Professional Documents

Culture Documents

The Effects of Moisture Damage On Asphalt Mixtures Modified With Additives

Uploaded by

Yheral Antonio C TOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effects of Moisture Damage On Asphalt Mixtures Modified With Additives

Uploaded by

Yheral Antonio C TCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/318296123

The Effects of Moisture Damage on Asphalt Mixtures Modified with Additives

and Polymer

Article in Journal of Engineering · July 2017

DOI: 10.17576/jkukm-s-01-01

CITATIONS READS

3 1,458

4 authors, including:

Ahmad Nazrul Hakimi Ibrahim Naeem Aziz Memon

Universiti Kebangsaan Malaysia University of Nottingham

35 PUBLICATIONS 145 CITATIONS 11 PUBLICATIONS 24 CITATIONS

SEE PROFILE SEE PROFILE

Nur Izzi Md. Yusoff

Universiti Kebangsaan Malaysia

200 PUBLICATIONS 1,819 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Bio-asphalt Binders View project

Pavement Materials and Mechanics Team View project

All content following this page was uploaded by Ahmad Nazrul Hakimi Ibrahim on 09 July 2017.

The user has requested enhancement of the downloaded file.

Jurnal Kejuruteraan - Isu Khas 1 (Special Issue 1) 2017: 3-8

The Effects of Moisture Damage on Asphalt Mixtures Modified with Additives

and Polymer

Kesan Kerosakan Lembapan kepada Campuran Asphalt Terbubah bersama Bahan Tambahan dan Polimer

Akmal Othman, Ahmad Nazrul Hakimi Ibrahim, Naeem Aziz Memon &

Nur Izzi Md. Yusoff*

ABSTRACT

One of the causes of premature failure is moisture damage due to loss of adhesion and cohesion which then lead to stripping

and decrease in mixture strength. Previous studies have shown that adding additive, such as nano clay, nano carbon and

nano calcium, to binder is useful in enhancing mixture properties. In this study, the effect of adding nano-clay on mixture

properties was determined. Nano clay in the amount of 2 and 4% by weight of bitumen was added to 60/70 penetration

grade bitumen and mixed at a temperature of 150°C using the melt blending technique at a shear rate of 2000 rpm. The

indirect tensile strength (ITS) test was used to evaluate the cracking properties of the asphalt mixtures and the tensile

strength ratio (TSR) was calculated to determine the degree of asphalt mixtures’ resistance to moisture damage. The results

for the mixtures modified with nano clay were compared with results for mixtures modified by adding 2 and 4% by weight

of bitumen polymer modified bitumen (PG76), hydrated lime and cement. The addition of polymer appears to result in the

greatest potential benefit amongst the modified binders and its highest TSR value indicate that polymer modified binder is

the least susceptible to moisture damage.

Keywords: Nano-clay, polymer, moisture damage, indirect tensile strength

ABSTRAK

Salah satu sebab bagi kegagalan pramatang ialah kerosakan lembapan yang disebabkan oleh kemerosotan dalam

lekatan dan kejelikitan yang seterusnya menyebabkan pelucutan dan menjejaskan kekuatan campuran asfalt. Kajian lalu

menunjukkan bahawa penambahan bahan tambah seperti nanolempung, nanokarbon dan nanokalsium kepada pengikat

berbitumen telah meningkatkan sifat campuran asfalt. Dalam kajian ini, nanolempung digunakan sebagai bahan tambah

untuk menguji kesan terhadap sifat campuran panas asfalt (HMA). Proses pencampuran nanolempung sebanyak 2 dan

4% mengikut berat bitumen ke dalam bitumen gred penusukan 60/70 dilakukan pada suhu 150°C dengan menggunakan

kaedah pencampuran cair pada kadar putaran 2000 rpm. Ujian kekuatan tegangan tak langsung (ITS) digunakan untuk

menguji rintangan retakan p campuran asfalt dan nisbah kekuatan tegangan (TSR) telah dihitung untuk menentukan tahap

rintangan campuran HMA terhadap kerosakan lembapan. Keputusan yang diperoleh untuk nanolempung dibandingkan

dengan keputusan untuk ujian campuran bitumen terubah suai polimer (PG76), kapur terhidrat dan simen dalam peratus yang

sama, iaitu 2 dan 4% mengikut berat bitumen. Keputusan ujian menunjukkan bahawa penambahan polimer menghasilkan

keputusan positif dengan nilai TSR tertinggi berbanding bitumen terubah suai lain.

Kata Kunci: Nanolempung, polimer, kerosakan lembapan, kekuatan tegangan tak langsung.

INTRODUCTION Apart from fiber and polymer, hydrated lime and cement

are also commonly used in the modification of bitumen.

