Professional Documents

Culture Documents

LF-Example 2 - Exercise

Uploaded by

edwardo0 ratings0% found this document useful (0 votes)

13 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesLF-Example 2 - Exercise

Uploaded by

edwardoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

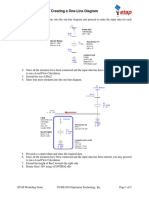

Load Flow Example B2

I. Exercise 1 – Create Configurations

1. Use Load Flow Example 1 for all exercises.

2. Create new configurations and study cases

New Configurations

Name Configuration

Normal Open Tie-Breaker CB3 and CB4 and close all other CBs.

Load Shift Close tie- breaker CB3 & CB4 and open both side CBs of T5 and Cable5

T3 Down Based on Normal configuration, close CB3 and open both side CBs of T3.

T4 Down Based on Normal configuration, close CB4 and open both side CBs of T4.

TieCBClosed Both Tie- Breaker CB3 and CB4 are Closed.

New Study Cases

Name Configuration

DesignLoad • Use Design load without diversity factor.

• Use Design for generation category.

• Use default values for Adjustment Page.

• Loading and generator overexcited alert: Critical = 100%, Marginal =

95%.

90%Load • Use global diversity factor to set all load to 90

• Use the default setting for Adjustment.

• All Loading and generator overexcited alert: Critical = 100%, Marginal

= 95%.

II. Exercise 2 – Check System Voltage Condition

1. Check System Voltage Condition

• Run different cases to see if there is voltage problem.

• If there is any problem, fix it.

III. Exercise 3 – Use LF Calculation to Check Equipment Rating

1. Check Cable 2 Rating (Use Revision)

• Run different cases to see if Cable2 is over/under sized.

• Consider different operating conditions.

• Use derated ampacity based on default Tray setup (ICEA P54-440, H=6, W=18, Fill=30%, No

cover, cumulative effect and fire protection).

2. Check Cable 5 & Cable 7 Rating (Use Revision)

• Run different cases to see if Cables 5 & 7 is under over/under sized.

• Consider all possible configurations.

• Use derated ampacity based on default Tray setup (ICEA P54-440, H=6, W=18, Fill=30%, No

cover, cumulative effect and fire protection).

3. Check XFMR T4 and T5 Rating

• For all cases under consideration, are T4 and T5 under/over sized.

• What size would be more adequate?

• Check system voltage condition again.

ETAP Workshop Notes ©1996-2010 Operation Technology, Inc. Page 1 of 2

Load Flow Example B2

4. Determine Rating For Bus8, Bus12, CB8 and CB9

• Operating conditions to be considered: configuration, loading, compatibility with upper stream

elements.

• Consider the condition when one transformer (T4 or T5) is down.

III. Exercise 4 – Maximize Generator Output

1. Fully utilize co-gen capability

• Let generator output 10 MW.

• Check if there is any problem with system voltage, utility operating PF, etc.

III. Exercise 5 – Voltage Regulation

1. Operating without co-gen

• See if high voltage buses can maintain V >= 98%.

• Use transformer tap to correct voltage problem. Does it cause over voltage condition when

generator is in?

• Try LTC or use LTC tool to determine tap position.

IV. Exercise 6 – Element Sizing

1. Size Cable 2 (Use Revision)

• 2 by 2 conduit

• Ta=25, Tc=90, Rho = 95

2. Size Cable 5 & 7 (Use Revision)

• A/G Tray with Height = 6, Width = 20, Fill = 25%

• Tray Ta = 30, Tc=90

• Use ICEA method.

3. Size equipment cable for Mtr4

• Set up Ampacity page data: Ta=35, Tc=90, NEC, A/G Tray with top cover.

• Size requirements: Vd (2%), Vst(80%), Ampacity (Mtr4 with MF), and SC (26kA, 0.06 second).

• Use library: ICEA, Rubber, Magnetic installation, 100% insulation level, 0.6kV, 3/C, CU

conductor, 200ft.

