Professional Documents

Culture Documents

PROPOSED Precast For Fire Exit Curtain Wall

Uploaded by

Czar VincentOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PROPOSED Precast For Fire Exit Curtain Wall

Uploaded by

Czar VincentCopyright:

Available Formats

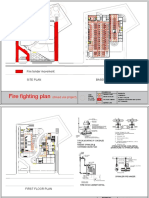

VISION PROPERTIES DEVELOPMENT CORPORATION

PROJECT SUNTRUST SOLANA

NATIVIDAD LOPEZ ST., COR. AYALA BLVD., ERMITA, MANILA

PROPOSED PRECAST FOR THE

FIRE EXIT CURTAIN WALL

(RECTIFICATION METHODOLOGY FOR THE CURTAIN WALL OPENING INCLUDING PRECAST PANELIZATION AND INSTALLATION)

PRESENTED TO:

SUNTRUST PROPERTIES INCORPORATION

JULY 2021

PROJECT: SOLANA CONDOMINIUM

VISION

PROPERTIES DEVELOPMENT

OWNER: SUNTRUST PROPERTIES

SUBMITTAL

CONTRACT SCOPE: 0000014730 REQUEST FOR APPROVAL

8

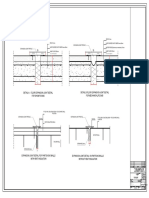

CONCRETE LEDGE CONCRETE LEDGE

A3

350

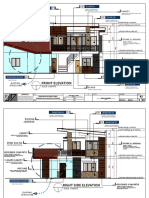

PROPOSED PRECAST

1900

128

300

300

E

127

SEE PRECAST PLAN PROPOSED PRECAST

A2 PANEL SEE DRAWING A2

219122

FIRE EXIT CURTAIN WALL

PROPOSED PRECAST CONCRETE

A1 CURTAIN WALL

MULLION

243 JOBMIX

SCALE :NTS

PROJECT: SOLANA CONDOMINIUM

VISION

PROPERTIES DEVELOPMENT

OWNER: SUNTRUST PROPERTIES

SUBMITTAL

CONTRACT SCOPE: 0000014730 REQUEST FOR APPROVAL

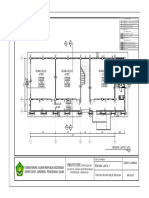

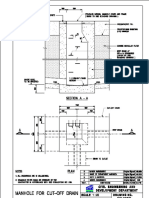

20MM DIA REBAR DOWEL 20MM DIA REBAR DOWEL

EMBEDDED TO EXISTING EMBEDDED TO CONCRETE LEDGE

PRECAST/BEAM BY 100MM BY 100MM DEPTH WITH

DEPTH WITH CONCRETE EPOXY CONCRETE EPOXY

100

150

CONCRETE LEDGE

20MM DIA. REBAR NON-SHRINK GROUT

LENGTH OF PRECAST = 2450

15MM THK STYROFOAM

PROPOSED ADD'L PRECAST

STEEL MESH

20MM DIA. PRECAST

EXISTING PRECAST

DOWEL FULL WELDED TO

2650

PRECAST/BEAM AND

150

CONCRETE LEDGE DOWEL

(EXTERIOR SIDE)

(INTERIOR SIDE)

FIRE EXIT CURTAIN WALL

PRECAST PLAN DETAIL

A2

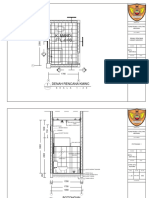

SCALE :NTS FIRE EXIT CURTAIN WALL

PRECAST CONNECTION DETAIL

A3

SCALE :NTS

PROJECT: SOLANA CONDOMINIUM

VISION

PROPERTIES DEVELOPMENT

OWNER: SUNTRUST PROPERTIES

SUBMITTAL

CONTRACT SCOPE: 0000014730 REQUEST FOR APPROVAL

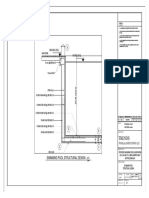

METHODOLOGY STATEMENT FOR THE RECTIFICATION OF FIRE EXIT STAIR

CURTAIN WALL OPENING AND INSTALLATION OF PRECAST WALL.