In recent decades, researchers have tried utilizing various Hydrated lime is an active filler in bitumen. According to

types of additives to modify binder and improve road Little et al. (2001), the addition of materials has the beneficial

pavement resistance to damage (Al-Hadidy & Tan 2009; effect of enhancing binder and asphalt mixtures’ ability

Moghaddam & Karim 2012; Sanchez-Alonso et al. 2013; to resist deformation and cracking at low temperature. In

Yao et al. 2012). In general, fibers and polymers are the two addition, cement-based materials have been widely used

main materials used to modify bitumen. Fiber is one of the for many years as composite materials for various types

most common additives used to enhance the bond between of structures. To reduce or control permanent deformation

bitumen and aggregate (Yao et al. 2012). Studies have proven due to water damage, various studies have been conducted

that bituminous materials reinforced with fibers such as which have resulted in anti-stripping additives such as

nylon fibers, carbon fibers and glass fibers could improve cement additives. These additives are used to enhance the

resistance against aging, cracking, fatigue and damage due physico-chemical properties of bitumen and aggregates

to moisture (Yao et al. 2012). (Behiry 2013).

Chap 1.indd 3 09/06/2017 15:31:35

4

During the past decade nanotechnology has emerged MATERIALS AND EXPERIMENTAL DESIGN

as an alternative solution to improve the performance and

durability of construction materials. Due to their small size BINDER

and high surface area, the nature of nano-scale materials is

very different from the nature of the ordinary sized materials. The binder used in this study is 60/70 penetration grade

Several researches have been conducted and results of these bitumen and its properties are presented in Table 1. It was

researchers showed that the rutting and fatigue resistance of found that the 60/70 penetration grade bitumen used meet

asphalt mixtures increased with the addition of nano materials all the required specifications.

(You et al. 2011). According to Liu (2007), the physical

characteristics of bituminous binder can be improved when POLYMER MODIFIED BINDER

the polymer is modified with a small amount of nano-clay

The climatic condition in countries such as Malaysia is

under nanoscopic conditions.

fairly consistent throughout the country and the supply of

To deal with the problems related to the environmental

performance graded (PG) binder in this region is based on

factors in Malaysia, a study need to be conducted to find a way

the higher temperature. This study does not consider low

to increase the asphalt mixtures’ resistance against moisture

temperature environment since the temperature in this country

damage. Alternative methods should be identified to be used

rarely falls below 30°C during daylight hours and usually

in the construction and maintenance of roads. This study

range between 35-45°C. A polymer-modified bitumen,

was conducted to investigate the effect of adding materials

PG-76, was used as a control sample and its physical and

such as nano-clay (NC), Portland cement (PC), hydrated lime

rheological properties are presented in Table 2. The physical

(HL) and polymer modified bitumen on the performance of

and rheological properties of PG-76 meet the minimum

asphalt mixtures.

requirements as compared to the standard specifications.

TABLE 1. Properties of 60/70 penetration grade bitumen

Binder Tests Value Unit Specification Method

Penetration@25°C 63 0.1 mm 60-70 ASTM D5

Softening Point 47.2 °C 47 Min ASTM D36

Ductility >100 Cm >100 ASTM D113

Specific Gravity@25° 1.0354 D-70 ASTM D70

Flash Point 318 °C 250 Min D-92

Trichloroethylene Solution 99.5 wt% 99.5 Min D-2042

Wax content 1.84 wt% 2.0 Max DIN 52015

Loss of Ignition 0.2 wt% 0.2 Max D-5

Penetration Balance 76.0 % 75 Min D-5

TABLE 2. Physical and rheological properties of PG-76

Test Unit Result Requirement Test Standard

Quality Specification

Softening Point °C 93 Min 70°C ASTM D36

Penetration 0.1 mm 46 Min. 45 ASTM D5

Flash Point °C 343 Min 260°C AASHTO T48

Performance Specification

Viscosity at 135°C Pa.s 2.45 Max. 3 Pa.s ASTM D4402

Dynamic shear, G*/sin δ kPa 2.10 Min 1.00 AASHTO T315

Test temp @ 10 rad/s, 76°C kPa

Rolling Thin film Oven Test Residue (AASHTO T240)

Mass Loss % 0.04 Max 1% AASHTO T48

Dynamic shear, G*/sin δ kPa 3.40 Min 2.20 AASHTO T315

Test temp @ 10 rad/s, 76°C kPa

Pressure Ageing Vessel Residue (AASHTO R28)

