Professional Documents

Culture Documents

Therminol Bulletin 3 - Filtration

Therminol Bulletin 3 - Filtration

Uploaded by

Anonymous 20VAruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Therminol Bulletin 3 - Filtration

Therminol Bulletin 3 - Filtration

Uploaded by

Anonymous 20VAruCopyright:

Available Formats

THERMINOL INFORMATION BULLETIN NO.

Solutia Inc.

® 3

Pub. No. 7239123B

P.O. Box 66760

St. Louis, Missouri 63166-6760

(314) 674-1000

TM

THERMINOL® HEAT TRANSFER FLUID FILTRATION: HOW AND WHY

Indirect heating of processes by organic thermal temperatures of 750˚F (400˚C), have excellent dirt

liquid fluids, such as Therminol® heat transfer fluids, holding capacity, and are economical and disposable

offer highly reliable operation, and the heat transfer filter elements. Other filters made of metal have the

systems are generally treated as low-maintenance temperature capability but are difficult to clean and

utilities. Occasionally the Therminol heat transfer are usually expensive. Earth filtration is not effective

fluid can become contaminated, resulting in the at high temperatures and should be backed up by

formation of sludge particles, or other sources of a mechanical filtration.

dirt can infiltrate the system. This contamination can The glass fiber-wound element size is generally

cause operational problems. The solid particulates 2.5 in. (6.4 cm) diameter with 10 in. [25 cm] incre-

can cause circulation pump shaft seal leakage prob- mental lengths. The glass fiber is wound around a

lems, valve stem wear, plugging of flow passages perforated metal tube with the closeness of the fibers

and sometimes fouling of heat exchange surfaces. and the fiber size determining the particle size

After contamination, the fluid can sometimes be removal capability of the element. The filtration

cleaned by in-system side stream filtration. For seri- is accomplished by the heat transfer fluid flowing

ously fouled systems requiring more extensive clean- radially inward past the overlapping glass fibers and

ing, the heat transfer fluid can sometimes be cold out of one end of the metal tube. The filter cartridges

filtered outside of the system. Filtration also may help are fixed in the filter housing by a variety of end

protect the system from solids problems by installa- fixtures. The filter housing should be capable of high-

tion before start up. temperature operation. To help assure safe operation,

What Is the Dirt? the housing should meet local and national codes

for the maximum heat transfer fluid temperature and

It can be a variety of materials, such as con- the maximum system pressures expected in the heat

struction site debris left in the system, millscale that transfer system. Many filter housings use “O” ring

dislodges from the system piping during operation elastomer seals which are not safe for high-tempera-

and reaction products of the heat transfer fluid with ture operation because they can lose strength and

oxidizing agents, i.e., air, acids and process leaks in some cases partially dissolve in the heat transfer

to the heat transfer fluid. Contaminants can also fluid. The seal should be made of a reinforced flexible

form insoluble products with metals in the heat graphite flat gasket in a captured gland to help

transfer system, i.e., rust, metal oxides. Some heat prevent fluid sprays in the case of gasket failure.

transfer fluids, when operated slightly over their Spiral-wound gaskets are a good choice for the filter

maximum use temperature limit, will form insoluble housing. If springs are used to fix the filter cartridges

solids naturally. in the housing, they should be made of materials

which do not have much spring rate reduction at

What Filters Are Used?

the maximum operating temperature. For use in

For in-system filtration, experience shows that Therminol® heat transfer fluid systems, carbon steel

glass fiber-wound filter cartridges are generally the housings are adequate below 750˚F (400˚C) opera-

most satisfactory, since they can withstand system tion. There are major manufacturers of glass-wound

filter elements as described in many countries. Sizing the Filter

If the decision is to filter the heat transfer fluid at The FLUID ANALYSIS PROGRAM (see TIB No. 2)

ambient temperature, a large variety of filter media determines the insoluble solids particle size level

and filter types can be employed along with low- above 1 micron for used fluid samples. The insoluble

temperature filter housings. For Therminol filters, solids level is determined by laboratory filtration

media made of polyester, nylon and cellulose fibers through a 1-micron membrane filter with the solids

are generally compatible at ambient temperatures. on the filter being washed with acetone or pentane.