1. RECTIFICATION OF FIRE EXIT CURTAIN WALL OPENING

1.1 FOR THE CLEAR OPENING, REFERENCE LINE (HEREAFTER REFERRED TO AS "PITIK" ) SHALL BE PROVIDED. FROM "PITIK",

950MM SHALL BE PROJECTED TO BOTH SIDES TO ESTABLISH 1900MM CLEAR OPENING. THE FIRE EXIT CURTAIN WALL SHALL

HAVE 1900MM CLEAR OPENING FROM FIFTH FLOOR UP TO THE ROOFDECK.

1.2 IN CASES WHEREIN THE EXISTING SIDE OF THE CURTAIL WALL OPENING LACKED OR EXCEEDED FROM THE ESTABLISHED

"PITIK", CHIPPING WORKS AND PLASTERING WORKS WILL BE EXECUTED. IF THE REQUIRED PLASTERING WORKS EXCEEDED

40MM, STRUCTURAL SUPPORT SUCH AS STEEL MESH OR REBAR SHALL BE ADDED.

1.3 PRIOR TO THE MOBILIZATION OF PLASTERING WORKS, ALL SURFACES SHALL BE CHISELED TO ATTAIN A ROUGH

CONCRETE SURFACE. NEXT, APPLY CONCRETE EPOXY, WAIT UNTIL THE EPOXY IS HALFWAY CURED, THEN PROCEED TO THE

PLASTERING WORK.

1.4 FOR THE ALIGNMENT OF STAIR MIDLANDING BEAM AND PERIMETER BEAM, GRIDLINE "PITIK" SHALL BE ESTABLISHED

FIRST. FROM THE "PITIK" 127MM OFFSET SHALL BE PROJECTED (SEE DRAWING A-1). ALL BEAM FACES THAT WOULD EXCEED

FROM THE 127MM OFFSET SHALL BE CHIPPED AND RECTIFIED TO THE REQUIRED ALIGNMENT. HOWEVER, BEAM FACES THAT

WOULD NOT EXCEED FROM THE 127MM OFFSET SHALL BE RETAINED, THESE BEAMS WILL BE RECTIFIED FOR ITS AESTHETIC.

2. FABRICATION OF PRECAST PANELS:

2.1 ON THE CASTING BED, FIRST, ESTABLISH "PITIK" FOR THE REQUIRED SIZE OF THE PRECAST. THEN PROCEED TO THE

FABRICATION OF FORMWORKS. AFTER FORMWORKS, LAY THE STYROFOAM, STEEL MESH, AND 20MM REBAR AS PRESCRIBE

IN THE DRAWING (SEE DRAWING A-2).

2.2 MIXTURE OF 1:3 CEMENT-SAND RATIO SHALL BE USE AS CONCRETE JOB MIX FOR THE PRECAST. MAKE SURE THAT THE

PRECAST REINFORCEMENTS ARE IN PLACE AND THE FORMWORKS IS FIXED, THEN PROCEED TO THE POURING OF CONCRETE

ON TO THE FORMWORKS. USE VIBRATOR TO VIBRATE THE CONCRETE IN ORDER TO AVOID HONEYCOMBS.

2.3 LET THE CONCRETE MIXTURE SET FOR AT LEAST 2 DAYS TO CURE. AFTER CURING PERIOD, STRIP THE PRECAST FROM ITS

FORMWORKS.

3. INSTALLATION OF PRECAST PANELS:

3.1 PREPARE THE AREA WHERE THE PRECAST WILL BE INSTALLED. DRILL 22MM DIAMETER HOLES FOR THE EMBEDMENT OF

PRECAST DOWELS. EMBED 100MM DEEP 20MM DIAMETER REBAR DOWELS WITH CONCRETE EPOXY ON THE DRILLED HOLES.

3.2 PRECAST PANEL MAY BE LIFTED TO ITS LOCATION USING GONDOLA OR TOWER CRANE. IF USING GONDOLA, ONLY SINGLE

PANEL PER LIFT WILL BE ALLOWED. MAKE SURE THAT THE EMBEDDED REBAR DOWELS ARE SECURE. FIX THE PRECAST TO ITS

LOCATION, FULL WELD PRECAST TO THE DOWELS (SEE DRAWING A-3). MAKE SURE TO SATISFY THE REQUIRED 1900MM CLEAR

OPENING BEFORE FIXING THE PRECAST.

