Professional Documents

Culture Documents

EMCO Plywood Corporation

Uploaded by

Kuro Hanabusa0 ratings0% found this document useful (0 votes)

176 views1 pageThe production head reports on recent issues causing high reject rates of plywood panels. A dysfunctional hot press resulted in 900 grade E panels being rejected on July 18th. Moisture and temperature controls were adjusted on dryers and presses to address wet or blistered panels. The glue spreader was found to have an issue with its spring releasing, causing uneven spreading that contributed to rejects, and monitoring of the spring was increased. Overall rejects were minimized but the spring issue persisted overnight and continued being addressed.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe production head reports on recent issues causing high reject rates of plywood panels. A dysfunctional hot press resulted in 900 grade E panels being rejected on July 18th. Moisture and temperature controls were adjusted on dryers and presses to address wet or blistered panels. The glue spreader was found to have an issue with its spring releasing, causing uneven spreading that contributed to rejects, and monitoring of the spring was increased. Overall rejects were minimized but the spring issue persisted overnight and continued being addressed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

176 views1 pageEMCO Plywood Corporation

Uploaded by

Kuro HanabusaThe production head reports on recent issues causing high reject rates of plywood panels. A dysfunctional hot press resulted in 900 grade E panels being rejected on July 18th. Moisture and temperature controls were adjusted on dryers and presses to address wet or blistered panels. The glue spreader was found to have an issue with its spring releasing, causing uneven spreading that contributed to rejects, and monitoring of the spring was increased. Overall rejects were minimized but the spring issue persisted overnight and continued being addressed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

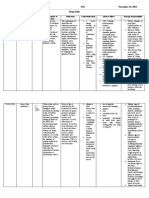

EMCO Plywood Corporation

Magallanes, Agusan Del Norte

July 24, 2020

MR. & MRS. DONALD G. ELORDE

Company Owners

Dear Ma’am/Sir,

This letter is to report to you about the rejects in the production

of plywood.

Regarding the rejects, especially those on July 18, what happened

was that the hot press got dysfunctional. We graded almost 1,500

panels of plywood that were not frozen, around 900 panels of which

were grade E. For the production, we analysed it together with the idle

time that is why ma’am got confused why there were many grade E

falldowns. Regarding the dryer, the moisture control for the short core

is 10-16 and the speed is 200rpm. Mr. Bob Busico was there since the

beginning of the process and that is what we have been applying right

now. For the moisture control of the F-bk, we redry it if there is a

double light. We reduced the speed for the ruler dryer to 175rpm

because there were still those that were wet that got through with a

200 rpm speed. There were also blisters and we checked the

temperature of the hot press and found it at 112°C so we lowered it to

105°C. Finally, we also checked the glue spread and found out that the

top rubber roll was thin and the back was thick. We discovered the

problem to be that the spring of the spreader’s knob would release. We

are currently monitoring the spring knob every 30 min. and yesterday

the rejects were minimized. However, after the break at dawn, the

spring released again from 1 AM-7AM so we are still monitoring it.

Respectfully yours,

EDGAR E. JOSOL

Production Head

You might also like

- ASP Meeting With Samator, January 10Th, 2020 - STNI OfficeDocument11 pagesASP Meeting With Samator, January 10Th, 2020 - STNI OfficeferdinanNo ratings yet

- Gypsum Products in DentistryDocument14 pagesGypsum Products in Dentistryindra_2013100% (1)

- Experience in Pot Rebuilding, Siderar, ArgentinaDocument13 pagesExperience in Pot Rebuilding, Siderar, ArgentinaToàn Lê ĐìnhNo ratings yet

- A Case Study On QTDocument8 pagesA Case Study On QTTanu SinghNo ratings yet

- Alp Bulent GULES ANNA 2010 Presentation - ShareDocument54 pagesAlp Bulent GULES ANNA 2010 Presentation - ShareMohamed KilanyNo ratings yet