The filter manufacturer should be consulted to These particles, larger than one micron, are respon-

determine the filter compatibility with Therminol sible for the vast majority of heat transfer system

heat transfer fluids and other heat transfer fluids. problems. The units used to express the insoluble

solids level are milligrams per 100 milliliters of

Filter, Installation and Operation

filtered fluid or in parts per million, ppm. Assuming

For the in situ high-temperature operation, the the heat transfer fluid and insolubles have a density

glass fiber-wound filters can be placed anywhere of 1 gram per milliliter, 1 mg/100 ml is equal to

there is a pressure drop between 20 and 40 psi (1.4 10 ppm. The filters can generally capture between

to 2.8 kg/cm2). The maximum flow rate through the 40,000 and 100,000 milligrams of solids per 10 in.

filters should be no more than 1% of the main flow (25 cm) of filter length.

rate in the system and generally should not exceed Conservatively assuming the dirt-holding capacity

5 GPM (18 liter/min.) per 10 in. (25 cm) of cartridge of the filters to be only 40,000 mg per 10 in. (25 cm)

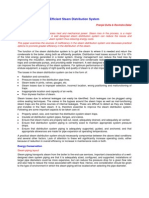

length (see Figure 1). At the desired flow, the initial of filter element length, the number of 10 in. (25 cm)

pressure drop through the filter should be 1 to 2 psi filter elements needed to clean up a system above

(.07 to .14 kg/cm2). Under these conditions, one the one-micron nominal particle removal rating of a

or more heat transfer system volumes should pass glass string-wound filter usually can be determined

through the filter each day. To help protect the filter through the following formula:

from excessive pressure drop, a bypass pressure

relief valve should be set at 25 to 40 psi (1.8 to 2.1 N = 0.00025 (V) (IS)

kg/cm2). If there is a possibility of back flow through Where N = number of 10 in. (25 cm) filter

the filter, a check valve should be installed to help element segments

prevent filter rupture. High-temperature gaskets V = heat transfer system volume (liters)

made of reinforced flexible graphite or spiral-wound IS = insoluble solids (mg/100 ml)

gaskets should be used to seal the filter housing

cover. Elastomer “O” ring seals are generally not While one-micron filters could be used initially,

stable enough for high-temperature use, but with there is always a danger of filter blinding or surface

improving technology your seal manufacturer should compaction. The better technique is to use a combi-

be consulted, especially for use temperatures below nation of nominal particle-removing elements starting

400˚F (204˚C). As is good practice in the rest of the out with coarse filtration, i.e., 50 to 100 micron ele-

system, the filter piping should be welded construction ments and working down to 1 to 10 micron element

to reduce leakage. The filter housing can be insulated, levels. The filter element changeout frequency needs

but the insulation should be of a type that will not to be balanced against the filter housing size, and

absorb heat transfer fluid (e.g., cellular glass). The the filter suppliers should be consulted on the filter

filter house should be placed in a convenient-to- housing sizing. Sometimes, depending on the nature

service location. of the insoluble solids and their level in the heat

transfer system, the best clean-up method is disposal

During operation the pressure drop or flow rate of the heat transfer fluid and total system cleaning

through the filter should be checked and adjusted (see TIB No. 1). After the clean-up, a 5-micron

daily to determine if the cartridges need changing. filtration should be kept in the system permanently

If the pressure rise across the filters is gradual, it as a continuous clean-up and a diagnostic element to

often will hold more solids before plugging. Hard help detect any future contamination, should it occur.

solid particulates build a coating which can cover

the string-wound texture of the filter, giving a glossy

surface when wet. The used filters should be disposed

of in an environmentally acceptable manner.

INFORMATION BULLETIN

Figure 1

Filter in Side Stream Operation

INLET FROM OUTLET TO

SYSTEM PIPING SYSTEM PIPING

GLASS FIBER-

FLOW WOUND FILTER

SHUT-OFF RESTRICTION CARTRIDGES

VALVE VALVE (ELEMENTS)

SHUT-OFF

CHECK VALVE

VALVE

PRESSURE DIFFERENTIAL DRAIN

RELIEF PRESSURE GAUGE/

VALVE TRANSDUCER

Notes:

• The side stream filtration should be less than • The pressure relief valve is used when the

1% of the primary system flow rate and should differential pressure across the filter can

not exceed 5 GPM (18 liter/min) per 10 in. exceed 50 psi.