PAV Ageing Test Temperature

Dynamic shear, G*/sin δ kPa 1200 Max. 5000 AASHTO T315

Test temp @ 10 rad/s, 37°C kPa

Chap 1.indd 4 09/06/2017 15:31:35

5

NANO CLAY MOISTURE DAMAGE

According to Sarsam (2013), the effect of binding the filler A widely accepted test method known as the Modified

particles increase with the decrease in the particle size of Lottman test (AASHTO T283) was used to determine moisture

the filler. Researchers in China have studied the effect of susceptibility of asphalt mixes, and this method was adopted

montmorillonite nano-clay on the copolymer properties of in the Superpave system. The AASHTO T283 test method is a

bitumen modified with styrene-butadiene styrene (SBS) by better procedure than the immersion-compression test (ASTM

mixing the molten mixture with sodium montmorillonite (Na- D1075) or Marshall Immersion method since both these

MMT) and organophilic montmorillonite (OMMT). The result methods fail to effectively predict the moisture susceptibility

of the study showed that the addition of Na-MMT and OMMT of mixtures (Behiry 2013). The immersion compression test

enhanced the viscosity SBS modified bitumen. In addition, the was introduced in the 1950s as the first moisture damage test

mixture showed a higher complex modulus and lower phase on compacted samples under the ASTM standard. More recent

angle, which resulted in a tougher and more elastic bitumen. attempts to develop a test to predict the moisture sensitivity of

Therefore, asphalt mixtures modified with nano-clay could asphalt mixtures took place in the 1960s and 1970s with the

improve rutting resistance compared to unmodified bitumen work of Lottman (1978) and Schmidt and Graf (1972). The

(Polaccoa et al. 2008). importance of simulating field condition by accelerating test

conditions in the laboratory is generally acknowledged.

HYDRATED LIME The specimens were placed between the steel loading

strips using the UTM-25 in the indirect tensile test. Load was

Limestone consists of calcium carbonate, CaCO3, and has applied on specimen at a constant head rate of 50 mm/min

a heating temperature of 980°C at which there is no carbon and the maximum compressive force was recorded until the

dioxide left and only hydrated lime (CaO) is present. When specimen cracked. The ratio of the average tensile strengths

water is added to the hydrated lime, it will expand and crack of the conditioned (saturated) subset to the average tensile

(Little et al. 2001). Adding hydrated lime to asphalt mixtures strength of the controlled (unconditioned) subset is the tensile

produce many benefits such as anti-stripping which could strength ratio (TSR). Moisture sensitivity could be calculated

improve performance under heavy traffic load. using the following Equations 1 and 2:

CEMENT ITS = 2P/πLD (1)

For many years cement-based materials have been widely and

used as composite materials in various types of structures.

TSR = ITS (cond)/ITS (dry) (2)

In order to reduce or control permanent deformation due to

water damage. Various studies have been conducted which where ITS is tensile strength (kPa), P is maximum load (N),

produced anti-stripping additives such as cement additives. L is sample thickness (mm), D is sample diameter (mm),

These additives are used to enhance the physico-chemical ITScond is average tensile strength of the moisture-conditioned

properties of bitumen and aggregates to improve wetting subset (kPa), and ITSdry is average tensile strength of the dry

by lowering the surface tension of bitumen (Behiry 2013). subset (kPa).

Portland cement is one of the additives used in this study.

AGGREGATE PROPERTIES

RESULTS AND DISCUSSION

The aggregate used in this study was excavated from a mine AGGREGATE PROPERTIES ANALYSIS

located in Kajang, in the eastern part of the state of Selangor,

Malaysia. The aggregate gradation was selected according The physical properties of the aggregates used are presented

to the ASTM D 3515-96 (D-5). The physical properties of the in Table 3. The table shows that the aggregates used met all

aggregates used was determined through several aggregate the requirement of the specifications. The selected gradation

tests, namely Aggregate Crushing Value (ACV), Aggregate of the aggregate and the specific gravity values are presented

Impact Value (AIV), Flakiness Index (FI), Elongation Index in Table 4. The specific gravity values for both coarse and

(EI), Los Angeles Abrasion Value (LAAV) and Polished Stone fine aggregates are between 2.53 and 2.64 and the specific

Value (PSV). The results for all tests must be below the limit gravity for the bitumen was taken as 1.03.

of the standard specifications. The specific gravity test for

coarse and fine aggregates was conducted to measure the MOISTURE DAMAGE ANALYSIS

strength and quality of materials by determining the relative

density and porosity of an aggregate in accordance with the Moisture damage is among the most critical distresses exerted

BS 812: Part: 1975 standard. upon asphalt pavements. Moisture damage can be defined

as a decrease in the values of asphalt mixtures’ stiffness and

strength durability caused by moisture (Yusoff et al. 2014).