ETAP Workshop Notes ©1996-2010 Operation Technology, Inc. Page 2 of 2

You might also like

- LF-Example 2 - ExerciseDocument3 pagesLF-Example 2 - ExerciseJavier Madrigal OviedoNo ratings yet

- LF Exercise WorkshopDocument7 pagesLF Exercise WorkshopIlham LuthfiNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Transformer SizingDocument19 pagesTransformer Sizingjokanov0% (1)

- Ejercicios_CC_ANSIDocument6 pagesEjercicios_CC_ANSIa.anonimo.01.01.1950No ratings yet

- IEC: Short-Circuit Example 1: ObjectivesDocument10 pagesIEC: Short-Circuit Example 1: ObjectivesEma Robertho NaniNo ratings yet

- Short-Circuit ANSI Examples: DescriptionDocument6 pagesShort-Circuit ANSI Examples: DescriptionNikola ZherNo ratings yet

- L15-L16 Testing of CBDocument21 pagesL15-L16 Testing of CBAkshat PradhanNo ratings yet

- Motor Starting Study Exercise ETAP PDFDocument5 pagesMotor Starting Study Exercise ETAP PDFLoretta KimNo ratings yet

- Etap OcpDocument20 pagesEtap OcpAndres VergaraNo ratings yet

- PGCIL Spec-4Document25 pagesPGCIL Spec-4Sumit SrivastavaNo ratings yet

- Numerical Bus Bar Protection Testing ProcedureDocument49 pagesNumerical Bus Bar Protection Testing ProcedureMuhammad asifNo ratings yet

- SC Exercise IEC PDFDocument10 pagesSC Exercise IEC PDFRikarjo SilitongaNo ratings yet

- ETAP Workshop Notes ANSI Short Circuit Example: DescriptionDocument6 pagesETAP Workshop Notes ANSI Short Circuit Example: DescriptionGanti KameshNo ratings yet

- Troubleshooting For Battery AnalyzerDocument13 pagesTroubleshooting For Battery AnalyzerRizki FebrianNo ratings yet

- VRLA Battery TestingDocument3 pagesVRLA Battery TestingedgardNo ratings yet

- Optimize Capacitor Placement Using ETAPDocument4 pagesOptimize Capacitor Placement Using ETAPMuhammad AbbasiNo ratings yet

- Testing of Breakers: Unit-4Document31 pagesTesting of Breakers: Unit-4REDAPPLE MEDIA100% (1)

- Switchgear Pre-Commissioning TestsDocument14 pagesSwitchgear Pre-Commissioning TestsKarthikeyan SNo ratings yet

- E. Gasturbine RetrofitDocument46 pagesE. Gasturbine RetrofitMuhammadAsimNo ratings yet

- finalDocument9 pagesfinalSaurabh DeshmukhNo ratings yet

- Micro Turbine Testing ProgramDocument27 pagesMicro Turbine Testing Programarrester97No ratings yet

- Current Boosting Test For Main Transformer 4, 500kV GIS in CCS Hydropower PlantDocument15 pagesCurrent Boosting Test For Main Transformer 4, 500kV GIS in CCS Hydropower Plantcyrus188No ratings yet

- ECNG1007 SinglePhaseTransformers LabDocument15 pagesECNG1007 SinglePhaseTransformers LabLaquita Franklin100% (1)

- Circuit Breaker TestingDocument27 pagesCircuit Breaker TestingAjay Talajiya50% (2)

- IEC - Short-Circuit Example 2: DescriptionDocument9 pagesIEC - Short-Circuit Example 2: DescriptionFrancisco AndradeNo ratings yet

- f05 Amirdatoo Rendallfarley ppt1Document26 pagesf05 Amirdatoo Rendallfarley ppt1edgarafonsecaNo ratings yet

- 24-Idl-ee 467-Unit 5-Maintaining Optimum Generation ScheduleDocument53 pages24-Idl-ee 467-Unit 5-Maintaining Optimum Generation SchedulejenyonamsurveyNo ratings yet