(25 cm) cartridge length. • The check valve is needed when there is

• Use the restriction valve to set the initial pressure a possibility of back flow through the filter.

drop through the filter between 1 and 2 psi

(0.07-0.14 kg/cm2). A 20 to 40 psi (1.8-2.8

kg/cm2) pressure drop should be available

for filtration.

This data does not constitute an express or implied warranty.

See NOTICE on the back of this bulletin.

FOR YOUR PEOPLE Start-Up Assistance Operational Training Technical Service Hotline

FOR YOUR FACILITY System Design Quality Therminol Sample Flush Fluid & Refill Fluid Trade-In Program

Products Analysis

Total Lifecycle Care from Solutia

Solutia developed the Total Lifecycle Care the varied needs of front line technicians, opera-

Program to support Therminol customers throughout tions supervisors, maintenance technicians and

the lifecycle of their heat transfer fluid systems. This design engineers.

comprehensive program includes system design sup- • Sample Analysis - Complimentary sample kits and

port, start-up assistance, training, sample analysis, fluid analysis supports the effective monitoring of

flush and refill fluids and a fluid trade-in program. fluid condition from purchase to the end of the

The program includes the following helpful features: fluid’s useful life.

• Technical Services Hotline - Experienced technical • Flush Fluid and Fluid Refill - Liquid phase heat

service specialists can help answer questions transfer systems can be cleaned with Therminol® FF

regarding heat transfer fluid selection, system Flush Fluid. This synthetic hydrocarbon heat trans-

start-ups, system design and operational issues. fer fluid features a flash point over 200° F (95° C)

They can be reached at 1-800-433-6997. and an initial boiling point over 400° F (200° C).

• System Design Support - Solutia engineers assist Therminol FF can be circulated over a wide tem-

engineering firms and heat transfer users in evalu- perature range and is compatible with mechanical

ating key aspects of design and in performing system components found in heat transfer systems.

system troubleshooting. • Trade-In Program - As part of its commitment to

• Start-Up Assistance - Solutia provides start-up the environment, Solutia offers a trade-in program

assistance by reviewing procedures and making for used Therminol and some competitive heat

suggestions to reduce typical start-up problems. transfer fluids. Depending on the particular fluid

On-site assistance can be provided to help identify and its condition, it can often be returned to

and resolve fluid-related system commissioning issues. Solutia for credit toward the purchase of new

• Operational Training - Customers can take advan- Therminol heat transfer fluid. This program is a

tage of Solutia’s heat transfer system operation very attractive alternative when compared to the

and product training programs, customized to suit cost and the burden of conventional fluid disposal.

For more information: call toll free 800-433-6997

visit our web site – www.therminol.com

NOTICE: Although the information and recommendations set forth herein (hereinafter “Information”) are presented in good faith

and believed to be correct as of the date hereof, Solutia Inc. makes no representations or warranties as to the completeness or

accuracy thereof. Information is supplied upon the condition that the persons receiving same will make their own determination

as to its suitability for their purposes prior to use. In no event will Solutia Inc. be responsible for damages of any nature what-

soever resulting from the use of or reliance upon Information or the product to which Information refers. Nothing contained

herein is to be construed as a recommendation to use any product, process, equipment or formulation in conflict with any patent,

and Solutia Inc. makes no representation or warranty, express or implied, that the use thereof will not infringe any patent. NO

REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE OR OF ANY OTHER NATURE ARE MADE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO

WHICH INFORMATION REFERS.

Solutia ® Therminol is a registered trademark of Solutia Inc.

P.O. Box 66760 © Solutia Inc., 2004. All rights reserved.

St. Louis, MO 63166-6760 Printed on recycled paper

Tel: (314) 674-1000 Litho in U.S.A.

You might also like

- Raffia Tape Line ProcessDocument20 pagesRaffia Tape Line ProcessSumeet Rathor100% (12)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Apparatus Dew PointDocument4 pagesApparatus Dew PointS DasNo ratings yet

- Facts at Your Fingertips-201008-Heat Transfer Fluids System FiltrationDocument1 pageFacts at Your Fingertips-201008-Heat Transfer Fluids System Filtrationonizuka-t2263No ratings yet

- Therminol Information Bulletin No.1: Cleaning Organic Heat Transfer Fluid SystemsDocument4 pagesTherminol Information Bulletin No.1: Cleaning Organic Heat Transfer Fluid SystemsSteranskoNo ratings yet