4. MAKING GOOD OF THE INSTALLED PRECAST:

4.1 PRECAST GAP CONNECTION WILL BE SEALED UP WITH NON-SHRINK GROUT (SEE DRAWING A-3). TO SATISFY THE 128MM

MULLION WIDTH OF THE CURTAIN WALL, 122MM DEPTH PATCHING OF CONCRETE JOBMIX WILL BE EXECUTED AT THE INTERIOR

SIDE OF THE PRECAST PANEL (SEE DRAWING A-1).

4.2 PROCEED TO THE RUBCON OF THE PRECAST THEN APPLY PRIMER TO THE OPENING OF THE CURTAIN WALL. AFTER THAT,

THE INSTALLED PRECAST AND THE ENTIRE CURTAIN WALL OPENING MAY NOW BE HANDOVER TO THE CURTAIL WALL

CONTRACTOR FOR ACCEPTANCE.

PROJECT: SOLANA CONDOMINIUM

OWNER: SUNTRUST PROPERTIES

SUBMITTAL

VISION

PROPERTIES DEVELOPMENT

CONTRACT SCOPE: 0000014730 REQUEST FOR APPROVAL

You might also like

- Banawe 3 PDFDocument1 pageBanawe 3 PDFkrimeo0% (1)

- Kali Kaula A Manual of Tantric Magick HardbackDocument3 pagesKali Kaula A Manual of Tantric Magick Hardbackalintuta20% (1)

- How To ApplyDocument129 pagesHow To ApplySasa KasaNo ratings yet

- 2 StoreyDocument19 pages2 Storeyarkitravel onthego100% (5)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Calculus: Early Transcendental Functions 7th Edition by Ron Larson, Bruce H. Edwards Test Bank and Solution ManualDocument8 pagesCalculus: Early Transcendental Functions 7th Edition by Ron Larson, Bruce H. Edwards Test Bank and Solution ManualMiguel Tejeda0% (1)

- Esp-English For Tour GuidesDocument13 pagesEsp-English For Tour GuidestijehNo ratings yet

- Shattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsDocument15 pagesShattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsFishing ManiaNo ratings yet

- CS ElevDocument1 pageCS Elevsuhel29No ratings yet

- Shopdrawing Installation 1mva Cat Genset - Globe Mandalagan - 8.18.23Document4 pagesShopdrawing Installation 1mva Cat Genset - Globe Mandalagan - 8.18.23Camille DiokoNo ratings yet

- Ceiling Gypsum 2.700 Wall Finish HT UK.300X600MM: Potongan A Toilet Karyawan Pria L1 (Gmb3)Document1 pageCeiling Gypsum 2.700 Wall Finish HT UK.300X600MM: Potongan A Toilet Karyawan Pria L1 (Gmb3)pingki04No ratings yet

- Sec BB PDFDocument1 pageSec BB PDFNagabharan GowdaNo ratings yet

- Section A-ADocument1 pageSection A-AAlex AidaboeNo ratings yet

- Working Drawing Isa4Document1 pageWorking Drawing Isa4Aakash ReddyNo ratings yet

- 2.ornamen & Huruf TimbulDocument1 page2.ornamen & Huruf TimbulResya AstinNo ratings yet

- SafeOz - Bursil Sewer - Asset Protection DetailsDocument2 pagesSafeOz - Bursil Sewer - Asset Protection Detailsrao_vinay8296No ratings yet

- PERIMETER FENCE-Layout1Document1 pagePERIMETER FENCE-Layout1Stefen SalvadorNo ratings yet

- 25571-DRG-2020Jan Fusion T2 StandardDocument5 pages25571-DRG-2020Jan Fusion T2 StandardKevin KuanNo ratings yet

- Section 1-1 (Pier Side View)Document1 pageSection 1-1 (Pier Side View)Alex John Carlos UlepNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- 7568-2143 Typical Watermain DetailsDocument1 page7568-2143 Typical Watermain Detailsmuhammud amirNo ratings yet

- SDCS 02 14Document11 pagesSDCS 02 14Mahmoud AbdulmonemNo ratings yet

- Washroom Details and Fitting SelectionsDocument19 pagesWashroom Details and Fitting SelectionsKyrshan HynniewtaNo ratings yet

- Khung Zamil-Tho Sua - 222Document17 pagesKhung Zamil-Tho Sua - 222Al-Razzaq Al-WahhabNo ratings yet

- Gutters and Boxes GFDocument2 pagesGutters and Boxes GFmighty owlNo ratings yet

