Professional Documents

Culture Documents

Shriram Pistons & Rings: Engine Troubleshooting Checklist

Uploaded by

deepak sharma0 ratings0% found this document useful (0 votes)

16 views1 pageThis document provides an engine troubleshooting checklist covering various systems including:

- Air intake system checks for issues like a holed air cleaner element or restricted intake.

- Bottom end and top end wear checks like abnormal noise, low compression, or excessive blow-by.

- Cooling system checks such as a faulty thermostat, radiator issues, or low coolant level.

- Fuel dilution checks like a leaking fuel system or extended idling causing fuel in the oil.

- Incomplete combustion issues related to restricted air or exhaust, fuel/injector problems, or extended oil change intervals.

- Water or coolant leak checks including pressure testing to locate leaks in the

Original Description:

Engine Check sheet

Original Title

Engine Checksheet-Phenomenon type analysis

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an engine troubleshooting checklist covering various systems including:

- Air intake system checks for issues like a holed air cleaner element or restricted intake.

- Bottom end and top end wear checks like abnormal noise, low compression, or excessive blow-by.

- Cooling system checks such as a faulty thermostat, radiator issues, or low coolant level.

- Fuel dilution checks like a leaking fuel system or extended idling causing fuel in the oil.

- Incomplete combustion issues related to restricted air or exhaust, fuel/injector problems, or extended oil change intervals.

- Water or coolant leak checks including pressure testing to locate leaks in the

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageShriram Pistons & Rings: Engine Troubleshooting Checklist

Uploaded by

deepak sharmaThis document provides an engine troubleshooting checklist covering various systems including:

- Air intake system checks for issues like a holed air cleaner element or restricted intake.

- Bottom end and top end wear checks like abnormal noise, low compression, or excessive blow-by.

- Cooling system checks such as a faulty thermostat, radiator issues, or low coolant level.

- Fuel dilution checks like a leaking fuel system or extended idling causing fuel in the oil.

- Incomplete combustion issues related to restricted air or exhaust, fuel/injector problems, or extended oil change intervals.

- Water or coolant leak checks including pressure testing to locate leaks in the

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

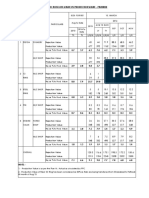

Doc No: RD/PFC/DOC/02

SHRIRAM PISTONS & RINGS Rev No: 00

Rev Date:

ENGINE TROUBLESHOOTING CHECKLIST

AIR INTAKE SYSTEM CHECKS BOTTOM END WEAR CHECKS

• Air cleaner element holed or not sealing correctly. • Check filter for abnormal wear particles.

• Incorrect size air cleaner element for type of housing. • Abnormal noise on start up.

• Cracked or distorted air cleaner element housing. • Check for low oil level.

• Restriction gauge adapter broken. • Check oil pressure profile.

• Inlet or induction system from air cleaner to engine • Check for faulty oil pump, oil pick up and pressure

damaged. relief valve.

• Leak in vacuum piping. • Overheating.

• Leak in air feed to compressor. • Coarse dirt entry.

• Inlet manifold gasket leaking or cracked. • Check for cause of fuel dilution.

• Injector seat leaking (petrol engines). • Incorrect oil grade used.

• Damaged or missing breather.

• Damaged or missing dip-stick seal. TOP END WEAR CHECKS

• Faulty or missing oil filler cap. • High blow-by and crankcase pressure.

• Faulty or missing crankcase ventilation. • Low compression.

• Oil storage or top-up containers and funnels dirty. • Lack of power.

• Dirt entry in air intake system.

COOLING SYSTEM CHECKS • Abnormal noise.

• Faulty thermostats, radiator shutters or shutterstats. • Piston torching caused by defective injector spray

• Radiator fins or cores blocked or clogged. pattern

• Defective water pump. and timing.

• Coolant level low.

• Radiator pressure relief cap defective. INCOMPLETE COMBUSTION (SLUDGE) CHECKS

• Fan belts loose. • Restricted air intake system.

• Faulty thermostatic fan. • Restricted exhaust system (damaged exhaust pipe or

• Engine overloaded (lugging). silencer).

• Cooling fins clogged or defective (air cooled engines). • Fuel system malfunction (timing and faulty injectors).

• Engine caked with dirt. • Faulty turbocharger operation or pressures.

• Defective water hoses. • Check for low compression and excessive blow-by.

• Pressurise system and check for leaks. • Extended oil and filter change periods.

