Professional Documents

Culture Documents

Emperical Design Method of Pelton Turbine

Emperical Design Method of Pelton Turbine

Uploaded by

Balkrishna ChaudharyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emperical Design Method of Pelton Turbine

Emperical Design Method of Pelton Turbine

Uploaded by

Balkrishna ChaudharyCopyright:

Available Formats

1.

Collect as much empirical design methods of Pelton Turbine components you can

from the available resources. Bucket, runner, nozzle, manifold, others.

Pelton turbine is an impulse-type water turbine. The Pelton wheel extract energy from the

impulse of moving water, as opposed to water's dead weight like the traditional overshot water

wheel. The major components of Pelton turbine are wheel assemble and bucket, nozzle assemble

and manifold. These major components are explained below:

Bucket

Bucket is a component where water jet strikes and results the rotation of wheel. Bucket is

attached at the outside rim of wheel. The Shape of the bucket is of a double hemispherical cup or

bowl. Each bucket is divided into two symmetrical parts with splitter at the middle where water

jet get strike. The splitter splits water jet in both opposite direction and makes the water to

provide proper impulsive force in turbine. The bucket is shaped in such a way that the jet gets

deflected through 160 degrees or 170 degrees. The bucket is made of cast iron, cast Steel bronze

or stainless steel depending upon the head at the inlet of the turbine.

. The empirical design methods for a bucket are as follows:

Velocity of jet (v) = Cd √2 ∗ 𝑔 ∗ 𝐻

Where H = net head of the turbine

And, Cd = coefficient of velocity (0.98 to 0.99)

4Q

Diameter of jet (d) = √

z∗π∗v

Where Q= flow rate

And, Z = Number of Nozzles.

Bucket axial width (B) = 3.4*d

Bucket radial length (L) = 3*d

Bucket depth (e) = 1.2*d

𝐷

Number of Buckets (N) = 15 +2𝑑

Where, D is the pitch diameter of the runner.

Runner

Runner is a rotating part of the turbine. It is a circular disc on the periphery of which a number of

bucket evenly spaced are fixed. . The detachable buckets are attached to the runner using nuts

and bolts.

Diameter of runner can be calculated as,

𝐷

= 0.005*H + 8

𝑑

Where H and d are already calculated parameters.

Also, if the velocity of wheel is required,

𝜋∗𝐷∗𝑁

u=

60

Where N is the speed of the turbine.

Nozzle:

A nozzle is designed to control the direction or characteristics of a fluid flow (especially to

increase velocity) as it exits (or enters) an enclosed chamber or pipe. A nozzle is often a pipe or

tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid

(liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass,

shape, and/or the pressure of the stream that emerges from them. In a nozzle, the velocity of fluid

increases at the expense of its pressure energy.

The Nozzle works in the principle of

continuity given as,

A1 *V1 = A2 * V2 = Q (constant.)

Which means that when area of cross section decreases velocity increases and so does the kinetic

energy.

The nozzle is horizontal and the nozzle axis is assumed as datum for elevation and hence head at

nozzle is given by:

v^2 𝑝

H= +𝜌

2𝑔

Coefficient of velocity is given as :

𝑣2

Cv =

√2𝑔𝐻1

Where, H1 = gross head;

Efficiency of Nozzle,

ᶯ = Cv 2

The efficiency ranges from 90 to 98 percent.

Manifold

Most of the time a single nozzle with a horizontal shaft is used in a pelton turbine but number of

jets are adopted depending upon the specific speed required. The manifold decreases in size

along the circular pathway to increase velocity and provide equal flow through each nozzle and

make the turbine rotation smooth.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Research Report On 3D PrintingDocument19 pagesResearch Report On 3D PrintingBalkrishna ChaudharyNo ratings yet

- 30GXR160-A-54 Vs 55 Vs 56Document8 pages30GXR160-A-54 Vs 55 Vs 56ANGEL MURILLONo ratings yet

- Unit-I Aircraft Systems (Hydraulic System)Document70 pagesUnit-I Aircraft Systems (Hydraulic System)Ram Kumar100% (1)

- Green Hydrogen Technologies Change The Future of Hydropower Developments in NepalDocument12 pagesGreen Hydrogen Technologies Change The Future of Hydropower Developments in NepalBalkrishna Chaudhary100% (1)

- Design of Hydro-Mechanical Equipment Gates Module-VDocument119 pagesDesign of Hydro-Mechanical Equipment Gates Module-VBalkrishna ChaudharyNo ratings yet

- Positive Displacement CompressorDocument30 pagesPositive Displacement CompressorchaitanyaNo ratings yet

- LM6000 PC O&M - GEK 105059 CHG 06Document1,988 pagesLM6000 PC O&M - GEK 105059 CHG 06Alejandro J. Vigo50% (2)

- Tab 4 Fuel SystemsDocument96 pagesTab 4 Fuel SystemsAeroservicios M&CNo ratings yet

- Trend of Surge DesignDocument34 pagesTrend of Surge DesignBalkrishna ChaudharyNo ratings yet

- L2 Francis Turbine 2020 PDFDocument73 pagesL2 Francis Turbine 2020 PDFBalkrishna ChaudharyNo ratings yet