- 5bd SCTDocument1 page5bd SCTconcept coderNo ratings yet

- Gd. MI RKBDocument15 pagesGd. MI RKBerik indra islamiNo ratings yet

- Det-0104-Window Jamb - Brick Veneer Wall-CDocument1 pageDet-0104-Window Jamb - Brick Veneer Wall-Cnathan.liuNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrintermoNo ratings yet

- Bayu Dwiyan S - 06 - Xiiab-Detail Km-1Document5 pagesBayu Dwiyan S - 06 - Xiiab-Detail Km-1Citra Ayu NovianiNo ratings yet

- Sto. Cristo 1Document1 pageSto. Cristo 1rhenzyNo ratings yet

- FireFighting Sreejith170823013Document2 pagesFireFighting Sreejith170823013SreejithNo ratings yet

- Pipe PrecastDocument2 pagesPipe Precastmighty owlNo ratings yet

- S-005-Typical Structural Detail-3Document1 pageS-005-Typical Structural Detail-3JohnIsaacNo ratings yet

- 18-010-T-05 Tech DWG - Side Elevation 1Document1 page18-010-T-05 Tech DWG - Side Elevation 1Monique BarbaraNo ratings yet

- Ground FloorDocument1 pageGround FloorsandaNo ratings yet

- A1 2 DV Office HR - A3formatDocument1 pageA1 2 DV Office HR - A3formatRanz DewNo ratings yet

- Section X-X: Bar Dinning Master BedroomDocument1 pageSection X-X: Bar Dinning Master BedroomCoperate PraiseNo ratings yet

- Typical Details of Brick Work Compound Wall in Sewage Pumping Stations - Plan & Section - CompressedDocument1 pageTypical Details of Brick Work Compound Wall in Sewage Pumping Stations - Plan & Section - CompresseddineshNo ratings yet

- Lawrenz Exam CadDocument1 pageLawrenz Exam CadAQUINO, LAWRENZ DAVE B.No ratings yet

- Standard ModelsDocument1 pageStandard ModelswalterNo ratings yet

- Details - 01Document1 pageDetails - 01Mcr KumaraNo ratings yet

- Fasilitator Teknik: National Slump Upgrading Program (NSUP)Document1 pageFasilitator Teknik: National Slump Upgrading Program (NSUP)enQNo ratings yet

- 01 Packing Conveyor 2000 GaDocument1 page01 Packing Conveyor 2000 GaRD Rohan EnterprisesNo ratings yet

- Sewer Cover NewDocument1 pageSewer Cover NewJulius Dean DumaguingNo ratings yet

- New Water Meter CabinetDocument1 pageNew Water Meter CabinetEng. JamalNo ratings yet

- Famu Reflected Ceiling Plan A127.1 0: Scale 1:40Document1 pageFamu Reflected Ceiling Plan A127.1 0: Scale 1:40Jim Bryan RazNo ratings yet

- Electrical Layout: (First Floor Plan)Document1 pageElectrical Layout: (First Floor Plan)Ambright MullerNo ratings yet

- Electrical Layout: (Ground Floor Plan)Document1 pageElectrical Layout: (Ground Floor Plan)Ambright MullerNo ratings yet

- Space Maker DrawingsDocument1 pageSpace Maker DrawingsAbd RaNo ratings yet

- Arc-01 (A3)Document1 pageArc-01 (A3)SS INFRAZONENo ratings yet

- Shoring Plan & DetailsDocument1 pageShoring Plan & DetailsahedwaelNo ratings yet

- 01 Car Expo 7 Oct 022 Final 32Document1 page01 Car Expo 7 Oct 022 Final 32adnan-651358No ratings yet

- B FootingsDocument12 pagesB FootingsRiham Massoud SobhyNo ratings yet

- Det-0102-Stepped Recessed Threshold Balcony-FDocument1 pageDet-0102-Stepped Recessed Threshold Balcony-Fnathan.liuNo ratings yet

- Microbank ModelDocument1 pageMicrobank ModelJayson MariNo ratings yet

- SCHOOL2Document1 pageSCHOOL2rhenzyNo ratings yet

- 13-12-2022 OG 1 Layout Wd-2-ModelDocument1 page13-12-2022 OG 1 Layout Wd-2-ModeljitNo ratings yet

- Sheet 3 PrecastDocument1 pageSheet 3 PrecastManish SainiNo ratings yet

- Mondano Calamba 2Document1 pageMondano Calamba 2Ray AlbivaNo ratings yet

- Manhole For Cut-Off Drain: Section A - ADocument1 pageManhole For Cut-Off Drain: Section A - AStephenNo ratings yet