• Check sampling technique, was sample taken cold? • Excessive exhaust back pressure (exhaust brake

• Oil cooler passages blocked or restricted. malfunction).

• Air entrained in cooling system. • Low engine operating temperature.

• Insufficient coolant capacity. • After-cooler or inter-cooler malfunction.

• Incorrect air/fuel ratio or timing (gas and petrol • Dirty oil or filter by-pass valve defective.

engines). • Extended idling periods.

• Incorrect coolant mixture. • Faulty altitude compensation device.

• Incompatible coolant mixture. • Dirty or contaminated/adulterated fuel.

• Faulty thermostats or radiator shutters (incorrect

FUEL DILUTION CHECKS operating temperature).

• Sampling technique (sample pump washed out with • Faulty or incorrect engine brake operation.

fuel or solvent). • Incorrect thermostat fitted.

• Leaking fuel inlet and return pipes, pump seals and

unions. WATER OR INTERNAL COOLANT LEAK CHECKS

• Faulty lift/transfer pump. • Pressure test cooling system to locate leak.

• Worn or faulty injectors (e.g. incorrect spray pattern or • Pressure test with sump removed to locate leak.

break out pressure). • Release pressure with sump removed to locate leak.

• Extended idling periods. • Blown cylinder head gasket.

• Faulty internal injector seals or O-rings. • Defective cylinder head seals.

• Fuel leaks - pressure test system. • Leaking sleeve seals.

• Incorrect thermostat fitted. • Leaking oil cooler.

• Extended periods under low engine load. • Cylinder liner cracked or holed.

• Pump calibration or timing incorrect. • Injector cooling seals leaking.

• Restricted fuel return lines. • Engine breather blocked, missing or damaged.

• Contaminated fuel. • Low engine operating temperature.

• Faulty engine protection system. • Extended idling periods.

• Low operating temperature.

You might also like

- Tips For Troubleshooting EngineDocument22 pagesTips For Troubleshooting EngineSandeep NikhilNo ratings yet

- Procedure - Context of The OrganizationDocument5 pagesProcedure - Context of The OrganizationMarjorie Dulay DumolNo ratings yet

- Cooling System OBH KomatsuDocument55 pagesCooling System OBH KomatsuYUDI WAHYUDI 17249No ratings yet

- Gas Turbines PPT SMPDocument30 pagesGas Turbines PPT SMPSidharthNo ratings yet

- Layered Audit Check SheetsDocument5 pagesLayered Audit Check Sheetsdeepak sharma100% (1)

- Turbo TroubleShooting PDFDocument1 pageTurbo TroubleShooting PDFnamduong368No ratings yet

- Maintenance and Trouble Shooting of Hydraulic SystemsDocument11 pagesMaintenance and Trouble Shooting of Hydraulic SystemsKannan Devadass100% (1)

- pt6 Engine TroubleshootingDocument11 pagespt6 Engine TroubleshootingDade Sobarna94% (18)

- Fault Diagnosis: Problems and Possible Causes: ProblemDocument4 pagesFault Diagnosis: Problems and Possible Causes: ProblemAhmedNo ratings yet

- List of Indian Standard Code For Civil and Structural Works PDFDocument148 pagesList of Indian Standard Code For Civil and Structural Works PDFKalipada Sen100% (1)

- Presentation On Basic Information of Engine (CATERPILLAR)Document50 pagesPresentation On Basic Information of Engine (CATERPILLAR)SAVANT PANWARNo ratings yet

- PEGJ0042-02 - Caterpillar Quick Reference GuideDocument15 pagesPEGJ0042-02 - Caterpillar Quick Reference GuidefrankianiNo ratings yet

- Automatic protection ensures safe operation of refrigeration compressorsDocument50 pagesAutomatic protection ensures safe operation of refrigeration compressorsAhmed SalemNo ratings yet

- Piston Damage and Causes: Piston Crown Damage Damage To The Piston SkirtDocument1 pagePiston Damage and Causes: Piston Crown Damage Damage To The Piston SkirtMoaed KanbarNo ratings yet

- PVF Pvaf CVF Cvaf Tables For Financial ManagementDocument11 pagesPVF Pvaf CVF Cvaf Tables For Financial Managementvikas25% (4)

- Cooling Syatem TestingDocument68 pagesCooling Syatem TestingTung NguyenNo ratings yet

- Why Compressors FailDocument57 pagesWhy Compressors FailNowshad AlamNo ratings yet