- SterilizationDocument15 pagesSterilizationSanjay KumarNo ratings yet

- Therminol Bulletin1Document4 pagesTherminol Bulletin1anoopsreNo ratings yet

- FiltrationDocument46 pagesFiltrationSharmimi RazakNo ratings yet

- UNIT 3 II APCEDocument13 pagesUNIT 3 II APCEDinesh JeyakumarNo ratings yet

- Filtro de Vapor SPIRAX SARCODocument4 pagesFiltro de Vapor SPIRAX SARCOmaurozuriNo ratings yet

- The Basics of Hydraulic FiltrationDocument3 pagesThe Basics of Hydraulic Filtrationbee1406763181No ratings yet

- Cooling Tower Side Stream FiltrationDocument5 pagesCooling Tower Side Stream FiltrationChandrakant JuikarNo ratings yet

- Texatherm: Industrial Heat Transfer OilDocument2 pagesTexatherm: Industrial Heat Transfer OilCharith LiyanageNo ratings yet

- Process Filters EngDocument12 pagesProcess Filters Engmaurozuri100% (1)

- Cleaning Plate Heat Exchangers PDFDocument2 pagesCleaning Plate Heat Exchangers PDFukalNo ratings yet

- 1 PBDocument7 pages1 PBanandhra2010No ratings yet

- Filtration OptionsDocument5 pagesFiltration OptionssyeddanishrasoolNo ratings yet

- HF-2013 HankisonDocument10 pagesHF-2013 HankisonAriep RachmanNo ratings yet

- Steam Tracing TipsDocument2 pagesSteam Tracing TipsRam SudarshanNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Side Stream FiltrationDocument8 pagesSide Stream FiltrationAhmed WagihNo ratings yet

- Filter - 5 Stage Reverse OsmosisDocument3 pagesFilter - 5 Stage Reverse OsmosisPhilip Anthony MasilangNo ratings yet

- Name: Safira Fereste Class: 2A D4 TKI NIM: 1941420104: 1. Make A Text With Maximum 4 ParagraphDocument7 pagesName: Safira Fereste Class: 2A D4 TKI NIM: 1941420104: 1. Make A Text With Maximum 4 ParagraphSAFIRA FERESTENo ratings yet

- Ultrafiltration Explained: Ultrafilter vs. Conventional FilterDocument5 pagesUltrafiltration Explained: Ultrafilter vs. Conventional Filteran_iboreg8720No ratings yet

- Filter CakeDocument7 pagesFilter CakeMarion AlyssaNo ratings yet

- Bioprocess Principles Chapter1Document96 pagesBioprocess Principles Chapter1Catharanthus9No ratings yet

- Filtration 28 Written Report 29Document9 pagesFiltration 28 Written Report 29Sehwanie Mariel BrazilNo ratings yet

- Hydraulic Reservoirs and FiltersDocument22 pagesHydraulic Reservoirs and FiltersMohamed ZahranNo ratings yet

- Sterilization of AirDocument5 pagesSterilization of AirBeena KakranNo ratings yet

- Efficient Steam Distribution SystemDocument8 pagesEfficient Steam Distribution Systempavan_chinta_2No ratings yet

- Gas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06Document4 pagesGas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06michael_payne3532No ratings yet

- Heat Exchangers: 12.7.1. Fluid Allocation: Shell or TubesDocument8 pagesHeat Exchangers: 12.7.1. Fluid Allocation: Shell or TubesAravind MuthiahNo ratings yet

- Hot Oil System GuideDocument13 pagesHot Oil System GuideAnonymous QSfDsVxjZ100% (3)

- Fouling & Other Related NotesDocument10 pagesFouling & Other Related NotesSudeshna AcharyyaNo ratings yet

- New Approaches For Removing Catalyst Fines From Chemical and Pharma SlurriesDocument10 pagesNew Approaches For Removing Catalyst Fines From Chemical and Pharma SlurriesBarry PerlmutterNo ratings yet

- Heat Transfer System CleaningDocument4 pagesHeat Transfer System CleaningMicheal BrooksNo ratings yet

- Electrocoat 101 105Document5 pagesElectrocoat 101 105Sy Nguyen VietNo ratings yet

- Cooling Tower Side Stream FiltrationDocument6 pagesCooling Tower Side Stream FiltrationVenkat DoraNo ratings yet

