Professional Documents

Culture Documents

Module05 Demand MGT

Uploaded by

Alango Jr TzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module05 Demand MGT

Uploaded by

Alango Jr TzCopyright:

Available Formats

MODULE 5

LEARNING OBJECTIVES

In this module you will learn about:

General Objectives:

MANAGEMENT

L Demand Management

Specific Objectives:

DEMAND

L Active and Reactive Power Demand and Energy,

L Three-Phase Systems,

L Power Factor,

L Power Factor Correction,

L Demand Management,

L Load Factor,

L Load Shedding,

L Load Shifting.

Performance Objectives:

After successful completion of this module you will be able to perform

the following:

L Measure 1-phase and 3-phase electrical power and energy,

L Monitor plant load profiles,

L Calculate benefits of power factor correction,

L Evaluate the benefits of demand management.

SADC Industrial Energy Management Project

Implemented by AGRA Monenco Atlantic Limited for the Canadian International Development Agency

Module 5

Demand Management

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 ELECTRICAL FUNDAMENTALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Ohm's Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 Alternating Voltage and Current . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Active or Virtual Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Power andEnergy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.5 Three Phase Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Three Phase Power and Energy . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Worked Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0 POWER FACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Low Power Factor - Cost to Suppliers . . . . . . . . . . . . . . . . . . 8

3.2 Low Power Factor - Cost to Consumers . . . . . . . . . . . . . . . . . 9

3.3 Power Factor Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Capacitor Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Sizing Capacitors - Worked Example . . . . . . . . . . . . . . . . . . 10

4.0 DEMAND MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Load Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Load Profile Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Load Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Load Shedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Worked Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.0 ASSIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.0 SUMMARY - Module 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MODULE 5

DEMAND MANAGEMENT

1.0 INTRODUCTION

An understanding of the way in which electrical energy is utilized in your plant is

essential for an effective energy management programme.

Electricity from the supply utility is delivered on demand to a service entry point

within consumers premises, where it is metered and distributed to end users. In

large plants the service entry point may be a substation with transformers to lower

the voltage to a level suitable for the equipment.

Motors, lighting and heating loads are the main consumers of electrical energy in

industrial plants. The number and size of these loads in service at a plant will

determine the amount of active and reactive energy supplied by the electricity

supply authority and subsequently the size of the energy bills.

This module discusses the relationship between the loads and energy, and power

factor, and covers ways of reducing the power demand and electricity bills.

2.0 ELECTRICAL FUNDAMENTALS

2.1 Ohm's Law

When a Load of Z (ohms) (e.g. a motor, lamp, or heater) is connected across a

Voltage V (volts), a Current of I (amperes) will flow through the load according to

Ohm's Law (see Figure 5.1):

V

I '

Z

SADC Industrial Energy Management Project Page 1 of 16

Module 5 - Demand Management ....

2.2 Alternating Voltage and Current (ac)

The voltages generated by supply utilities in the SADC countries oscillate

sinusoidally with a cyclic rate of 50 cycles per second (50 Hz), as illustrated in

Figure 5.1.

When such an alternating voltage is applied to a circuit as shown in Figure 5.2, an

alternating current (ac), i, will be caused to flow between the supply and the loads;

first in the forward direction, i.e. the positive direction (i-positive), and then in the

reverse or negative direction (i-negative). This cycle of change will be repeated

100 times a second; 50 times in the positive direction and 50 times in the negative

direction. As loads are paralleled across the voltage the current i will increase

proportionally.

Figure 5.2

Figure 5.3

EFFECTIVE OR RMS VOLTAGE

2.3 Active or Virtual Voltage

The active or virtual value of an alternating voltage, as measured by a voltmeter,

is the Root Mean Squared (RMS) value of the alternating voltage. It is derived from

the square root of the average squared value of the waveform, and is the same as

the direct current (dc) value that would provide the same amount of heating of a

resistive load. For a pure sinusoidal waveform it can be seen from Figure 5.3 that:

SADC Industrial Energy Management Project Page 2 of 16

Module 5 - Demand Management ....

v Max

VRMS ' ' 0.707

2

Similarly for a sinusoidally alternating current:

iMax

IRMS ' ' 0.707

2

Unless otherwise noted, further references to voltage and current imply RMS

values.

2.4 Power and Energy

Energy is the capacity for action or work. Power is defined as the rate of energy

conversion. In an ac circuit the total power input from the supply at any instant in

time is:

p ' v × i

where: p, v and i are instantaneous values.