- UniEquip Unicryo Cold Trap MC 2LDocument6 pagesUniEquip Unicryo Cold Trap MC 2Lhb04155No ratings yet

- WP PPR - Thermopipe SubmittalDocument36 pagesWP PPR - Thermopipe SubmittalMohammad Rashad BarakatNo ratings yet

- Saint Gobain - ReportDocument24 pagesSaint Gobain - ReportIIC ZHCETNo ratings yet

- Report On Gunj GlassDocument4 pagesReport On Gunj Glassumer263No ratings yet

- Product Data Sheet: HDPE Made Via Hostalen ProcessDocument2 pagesProduct Data Sheet: HDPE Made Via Hostalen ProcessvahidNo ratings yet

- Vocs and Haps For Air/Force Dry Paints: by Ron JosephDocument3 pagesVocs and Haps For Air/Force Dry Paints: by Ron JosephashishNo ratings yet

- Amine Cold Box Core Making: - The Need of The HourDocument38 pagesAmine Cold Box Core Making: - The Need of The HourNayan Patel100% (2)

- Approval LetterDocument1 pageApproval LetterlalijuuhNo ratings yet

- Write Down The Chemical Reactions Take Place in The Kiln or Rotary KilnDocument11 pagesWrite Down The Chemical Reactions Take Place in The Kiln or Rotary KilnMD.MOSHIUR RAHMANNo ratings yet

- Eldan RecyclingDocument10 pagesEldan RecyclingIvan BrcelicNo ratings yet

- Lecture 2 Cement Contd.Document37 pagesLecture 2 Cement Contd.Adharsh SelvarajNo ratings yet

- Slimpulse Austin Chalk TexasDocument1 pageSlimpulse Austin Chalk TexascesarjulioNo ratings yet

- U5 - Adj - 01 - Summary of The Steps of The Ceramic ProcessDocument4 pagesU5 - Adj - 01 - Summary of The Steps of The Ceramic Processbonsenso.engenhariaNo ratings yet

- Home Made Solar PanelDocument24 pagesHome Made Solar PanelLuis FisherNo ratings yet

- Geography SbaDocument25 pagesGeography SbaannmarieNo ratings yet

- Reading Practice Test 3 - Runi - CORRECRTEDDocument15 pagesReading Practice Test 3 - Runi - CORRECRTEDPutri Afra Laillatul UllaNo ratings yet

- Condensation in Switchgears and Anti Condensation Heater PDFDocument2 pagesCondensation in Switchgears and Anti Condensation Heater PDFKok WaiNo ratings yet

- 30 Tons /day Ice PlantDocument4 pages30 Tons /day Ice PlantsureshNo ratings yet

- Issue1 2Document2 pagesIssue1 2api-3764122No ratings yet

- AL13P Laminator ManualDocument5 pagesAL13P Laminator ManualmikaelNo ratings yet

- Kup FL Rapid en 2006Document2 pagesKup FL Rapid en 2006Arief RakhmadNo ratings yet

- Elmer'S Products, Inc: Pegamento para Madera. (E7040) Hoja TecnicaDocument3 pagesElmer'S Products, Inc: Pegamento para Madera. (E7040) Hoja TecnicaRafael Mul OcampoNo ratings yet

- Data Sheet ST GOLFDocument3 pagesData Sheet ST GOLFJuan Antonio Barco MorenoNo ratings yet

- CompressorDocument2 pagesCompressorAbderrahim AbarayNo ratings yet

- Company-Profile 2Document27 pagesCompany-Profile 2Solar OngridNo ratings yet

- Leed U.S. Green Building CouncilDocument6 pagesLeed U.S. Green Building CouncilMiftah FauzanNo ratings yet

- Silo 9 Boulders Investigation ReportDocument20 pagesSilo 9 Boulders Investigation ReportWaka OngetiNo ratings yet

- Ventilacion Molienda de BolasDocument26 pagesVentilacion Molienda de BolasFran jimenezNo ratings yet

