose to cylinder outlet port. Repeat for each cylinder in

system.

Connect Copper tubing or pilot hose between the pilot cylinder or the Master Cylinder

and the first slave cylinder, pneumatic actuation port. Repeat for the other slave

cylinders.

Each cylinder bracket must be securely anchored to structural supports to absorb the

force generated by cylinder discharge.

3.7 LEVER OPERATED CONTROL HEAD

The lever to be installed on every cylinder on the valve.

Ensure safety seal wire intact before testing and commissioning. This is to prevent

any accidental discharge by pulling the lever.

3.8 PILOT CYLINDER AND MOUNTING BRACKET

Locate pilot cylinder mounting bracket in area where cylinder will be protected from

inclement weather by a suitable total or partial enclosure, preferably adjacent to

cylinders.

- 20 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Locate pilot cylinder mounting bracket in area where cylinder will be protected from

inclement weather by a suitable total or partial enclosure, preferably adjacent to

cylinders.

Install pilot cylinder in position onto mounting bracket, tighten sufficiently to hold

cylinder in place while allowing cylinder enough free space to be manually rotated.

Manually rotate cylinder until cylinder valve discharge outlet is in desired position.

CAUTION: Pilot cylinder must be positioned so that actuation device, when

installed, is readily accessible and cannot be obstructed during

manual operation.

Securely tighten mounting bracket clamps and hardware.

3.9 PRESSURE SWITCH

WARNING: Warn text to prevent personnel injury, de-energise all

electrical components prior to pressure switch installation.

Pressure switches must be connected to the piping in an upright position as shown

on the technical drawings. The standard switches have pressure inlets to connect to

the system piping. The electrical connections are either conduit knockouts for the

standard pressure switch.

3.10 MANUAL PULL STATION

Locate the remote pull boxes as shown on the technical drawings.

Connect pull boxes to the pilot cylinder or master cylinder using 3/8 inch schedule 40

pipe or approved conduit. Do not run more than one cable in each pipe run.

Install a corner pulley at each change in pipe direction. Do not bend the pipe.

Beginning at the pull boxes, remove the covers of the first corner pulley. Feed the

cable through the pulley into the 3/8 inch pipe. Connect one end of the cable to the

cable fastener and cable into handle. Route the other end to the pilot cylinder or

master cylinder, taking up as much slack as possible. Attach the end of the cable to

the lever of the valve at appropriate angle to ensure the lever can be pull down

without difficulty.

Reattach the corner pulley covers.

3.11 POST INSTALLATION CHECK-OUT

After the C02 system installation has been completed, perform the following

inspection and tests.

Verify that cylinders are installed in accordance with installation drawings.

- 21 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

Verify that cylinder brackets and U-Bolts are properly installed and all fittings are

secured.

The piping distribution system must be inspected for compliance with the system

drawings, NFPA 12 and design limitations within this manual.

Check that discharge piping and actuation piping are securely hung. Ensure all

fittings are tight and securely fastened to prevent gas leakage and hazardous

movement during discharge. Means of pipe size reduction and installation position of

tees must be checked for conformance to the design requirements.

The piping distribution system must be cleaned, blown free of foreign material and

inspected internally to prevent the possibility of any oil or particulate matter that may

soil the hazard area or affect the agent distribution due to a reduction in the effective

nozzle orifice area.

The system piping should be pressure tested in accordance with the requirements of

NFPA 12 and the Authority Having Jurisdiction.

Verify nozzles are installed in the correct location as indicated on installation

drawings. Discharge nozzle must be oriented such that optimum gas dispersal can

be achieved. Check nozzle orifices for obstructions.

The discharge nozzles, piping and mounting brackets must be installed such that they

will not cause potential injury to personnel. Gas must not be discharged at head

height or below, where personnel in the normal work area would be injured by the gas

discharge. Gas just not directly impinges on any loose objects or shelves, cabinet

tops or similar surfaces where loose objects could be propelled upon agent

discharge.

Manual pull stations must be properly installed, readily accessible, and accurately

identified. All manual stations used to activate SRI C02 systems should be properly

identified as to their purpose. Particular care should be taken where manual pull

stations for more than one system are in close proximity and could be confused or the

wrong system actuated. In this case, manual stations should be clearly identified as

to which hazard area they affect.