Figure 5.4 Figure 5.5

RESISTIVE CIRCUIT INDUCTIVE CIRCUIT

Figure 5.6

INDUCTIVE - RESISTIVE CIRCUIT

Waveforms of instantaneous current, voltage and total power flowing in

resistance and inductive circuits are illustrated in Figures 5.4, 5.5 and 5.6. Note

SADC Industrial Energy Management Project Page 3 of 16

Module 5 - Demand Management ....

that current in phase with the supply voltage results in positive power or active

power, i.e. power that flows into the load and is dissipated as heat energy. Power

resulting from current that is 90E (¼ phase) out of phase with the voltage alternates

equally between positive and negative. This illustrates that alternating power or

reactive power flows backwards and forwards between the supply and the load.

In other words the reactive energy is stored temporarily (for ¼ cycle) in the

inductance and then flows back to the supply. The active power is always in

phase with the supply voltage and the reactive power is always 90E (leading or

lagging) out of phase with the supply voltage. This relationship is illustrated in

power triangle, Figure 5.7, with effective or RMS values used, where:

Total Power Pt ' V × I VA

Active Power Pa ' V × I Cos Ø Watts

Reactive Power Pr ' V × I Sin Ø VAr

where: O

/ is the phase displacement between the supply voltage and the circuit current.

The circuit Power Factor is the ratio of the active power to the total power:

Active Power

Power Factor PF '

Total Power

' Cos Ø

The more reactive power demanded by a plant, due to motor loads say, the lower

will be the power factor.

Figure 5.7

POWER TRIANGLE

2.5 Three Phase Systems

A 3-phase system is an ac circuit or network with 3 supply voltages of the same

frequency but displaced in time by 120E ( a third of a cycle) as shown in Figure 5.8.

A 3-phase generator comprises 3 single phase generators angularly placed around

the same shaft. A 3-phase motor has three separate windings spaced round the

stator. When the 3 phase system of voltages are equal in magnitude the system

is said to be symmetrical. When the currents in a star (wye) connected load

SADC Industrial Energy Management Project Page 4 of 16

Module 5 - Demand Management ....

(lighting systems) are balanced there will be zero neutral current (Figure 5.9). In

the mesh (delta) connected load (motors) there is no neutral conductor. The

voltage across each phase load is the vectorial sum of two phase to neutral

voltages.

It can be shown that in a star connected load:

Line Voltage VL ' 3 VA OR ' 3 VB OR ' 3 V

LineCurrent IL ' IA OR ' IB OR ' IC

Also, that in a delta connected load:

Line Current IL ' 3 IA OR ' 3 IB OR ' 3

LineVoltage VL ' VA OR ' VB OR '

The advantages of a 3-phase system over a single-phase system are:

< For a given physical size, motors have higher outputs,

< Less copper is used to transmit the same power,

< Motors have uniform rather than pulsating torques,

< Motors are self starting.

Figure 5.8

3-PHASE WAVEFORMS

2.6 Three Phase Power and Energy

The total power in a three phase circuit is the sum of the power demands of the

individual phases:

Total Power Pt ' VA × I A % V B × IB % VC × I C

SADC Industrial Energy Management Project Page 5 of 16

Module 5 - Demand Management ....

Assuming a symmetrical, i.e. balanced system, either star or delta connected load:

Total Power: Pt ' 3 × V A × IA VA

VL

For a Star load: VA ' , and IA ' IL

3

IL

For a Delta load: IA ' , and VA ' VL

3

3 × VL × I L

ˆ Pt ' VA

3

' 3 × VL × I L VA

Active Power Pa ' 3 × VL × I L × Cos Ø Watts

Reactive Power Pr ' 3 × VL × I L × SinØ VAr

Figure 5.9

3-PHASE SYSTEM CONNECTIONS

SADC Industrial Energy Management Project Page 6 of 16

Module 5 - Demand Management ....

2.7 Worked Example

The supply utility provides a plant with 3-phase, 600 volt power. The actual phase

to phase voltages (line voltages) were measured at 598V, 599V and 600V respect-

ively.