- Troubleshooting. Compressor PDFDocument3 pagesTroubleshooting. Compressor PDFHasib KhanNo ratings yet

- Air Compressor Maintenance Log PDFDocument2 pagesAir Compressor Maintenance Log PDFCanh Luongtien100% (3)

- Troubleshoot engine issues with this comprehensive guideDocument20 pagesTroubleshoot engine issues with this comprehensive guideAbdallah MansourNo ratings yet

- ST - MaintenanceDocument26 pagesST - MaintenanceHayderr HassNo ratings yet

- Preventive Maintenance Scope-TG and BOPDocument9 pagesPreventive Maintenance Scope-TG and BOPGmail44No ratings yet

- Main Engine Safety AlarmsDocument32 pagesMain Engine Safety AlarmsHarishbhusan PanigrahiNo ratings yet

- Ajax Cause & EffectDocument3 pagesAjax Cause & EffectgustavoespinosamNo ratings yet

- Vda Libro 3 PDFDocument157 pagesVda Libro 3 PDFsofilanda100% (3)

- 4 - Lighting and Energy Standards and CodesDocument34 pages4 - Lighting and Energy Standards and CodesMark Jeffrey PigaNo ratings yet

- Quality Maintenance Training Programme: Concept & ImplementationDocument46 pagesQuality Maintenance Training Programme: Concept & Implementationdeepak sharmaNo ratings yet

- Pump TroubleshootingDocument514 pagesPump Troubleshootingmohamed hamedNo ratings yet

- C 7Document183 pagesC 7Liza Cabalquinto LorejoNo ratings yet

- Engine troubleshooting guideDocument94 pagesEngine troubleshooting guideGanapathi SankarNo ratings yet

- Engine Systems SpecificationDocument10 pagesEngine Systems SpecificationAroonBhagwandinNo ratings yet

- Operation RelatedDocument11 pagesOperation RelatedKamalGoelNo ratings yet

- CN 04-007 Trouble ShootingDocument5 pagesCN 04-007 Trouble ShootingTelemetria EnerflexNo ratings yet

- MinMach HomePage14Document25 pagesMinMach HomePage14miningnova2100% (1)

- Trouble ShootingDocument25 pagesTrouble ShootingPrem SagarNo ratings yet

- Generator in India, Delhi Gensets, India Generator, Gensets Delhi 4Document3 pagesGenerator in India, Delhi Gensets, India Generator, Gensets Delhi 4gbaludbNo ratings yet

- General Maintenance InformationDocument19 pagesGeneral Maintenance InformationAung Kyaw Zaw100% (1)

- Pump Troubleshooting GuideDocument2 pagesPump Troubleshooting GuideFallo SusiloNo ratings yet

- Tuneup Engine FormDocument2 pagesTuneup Engine FormDedik SudarwantoNo ratings yet

- Troubleshooting Guide for Marine EnginesDocument7 pagesTroubleshooting Guide for Marine EnginesAlejandroPalenciaNo ratings yet

- Crdi - Symptom Troubleshooting Guide TableDocument6 pagesCrdi - Symptom Troubleshooting Guide TableJonnifer BundaNo ratings yet

- Lapping inDocument40 pagesLapping inLee Martin DomingoNo ratings yet

- Boiler Starting Failure - Troubleshooting: 2) Line Filter at The Inlet of The Fuel Line For Burner Is ChokedDocument36 pagesBoiler Starting Failure - Troubleshooting: 2) Line Filter at The Inlet of The Fuel Line For Burner Is ChokedJhay SustiguerNo ratings yet

- Compressor Troubleshooting ChecklistDocument8 pagesCompressor Troubleshooting Checklistankur2061No ratings yet

- 11.3.1 Explain Causes of Scavenge Fires and Remedial ActionsDocument13 pages11.3.1 Explain Causes of Scavenge Fires and Remedial ActionsVishu SharmaNo ratings yet

- CarbuerationDocument16 pagesCarbuerationDennis DaleNo ratings yet

- Chapter 37 Heating and Air-Conditioning System Maintenanc, Diagnosis and ServiceDocument22 pagesChapter 37 Heating and Air-Conditioning System Maintenanc, Diagnosis and ServiceROSAN YUMANGNo ratings yet

- Kymco Vitality Carburador PDFDocument29 pagesKymco Vitality Carburador PDFFlanagan MatusNo ratings yet

- 7th Turbine Emergency Conditions SanthoshDocument12 pages7th Turbine Emergency Conditions SanthoshgauravNo ratings yet