- Motor Starting Study Exercise ETAPDocument5 pagesMotor Starting Study Exercise ETAPFebriyanto Saja0% (1)

- RT 06 Centrif Comp PDFDocument22 pagesRT 06 Centrif Comp PDFAdrian García MoyanoNo ratings yet

- T&C ManualDocument65 pagesT&C ManualKarthikeyan S100% (1)

- Ace Tut 02 Turbulent BackstepDocument22 pagesAce Tut 02 Turbulent BackstepHilario de JesusNo ratings yet

- LT Panel Pre-Commissioning TestsDocument42 pagesLT Panel Pre-Commissioning TestsDhivagar Namakkal100% (1)

- 04 - Transformer SizingDocument19 pages04 - Transformer Sizingashraf-84No ratings yet

- Loading Power Transformers Beyond Nameplate RatingsDocument23 pagesLoading Power Transformers Beyond Nameplate RatingsHamayoun MurtazaNo ratings yet

- Feeding System PDFDocument52 pagesFeeding System PDFWrya SaeedNo ratings yet

- Temperature Rise Test Procedure - Rev-01Document3 pagesTemperature Rise Test Procedure - Rev-01Soumya ranjan BasuriNo ratings yet

- Power Transformers TestDocument77 pagesPower Transformers TestSamuel Ndopu88% (17)

- Test Universe Meter Module Application Note Example of Use El Mech ENUDocument24 pagesTest Universe Meter Module Application Note Example of Use El Mech ENUzinab90No ratings yet

- Assignment - 2: 1. ScopeDocument2 pagesAssignment - 2: 1. ScopeSanjay IraniNo ratings yet

- 野村商会 7043125SH1-SP1-R&D-77G Ver0Document9 pages野村商会 7043125SH1-SP1-R&D-77G Ver0Anonymous RgLs9INo ratings yet

- Trafo Winding ResistanceDocument17 pagesTrafo Winding ResistanceAde YahyaNo ratings yet

- Transformer Testing Station: Determining Sensitivity of A Relay To Inter-Turn Faults On An Energized Power TransformerDocument31 pagesTransformer Testing Station: Determining Sensitivity of A Relay To Inter-Turn Faults On An Energized Power TransformerbhuvaneswarimpNo ratings yet

- PID Control Experiment: Mechanical Engineering LabDocument4 pagesPID Control Experiment: Mechanical Engineering LabFreddy A. SanchezNo ratings yet

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDocument9 pagesSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhNo ratings yet

- Accelerated creep testing QA in less than 200 hoursDocument16 pagesAccelerated creep testing QA in less than 200 hoursBhukya Pavan KumarNo ratings yet

- How Do We Design A 60VA Non Inherently Short Circuit Proof Safety TransformerDocument11 pagesHow Do We Design A 60VA Non Inherently Short Circuit Proof Safety TransformeryoganandvNo ratings yet

- BIIT-04 Testing Bushings With Two Taps Galera PPTDocument25 pagesBIIT-04 Testing Bushings With Two Taps Galera PPTPedro LombardoNo ratings yet

- Transformer Sizing CalculationDocument9 pagesTransformer Sizing CalculationMirko Yanque TomasevichNo ratings yet

- WindMil 101: Distribution System Modeling and AnalysisDocument114 pagesWindMil 101: Distribution System Modeling and AnalysisJohnny FrazierNo ratings yet

- Presentasi Raytech wr50Document31 pagesPresentasi Raytech wr50yori arifNo ratings yet

- 06 - Variations ExercisesDocument53 pages06 - Variations ExercisesasnovitasariduhriNo ratings yet

- 08 - Stability Exercises v1.5Document66 pages08 - Stability Exercises v1.5asnovitasariduhriNo ratings yet

- EERI 311 Practical 1Document2 pagesEERI 311 Practical 1Andrew GeldenhuysNo ratings yet

- Transformer Testing and Commissioning GuidelinesDocument7 pagesTransformer Testing and Commissioning Guidelineselia nugraha adi100% (1)