The measured three phase voltages, currents, and power factor levels were:

A Phase B Phase C Phase

Voltage 345V 346V 346V

Current 220A 218A 215A

Power Factor 0.85 0.84 0.85

Total Power:

Pt ' VA × I A % VB × I B % VC × I C

' 345 × 220 % 346 × 218 % 346 × 215 VA

' 225.72 kVA

Active Power:

Pa ' V A × IA × Cos iA % V B × IB × Cos iB % V C × IC × Cos iC

' 345 × 220 × 0.85 % 346 × 218 × 0.84 % 346 × 215 × 0.85

' 191.1 kW

Reactive Power:

Pr ' V A × IA × SiniA % V B × IB × SiniB % VC × IC × Sin iC W

[Where: Sin i ' (1 & Cos 2i)]

' 345 × 220 × 0.53 % 346 × 218 × 0.54 % 346 × 215 × 0.53

' 120.39 kVAr

These results can be checked using the formula:

kVA 2 ' kW 2 % kVAr 2

As the plant 3-phase loads are reasonably balanced (220A, 218A, 215A);

comparable results can be obtained by using the 3-phase formulae:

SADC Industrial Energy Management Project Page 7 of 16

Module 5 - Demand Management ....

Total Power Pt ' 3 × VL × I L

' 3 × 599 × 218 VA

' 226.17 kVA

Active Power Pa ' 3 × VL × I L × Cosi

' 3 × 599 × 218 × 0.85 W

' 192.25 kW

Reactive Power Pr ' 3 × VL × I L × Sini

' 3 × 599 × 218 × 0.53 kVAr

' 119.87 kVAr

Assuming that conditions are constant over a 24 hour period, the energy expended

by the load over that period will be:

Active Energy ' 226.17 kW × 24 hrs

' 5,428 kWh

3.0 POWER FACTOR

The power factor level of an industrial plant is an indication of the amount of

reactive power the plant demands. A plant with induction motors will require

lagging reactive power. A plant with a capacitive load will require leading reactive

power. Supply authorities generally require consumers to restrict their reactive

power demand such that their power factor level is maintained above 0.9.

Defaulters are subject to significant cost penalties.

3.1 Low Power Factor - Costs to the Supplier

! With a power factor less than unity, the amount of useful power that can be

supplied by the supply system's generating plant will be less than its full total

power capacity. In other words, although the generators may be delivering their

full current capacity, not all of this current results in useful power. The same

applies with the current carrying capacity of system cables, transformers and

in fact all equipment located between the generators and the consumer with the

low power factor.

SADC Industrial Energy Management Project Page 8 of 16

Module 5 - Demand Management ....

! Reactive power actually costs something to produce at the generating station.

It also increases transmission and distribution losses.

! A poor power factor causes a large drop of volts in the generators requiring

larger exciters.

! The voltage drop of an overhead transmission line increases with a decrease

in power factor level.

3.2 Low Power Factor - Cost to the Consumer

! Electricity Costs

When demand charges are based on the total power demand (kVA), then costs

are inversely proportional to the power factor level, i.e. a low power factor

results in higher costs.

The cost of electricity to consumers whose demand charges are based on their

kW or active demand is unaffected by the level of the plant power factor,

unless there is a low power factor penalty provision in their tariff agreement.

Improving the power factor level can save thousands of dollars in electrical

costs.

! Voltage Levels

A low power factor level causes poor voltage regulation resulting in inefficient

operation of equipment such as motors and lighting.

3.3 Power Factor Correction

To produce the lagging reactive power required by inductive loads (motors), the

supply authority must over-excite their generators to make them more capacitive.

To produce the leading reactive power required by capacitive loads like

transmission lines, the supply authority under-excite their generators to make them

more inductive.

Lagging reactive power can equally well be generated by capacitors installed local

to the load, reducing the reactive power demanded from the supply utility and thus

lowering the overall plant power factor and the associated charges. Significant cost

savings on electrical bills can be realized by maintaining plant power factor levels

as high as possible. A power factor of unity is the optimum level, but this is not

always feasible.

3.4 Capacitor Installations

Ideally power factor correction capacitors should be matched with and located as

close as physically possible to the inductive equipment, e.g. connected to the

SADC Industrial Energy Management Project Page 9 of 16

Module 5 - Demand Management ....

terminals of motors, etc. This would minimize plant distribution losses caused by

transmission of the reactive current between the equipment and the capacitors.

Also, additional switchgear would not be required for the capacitors.