Chap 1.indd 5 09/06/2017 15:31:35

6

TABLE 3. Aggregate properties

Aggregate test Result (%) Criteria (%) Method

Aggregate Crushing Value (ACV) 22.57 <30 BS 812: Part 110:1990

Aggregate Impact Value (AIV) 15.10 <30 BS 812: Part 110:1990

Flakiness Index (FI) 6.00 <20 BS 812: Section 105.1:1989

Elongation Index (EI) 12.00 <20 BS 812: Part 1:1975

Los Angeles Abrasion Value (LAAV) 32.13 <45 ASTM C: 131-81

Polished Stone Value (PSV) 45.00 >40 ASTM E303-93

TABLE 4. Gradation of aggregates and their specific gravity (SG) values

Percent Passing (%)

Sieve Size

Upper Limit Lower Limit Design SG (g/cm3)

12.5 mm 100 90 95 2.63

9.5 mm - - - 2.64

4.75 mm 74 44 59 2.64

2.36 mm 58 28 43 2.54

300 µm 21 5 13 2.53

75 µm 10 2 6 2.64

Dust 2 0 1 2.65

The water trapped in the coated aggregate might cause for both conditioned and unconditioned samples. Mixtures

moisture damage, which then cause severe distresses on the prepared with 2% of cement have the lowest ITS value for

pavement, such as stripping, localized bleeding, potholes, unconditioned sample while the addition of 4% of hydrated

shoving and structural failure due to moisture intrusion lime shows the lowest ITS value for conditioned samples.

into the asphalt pavements. The moisture damage test was On the other hand, mixtures prepared with 2% HL have the

conducted on all mixtures at the OBC for each individual highest ITS values before conditioning which is higher than

mix. the control mixture, and mixtures prepared with 2% NC has

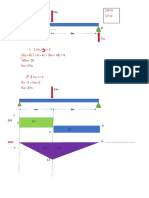

The indirect tensile strength (ITS) values for unconditioned the highest ITS value after conditioning (higher than control

and conditioned mixtures are shown in Figure 1. The use of mixtures).

different type of additives showed varying values of ITS

700

600

Indirect Tensile Strength

500

(ITS, kPa)

400

300

200

100

0

2% 4% 2% 4%

60/70 PG76 2% HL 4% HL CEME CEME NANO NANO

NT NT CLAY CLAY

Unconditioned 593.56 576.96 597.05 583.05 572.45 587.08 594.06 578.36

Conditioned 474.05 571.57 472.48 443.14 507.68 554.45 574.27 565.61

FIGURE 1. ITS values of unconditioned and conditioned mixtures

Chap 1.indd 6 09/06/2017 15:31:36

7

120

100

Tensile strength ratio

80

(TSR, %)

60

40

20

0

2% 4% 2% 4%

60/70 PG76 2% HL 4% HL CEME CEME NANO NANO

NT NT CLAY CLAY

TSR (%) 79.01 99.07 79.14 76 88.69 94.44 96.67 97.79

FIGURE 2. TSR values of mixtures

As can be seen in Figure 2, except for the mixtures Little, D. N., Epps, J. A. & Sebaaly, P. E. 2001. The benefits

prepared with hydrated lime and the control mixtures, all other of hydrated lime in hot mix asphalt. National Lime

mixtures meet the 80% lower limit on TSR value of Superpave Association.

specifications. The mixtures modified with polymer (PG76) Liu, P. 2007. Polymer modified clay minerals: A review.

is the least susceptible to moisture damage with a TSR of Applied Clay Science 38(1-2):.0 12 64-76.

99.07% followed by mixtures with 4% NC (97.79%), 2% NC Lottman RP. 1978. NCHRP Report 192: Predicting Moisture-

(96.67), 4% PC (94.44%) and 2% PC (88.69%). This finding Induced Damage To Asphaltic Concrete. Washington,

indicates that the strength of the asphalt mixtures increase DC.

with the addition of polymer. Moghaddam, T. & Karim, M. 2012. Properties of SMA

Mixtures Containing Waste Polyethylene Terephthalate.

Proceedings of World Academy of Science 618-621.

CONCLUSIONS

Polaccoa, G., Křížb, P., Filippia, S., Stastnab, J., Biondia, D.

& Zanzotto, L. 2008. Rheological Properties of Asphalt/

Based on the laboratory work done in this study, it can be SBS/Clay Blends. European Polymer Journal 44(11):

concluded that the addition of polymer could improve asphalt 3512-3521.

mixtures’ performance against moisture damage. Similarly, Sanchez-Alonso, E., Vega-Zamanillo, A., Calzada-Perez, M.

the addition of NC also shows a great improvement in A. & Castro-Fresno, D. 2013. Effect of warm additives

enhancing asphalt mixtures’ resistance to moisture damage. on rutting and fatigue behaviour of asphalt mixtures.