- Load DiagramDocument26 pagesLoad DiagramnareshNo ratings yet

- ValvesDocument40 pagesValvesMizta KunaNo ratings yet

- 11 SPS System Trouble ShootingDocument36 pages11 SPS System Trouble Shootingjuliocanel2009No ratings yet

- Suggested Installation Procedures and Instructions For Gasoline EnginesDocument7 pagesSuggested Installation Procedures and Instructions For Gasoline EnginesRyan Tai Hwa ChenNo ratings yet

- 4BT Maintance PlanDocument5 pages4BT Maintance PlanMaurice ConnorNo ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- Quiz: When Experiencing Engine Knock, What Are The Possible Problems? What Are The Possible Solutions?Document3 pagesQuiz: When Experiencing Engine Knock, What Are The Possible Problems? What Are The Possible Solutions?Teptep GonzalesNo ratings yet

- Engine Maintenance OverhaulDocument54 pagesEngine Maintenance OverhaulfarahNo ratings yet

- Maintenance and Troubleshooting of Positive Displacement BlowersDocument36 pagesMaintenance and Troubleshooting of Positive Displacement Blowersanup_nairNo ratings yet

- Ariel MANUAL 08350-353 NigeriaDocument3 pagesAriel MANUAL 08350-353 Nigeriazohaib shabirNo ratings yet

- Motorcycle BasicDocument84 pagesMotorcycle BasicJohn Lester M. Dela CruzNo ratings yet

- Microsoft Word - Viscous FansDocument9 pagesMicrosoft Word - Viscous Fanswayne kiwicylinderheadsNo ratings yet

- Epc 4 Basic Engine TestingDocument33 pagesEpc 4 Basic Engine Testingraumil1237590No ratings yet

- Recip Engine Troubleshooting GuideDocument15 pagesRecip Engine Troubleshooting GuideKaung Htet Cho100% (2)

- Petrol 1Document66 pagesPetrol 1deepak sharmaNo ratings yet

- 1 Rejection Data - Budget Vs Actual - PathrediDocument1 page1 Rejection Data - Budget Vs Actual - Pathredideepak sharmaNo ratings yet

- Diesel 1Document50 pagesDiesel 1deepak sharmaNo ratings yet

- Tss BasicDocument148 pagesTss Basicdeepak sharmaNo ratings yet

- Welcome To The PresentationDocument29 pagesWelcome To The Presentationdeepak sharmaNo ratings yet

- 2 Rejection Loss Value VS Production Value - PathrediDocument1 page2 Rejection Loss Value VS Production Value - Pathredideepak sharmaNo ratings yet

- 16 - Aug S836Document1 page16 - Aug S836deepak sharmaNo ratings yet

- Shriram Pistons: Pathredi: Phenomenon Wise Analysis of Piston SeizureDocument1 pageShriram Pistons: Pathredi: Phenomenon Wise Analysis of Piston Seizuredeepak sharmaNo ratings yet

- Layered Audit Plan-PlantDocument4 pagesLayered Audit Plan-Plantdeepak sharmaNo ratings yet

- Annexure - C: A) Phenomenon Wise Analysis Chart For Blow byDocument3 pagesAnnexure - C: A) Phenomenon Wise Analysis Chart For Blow bydeepak sharmaNo ratings yet

- S109 Vendor Rating For The Current FY: 2016-17Document1 pageS109 Vendor Rating For The Current FY: 2016-17deepak sharmaNo ratings yet

- 16 Dec S836Document1 page16 Dec S836deepak sharmaNo ratings yet

- The Business Case For Implementing Machine VisionDocument175 pagesThe Business Case For Implementing Machine Visiondeepak sharmaNo ratings yet

- Failure Investigation Report - Gasoline EngineDocument3 pagesFailure Investigation Report - Gasoline Enginedeepak sharmaNo ratings yet

- Shriram Pistons: Pathredi: Phenomenon Wise A Nalysis Chart For High Oil Consumption (H.O.C.)Document1 pageShriram Pistons: Pathredi: Phenomenon Wise A Nalysis Chart For High Oil Consumption (H.O.C.)deepak sharmaNo ratings yet

- Epson DS-730NDocument2 pagesEpson DS-730Ndeepak sharmaNo ratings yet

- Shriram Pistons & Rings LTD.: Pathredi (Rajasthan)Document10 pagesShriram Pistons & Rings LTD.: Pathredi (Rajasthan)deepak sharmaNo ratings yet

