Professional Documents

Culture Documents

Farm Power

Uploaded by

Sushant Yadav0 ratings0% found this document useful (0 votes)

49 views18 pagesThe document discusses different sources of farm power, including human power, animal power, and mechanical power. Human power provides manual labor but has low efficiency. Animal power, primarily from buffalo and oxen, is an important traditional source and provides manure and fuel but has low efficiency. Mechanical power includes tractors of various sizes, power tillers, stationary diesel engines, and self-propelled combines which have higher efficiency but higher costs.

Original Description:

ckutuffuf

Original Title

farm power

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses different sources of farm power, including human power, animal power, and mechanical power. Human power provides manual labor but has low efficiency. Animal power, primarily from buffalo and oxen, is an important traditional source and provides manure and fuel but has low efficiency. Mechanical power includes tractors of various sizes, power tillers, stationary diesel engines, and self-propelled combines which have higher efficiency but higher costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views18 pagesFarm Power

Uploaded by

Sushant YadavThe document discusses different sources of farm power, including human power, animal power, and mechanical power. Human power provides manual labor but has low efficiency. Animal power, primarily from buffalo and oxen, is an important traditional source and provides manure and fuel but has low efficiency. Mechanical power includes tractors of various sizes, power tillers, stationary diesel engines, and self-propelled combines which have higher efficiency but higher costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

Source used for farm operation

Tractive work – seed bed preparation, cultivation,

harvesting and transportation

Stationary work- silage cutting, feed grinding,

threshing, winnowing and lifting of irrigation water.

Sources of Farm Power

A. Human Power:

Main sources of power for operating small tools and

implements and also needed for mechanical tools.

According to Campbell (1990), HP = 0.35 – 0.092 log t

Where, t is time in minute (if 3- 4 hr continuous work)

HP = 0.11, HP = Push (kgf) × Seed (m/s) ÷ 75, take S as 0.8

m/s, then push = 10.5 kgf

Advantages: Easily available and used for all types of

work.

Disadvantages : Costliest power compared to all other

farms of power

Very low efficiency, requires full maintenance when not

in use and affected by weather condition and seasons.

Rural labor shortages and have had to develop and use

machines to complete tasks on time

B. Animal power :

Most important source of power on the farm all

over the world and particularly in Nepal

Oxen and caribou or buffalo are the most popular

animal power source for agricultural practices although

horses, donkeys, mules and camels are used in many

countries for transportation.

Nearly 80% of total draft power used in world is still

provided by animals.

Average draft for animal is equal to one tenth of its body

weight.

Power developed by an average pair of bullocks is about

1 hp for usual farm work.

Advantages:

1. Easily available.

2. Used for all types of work.

3. Low initial investment.

4. Supplies manure to the field and fuels to farmers.

5. Live on farm products

Disadvantages:

1. Not very efficient.

2. Seasons and weather affect the efficiency.

3. Cannot work at a stretch.

4. Require full maintenance when there is no farm work.

5. Creates unhealthy and dirty atmosphere near residence.

6. Very slow in doing work.

C. Mechanical power

Used mechanical divice for converting fuel into useful

work.

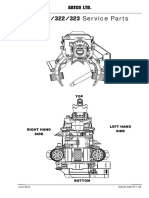

a) Tractors ( 4WD or 2-WD): 20, 20- 30, 31-40 and above 50

hp

used for pulling or pushing agricultural machinery or

trailers, for plowing, tilling, disking, harrowing, planting, and

similar tasks.

Tractors engine use as a prime mover for active tools and

stationary farm machinery through power take-off shaft (PTO)

or belt pulley.

Four-wheel tractors can be divided into 3 categories:

1. Two wheel drive,

2. Front wheel assist or unequal four wheel drive and

3. Equal four wheel drive tractors.

1. Two wheel drive Tractor:

commonly used tractors in dry or upland farming

situations and for transportation.

Range in size from 15-200 HP and need 80% of the

weight distributed over the rear axle to maximize

traction

Capable of delivering 45-50% of their rated engine

power at the drawbar.

Advantage of this type of tractor over others

• Smaller turning circle

• Simplicity of design

• Fewer mechanical parts, and

• Lower purchase price.

Most popular 4 wheel tractor used in rice production.