- Flow Around Bluff BodyDocument4 pagesFlow Around Bluff BodyBalkrishna ChaudharyNo ratings yet

- Brake Design AnalysisDocument16 pagesBrake Design AnalysisBalkrishna ChaudharyNo ratings yet

- Tuteriol 1Document2 pagesTuteriol 1Balkrishna ChaudharyNo ratings yet

- Corrosion Allowance Can Be NeglectedDocument2 pagesCorrosion Allowance Can Be NeglectedBalkrishna ChaudharyNo ratings yet

- Mid Term PDFDocument32 pagesMid Term PDFBalkrishna ChaudharyNo ratings yet

- Research Report On 3D PrintingDocument19 pagesResearch Report On 3D PrintingBalkrishna ChaudharyNo ratings yet

- A Multi-Objective Approach To Solve The Build Orientation Problem in Additive ManufacturingDocument17 pagesA Multi-Objective Approach To Solve The Build Orientation Problem in Additive ManufacturingBalkrishna ChaudharyNo ratings yet

- Laser Based System EditedDocument8 pagesLaser Based System EditedBalkrishna ChaudharyNo ratings yet

- TECHNICAL SPECIFICATION FOR CWS BUTTERFL WCJ3VZ v1 4Document29 pagesTECHNICAL SPECIFICATION FOR CWS BUTTERFL WCJ3VZ v1 4Balkrishna ChaudharyNo ratings yet

- A Multi-Objective Approach To Solve The Build Orientation Problem in Additive ManufacturingDocument17 pagesA Multi-Objective Approach To Solve The Build Orientation Problem in Additive ManufacturingBalkrishna ChaudharyNo ratings yet

- Piping B.O.Q - BreakupDocument26 pagesPiping B.O.Q - BreakupBalaji PNo ratings yet

- Check Valve AssessmentDocument7 pagesCheck Valve Assessmentjayrolling dollazNo ratings yet

- Pump Health MonitoringDocument2 pagesPump Health MonitoringAjwad HaziqNo ratings yet

- Sffeco Pumps Ul PDFDocument16 pagesSffeco Pumps Ul PDFMd.Asif Hassan Shipo100% (1)

- Refrigeration System Components: Compressors: LessonDocument44 pagesRefrigeration System Components: Compressors: LessonSuaid Tariq BalghariNo ratings yet

- Axial CompressorsDocument24 pagesAxial CompressorsVamsi MahantiNo ratings yet

- Euroflo EJDocument20 pagesEuroflo EJMEI JUN QUENNo ratings yet

- Problems in BookDocument32 pagesProblems in BookVeronica NocheNo ratings yet

- Liebherr LR 11350 984641608 - 999 - ENDocument3 pagesLiebherr LR 11350 984641608 - 999 - ENMohamed Rashed0% (1)

- Information Structure: Series 1 General ManualDocument8 pagesInformation Structure: Series 1 General ManualtomiNo ratings yet

- Pump FAQsDocument4 pagesPump FAQsashumishra007No ratings yet

- Presentasi UtDocument31 pagesPresentasi UtRiyan DwiNo ratings yet

- Assignment 7 - Fluidsim Pneumatics - Group 2Document10 pagesAssignment 7 - Fluidsim Pneumatics - Group 2muhammad izharNo ratings yet

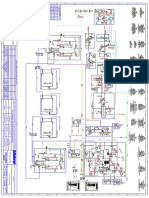

- Appendix 5 - P & ID Drawing OMV Petrom Baicoi 6600Document1 pageAppendix 5 - P & ID Drawing OMV Petrom Baicoi 6600Jean DuboisNo ratings yet

- 3236 P&ID SummaryDocument5 pages3236 P&ID Summarysource codeNo ratings yet

- Operation Manual TPL69-A PDFDocument65 pagesOperation Manual TPL69-A PDFмоно конечноNo ratings yet

- Chapter 4 - Process Fluid Flow (Pumps)Document16 pagesChapter 4 - Process Fluid Flow (Pumps)Nhlanhla PowerNo ratings yet

- Fichas Tecnicas Tyco Amd-2Document4 pagesFichas Tecnicas Tyco Amd-2Isaac Yull AguilarNo ratings yet

- 10FCY Y Strainer (10K) Valve KITZ 02233253 - MonotaRO PhilippinesDocument4 pages10FCY Y Strainer (10K) Valve KITZ 02233253 - MonotaRO PhilippinesFredie LabradorNo ratings yet

- Applications of Bernoulli EquationDocument12 pagesApplications of Bernoulli EquationahmedNo ratings yet

- Flow of Fluids QuizDocument2 pagesFlow of Fluids QuizJhon Oliver De JoseNo ratings yet

- HazopDocument1 pageHazopSyuhadah NoordinNo ratings yet

- 3 Direct Feb 2022 PricelistDocument12 pages3 Direct Feb 2022 PricelistAkash MmdlNo ratings yet

- Gas Dynamics LAB 02 PDFDocument16 pagesGas Dynamics LAB 02 PDFmuhammad zia ur rehmanNo ratings yet

- Spesifikasi SWISS LITHOCLAST MASTERDocument1 pageSpesifikasi SWISS LITHOCLAST MASTEReshandhanaNo ratings yet