- Watt-Hour Meter TestDocument15 pagesWatt-Hour Meter Testsherif ahmed moussaNo ratings yet

- FireAlarm Product GuideDocument12 pagesFireAlarm Product GuidekingNo ratings yet

- Load Flow Example B3: ETAP Workshop Notes ©1996-2010 Operation Technology, Inc. Page 1 of 1Document1 pageLoad Flow Example B3: ETAP Workshop Notes ©1996-2010 Operation Technology, Inc. Page 1 of 1edwardoNo ratings yet

- © 1996-2010 Operation Technology, Inc. - Workshop Notes: AC NetworkDocument63 pages© 1996-2010 Operation Technology, Inc. - Workshop Notes: AC NetworkedwardoNo ratings yet

- 03 - Loadflow - PanelDocument94 pages03 - Loadflow - PaneledwardoNo ratings yet

- 02 - Creating An OLDDocument5 pages02 - Creating An OLDedwardoNo ratings yet

- FireAlarm Product GuideDocument12 pagesFireAlarm Product GuidekingNo ratings yet

- Installation GuideDocument4 pagesInstallation GuideAnonymous ugAY1fsF0aNo ratings yet

- Load Flow Example B1: 1. Build The Following SystemDocument4 pagesLoad Flow Example B1: 1. Build The Following SystemedwardoNo ratings yet

- GW-Solar System Container PDFDocument4 pagesGW-Solar System Container PDFedwardoNo ratings yet

- PT Supraco Indonesia Company ProfileDocument28 pagesPT Supraco Indonesia Company ProfileedwardoNo ratings yet

- GW-Solar System Container PDFDocument4 pagesGW-Solar System Container PDFedwardoNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- Compro Etrama 28062021Document11 pagesCompro Etrama 28062021edwardoNo ratings yet

- Dredging Works for Sea Water Intake and JettyDocument7 pagesDredging Works for Sea Water Intake and Jettyedwardo100% (2)

- GW-Solar System Container PDFDocument4 pagesGW-Solar System Container PDFedwardoNo ratings yet

- OPGW产品运行维护手册sdfsdsfvesefvDocument11 pagesOPGW产品运行维护手册sdfsdsfvesefvedwardoNo ratings yet

- Vertical LityDocument44 pagesVertical LityedwardoNo ratings yet

- Project Daily Report: Row Stringing Cable TowerDocument2 pagesProject Daily Report: Row Stringing Cable ToweredwardoNo ratings yet

- Job application letter for System Development positionDocument1 pageJob application letter for System Development positionedwardoNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- Structural Member Inspection and Verticality InspectionDocument13 pagesStructural Member Inspection and Verticality InspectionedwardoNo ratings yet

- GE QA QC PlanDocument103 pagesGE QA QC PlanchezzkonsultNo ratings yet

- TesterDocument2 pagesTesteredwardoNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeedwardoNo ratings yet

- Update Progress Erection For Transmission Line (Oct, 12 2017)Document6 pagesUpdate Progress Erection For Transmission Line (Oct, 12 2017)edwardoNo ratings yet

- Sorik Marapi Geothermal Project: Transmission LinesDocument2 pagesSorik Marapi Geothermal Project: Transmission LinesedwardoNo ratings yet

- Types of Neutral Earthing in Power DistributionDocument8 pagesTypes of Neutral Earthing in Power Distributionedwardo100% (1)

- Project Daily Report: Row Stringing Cable TowerDocument2 pagesProject Daily Report: Row Stringing Cable ToweredwardoNo ratings yet

- Erection WorkloadDocument2 pagesErection WorkloadedwardoNo ratings yet

- Stock List - TR 1Document1 pageStock List - TR 1kshanmugaNo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffMarceloMeirellesNo ratings yet

- Mutual Inductance and Transformer Circuits With Ltspice IvDocument4 pagesMutual Inductance and Transformer Circuits With Ltspice IvSteinerNo ratings yet