All acceptance testing shall be in accordance with NFPA 12 current edition.

- 22 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

4.0 COMMISSIONING

This section described the commissioning procedure.

Before commencement of commissioning tests visually check the following:-

1. Check that the installation conforms to the engineering drawings. Any

deviations from drawings must be reported.

2. All work, e.g. electrical wiring, carried out by other contractors has been

completed satisfactorily.

3. Check the protected area for confinement of the extinguishing agent, i.e. that

no passage is allowed to other spaces through floor or ceiling voids, ductwork,

holes in partitions or vents, unless allowance has been made.

4. Check that all manual controls are accessible and correctly identified.

5. Check that the discharge nozzles are unobstructed and are adequately

secured. Check that the nozzles comply with sizes shown on the drawings.

6. Check that the C02 cylinder and valve manifolds are correctly sized, and that

check valves and Directional valves are installed for correct directional flow.

7. Check the manifold to cylinder installation for undue strain on connecting

loops because incorrect installation can cause service problems.

8. Check the cylinders are installed in an accessible location, that the area is

clean, dry and ventilated and meets the safe temperature requirements.

9. Check that all system controls, such as valves, lock off, pull boxes, manually

or electrically operated devices, and are accessible to operating personnel. If

located outdoors ensure that they conform to the required standards and that

adequate shelter has been provided.

10. Check that pipes and fittings are sized in accordance with the drawings and

are adequately secured. All piping must be rigidly secured to the nozzle to

prevent damage from recoil.

11. Check that all warning labels and notices give correct information for system

operation and that they are suitably located.

12. Check weigh of cylinders to ensure net content is in accordance with the

requirements.

13. Check all discharge hose are screw and secure tight at both ends.

14. Check all copper tubing for pneumatic actuation is secure and screw tight at

both ends.

15. Check that manual lever on the valve is available and is in standby position.

- 23 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

16. Discharge test should be recommended when there is any question about the

adequacy of the system.

WARNING: Do not proceed with any functional tests until every

precaution has been taken to prevent accidental discharge,

ensure that all personnel in protected areas know that you are

there and of the work you are doing.

Instruction for Re-commissioning the system after discharge

1. Refit the cylinder transport caps. Remove the empty C02 cylinders.

2. Replace with fully charged cylinder and secure.

3. Send back empty cylinder to SRI for refilling.

4. If distribution valves are fitted check that they are shut.

5. Check nozzles’ orifices for debris, clean if necessary.

6. Re-set all system ancillaries, including pressure switches, pressure trips,

dampers, curtains, door or window shutters, ventilators, remote lock-off

services and pull boxes.

- 24 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

5.0 OPERATION

5.1 GENERAL

Pressurized C02 gas is retained in the cylinder by a discharge valve. When the

discharge valve is actuated by a solenoid or electric control head, the C02 gas

discharges through the valve outlet and is directed through the distribution piping to

the nozzles. The nozzles provide the proper flow rate and distribution of C02 gas.

5.2 OPERATING PROCEDURES

5.2.1 Automatic Operation

When a system is operated automatically via the 2 zone detection and

control system, personnel must evacuate the hazard area promptly upon

hearing the alarm. Make sure no one enters the hazard area. Call the fire

brigade immediately.

5.2.2 Manual Pull Station or Remote Manual Operation

Operate as follows:-

1. Proceed to appropriate remote manual pull station for the hazard.

2. Operate the manual pull station.

3. Leave the hazard area quickly.

4. Allow no one to enter the hazard area. Call the fire brigade

immediately.

NOTE: These instructions must be posted on display in the

protected area.

5.2.3 Local Manual Operation

Operate as follows:-

CAUTION:This manual control is not part of the normal system

actuation and should only be used in a last resort,

emergency condition.

1. Proceed to the appropriate Master cylinder(s) or pilot cylinder (if used)

for the hazard.

2. Operate the lever by pull it downward.

3. Leave the hazard area quickly.

4. Allow no one to enter the hazard area. Call the fire brigade

immediately.

- 25 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

5.3 POST FIRE OPERATION

WARNING: Do not enter a hazard area with an open flame or lighted

cigarette. The possible presence of flammable vapours may

cause re-ignition or explosion.