- Filter Aid FiltrationDocument8 pagesFilter Aid FiltrationcatalinvsuNo ratings yet

- Cooling System Filtration Accessory or NecessityDocument3 pagesCooling System Filtration Accessory or Necessitynermeen ahmedNo ratings yet

- EUROWATER Bag Filters LeafletDocument4 pagesEUROWATER Bag Filters LeafletAsteriaA.SusantoNo ratings yet

- Applications 2007 enDocument12 pagesApplications 2007 enFaycel OuerdienNo ratings yet

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeeNo ratings yet

- 7 Common Issues in ExtrusionDocument5 pages7 Common Issues in Extrusiondavid SinangoteNo ratings yet

- Domestic Waste Water Treatment ProcessDocument11 pagesDomestic Waste Water Treatment ProcessThian Jun YiNo ratings yet

- Sidestream Filtration Guidelines1Document2 pagesSidestream Filtration Guidelines1syeddanishrasoolNo ratings yet

- Controlling Contamination in Hydraulic FluidsDocument3 pagesControlling Contamination in Hydraulic FluidsMrEngenhariaMecanicaNo ratings yet

- How To Choose A Wine Crossflow Microfiltration SystemDocument4 pagesHow To Choose A Wine Crossflow Microfiltration SystemEugen OdainiiNo ratings yet

- Gas Turbine Air Filter System OptimizationDocument10 pagesGas Turbine Air Filter System Optimizationsevero97100% (1)

- Agitation and MixingDocument19 pagesAgitation and MixingkrolkjgNo ratings yet

- Leak Free Diathermic Oil SystemsDocument10 pagesLeak Free Diathermic Oil SystemsADITYA_PATHAKNo ratings yet

- Reskem ResinmediatrapsDocument2 pagesReskem ResinmediatrapsdeyprasenNo ratings yet

- Filtration SystemDocument11 pagesFiltration Systemwaleed.murad@gmail.comNo ratings yet

- Pressure Filters: Body-Aid and PrecoatingDocument3 pagesPressure Filters: Body-Aid and Precoatingagrocel_bhv5591No ratings yet

- 9.0 Dust Collection SystemsDocument15 pages9.0 Dust Collection SystemsNol BarandonNo ratings yet

- Experienced-Based Rules of Chemical EngineeringDocument13 pagesExperienced-Based Rules of Chemical Engineeringvaibhav_agrawal_21No ratings yet

- Air Pollution ControlDocument4 pagesAir Pollution ControlvildehusNo ratings yet

- Side Stream Filter For Cooling TowersDocument4 pagesSide Stream Filter For Cooling TowersdkmauryaNo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- Calculations Membrane ProcessesDocument3 pagesCalculations Membrane ProcessesAnonymous 20VAruNo ratings yet

- Modeling, Simulation and Control of Liquid-Liquid Extraction ColumnsDocument16 pagesModeling, Simulation and Control of Liquid-Liquid Extraction ColumnsAnonymous 20VAruNo ratings yet

- Fm1e 09Document2 pagesFm1e 09Anonymous 20VAruNo ratings yet

- Ferric Chloride ParametersDocument7 pagesFerric Chloride ParametersAnonymous 20VAruNo ratings yet

- THERMINOL LT Technical BulletinDocument8 pagesTHERMINOL LT Technical BulletinAnonymous 20VAruNo ratings yet

- GEST 10 362 Edition 2 (Corrosion Behaviour of Carbon Steel in Wet and Dry Chlorine) PDFDocument16 pagesGEST 10 362 Edition 2 (Corrosion Behaviour of Carbon Steel in Wet and Dry Chlorine) PDFAnonymous 20VAruNo ratings yet

- GEST 91 168 Chapter 05 Edition 1 (Mechanical Properties)Document14 pagesGEST 91 168 Chapter 05 Edition 1 (Mechanical Properties)Anonymous 20VAru100% (1)

- GEST 79 79 Edition 4 (Transfer of Liquid Chlorine by Padding With A Chlorine Compressor)Document15 pagesGEST 79 79 Edition 4 (Transfer of Liquid Chlorine by Padding With A Chlorine Compressor)Anonymous 20VAruNo ratings yet