When capacitance is switched with a motor load, correction should be limited to no

more than 0.95 to ensure self-excitation of the motor does not occur. Economics

dictate that individual compensation is generally only feasible with larger motors,

say in excess of 30 kW. But each case must be considered individually. In most

plants the more practical solution is to install capacitor banks, with a control unit,

at the main service entrance board. The control unit senses the power factor level,

which changes with the load, and automatically switches the required capacitors in

and out of service to maintain the power factor level within prescribed limits.

Power factor capacitors have the potential for causing significant damage to

existing equipment from over-voltages and the capacitors themselves are

vulnerable to effects of harmonics. Installation should only be carried out by

experts.

3.5 Sizing Capacitor Installations (Worked Example)

A consumer has a maximum demand of 100 kVA at a power factor of 0.8.

Calculate the rating of the capacitors required to correct the power factor level to

0.95 at the same useful power demand.

! Step 1 - Calculate the Active Power Demand

Useful Power

Power Factor '

Total Power

ˆ Useful Power ' 0.8 x 100

' 80 kW

! Step 2 - Calculate the existing Reactive Power Demand at 0.8 power factor:

kVAr 2 ' kVA 2 & kW 2

ˆ Reactive Power ' 1002 & 802

' 60 kVAr

! Step 3 - Calculate the Total Power at the corrected power factor of 0.95:

It should be appreciated that as no production changes have been made, the

useful power demanded by the consumer will remain unchanged at 80kW.

SADC Industrial Energy Management Project Page 10 of 16

Module 5 - Demand Management ....

Useful Power

Total Power '

Power Factor

80

' kVA

0.95

' 84.2 kVA

! Step 4 - Calculate the reactive power at the corrected power factor 0.95.

kVAr 2 ' kVA 2 & kW 2

' 84.22 & 80.02

' 26.3 kVAr

! Step 5 - Calculate the required capacitance to correct power factor to 0.95.

< Useful active power demand = 80 kW

< Reactive power demand at 0.8 power factor = 60.0 kVAr

< Total power at 0.8 power factor = 100 kVA

< Reactive power demand at 0.95 power factor = 26.3 kVAr

< Total power at 0.95 power factor = 84.2 kVA

< Capacitor Rating required (60.0 - 26.3) = 33.7 kVAr

This is illustrated in Figure 5.10.

If the consumer changed his useful power demand, to say 60 kW, but the plant

power factor (uncorrected) remained at 0.8, then less capacitance would be

required to correct to 0.95. Repeating the above exercise will show that the

required capacitance would be 25.3kVAr.

Conversely if the useful power demand increases, the amount of capacitance

required will also increase. It is therefore necessary to ensure that plant

maximum load demands are considered in the calculations.

Figure 5.10

SADC Industrial Energy Management Project Page 11 of 16

Module 5 - Demand Management ....

4.0 DEMAND MANAGEMENT

Demand management is an exercise in flattening or averaging out the plant

demand profile curve as much as is possible. This may be implemented by shifting

loads and/or shedding non-essential loads. The extent of demand management

may be dictated by the need to maintain production. However, plant management

may decide that the cost benefits resulting from demand control adequately

compensate for production disruptions.

4.1 Load Factor

Load factor is defined as the ratio of average active load (kW) to the maximum kW

demand over a day, month or year and serves as an indicator of the effectiveness

with which electricity demand is managed. A load factor of 100% indicates that the

plant demand is constant, the demand profile being a straight line, e.g. a plant with

a maximum demand of 100 kW and energy consumption of 2,400 kWh over a 24

hour period.

2400 kWh

Load Factor ' x 100 ' 100 %

100 kW x 24 hrs

With a tariff including both energy and demand charges, a higher load factor will

result in lower electricity costs per kWh consumed.

4.2 Load Profile Analysis

The analysis of the profile curve of a plant load over a typical 24 hour period will

establish the potential for demand management.

A load profile can be drawn from plant demand levels recorded at specific times

throughout the plant production period. Plant kW demand can be obtained from

timing revolutions of the tariff kWh meter as described in Module 4. The frequency

of kW readings required will depend on the nature of the plant load.

The individual plant load schedules will establish which loads contribute to the peak

demands. Discussions with plant operators will indicate the feasibility of shedding

or shifting these loads to periods of low demand.

A demand recorder, monitoring the plant supplies will provide a more detailed and

accurate load profile.