WARNING: Ensure fire is completely extinguished before ventilating

area. Before permitting anyone to enter the hazard area, ventilate

area thoroughly or use self-contained breathing apparatus.

5.4 CYLINDER RECHARGE

5.4.1 Recharge all C02 and pilot cylinders immediately after use.

5.4.2 Return all cylinders to SRI for refilling.

- 26 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

6.0 MAINTENANCE

This part of the manual describes procedures which enable a proficient Service

Engineer to undertake the regular inspection and testing of a C02 safely in

accordance with the recommendation of NFPA 12.

Before going to site the Service Engineer should obtain the relevant details and

drawings of the systems to be serviced and refer to report of previous service visits

and of fault call-outs since the last service.

The Engineer’s signature on the Service Report and on the record card after carrying

out the work, is confirmation that the system, on that day is in complete operational

order. It is an advantage to have a witness to this fact, and he should therefore

encourage the Customer’s representative to accompany him while he does the work.

The first action to take, when arriving at site, is to report to the customer’s

representative and to ask if there any specific instructions with which to comply.

Ask if any particular problems have arisen since the last service visit.

Ask if any fires have occurred and how the system performed.

Similarly, record any false or accidental operation and get reason.

If it is necessary to take some action which may cause inconvenience to the

Customer, ask his permission first.

Notify all concerned that the fire protection system being maintained and may be

inoperative.

Work systematically and in a clean, tidy and professional manner.

Consider the possibility of genuine fire alarm occurring while you are working on the

system and make appropriate arrangements.

Prepare a service report. Submit a copy to the client, one to the Service Manager

and retain a copy.

Service visits should be on a six-monthly (minimum) basis.

Typical maintenance records are provided in this manual.

- 27 -

PDF created with pdfFactory trial version www.pdffactory.com

CO2 EXTINGUISHING SYSTEM

TECHNICAL DATA

AND

DRAWINGS

- 28 -

PDF created with pdfFactory trial version www.pdffactory.com

You might also like

- TBV Cryogenic Ball Valves CAMERONDocument20 pagesTBV Cryogenic Ball Valves CAMERONboudissaNo ratings yet

- CO2 System PresentationDocument23 pagesCO2 System PresentationPankaj PandeyNo ratings yet

- Flares ImDocument270 pagesFlares ImnelsonsenaNo ratings yet

- Total Control Controllers: Owner'S ManualDocument22 pagesTotal Control Controllers: Owner'S ManualPluot1No ratings yet

- A Comparison of The Fire Suppression Performance o PDFDocument34 pagesA Comparison of The Fire Suppression Performance o PDFDayanne MartinsNo ratings yet

- Calculating Relief Valves Under The New ASHRAEDocument2 pagesCalculating Relief Valves Under The New ASHRAEchandrashekharsNo ratings yet

- Danfoss Co2 dRZ0ZR102Document16 pagesDanfoss Co2 dRZ0ZR102Denis Alfafrio GotNo ratings yet

- Toxic Release and Dispersion Model May 2017Document48 pagesToxic Release and Dispersion Model May 2017QeseraReaNo ratings yet

- BS en 12953-12-2003Document22 pagesBS en 12953-12-2003Tuấn ChuNo ratings yet

- Type: Cocon 13: Operators-ManualDocument33 pagesType: Cocon 13: Operators-ManualAbraham Tellez FloresNo ratings yet

- CO2 High Pressure SystemsDocument4 pagesCO2 High Pressure SystemsCahya AuroraNo ratings yet

- LNG Boil Off Gas 1014Document4 pagesLNG Boil Off Gas 1014ابوالحروف العربي ابوالحروفNo ratings yet

- Relief SystemDocument24 pagesRelief SystemFarhanSaatNo ratings yet

- Sabroe SMC & TSMC Units Control 2009Document40 pagesSabroe SMC & TSMC Units Control 2009aveselov88No ratings yet

- LPG - Manual Gaze InerteDocument104 pagesLPG - Manual Gaze InerteCornelNo ratings yet

- Basic Depressuring - Why 15 Minutes PDFDocument3 pagesBasic Depressuring - Why 15 Minutes PDFanup_chem3772No ratings yet

- W6 Toxic Release and Dispersion Models UlearnDocument61 pagesW6 Toxic Release and Dispersion Models UlearnFakhrulShahrilEzanieNo ratings yet