Construction and Building Materials 47: 240-244.

ACKNOWLEDGEMENTS Sarsam, S. I. 2013. Nano Materials on Asphalt Cement

Properties. International Journal of Scientific research

in Knowledge (IJSRK) 1(10): 422-426.

The authors would like to express their gratitude to the

Schmidt, R. & Graf, P. 1972. The effect of water on the

Department of Civil & Structural Engineering, UKM for their

resilient modulus of asphalt treated mixes. Proceedings

cooperation and the information provided in ensuring the

of the Association of Asphalt Paving Technologists 41:

success of this study.

118-125.

Yao, H., You, Z., Li, L., Shi, X., Goh, S. W., Mills-Beale,

REFERENCES

J. & Wingard, D. 2012. Performance of asphalt binder

Al-Hadidy, A. I. & Tan, Y. Q. 2009. Mechanistic analysis of blended with non-modified and polymer-modified

ST and SBS-modified flexible pavements. Construction nanoclay. Construction and Building Materials 35:

and Building Materials 23(8): 2941-2950. 159-170.

Behiry, A. E. A. E. M. 2013. Laboratory evaluation of You, Z., Mills-Beale, J., Foley, J. M., Roy, S., Odegard, G. M.,

resistance to moisture damage in asphalt mixtures. Ain Dai, Q. & Goh, S. W. 2011. Nanoclay-modified asphalt

Shams Engineering Journal 4(3): 351-363. materials: Preparation and characterization. Construction

and Building Materials 25(2): 1072-1078.

Chap 1.indd 7 09/06/2017 15:31:37

8

Yusoff, N. I. M., Breem, A. A. S., Alattug, H. N. M.,

Hamim, A. & Ahmad, J. 2014. The effects of moisture

susceptibility and ageing conditions on nano-silica/

polymer-modified asphalt mixtures. Construction and

Building Materials 72: 139-147.

Akmal Othman

Ahmad Nazrul Hakimi Ibrahim

Nur Izzi Md. Yusoff1*

Department of Civil and Structural Engineering

Faculty of Engineering and Built Environment

Universiti Kebangsaan Malaysia

43600 UKM Bangi

Malaysia

Naeem Aziz Memon

Department of Civil Engineering

Mehran University of Engineering and Technology

Jamshoro, Pakistan

*Corresponding author; email: izzi@ukm.edu.my

Chap 1.indd 8 stats

View publication 09/06/2017 15:31:37

You might also like

- Oxford Six Class Science NotesDocument15 pagesOxford Six Class Science NotesLisha92% (12)

- Manual de Taller - Yamaha Crux 2006Document0 pagesManual de Taller - Yamaha Crux 2006Insomnia Dj Chile100% (13)

- Urdaneta City University College of Engineering and ArchitectureDocument10 pagesUrdaneta City University College of Engineering and Architecturezed cozNo ratings yet

- Effects of Moisture Damage on Asphalt Mixtures Modified with Additives and PolymerDocument7 pagesEffects of Moisture Damage on Asphalt Mixtures Modified with Additives and PolymerahmedNo ratings yet

- Construction and Building Materials: Mehmet Saltan, Serdal Terzi, Sebnem KarahancerDocument10 pagesConstruction and Building Materials: Mehmet Saltan, Serdal Terzi, Sebnem KarahancerAli YousefNo ratings yet

- NanoaspalDocument8 pagesNanoaspalrosaNo ratings yet

- Ijresm V4 I6 41Document6 pagesIjresm V4 I6 41Civil Engineering DepartmentNo ratings yet

- Experimental Investigation of Effect of PPSBR Polymer Blends On The Moisture Resistance and RuttDocument16 pagesExperimental Investigation of Effect of PPSBR Polymer Blends On The Moisture Resistance and RuttCRISTIAN FABIAN PACHERRES SANCHEZNo ratings yet

- The Use of Polyethylene in Hot Asphalt MixturesDocument7 pagesThe Use of Polyethylene in Hot Asphalt MixturesHanafi HamidNo ratings yet

- Evaluations of SomeDocument11 pagesEvaluations of SomeEris DNo ratings yet

- 919-RUGC Manuscript-2871-1-10-20200308Document8 pages919-RUGC Manuscript-2871-1-10-20200308Houari ABDELHADINo ratings yet

- Nanomaterials 11 01098 v3Document14 pagesNanomaterials 11 01098 v3jibin k pNo ratings yet

- 1 s2.0 S0950061816318141 MainDocument9 pages1 s2.0 S0950061816318141 MainahmadNo ratings yet

- Short and Long Term Rheological and Chemical Characteristics of Nanomodified Asphalt BinderDocument13 pagesShort and Long Term Rheological and Chemical Characteristics of Nanomodified Asphalt BinderAsif ZazaiNo ratings yet