4.3 Load Shifting

Figures 5.11 and 5.12 illustrate how the plant peak demand can be reduced by

shifting loads. The maximum demand has in fact been reduced by 30 kW. It

should be noted that although a reduction in demand has resulted there is no

reduction in the energy consumption. The electrical energy consumption has been

SADC Industrial Energy Management Project Page 12 of 16

Module 5 - Demand Management ....

shifted in time and the area under the profile curve remains constant. The result

is that the plant load factor has been increased and the cost of electricity has been

reduced. There may be operational costs associated with rescheduling production

and the plant management must take these into account when considering overall

cost benefits.

Figure 5.11 Figure 5.12

LOAD SHIFTING (BEFORE) LOAD SHIFTING (AFTER)

4.4 Load Shedding

Some plant management have a policy that the demand must not exceed a set

level. Such a policy, normally found in plants with very large demands, may be

necessary because of limitations of the plant electrical system, or to take

advantage of special reduced tariff charges offered by the supply utility.

In such cases a demand controller is employed to continuously monitor the plant

energy consumption. The controller forecasts the current block interval demand

from the rate at which energy is consumed, and computes the load changes

necessary to ensure that the block interval demand meets the target demand.

Preselected loads, initially non-essential loads, will accordingly be manually or

automatically switched. This is shown in Figure 5.13.

Figure 5.13

BLOCK INTERVAL MAX DEMAND CONTROL

SADC Industrial Energy Management Project Page 13 of 16

Module 5 - Demand Management ....

Typical non essential loads that must be energised for a certain amount of time

every day but may be shed at peak periods include water heaters, personnel air

conditioning, sewage pumps, water pumps.

Load shedding also reduces the energy consumption of the plant.

4.5 Worked Example

The typical daily kW demand profile for an industrial plant is indicated in the figure

below. Demand charges are $22.00 / kW / month.

It was decided to investigate the possibility of rescheduling some plant operations

to periods in the day when the demand is low to reduce the maximum demand and

the demand costs (per Figures 5.14 and 5.15).

Review of the plant operating schedules and loads established that an independent

production line with a 200 kW demand could be shifted from the peak demand

period to the low demand period without affecting production.

The cost savings resulting from the reduction in demand would amount to:

= $22.00/kW x 200 kW/month x 12 months/year

= $52,800 per annum.

Figure 5.14 Figure 5.15

EXISTING PLANT PROFILE PROPOSED PLANT PROFILE

5.0 ASSIGNMENT

! Plant Power Distribution

Draw a Single Line Diagram of your plant electrical distribution system. An

example is shown in Figure 5.16. This diagram will be a useful tool for energy

management in your plant.

SADC Industrial Energy Management Project Page 14 of 16

Module 5 - Demand Management ....

! Plant Demand

Record your plant demand profile, using the SmartReader current monitor

provided in the Audit Kit, and maintain a schedule of plant loads over a seven

day period.

Investigate the feasibility of load shedding or load shifting to reduce the plant

peak demand. Where the plant load schedule is not available it may be

necessary to record demand profiles for each of the plant feeders (ref. Plant

Single Line Diagram) to identify loads contributing to peak demands. Calculate

the potential demand and cost savings.

! Power Factor

Measure and record your plant power factor at maximum demand. Calculate

the capacitance required to improve the plant power factor to 0.98, as outlined

in Section 4.5. Calculate the demand and cost savings.

On existing power factor correction capacitors, measure the capacitor current

when the capacitors are in service. Compare with the capacitor rated current

on the capacitor nameplate or derived from the equation:

Capacitor kVAr Rating (Nameplate)

Capacitor Current ' Amps

Voltage Across Capacitor x 1000

Figure 5.16

TYPICAL SINGLE LINE DIAGRAM

OF PLANT DISTRIBUTION SYSTEM

SADC Industrial Energy Management Project Page 15 of 16

Module 5 - Demand Management ....

6.0 SUMMARY - Module 5

In this module you have learned about:

L Ohm's Law

L Alternating Current and Voltage

L Actual or Virtual Voltage

L Power and Energy

L Three-Phase Systems

L Power Factor and Load Factor

L Demand Management

L Load Profile Analysis

L Load Shifting and Shedding

You should now be able to perform the following tasks:

L Calculate Active, Reactive and Total Power Demand

L Calculate Total Power Reduction with Corrected Power Factor

L Calculate Required Capacitance to Correct Power Factor

L Investigate Feasibility of Improving Plant Power Factor

L Identify Plant Loads Contributing to Plant Maximum Demand

L Investigate Load Shedding Feasibility to Reduce Maximum

Demand

SADC Industrial Energy Management Project Page 16 of 16

You might also like

- Multiple Access TechnologyDocument9 pagesMultiple Access TechnologyAlango Jr TzNo ratings yet