- Compressor Stage Pressure - Design & OptimizationDocument4 pagesCompressor Stage Pressure - Design & OptimizationAshwin ChandaranaNo ratings yet

- Operation and Maintenance Instruction: Cryogenic PumpsDocument26 pagesOperation and Maintenance Instruction: Cryogenic PumpsMidhun Bhuvanesh.B 7ANo ratings yet

- Pur-15-02 - Air Purger Type PurDocument4 pagesPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNo ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- WSAC Alternative To CWDocument47 pagesWSAC Alternative To CWweweqweqwNo ratings yet

- EGE13B11Document18 pagesEGE13B11Jhonny Rafael Blanco CauraNo ratings yet

- The Definitive Guide To Cryogenic EngineeringDocument21 pagesThe Definitive Guide To Cryogenic EngineeringSamanthaPereraNo ratings yet

- HVAC Package-3 - SITC of AHU - Section - 3Document18 pagesHVAC Package-3 - SITC of AHU - Section - 3FarzanaShaik100% (1)

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- Product Manual DCP Trolley Mounted 25-50-75 KGDocument6 pagesProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Mobil-Branded Refrigeration Lubricant Selection Guide For Industrial SystemsDocument2 pagesMobil-Branded Refrigeration Lubricant Selection Guide For Industrial Systemskskr_44100% (1)

- 6.C.b Industrial Waste Incineration GB2009Document21 pages6.C.b Industrial Waste Incineration GB2009AgungGhaniKramawijayaNo ratings yet

- Norsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Document3 pagesNorsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Anonymous v4akjrQxKNo ratings yet

- CO2 Handbook IIARDocument190 pagesCO2 Handbook IIAROnofreHalberNo ratings yet

- NH3 Guidance EPADocument27 pagesNH3 Guidance EPAtfbennett100% (1)

- 05 V PattabathulaDocument16 pages05 V Pattabathulapcorreia_81No ratings yet

- Computer Simulation SO2Document4 pagesComputer Simulation SO2draj1875977No ratings yet

- Cryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467Document33 pagesCryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467meeraNo ratings yet

- Overall Heat Transfer Coefficient and Pipe Length CalculationDocument2 pagesOverall Heat Transfer Coefficient and Pipe Length CalculationCaleb FalcoteloNo ratings yet

- Steel Reheat: Combustion OptimizationDocument2 pagesSteel Reheat: Combustion OptimizationlpczyfansNo ratings yet

- Bw111a Engineroom and Pumproom Fixed SystemDocument6 pagesBw111a Engineroom and Pumproom Fixed SystemMihaela CimpeanuNo ratings yet

- REfrigeration CO2 GuidelinesDocument7 pagesREfrigeration CO2 GuidelinesMaheshNo ratings yet

- Guidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010Document26 pagesGuidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010elikruNo ratings yet

- English VRU EvolutionDocument64 pagesEnglish VRU Evolutionsnikolopou2740100% (1)

- Diagnostic Tools and Control Parameters For Refinery HeatersDocument7 pagesDiagnostic Tools and Control Parameters For Refinery HeaterskrishnaNo ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Document28 pagesAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Thermal Decomposition of Calcium Sulfate PDFDocument236 pagesThermal Decomposition of Calcium Sulfate PDFsupendra phuyalNo ratings yet

- 5-5 CO2 Low Pressure SystemDocument74 pages5-5 CO2 Low Pressure Systemhamzeh100% (1)

- Concepts For Efficient Hydrogen LiquefactionDocument16 pagesConcepts For Efficient Hydrogen LiquefactionDilla WahabNo ratings yet

- Air Purger & Ammonia PurifierDocument22 pagesAir Purger & Ammonia PurifierJulius Wahyu AgungNo ratings yet

- DMA BrochureDocument20 pagesDMA BrochurelongttNo ratings yet

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74No ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- 1.0 J1415 QF200-2 PSA DatasheetDocument2 pages1.0 J1415 QF200-2 PSA DatasheetCarlos MagNo ratings yet

- Trabajo RefrigeranteDocument42 pagesTrabajo RefrigeranteJavierNo ratings yet

- Toxic Release and Dispersion ModelsDocument42 pagesToxic Release and Dispersion ModelsAbhijit NathNo ratings yet