- Shriram Pistons & Rings: Engine Troubleshooting ChecklistDocument1 pageShriram Pistons & Rings: Engine Troubleshooting Checklistdeepak sharmaNo ratings yet

- 2.0 ChangesDocument32 pages2.0 Changesdeepak sharmaNo ratings yet

- Suzuki Green GuidelinesDocument21 pagesSuzuki Green Guidelinesdeepak sharmaNo ratings yet

- Unit 1 Modern ProcessorsDocument52 pagesUnit 1 Modern ProcessorsSudha PalaniNo ratings yet

- Mapua Institute of Technology Experiment Validates Bernoulli's TheoremDocument16 pagesMapua Institute of Technology Experiment Validates Bernoulli's TheoremNadine Pascual100% (2)

- PJ1000C-LCD: User ManualDocument30 pagesPJ1000C-LCD: User ManualQuive CarlosNo ratings yet

- Introduction To Structural AnalysisDocument15 pagesIntroduction To Structural AnalysisShereen RodrigoNo ratings yet

- Surveying NotesDocument7 pagesSurveying NotesTrina SambasNo ratings yet

- TM 11-6665-224-15Document113 pagesTM 11-6665-224-15SiviNo ratings yet

- Eseu MotivationalDocument6 pagesEseu MotivationalAlexandru RateaNo ratings yet

- Analyzing A Geographic Data Source A. B. Visualize. SAS Visual Analytics AppearsDocument5 pagesAnalyzing A Geographic Data Source A. B. Visualize. SAS Visual Analytics AppearsAdetola AdeosunNo ratings yet

- ISI Students' Brochure Details B.Stat. (Hons.) CurriculumDocument45 pagesISI Students' Brochure Details B.Stat. (Hons.) CurriculumDr. Mousumi BoralNo ratings yet

- Deep Learning For Environmentally Robust Speech Recognition - An Overview of Recent Developments PDFDocument28 pagesDeep Learning For Environmentally Robust Speech Recognition - An Overview of Recent Developments PDF福福No ratings yet

- PLC SCADA Based Temperature Control SystemDocument5 pagesPLC SCADA Based Temperature Control SystemSaurav TiwariNo ratings yet

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnDocument6 pagesKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnAshraf SeragNo ratings yet

- BE Information Technology 0Document655 pagesBE Information Technology 0virendra giraseNo ratings yet

- Igcse Chemistry Section 5 Lesson 1Document62 pagesIgcse Chemistry Section 5 Lesson 1XX OniiSan XXNo ratings yet

- Combo FixDocument4 pagesCombo FixJulio Cesar Camones CastilloNo ratings yet

- Astm D1014 PDFDocument4 pagesAstm D1014 PDFabilio_j_vieiraNo ratings yet

- Docu46403 White Paper EMC Documentum D2 4.1 InteroperabilityDocument16 pagesDocu46403 White Paper EMC Documentum D2 4.1 InteroperabilityHariprasad ManchiNo ratings yet

- Rules of Categorical Syllogism: Kimjoy S. Auxtero BSTM-3Document5 pagesRules of Categorical Syllogism: Kimjoy S. Auxtero BSTM-3Geviena Pinky Sy SarmientoNo ratings yet

- FINA 4250 Applications of Risk ModelsDocument67 pagesFINA 4250 Applications of Risk ModelsChristopherNo ratings yet

- Machine Design-I and II Lecture NotesDocument37 pagesMachine Design-I and II Lecture NotesAzeem MohammadNo ratings yet

- Jurimetrics 1Document24 pagesJurimetrics 1Maiko Lesmana D0% (1)

- Variant SHD0Document3 pagesVariant SHD0Kamal BatraNo ratings yet

- MRI ScriptDocument1 pageMRI ScriptPeter BolocelliNo ratings yet

- 2023 2024 S1 SB Assignment CorrectedDocument3 pages2023 2024 S1 SB Assignment Corrected31231022022No ratings yet

- INTRO TO ECE - HW Assignment 2:, I, I, I V, V, V, V, P P PDocument8 pagesINTRO TO ECE - HW Assignment 2:, I, I, I V, V, V, V, P P PVienNgocQuangNo ratings yet

- Python Coding ClubDocument36 pagesPython Coding ClubBlue GirlNo ratings yet

- Estimation of Power and Delay of CMOS Phase Detector Using Nano TransistorsDocument57 pagesEstimation of Power and Delay of CMOS Phase Detector Using Nano TransistorsViplav SangvaiNo ratings yet