- Digital Telecommunication: TN 320 Instructor: Sir Nasolwa, EdsonDocument14 pagesDigital Telecommunication: TN 320 Instructor: Sir Nasolwa, EdsonAlango Jr TzNo ratings yet

- Ways of Generating Cdma CodesDocument11 pagesWays of Generating Cdma CodesAlango Jr TzNo ratings yet

- Equalization in Digital TelecommunicationDocument15 pagesEqualization in Digital TelecommunicationAlango Jr TzNo ratings yet

- 1 - Introduction To Energy MGTDocument22 pages1 - Introduction To Energy MGTAlango Jr TzNo ratings yet

- Non-Uniform Sampling: DiscussionDocument13 pagesNon-Uniform Sampling: DiscussionAlango Jr TzNo ratings yet

- Factors Needed To Be Considered While Designing Any Digital Communication SystemDocument8 pagesFactors Needed To Be Considered While Designing Any Digital Communication SystemAlango Jr TzNo ratings yet

- Analog To DigitalDocument3 pagesAnalog To DigitalAlango Jr TzNo ratings yet

- Assignment Ya MvumaDocument5 pagesAssignment Ya MvumaAlango Jr TzNo ratings yet

- Binary Signalling F OrmatsDocument13 pagesBinary Signalling F OrmatsAlango Jr TzNo ratings yet

- TN 303 Digital Communications: Lecture #5 Differential Pulse Code Modulation & Delta ModulationDocument23 pagesTN 303 Digital Communications: Lecture #5 Differential Pulse Code Modulation & Delta ModulationAlango Jr TzNo ratings yet

- The University of Dodomacollege of Informatics and Virtual EducationDocument8 pagesThe University of Dodomacollege of Informatics and Virtual EducationAlango Jr TzNo ratings yet

- Tutorial 9Document4 pagesTutorial 9Alango Jr TzNo ratings yet

- Digital Telecommunication (TN 320) Tutorial 2Document2 pagesDigital Telecommunication (TN 320) Tutorial 2Alango Jr TzNo ratings yet

- Binary Signalling F OrmatsDocument12 pagesBinary Signalling F OrmatsAlango Jr TzNo ratings yet

- Instructor: MR Nasolwa Edson Mob: 0765278090 Office: AB14 (Administration Block)Document72 pagesInstructor: MR Nasolwa Edson Mob: 0765278090 Office: AB14 (Administration Block)Alango Jr TzNo ratings yet

- Student Bandpass QuestionsDocument4 pagesStudent Bandpass QuestionsAlango Jr TzNo ratings yet

- Erf TablesDocument2 pagesErf TablesAlango Jr TzNo ratings yet

- Digital Telecommunication (TN 320) Digital Modulation Tutorial 4Document2 pagesDigital Telecommunication (TN 320) Digital Modulation Tutorial 4Alango Jr TzNo ratings yet

- Instructor: MR Nasolwa Edson Mob: 0765278090 Office: AB14 (Administration Block)Document49 pagesInstructor: MR Nasolwa Edson Mob: 0765278090 Office: AB14 (Administration Block)Alango Jr TzNo ratings yet

- TN 320 FinalDocument179 pagesTN 320 FinalAlango Jr TzNo ratings yet

- TN 320 Tutorial QNS Set #4Document1 pageTN 320 Tutorial QNS Set #4Alango Jr TzNo ratings yet

- BT 0220 Proffesional Issues and EthicsDocument19 pagesBT 0220 Proffesional Issues and EthicsAlango Jr TzNo ratings yet

- TN 324: Intelligent InstrumentationDocument29 pagesTN 324: Intelligent InstrumentationAlango Jr TzNo ratings yet

- Digital Telecommunications Instructor: MR Nasolwa Edson Room: AB14 (Ground Floor)Document157 pagesDigital Telecommunications Instructor: MR Nasolwa Edson Room: AB14 (Ground Floor)Alango Jr TzNo ratings yet

- TN 324: Intelligent InstrumentationDocument27 pagesTN 324: Intelligent InstrumentationAlango Jr TzNo ratings yet

- BT 0220 Proffesional Issues and EthicsDocument25 pagesBT 0220 Proffesional Issues and EthicsAlango Jr TzNo ratings yet