- Refrigeration Liquid Recirculation SystemsDocument7 pagesRefrigeration Liquid Recirculation Systemsgoodspeed_phNo ratings yet

- ccc10-1 2018 222Document10 pagesccc10-1 2018 222Efari BahcevanNo ratings yet

- Manual of Induction Furnace For CustomerDocument66 pagesManual of Induction Furnace For CustomerAbdul Basit100% (14)

- MANUAL TUBEFORMER - 1602 - 2012 - 08 - 22 - enDocument44 pagesMANUAL TUBEFORMER - 1602 - 2012 - 08 - 22 - enBulboaca Bogdan100% (7)

- Company ProfileDocument76 pagesCompany ProfileChhomNo ratings yet

- 15 TMDocument1 page15 TMChhomNo ratings yet

- SRE05U: Floating / Modulating Digital ThermostatDocument1 pageSRE05U: Floating / Modulating Digital ThermostatChhomNo ratings yet

- 14 PG - PGG - PGCDocument1 page14 PG - PGG - PGCChhomNo ratings yet

- 16 MPF61KBDocument1 page16 MPF61KBChhomNo ratings yet

- Msp74Ja: Differential Pressure SwitchDocument1 pageMsp74Ja: Differential Pressure SwitchChhomNo ratings yet

- BIOTECH Catalog-EnglishDocument19 pagesBIOTECH Catalog-EnglishChhomNo ratings yet

- Liquid Flow Switch: DimensionDocument1 pageLiquid Flow Switch: DimensionChhomNo ratings yet

- SRE05B: On/Off Digital ThermostatDocument1 pageSRE05B: On/Off Digital ThermostatChhomNo ratings yet

- MP3000FCT-2A: Fan Coil Unit On/Off Digital Touch Screen ThermostatDocument1 pageMP3000FCT-2A: Fan Coil Unit On/Off Digital Touch Screen ThermostatChhomNo ratings yet

- MP810FCT-CO-CLS-MY: Fan Coil Unit Digital ThermostatDocument1 pageMP810FCT-CO-CLS-MY: Fan Coil Unit Digital ThermostatChhomNo ratings yet

- MP803FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP803FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomNo ratings yet

- MP908PIT-V1-S1-F3: Modulating Digital ThermostatDocument1 pageMP908PIT-V1-S1-F3: Modulating Digital ThermostatChhomNo ratings yet

- MP803PIT-V2-S1-F3: Modulating Digital ThermostatDocument1 pageMP803PIT-V2-S1-F3: Modulating Digital ThermostatChhomNo ratings yet

- MP810FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP810FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomNo ratings yet

- MP908FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP908FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomNo ratings yet

- MP8063BFCT-CO: Fan Coil Unit On/Off ThermostatDocument1 pageMP8063BFCT-CO: Fan Coil Unit On/Off ThermostatChhomNo ratings yet

- Control Valves: Leading The Way in Piping NeedsDocument32 pagesControl Valves: Leading The Way in Piping NeedsTanveer AzizNo ratings yet

- 11.ex Gas SensorDocument8 pages11.ex Gas SensorChhomNo ratings yet

- SRE04F: Fan Coil Unit Modulating ThermostatDocument1 pageSRE04F: Fan Coil Unit Modulating ThermostatChhomNo ratings yet

- MP803FCT-2W: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP803FCT-2W: Fan Coil Unit On/Off Digital ThermostatChhomNo ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- MP806FCT-CO: Fan Coil Unit On/Off ThermostatDocument1 pageMP806FCT-CO: Fan Coil Unit On/Off ThermostatChhomNo ratings yet

- ND112Document1 pageND112ChhomNo ratings yet

- Catalog of DaeyounDocument8 pagesCatalog of DaeyounChhomNo ratings yet

- Quality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsDocument2 pagesQuality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsChhomNo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsDocument40 pagesMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizNo ratings yet

- Foodservice Catalog Price ListDocument130 pagesFoodservice Catalog Price ListChhomNo ratings yet

- Think For The Environment and Human... : PEM Korea Rises Up To The Challenge of Creating A Pleasant and Fulfilling Life!Document11 pagesThink For The Environment and Human... : PEM Korea Rises Up To The Challenge of Creating A Pleasant and Fulfilling Life!ChhomNo ratings yet