- Mixed-Signal IC Floor Planning TechniquesDocument53 pagesMixed-Signal IC Floor Planning Techniquesvenkata satya challayya naidu PragadaNo ratings yet

- Understanding The Behavior of ExciterDocument4 pagesUnderstanding The Behavior of Exciterschauhan12No ratings yet

- Dual Slope Integrating DVMDocument4 pagesDual Slope Integrating DVMmohit100% (1)

- Panasonic+PT 53WX52F+Chassis+EP824Document28 pagesPanasonic+PT 53WX52F+Chassis+EP824vkezakanNo ratings yet

- Power in AC Circuit Lab ReportDocument8 pagesPower in AC Circuit Lab ReportJEJUNG67% (3)

- Autodoor Solution BrochureDocument8 pagesAutodoor Solution BrochureJohanNo ratings yet

- Unbalanced 3-Phase System PDFDocument16 pagesUnbalanced 3-Phase System PDFCandy ChocolateNo ratings yet

- Infineon FP40R12KE3G DS v03 00 en deDocument12 pagesInfineon FP40R12KE3G DS v03 00 en deZdenko PavićNo ratings yet

- 2 53Document3 pages2 53Eric KialNo ratings yet

- User Manual: 2-Phase Digital Stepper DriveDocument13 pagesUser Manual: 2-Phase Digital Stepper DriveWilliam BelascoNo ratings yet

- LCD Television Service Manual: Chassis MT5380 Product TypeDocument50 pagesLCD Television Service Manual: Chassis MT5380 Product Typekachappilly2012100% (1)

- Installation Manual APS596C - IMDocument16 pagesInstallation Manual APS596C - IMMauro SteffenNo ratings yet

- Electrical System TestingDocument10 pagesElectrical System TestingoritasNo ratings yet

- Starting of DC MotorDocument3 pagesStarting of DC MotorAnbalagan GuruNo ratings yet

- Diode Circuit AnalysisDocument13 pagesDiode Circuit AnalysisPhaniendra Kundeti0% (1)

- Armature Reaction in Alternator or Synchronous GeneratorDocument4 pagesArmature Reaction in Alternator or Synchronous GeneratorNimeshNo ratings yet

- Dxxx-690-960/1695-2690/1695-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R11V06Document1 pageDxxx-690-960/1695-2690/1695-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R11V06Лъчезар Амбов50% (2)

- Multilayer 180° Hybrid Coupler in LTCC Technology For 24GHz ApplicationsDocument4 pagesMultilayer 180° Hybrid Coupler in LTCC Technology For 24GHz Applicationsravi010582No ratings yet

- MCQs General Unit IDocument25 pagesMCQs General Unit IN1234m100% (1)

- MKT 000107 - Rev A - NX Malindi Solar Power Plant Case StudyDocument2 pagesMKT 000107 - Rev A - NX Malindi Solar Power Plant Case StudyRaj KamatNo ratings yet

- Mushrooms, Electricity, and Neural Networks! - Herbal Visionz.Document22 pagesMushrooms, Electricity, and Neural Networks! - Herbal Visionz.nicungNo ratings yet

- Powercommand Transfer Switches: Seamlessly, Reliably and Safely Meet Your Critical Power NeedsDocument13 pagesPowercommand Transfer Switches: Seamlessly, Reliably and Safely Meet Your Critical Power NeedsdouglasdmixNo ratings yet

- Especificación Fluke 1550bDocument3 pagesEspecificación Fluke 1550bAngel Morell OrtizNo ratings yet

- Vlf-Sinus-45kv Ds en v01Document2 pagesVlf-Sinus-45kv Ds en v01Hoku's NickNo ratings yet

- Mil STD 464aDocument121 pagesMil STD 464amuriel_reperant5867No ratings yet

- Importance of 7% Detuned ReactorsDocument2 pagesImportance of 7% Detuned ReactorsAditya PandeyNo ratings yet

- ABB Load Interrupter Switchgear Customer PresentationR2Document14 pagesABB Load Interrupter Switchgear Customer PresentationR2Mahyar MashayekhiNo ratings yet