- Case Studies: 200 MW, 5 Mills, Mill-F Reserve, Lignite Flow 203 T/hr. Suddenly Turbine Tripped What Action Will You Take ?Document7 pagesCase Studies: 200 MW, 5 Mills, Mill-F Reserve, Lignite Flow 203 T/hr. Suddenly Turbine Tripped What Action Will You Take ?Prudhvi Raj100% (1)

- Best Practices For Cold Weather Paving!Document2 pagesBest Practices For Cold Weather Paving!Joel ChilcaNo ratings yet

- Best Practices For Cold Weather PavingDocument2 pagesBest Practices For Cold Weather PavingCRISTINA QUISPENo ratings yet

- Difference Between Spiral Wound and Simple HDPE TankDocument1 pageDifference Between Spiral Wound and Simple HDPE Tankjokish0% (1)

- Gypsum: Gypsum As A Construction MaterialDocument29 pagesGypsum: Gypsum As A Construction Materialsarah KhalidNo ratings yet

- SP 200 Application ProcedureDocument2 pagesSP 200 Application ProcedureAhmad ShabaniNo ratings yet

- Maintenance Department: Montly Report April 2013Document5 pagesMaintenance Department: Montly Report April 2013syarifNo ratings yet

- Handbook - Submerged Arc ProductsDocument1 pageHandbook - Submerged Arc ProductsHoàng LongNo ratings yet

- Rotational Molding ProcessDocument5 pagesRotational Molding ProcessEdgar IbarraNo ratings yet

- Build A GeoDomeDocument22 pagesBuild A GeoDomeJohn Anderson100% (4)

- Duplo DB-200 Instruction Manual Perfect Binding DB-200Document18 pagesDuplo DB-200 Instruction Manual Perfect Binding DB-200Javier Rivera100% (1)

- 05 PEXb XP650 - 1. TDS (Data Sheet)Document2 pages05 PEXb XP650 - 1. TDS (Data Sheet)Mohammad Rashad BarakatNo ratings yet

- Modern WaterproofingDocument17 pagesModern WaterproofingDileepa DissanayakeNo ratings yet

- CementDocument14 pagesCementRewanta RegmiNo ratings yet

- Brosur Genteng M ClassDocument6 pagesBrosur Genteng M Classanon_795575819No ratings yet

- Waste Heat Boiler Recovery: YoshimineDocument12 pagesWaste Heat Boiler Recovery: YoshimineardiansyahhandikaNo ratings yet

- Alejandro - Insulation PowerpointDocument7 pagesAlejandro - Insulation Powerpointapi-502219049No ratings yet

- Approval LetterDocument1 pageApproval LetterlalijuuhNo ratings yet

- Hempel Interior Filler 38840Document3 pagesHempel Interior Filler 38840Noman AhmedNo ratings yet

- PP Sheet Ext GuideDocument21 pagesPP Sheet Ext GuideAliNo ratings yet

- Ingeo™ Biopolymer 8052D Technical Data Sheet Foam GradeDocument3 pagesIngeo™ Biopolymer 8052D Technical Data Sheet Foam Grademajid mehrabiNo ratings yet

- 1 - Hand Over A.Scarpete SurvilleDocument9 pages1 - Hand Over A.Scarpete Survillealex.verdzadze98No ratings yet

- DMD Insulation PaperDocument5 pagesDMD Insulation PaperSugansKandasamyNo ratings yet

- Company ProfileDocument12 pagesCompany ProfileanerdmermaidNo ratings yet

- Pittseal CW Sealant: 1. Description and Area of ApplicationDocument3 pagesPittseal CW Sealant: 1. Description and Area of ApplicationElie AouadNo ratings yet