- ECE Lab ManualDocument73 pagesECE Lab ManualPrasad ChamarajanagarNo ratings yet

- RAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and PaintingDocument4 pagesRAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and Paintingshaiful annuarNo ratings yet

- Safety Officer ExameDocument9 pagesSafety Officer ExameKhiyal HussainNo ratings yet

- CTT CTT: CI (H1 FJ 1. - (1) 1 311 CI d1Document20 pagesCTT CTT: CI (H1 FJ 1. - (1) 1 311 CI d1hheNo ratings yet

- Parts Manual Service Manual: GS-2668 RT GS-3268 RTDocument184 pagesParts Manual Service Manual: GS-2668 RT GS-3268 RTbaracuss323iNo ratings yet

- A Simple Problem To Explain and Clarify The Principles of Risk CalculationDocument20 pagesA Simple Problem To Explain and Clarify The Principles of Risk CalculationjoseoliverosNo ratings yet

- Newlife FamilyDocument420 pagesNewlife FamilyRobel MTNo ratings yet

- Hot Work Safety ProgramDocument11 pagesHot Work Safety ProgramZakirhasNo ratings yet

- EU HazMat PDF PDFDocument96 pagesEU HazMat PDF PDFMikaela SantosNo ratings yet

- Prof. Angel M. Caliguiran, Rcrim, M.A.Crim, PH.D.,CST, CSTD, CSC, CSPDocument19 pagesProf. Angel M. Caliguiran, Rcrim, M.A.Crim, PH.D.,CST, CSTD, CSC, CSPCharles James LacanilaoNo ratings yet

- US - Zerion FVS Series - US - EN - 4.2Document7 pagesUS - Zerion FVS Series - US - EN - 4.2ccorp0089No ratings yet

- 4 - Codes and Regulations MotorsDocument6 pages4 - Codes and Regulations MotorsENOD CONTROL E INSPECCION S.A.C.No ratings yet

- DCR 23 03 07Document243 pagesDCR 23 03 07Viraj MehtaNo ratings yet

- Machine/plant Safety StickersDocument16 pagesMachine/plant Safety Stickerssuhasphatak007No ratings yet

- Maeda LC785 8 Operation ManualDocument401 pagesMaeda LC785 8 Operation ManualSze Tim100% (1)

- Genie S-85 ManualDocument214 pagesGenie S-85 ManualBiuro ŁaszkiewiczNo ratings yet

- Fire Risk Assessment - 1Document4 pagesFire Risk Assessment - 1Zulfikar FitrahNo ratings yet

- VDCT01 02GB-WSMDocument343 pagesVDCT01 02GB-WSMANH LÊ100% (1)

- 1216-2006 (A1)Document49 pages1216-2006 (A1)John RainbirdNo ratings yet

- Road Safety Standard BookDocument228 pagesRoad Safety Standard BookNisar DeenNo ratings yet

- Bobcat E341 PDFDocument50 pagesBobcat E341 PDFAlexander Buchely40% (5)

- Is.4544.2000 0Document17 pagesIs.4544.2000 0Davorin IvićNo ratings yet

- Geni CrennDocument253 pagesGeni CrennRoyenNo ratings yet

- Ambassador InternationalDocument14 pagesAmbassador InternationalhrmlynNo ratings yet

- Assessment Tool For BSFDocument24 pagesAssessment Tool For BSFKristin VillasenotNo ratings yet

- Inzapol CB 733 - MSDSDocument8 pagesInzapol CB 733 - MSDSNew EmailNo ratings yet

- Model No 20501Document5 pagesModel No 20501Achmad HambaliNo ratings yet

- FSED 27F Places of Assembly Occupancy Checklist Rev01Document4 pagesFSED 27F Places of Assembly Occupancy Checklist Rev01Talaingod FirestationNo ratings yet

- FS One Max SDS 2016634Document7 pagesFS One Max SDS 2016634Mohammed KabiruddinNo ratings yet

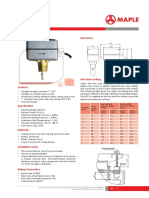

- Defend VPS-LightBody MSDS 1-1-2011Document1 pageDefend VPS-LightBody MSDS 1-1-2011M. White DentalNo ratings yet