- Structural CalculationDocument1 pageStructural CalculationNouman MohsinNo ratings yet

- JPLG - LDF 2021 - Qardho Xorgoble Tarmac Road DRAWINGS PDFDocument6 pagesJPLG - LDF 2021 - Qardho Xorgoble Tarmac Road DRAWINGS PDFCOSOB BILANo ratings yet

- 11.partial 09 Perforated ParkirDocument4 pages11.partial 09 Perforated Parkirengineering trimatraNo ratings yet

- Pre Desain Single Line Elektrik, AC, Fresh Air, Exhaust Doan Mall Artha GadingDocument4 pagesPre Desain Single Line Elektrik, AC, Fresh Air, Exhaust Doan Mall Artha GadingAgung SetiawanNo ratings yet

- Idbi - 5685 - Apr 2022Document15 pagesIdbi - 5685 - Apr 2022Rohan GuptaNo ratings yet

- English Language Unit 1 May 2011Document3 pagesEnglish Language Unit 1 May 2011Kieran RichardsNo ratings yet

- Physiology of LactationDocument5 pagesPhysiology of LactationJosephNo ratings yet

- ٣. المنقذ (١٠٠ سؤال)Document44 pages٣. المنقذ (١٠٠ سؤال)ايمان عبد الشافىNo ratings yet

- Hadoop Course Content PDFDocument9 pagesHadoop Course Content PDFNaveen ElancersoftNo ratings yet

- Basics of RainforestsDocument14 pagesBasics of RainforestspsrelianceNo ratings yet

- Behavioural Issues Associated With Long Duration Expedition Missions - NASADocument116 pagesBehavioural Issues Associated With Long Duration Expedition Missions - NASAJp VillalonNo ratings yet

- Masoneilan 31000 Series Rotary Control ValvesDocument12 pagesMasoneilan 31000 Series Rotary Control ValvesJuan Manuel AcebedoNo ratings yet

- ISTH v50 Porto Rico 2006 Trabalho Filme Morango OFSDocument169 pagesISTH v50 Porto Rico 2006 Trabalho Filme Morango OFSAlexandra MamedeNo ratings yet

- Perceived Effectiveness of Artificial Intelligence-Powered Calculators On The Academic Performance of Senior High School STEM Students in MathematicsDocument8 pagesPerceived Effectiveness of Artificial Intelligence-Powered Calculators On The Academic Performance of Senior High School STEM Students in MathematicsPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Activity 15 - Compass ErrorDocument3 pagesActivity 15 - Compass ErrorzeynNo ratings yet

- Aldabbagh 4417Document322 pagesAldabbagh 4417michael ballNo ratings yet

- Final Edit Na Talaga ToDocument82 pagesFinal Edit Na Talaga ToExequel DionisioNo ratings yet

- BUMBLE D2.2v1 FinalDocument51 pagesBUMBLE D2.2v1 FinalgtdreeeNo ratings yet

- Ocrsm Assignment 1Document13 pagesOcrsm Assignment 1Vaishnavi LoyaNo ratings yet

- Silentknight FACP Farenhyt IFP-1000 PDFDocument220 pagesSilentknight FACP Farenhyt IFP-1000 PDFwendy vegaNo ratings yet

- Sample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyDocument30 pagesSample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyM.R.ZNo ratings yet

- Bimedtral Ing. 4 Y 3Document2 pagesBimedtral Ing. 4 Y 3Derly Garcia0% (1)

- Expect The Unexpected: Evidence-Based TrainingDocument4 pagesExpect The Unexpected: Evidence-Based Trainingdionicio perezNo ratings yet

- Shashika Boteju Mathematics Grade 9Document12 pagesShashika Boteju Mathematics Grade 9Dilruk GallageNo ratings yet

- Revised EstimateDocument2 pagesRevised EstimateMd. Abdul HaiNo ratings yet

- Generators Portable Supersilent DCA60SSI2 Rev 3 STD Manual DataId 19056 Version 1Document164 pagesGenerators Portable Supersilent DCA60SSI2 Rev 3 STD Manual DataId 19056 Version 1andrealunalogoNo ratings yet

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocument100 pagesCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNo ratings yet

- Constructivism in Instrumental Music EducationDocument12 pagesConstructivism in Instrumental Music Educationapi-416613415No ratings yet