- TN 324: Intelligent InstrumentationDocument43 pagesTN 324: Intelligent InstrumentationAlango Jr Tz100% (1)

- TN 324: Intelligent InstrumentationDocument32 pagesTN 324: Intelligent InstrumentationAlango Jr TzNo ratings yet

- BT 0220 Proffesional Issues and EthicsDocument33 pagesBT 0220 Proffesional Issues and EthicsAlango Jr TzNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 4 NotesDocument2 pagesChapter 4 NotesYuxin LiuNo ratings yet

- Chapter 2 Example ProblemsDocument41 pagesChapter 2 Example ProblemsYaqein AliNo ratings yet

- 169 P5 SolDocument11 pages169 P5 SolSagir Musa SaniNo ratings yet

- Special Relativity PDFDocument6 pagesSpecial Relativity PDFJaki UmamNo ratings yet

- If The Distance Between Two Charges Is DoubledDocument6 pagesIf The Distance Between Two Charges Is DoubledFatehNo ratings yet

- Arihant AIEEE PhysicsDocument376 pagesArihant AIEEE Physicssachchidanandpatel50% (4)

- Department of Academics: 1.0 Stability 1.1 DisplacementDocument10 pagesDepartment of Academics: 1.0 Stability 1.1 DisplacementIvan SimonNo ratings yet

- En 3GBP082470-BSKDocument3 pagesEn 3GBP082470-BSKramy alfonsNo ratings yet

- Class 12 Physics Notes Chapter 3&4 Studyguide360Document46 pagesClass 12 Physics Notes Chapter 3&4 Studyguide360Erika Marie DequinaNo ratings yet

- Pressure Loss CorrelationsDocument57 pagesPressure Loss Correlationseandresmar100% (1)

- Lectur Power Sys Representation 30032020 110408pmDocument20 pagesLectur Power Sys Representation 30032020 110408pmGaylethunder007No ratings yet

- Chapter 1 - FluidDocument9 pagesChapter 1 - Fluidfieyza adnNo ratings yet

- Extra Metric Practice Worksheet ANSWER KEYDocument2 pagesExtra Metric Practice Worksheet ANSWER KEYMichael TuroNo ratings yet

- Physics AnswersDocument24 pagesPhysics AnswersSyed Mairaj Ul HaqNo ratings yet

- Instrumentación, Manejo de Multímetros DigitalesDocument6 pagesInstrumentación, Manejo de Multímetros DigitalesJorly TorresNo ratings yet

- GenPhysics2 Module 2Document20 pagesGenPhysics2 Module 2Real Talk / Music '20No ratings yet

- Datasheet Growatt 12000-15000 tl3-s PDFDocument2 pagesDatasheet Growatt 12000-15000 tl3-s PDFTelecomMasterNo ratings yet

- Star DeltaDocument7 pagesStar DeltagopikrishnaraoNo ratings yet

- Objectives:: Experiment No.3 Radial ConductionDocument5 pagesObjectives:: Experiment No.3 Radial ConductionWalid AdnanNo ratings yet

- Transport Processes: - Intro & ConductionDocument24 pagesTransport Processes: - Intro & ConductionDivyeshNo ratings yet

- The Theory Behind Heat TransferDocument7 pagesThe Theory Behind Heat TransferselisenNo ratings yet

- Reviewer For General Physics 2Document3 pagesReviewer For General Physics 2Ezel MayNo ratings yet

- Ic Engine 4Document25 pagesIc Engine 4Manish ChoudharyNo ratings yet

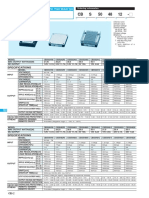

- DC-DC Converters Power Module Type DC-DC Converters Bus Converter - Power Module TypeDocument10 pagesDC-DC Converters Power Module Type DC-DC Converters Bus Converter - Power Module TypetotoNo ratings yet

- Chapter 6Document45 pagesChapter 6Paolo EsguerraNo ratings yet

- CET1Document4 pagesCET1tiki alladoNo ratings yet

- Conversion Factors For Environmental EngineersDocument20 pagesConversion Factors For Environmental EngineersCharleneKronstedtNo ratings yet

- E44 Quick-Start 2019-08 547980C MultiDocument2 pagesE44 Quick-Start 2019-08 547980C Multideri mardiNo ratings yet

- 05 Physics 11se Ub EndDocument6 pages05 Physics 11se Ub Endpecan_lisa38No ratings yet