- PDFDocument10 pagesPDFAnonymous 20VAruNo ratings yet

- United States Patent: Commarieu Et Al. (45) Date of Patent: May 22, 2001Document3 pagesUnited States Patent: Commarieu Et Al. (45) Date of Patent: May 22, 2001Anonymous 20VAruNo ratings yet

- Animation Project HosaDocument95 pagesAnimation Project Hosamerwin23No ratings yet

- Pipelines and Pipe NetworksDocument56 pagesPipelines and Pipe NetworksAlok KumarNo ratings yet

- HSE Information Sheet: Industrial Radiography - Managing Radiation RisksDocument5 pagesHSE Information Sheet: Industrial Radiography - Managing Radiation Riskssamer alrawashdehNo ratings yet

- Ps 2309Document2 pagesPs 2309Benjamin BnNo ratings yet

- 030 826 4Document2 pages030 826 4Diego Orlando Santos BuitragoNo ratings yet

- BinaryDocument2 pagesBinaryAidanNo ratings yet

- ALBPDocument68 pagesALBPminh tanNo ratings yet

- Igcse English A Past Paper Quesstions and AnswersDocument6 pagesIgcse English A Past Paper Quesstions and Answersmsml kml100% (2)

- Programmer's Guide For LIFE2's Rainflow Counting AlgorithmDocument30 pagesProgrammer's Guide For LIFE2's Rainflow Counting AlgorithmfddddddNo ratings yet

- Periodontal ExodontiaDocument5 pagesPeriodontal ExodontiaDARKS_EDSNo ratings yet

- Hareda 427466857Document86 pagesHareda 427466857Abhishek HandaNo ratings yet

- E10 - Revision For The Final Test - 01: YearDocument6 pagesE10 - Revision For The Final Test - 01: YearĐình VũNo ratings yet

- Nios 2 ReferenceDocument284 pagesNios 2 ReferenceaejtNo ratings yet

- Marketing Principles: in A NutshellDocument41 pagesMarketing Principles: in A NutshellkeithNo ratings yet

- Video Wall UsDocument16 pagesVideo Wall UsCopylucasNo ratings yet

- Technical Update - Techlube 2 (8-19)Document2 pagesTechnical Update - Techlube 2 (8-19)Onie Hammamz OylNo ratings yet

- W1 Des For Manuf Assembly DFA DFMDocument16 pagesW1 Des For Manuf Assembly DFA DFMFaiz Aiman RomelyNo ratings yet

- Healthcare Process Management GuideDocument5 pagesHealthcare Process Management Guideapi-388173202No ratings yet

- SanthoshDocument13 pagesSanthoshRSK_1No ratings yet

- Analysis of Open Source Computing Techniques & Comparison On Cloud-Based ERPDocument7 pagesAnalysis of Open Source Computing Techniques & Comparison On Cloud-Based ERPInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- UniSim Plate Fin Exchanger Modeler PIN PDFDocument2 pagesUniSim Plate Fin Exchanger Modeler PIN PDFmember1000No ratings yet

- Feature Article: Electronic Wave Functions in Semiconductor Clusters: Experiment and TheoryDocument6 pagesFeature Article: Electronic Wave Functions in Semiconductor Clusters: Experiment and TheoryNitika GuptaNo ratings yet

- Lab - #3. - Riverine HydraulicsDocument8 pagesLab - #3. - Riverine HydraulicsJuan CallesNo ratings yet

- SAP Business AnalystDocument2 pagesSAP Business Analystapi-78252080No ratings yet

- Physics of MaterialsDocument237 pagesPhysics of MaterialsNivashini VindhyaNo ratings yet

- Annual Product Quality ReviewDocument3 pagesAnnual Product Quality ReviewMITON CHOWDHURY100% (2)

- 30mm TWND Series Pushbutton Flush Momentary ABN131B - Switches - IDEC Asia Pacific PDFDocument2 pages30mm TWND Series Pushbutton Flush Momentary ABN131B - Switches - IDEC Asia Pacific PDFjckrishnahNo ratings yet

- EV314 RCC Design 2: Taha AlesawyDocument48 pagesEV314 RCC Design 2: Taha AlesawySam KhorNo ratings yet

- CvdictDocument309 pagesCvdictNeev TighnavardNo ratings yet

- ED 305-ASESSMENT OF LEARNING 2 Module 3Document4 pagesED 305-ASESSMENT OF LEARNING 2 Module 3Aljun Bernadez EmperadoNo ratings yet