- RIL BoppDocument14 pagesRIL BoppSaurabh PariharNo ratings yet

- CombinepdfDocument280 pagesCombinepdfKuro HanabusaNo ratings yet

- Final NCP PediaDocument2 pagesFinal NCP PediaKuro HanabusaNo ratings yet

- Placenta PreviaDocument5 pagesPlacenta PreviaKuro HanabusaNo ratings yet

- Anna Trisha B. Crosrojas N42 November 24, 2021 Drug Study: 3G IvttDocument3 pagesAnna Trisha B. Crosrojas N42 November 24, 2021 Drug Study: 3G IvttKuro HanabusaNo ratings yet

- Pedia Drug StudyDocument6 pagesPedia Drug StudyKuro HanabusaNo ratings yet

- Cues Nursing Diagnosis Planning Interventions Rationale Evaluation SubjectiveDocument2 pagesCues Nursing Diagnosis Planning Interventions Rationale Evaluation SubjectiveKuro HanabusaNo ratings yet

- "Nag Dugo Akong Gums Kaduha" AsDocument3 pages"Nag Dugo Akong Gums Kaduha" AsKuro HanabusaNo ratings yet

- Humoral Immunity Cell-Mediated ImmunityDocument2 pagesHumoral Immunity Cell-Mediated ImmunityKuro HanabusaNo ratings yet

- This Study Resource WasDocument2 pagesThis Study Resource WasKuro HanabusaNo ratings yet

- Pedia Drug Study NaproxenparacetamolDocument3 pagesPedia Drug Study NaproxenparacetamolKuro HanabusaNo ratings yet

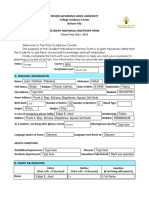

- Father Saturnino Urios University: (Name of Student)Document1 pageFather Saturnino Urios University: (Name of Student)Kuro HanabusaNo ratings yet

- Submissions PANITIKANG FILIPINO N41 Pamprelim Na Pagsusulit Father Saturnino Urios UniversityDocument6 pagesSubmissions PANITIKANG FILIPINO N41 Pamprelim Na Pagsusulit Father Saturnino Urios UniversityKuro HanabusaNo ratings yet

- Mental Status Examination (DSM V) : Magnetic Resonance Imaging (MRI) Chest X-Ray CT Scan SpirometryDocument3 pagesMental Status Examination (DSM V) : Magnetic Resonance Imaging (MRI) Chest X-Ray CT Scan SpirometryKuro HanabusaNo ratings yet

- What ATROPINE Is and What It Is Used For?Document3 pagesWhat ATROPINE Is and What It Is Used For?Kuro HanabusaNo ratings yet

- Drug Study (Chlordiazepoxide, Lorazepam)Document4 pagesDrug Study (Chlordiazepoxide, Lorazepam)Kuro Hanabusa100% (2)

- Resumption of Sustained PerfusingDocument14 pagesResumption of Sustained PerfusingKuro HanabusaNo ratings yet

- Image of A LeaderDocument1 pageImage of A LeaderKuro HanabusaNo ratings yet

- Father Saturnino Urios University College Guidance Center Butuan City Student Individual Inventory FormDocument4 pagesFather Saturnino Urios University College Guidance Center Butuan City Student Individual Inventory FormKuro HanabusaNo ratings yet

- Image of A LeaderDocument1 pageImage of A LeaderKuro HanabusaNo ratings yet

- Mr. Eubert Tagupa: Certificate of AppreciationDocument4 pagesMr. Eubert Tagupa: Certificate of AppreciationKuro HanabusaNo ratings yet

- Excel Professional Services, Inc.: Cpa ReviewDocument11 pagesExcel Professional Services, Inc.: Cpa ReviewKuro HanabusaNo ratings yet

- Butao - Nursing Assessment MseDocument4 pagesButao - Nursing Assessment MseKuro HanabusaNo ratings yet

- Case Study Pressure Ulcer StudentDocument8 pagesCase Study Pressure Ulcer StudentKuro HanabusaNo ratings yet

- Coping With AnxietyDocument13 pagesCoping With AnxietyKuro HanabusaNo ratings yet

- Nursing Care Plan 1Document3 pagesNursing Care Plan 1Kuro HanabusaNo ratings yet