- Construction and Building MaterialsDocument7 pagesConstruction and Building MaterialsWuerNo ratings yet

- A Discussion On Additives Used in Asphalt Concrete For The Enhancement of PropertiesDocument7 pagesA Discussion On Additives Used in Asphalt Concrete For The Enhancement of PropertiesIJRASETPublicationsNo ratings yet

- Jurnal Nano TeknologiDocument22 pagesJurnal Nano TeknologiBayu Aziz FirmansyahNo ratings yet

- Nanoparticles Effect On FRP Filament-Winded Composites PerformanceDocument13 pagesNanoparticles Effect On FRP Filament-Winded Composites PerformanceUday MavooriNo ratings yet

- He Effect of Using Polypropylene Fiber On Deformation Resistance of Asphalt ConcreteDocument6 pagesHe Effect of Using Polypropylene Fiber On Deformation Resistance of Asphalt ConcreteAaron VillasanteNo ratings yet

- Effectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisDocument8 pagesEffectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisFajuyigbeNo ratings yet

- .Natural Rubber Latex Modified Cement Concrete - A ReviewDocument3 pages.Natural Rubber Latex Modified Cement Concrete - A ReviewAnonymous 5PJMzDf45No ratings yet

- Investigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsDocument5 pagesInvestigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsMoslem AghapourNo ratings yet

- 3.improving Mechanics Behavior of Hot Mix Asphalt Using Graphene-OxideDocument8 pages3.improving Mechanics Behavior of Hot Mix Asphalt Using Graphene-OxideDharmendraMahtoNo ratings yet

- Literature Review ZairadziDocument5 pagesLiterature Review Zairadzisiti elferaNo ratings yet

- IJTSEV2I504Document3 pagesIJTSEV2I504Alamgir kabirNo ratings yet

- Jurnal TeknologiDocument8 pagesJurnal TeknologiIgbinwole Kehinde SolomonNo ratings yet

- Micro Estructural 2Document16 pagesMicro Estructural 2Luis FelixNo ratings yet

- Construction and Building Materials: Tahir GonenDocument7 pagesConstruction and Building Materials: Tahir GonenmynameisgunaNo ratings yet

- Modification of 80-100 Penetration Grade BitumenDocument14 pagesModification of 80-100 Penetration Grade BitumenShah Mohammad IqbalNo ratings yet

- Effect of Polythene Modified Bitumen On Properties of Hot Mix AsphaltDocument6 pagesEffect of Polythene Modified Bitumen On Properties of Hot Mix Asphaltsaurabh agrahariNo ratings yet

- Improving Mortar Properties in Saline Environment: November 2016Document5 pagesImproving Mortar Properties in Saline Environment: November 2016Arbi811No ratings yet

- Laboratory Study On Nano Clay Modified Asphalt PavementDocument17 pagesLaboratory Study On Nano Clay Modified Asphalt PavementAli YousefNo ratings yet

- Plastering Mortar For Fire ResistenceDocument8 pagesPlastering Mortar For Fire ResistenceDan AvNo ratings yet

- Properties of Polymer Modified Bitumen After Rubber-Bitumen InteractionDocument40 pagesProperties of Polymer Modified Bitumen After Rubber-Bitumen InteractionAhmed Tahsin100% (1)

- The Effect of Hybrid Anti Stripping AgenDocument15 pagesThe Effect of Hybrid Anti Stripping AgenMILON KUMAR HORENo ratings yet

- Evaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesDocument10 pagesEvaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesMa VeloNo ratings yet

- Experimental Study On The Properties of Self-Curing ConcreteDocument7 pagesExperimental Study On The Properties of Self-Curing ConcreteSaurabh BhoyeNo ratings yet

- Effect of Cementation Level On Performance of Rubb 221201 104645Document10 pagesEffect of Cementation Level On Performance of Rubb 221201 104645hanis hanisahNo ratings yet

- Chapter One: 1.1. Problem StatementDocument11 pagesChapter One: 1.1. Problem StatementetayhailuNo ratings yet

- Indirect Tensile Strength Method For Defining A PRDocument12 pagesIndirect Tensile Strength Method For Defining A PRGV RamasubbaraoNo ratings yet

- Moisture Damage 5Document10 pagesMoisture Damage 5حسين الشهريNo ratings yet

- Badry 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012032Document17 pagesBadry 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012032rahul kumarNo ratings yet

- Paper Advance MaterialDocument9 pagesPaper Advance MaterialDo KyungsooNo ratings yet

- Effect of coconut fibers on asphalt mixture characteristicsDocument13 pagesEffect of coconut fibers on asphalt mixture characteristicsAbdu Almenam EkhmiraNo ratings yet

- bitum məqaləDocument6 pagesbitum məqaləf.maharramovaNo ratings yet

- 02 Finale File For PrintDocument83 pages02 Finale File For Printvidhya associateNo ratings yet

- PP Reinforced With Recycled and Treated Rubber Particles: ArticleDocument6 pagesPP Reinforced With Recycled and Treated Rubber Particles: ArticleCristina VladutaNo ratings yet

- Review On Laboratory Work Used To Improve Quality of Asphalt Mix Using Different Waste Material Adding Stone Matrix Asphalt and Banana FibreDocument5 pagesReview On Laboratory Work Used To Improve Quality of Asphalt Mix Using Different Waste Material Adding Stone Matrix Asphalt and Banana FibreIJRASETPublicationsNo ratings yet

- Behavior of Concrete With Polymer Additive at FresDocument9 pagesBehavior of Concrete With Polymer Additive at Freslleonora.zeqiriNo ratings yet

- Cement-Bound Granular Materials Crack Propagation Reinforced FibersDocument13 pagesCement-Bound Granular Materials Crack Propagation Reinforced FibersSatish Kumar GautamNo ratings yet

- Investigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyDocument12 pagesInvestigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyAbdalla Mohamed AbdallaNo ratings yet

- Evaluation of Mechanical Properties of Nano-Clay Modified Asphalt MixturesDocument13 pagesEvaluation of Mechanical Properties of Nano-Clay Modified Asphalt MixturesRavichandran.PNo ratings yet

- The Role of Nanomaterials in Reducing Moisture Damage of Asphalt MixesDocument14 pagesThe Role of Nanomaterials in Reducing Moisture Damage of Asphalt MixesEizu YangNo ratings yet

- 10.3934 Matersci.2019.6.1164Document12 pages10.3934 Matersci.2019.6.1164Romil SharmaNo ratings yet

- Laboratory investigation of cement and fly ash modified asphalt mixturesDocument8 pagesLaboratory investigation of cement and fly ash modified asphalt mixturesMan ManNo ratings yet

- ICPIC2018 122 Final v4Document7 pagesICPIC2018 122 Final v4Long An DoNo ratings yet

- Investigation of The Deformability Properties of Fiber Reinforced Cemented SandDocument27 pagesInvestigation of The Deformability Properties of Fiber Reinforced Cemented SandDralex SmithNo ratings yet

- Strength Properties of Soft Clay Treated With Mixture of nano-SiO2 and Recycled Polyester Fiber PDFDocument12 pagesStrength Properties of Soft Clay Treated With Mixture of nano-SiO2 and Recycled Polyester Fiber PDFFahim KhanNo ratings yet

- 1 s2.0 S1359836817301798 MainDocument9 pages1 s2.0 S1359836817301798 MainMiritoiu CosminNo ratings yet

- Coir Epoxy CompositeDocument16 pagesCoir Epoxy CompositeSSN MFGNo ratings yet

- Natural Rubber and Reclaimed Rubber Composites A Systematic ReviewDocument19 pagesNatural Rubber and Reclaimed Rubber Composites A Systematic ReviewalokaNo ratings yet

- IOP Conf Ser Earth Environ Sci 212 012079Document6 pagesIOP Conf Ser Earth Environ Sci 212 012079Aisyah Indah IrmayaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Pregunta 02 RedDocument2 pagesPregunta 02 RedYheral Antonio C TNo ratings yet

- Pregunta 02 RedDocument2 pagesPregunta 02 RedYheral Antonio C TNo ratings yet

- CaudalDocument1 pageCaudalYheral Antonio C TNo ratings yet

- Pregunta 02-RedDocument2 pagesPregunta 02-RedYheral Antonio C TNo ratings yet

- Ejercicio 01 Practica 01Document1 pageEjercicio 01 Practica 01Yheral Antonio C TNo ratings yet

- CaudalDocument1 pageCaudalYheral Antonio C TNo ratings yet

- Construction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuDocument9 pagesConstruction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuYheral Antonio C TNo ratings yet

- Construction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuDocument9 pagesConstruction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuYheral Antonio C TNo ratings yet

- One (1) Year Standard Limited WarrantyDocument8 pagesOne (1) Year Standard Limited WarrantymarcoNo ratings yet

- Efecto de Agregado-Betún Compatibilidad en Humedad Susceptibilidad de Asfalto MezclasDocument13 pagesEfecto de Agregado-Betún Compatibilidad en Humedad Susceptibilidad de Asfalto MezclasYheral Antonio C TNo ratings yet

- Construction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuDocument9 pagesConstruction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuYheral Antonio C TNo ratings yet

- Construction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuDocument9 pagesConstruction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuYheral Antonio C TNo ratings yet

- Efecto de Agregado-Betún Compatibilidad en Humedad Susceptibilidad de Asfalto MezclasDocument13 pagesEfecto de Agregado-Betún Compatibilidad en Humedad Susceptibilidad de Asfalto MezclasYheral Antonio C TNo ratings yet

- Construction and Building Materials: Mona Nobakht, Derun Zhang, Maryam S. Sakhaeifar, Robert L. LyttonDocument13 pagesConstruction and Building Materials: Mona Nobakht, Derun Zhang, Maryam S. Sakhaeifar, Robert L. LyttonYheral Antonio C TNo ratings yet

- Construction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuDocument9 pagesConstruction and Building Materials: Lei Xi, Rong Luo, Hanqi LiuYheral Antonio C TNo ratings yet

- Control de Flama Honeywell 215Document12 pagesControl de Flama Honeywell 215Moreno NuevoNo ratings yet

- AL300ULXD Power Supply PDFDocument1 pageAL300ULXD Power Supply PDFSaber HussainiNo ratings yet

- 105mm Enhanced GunDocument38 pages105mm Enhanced Gungrindormh53100% (1)

- Membrane Filtration Processes ExplainedDocument93 pagesMembrane Filtration Processes ExplainedMilind MatangNo ratings yet

- Development of Graphitic Carbon NitrideDocument64 pagesDevelopment of Graphitic Carbon NitrideKoorosh IraniNo ratings yet

- 1687 0 3 Distance Measurement v3Document40 pages1687 0 3 Distance Measurement v3RICKY SHIMADHIBRATA ISKANDARNo ratings yet

- Pharmaceutical ChemistryDocument21 pagesPharmaceutical ChemistryBISMA RAFIQNo ratings yet

- MEng 136 - QuizDocument1 pageMEng 136 - QuizCollano M. Noel RogieNo ratings yet

- Stranded Solid Copperweld Wire ChartDocument1 pageStranded Solid Copperweld Wire ChartKhan KakarNo ratings yet

- Green Protect: Protection of PV SystemsDocument86 pagesGreen Protect: Protection of PV Systemsgoguta gigelNo ratings yet

- Investigatory ProjectDocument15 pagesInvestigatory ProjectKarthiyayini KVRNo ratings yet

- Material Science SyllabusDocument2 pagesMaterial Science Syllabus1DA20ME023 Girish M BNo ratings yet

- CCLG Part 1 - Freight 2-2014Document66 pagesCCLG Part 1 - Freight 2-2014Rogerio Tropia GranjaNo ratings yet

- Portable X-Ray Unit: 1. Manufacture Company InformationDocument17 pagesPortable X-Ray Unit: 1. Manufacture Company Informationcomphome100% (2)

- 1 s2.0 S0925400514000859 MainDocument8 pages1 s2.0 S0925400514000859 Main1900066No ratings yet

- Gravitational Slingshot Effect Speed BoostDocument3 pagesGravitational Slingshot Effect Speed BoostFalihah BalqisNo ratings yet

- Astm B247Document14 pagesAstm B247Nav TalukdarNo ratings yet

- Physica A: Tingting Gao, Yu ChenDocument8 pagesPhysica A: Tingting Gao, Yu ChenZoe RossiNo ratings yet

- Kinetic Theory Explains Phases of MatterDocument9 pagesKinetic Theory Explains Phases of MatterPeterClomaJr.No ratings yet

- AIAA - International Aerospace Literature AIAA-7475-374Document18 pagesAIAA - International Aerospace Literature AIAA-7475-374Nestor HidalgoNo ratings yet

- Shear StudDocument2 pagesShear Studminhthanha6No ratings yet

- ANNUAL-11th PHYSICS-SAMPLEDocument8 pagesANNUAL-11th PHYSICS-SAMPLEsyed ayaaanNo ratings yet

- Iec Lab - Exp 08 - Fall 23-24Document8 pagesIec Lab - Exp 08 - Fall 23-24rakibulislamakash40No ratings yet

- Solar NanoantennaDocument38 pagesSolar Nanoantennaanu balakrishnanNo ratings yet

- 708 WF Ire Jan 06.01.23 WebsiteDocument24 pages708 WF Ire Jan 06.01.23 WebsitetedNo ratings yet

- Chapter 8 Periodic Relationships Among The Elements - NewDocument37 pagesChapter 8 Periodic Relationships Among The Elements - NewFauji Islami PhasyaNo ratings yet

- VX Spectra 19mm Metrological Performance - 6620824 - 01Document10 pagesVX Spectra 19mm Metrological Performance - 6620824 - 01FredyNo ratings yet