These tractors range in size from 15-250 hp

Capable of delivering between 50-55% of the rated

power at the drawbar

Name suggests the front drive tires and are smaller

than the rear tires

Front wheel drive should be used at all times when the

tractor is working in the field. If not at least 10% efficiency

will be lost.

One 80 tractor is capable of ploughing 7-8ha per day or

1 ha/hr and 1kW (1.33 hp) of engine power will need 0.25

liters of fuel/hour.

Major advantages

It can deliver 10% more power to the ground for

the same fuel consumption, and has much better

traction and flotation capabilities than 2 wheel

tractors of the same size.

Major disadvantages

Has more mechanical failures, displays unequal tire

wear front to rear and is less maneuverable than a 2

wheel drive tractor.

Inability to work in very wet and muddy conditions.

3. Equal Four Wheel Drive tractors (4WD)

Four tires are almost equal size and range in size from 34-

600HP power rating.

These tractors should be ballasted with 60% of the weight

distributed over the front axle and 40% over the rear axle.

Has the greatest power to weight ratio and can deliver

between 55-60% of power at the drawbar.

Very few of these tractors are used in rice production in

Asia because of their large size, greater turning radius and

purchase price

b) 2-wheel tractors or Power Tiller.

Also called the walking tractor, iron buffalo, steel buffalo

or hand tractor, are used in many countries.

Have a forward mounted engine which is counterbalanced

by the equipment attached behind the two drive wheels.

Operator walks behind the tractor.

Are powered by 5-16 hp gasoline or diesel engines and

are fitted with either rubber tires or steel cage wheels.

Independent drive clutch as well as individual steering

clutches or brakes incorporate . Three forward and one

reverse working gear are most common,

Attachments are used with it as the moldboard plough,

the disc plough, harrows and rotovators.

One 12 HP tractor is capable of plowing 1 ha/day, and

fuel consumption is range from 2 to 5 l/hr

Advantages:

Multi-purpose vehicle

Operate in harder conditions than animals or humans

Operate in both wet and dry conditions

Fairly simple mechanical design

Disadvantages:

Cost of owning and operating

Operator fatigue, although ride-on versions are now

available

c) Oil Engine (Diesel engine and Petrol engine)

Efficiency of diesel engine varies between 32 and 38% and

carburetor engine (Petrol engine) is in the range of 25 and

32%

Normally, stationery diesel engines are used for pumping

water, flour mills, oil grains, cotton gins, chaff cutter,

sugarcane crusher, threshers and winnowers

d) Self Propelled Combines

Advantages of Mechanical Power.

Efficiency is high and not affected by weather

Requires less space and cheaper form of power.

Disadvantages: Initial capital investment is high; fuel

is costly and repairs and maintenance needs technical

knowledge.

You might also like

- Komatsu Truck HM400-2+SEN00239-03D ManualDocument1,356 pagesKomatsu Truck HM400-2+SEN00239-03D Manual江柄宏100% (8)

- 01 Farm MechanizationDocument21 pages01 Farm MechanizationMuhammad Aliuddin Bakar100% (5)

- Advantages & Disadvantages, Technology of Mechanisation in Oil Palm PlantationDocument15 pagesAdvantages & Disadvantages, Technology of Mechanisation in Oil Palm PlantationFarhan Shabri100% (1)

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDocument19 pagesWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Farm Machinery and PowerDocument111 pagesFarm Machinery and PowerGary Bhullar83% (12)

- Major Components and Functions of a Farm Tractor (39Document8 pagesMajor Components and Functions of a Farm Tractor (39Noor Syazwan Nasir100% (2)

- Section C: Service Manual - Side Engine LoadallsDocument140 pagesSection C: Service Manual - Side Engine LoadallsP GlNo ratings yet

- Perkins Parts Catalog 1104D-E44TA Engine Tier 3 NM75392 890-990Document164 pagesPerkins Parts Catalog 1104D-E44TA Engine Tier 3 NM75392 890-990Konstantin T100% (2)

- SAT3series Parts Section-June2014Document72 pagesSAT3series Parts Section-June2014Heidi Cuevas Venegas100% (2)

- Vehicle Safety Inspection ChecklistDocument2 pagesVehicle Safety Inspection ChecklistALMEDA INCNo ratings yet

- Service Manual E55 Compact Excavator: S/N ARWM11001 & Above S/N ASW311001 & AboveDocument6 pagesService Manual E55 Compact Excavator: S/N ARWM11001 & Above S/N ASW311001 & AboveNacer NacerNo ratings yet

- STEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFDocument59 pagesSTEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- John Deere STX30 Technical - Manual - DownloadDocument314 pagesJohn Deere STX30 Technical - Manual - DownloadHansruedi Stebler100% (1)

- Rice Production Manual - Farm Power Sources in 40 CharactersDocument7 pagesRice Production Manual - Farm Power Sources in 40 CharactersRavikanth ReddyNo ratings yet

- FMP Notes 2nd YearDocument40 pagesFMP Notes 2nd YearAditi MeenaNo ratings yet

- Tractors - Types and UtilitiesDocument14 pagesTractors - Types and UtilitiesZicoelyamny100% (2)

- Aeng251coursematerialfinal PDFDocument111 pagesAeng251coursematerialfinal PDFthirumangai6No ratings yet

- Tractors and TransmissionDocument62 pagesTractors and Transmissionaneir0356No ratings yet

- LECTURE-6_TRACTORS-2.0Document42 pagesLECTURE-6_TRACTORS-2.0Heleana Faye BundocNo ratings yet

- Lecture 2 Sources of Farm PowerDocument5 pagesLecture 2 Sources of Farm Powerapi-284140498No ratings yet

- Sources of Farm PowerDocument22 pagesSources of Farm PowerSunil DhankharNo ratings yet

- Agricultural Report on Farm MechanizationDocument12 pagesAgricultural Report on Farm MechanizationRubie EstherNo ratings yet

- Farm Machinery and Power Components and CyclesDocument111 pagesFarm Machinery and Power Components and CyclesJwala nanda kumar ReddyNo ratings yet

- Tractor - Paddy Updated PackageDocument16 pagesTractor - Paddy Updated PackagebharathNo ratings yet

- Farm Machinery and Power: C. No. AENG 251 2 (1+1)Document111 pagesFarm Machinery and Power: C. No. AENG 251 2 (1+1)Tushar JadhavNo ratings yet

- Power TillerDocument68 pagesPower TillerJordan Yap100% (3)

- Farm Power & Machinery: Understanding Sources and Implementing MechanizationDocument18 pagesFarm Power & Machinery: Understanding Sources and Implementing MechanizationAshim ShresthaNo ratings yet

- Farm Machinery and Implements Chapter 1 and 2Document90 pagesFarm Machinery and Implements Chapter 1 and 2Tariku TadesaNo ratings yet

- Sources of Farm PowerDocument48 pagesSources of Farm PowerNandiniNo ratings yet

- ABEN 3423 Homework #2: Four-Wheel TractorDocument4 pagesABEN 3423 Homework #2: Four-Wheel TractorZACK PHILIP AQUINONo ratings yet

- Aht Forest TractorDocument19 pagesAht Forest Tractorapi-287842695No ratings yet

- Industrial Training ReportDocument57 pagesIndustrial Training ReportSOMI REDDY PALLI GURUPRASAD AUTO-2018 BATCHNo ratings yet

- Agricultural Tractors Types and SelectionDocument10 pagesAgricultural Tractors Types and SelectionSunil DhankharNo ratings yet

- Agricultural Machinery: Power Sources and Tractor TypesDocument7 pagesAgricultural Machinery: Power Sources and Tractor TypesRica de los SantosNo ratings yet

- Farm TractorDocument8 pagesFarm TractoriplascakNo ratings yet

- Chapter 1 Introduction Farm MachineryDocument21 pagesChapter 1 Introduction Farm MachinerySiraj Busse0% (1)

- M5Document8 pagesM5rashikawrk25No ratings yet

- GABATO, Jecel Jean GDocument2 pagesGABATO, Jecel Jean GJecel Jean Gaudicos GabatoNo ratings yet

- UNIT 3 Tractors and Power TrailersDocument14 pagesUNIT 3 Tractors and Power TrailersVasantha SeelanNo ratings yet

- Roleoffarmpowerinagric SeminarDocument22 pagesRoleoffarmpowerinagric SeminarJohan SanchezNo ratings yet

- Form Three NOTES 2019Document58 pagesForm Three NOTES 2019PAMAJANo ratings yet

- Agricultural Machinery Laboratory: Research Paper 1: Agricultural TractorDocument59 pagesAgricultural Machinery Laboratory: Research Paper 1: Agricultural TractorAce Gerson GamboaNo ratings yet

- Farm Power and MachinaryDocument101 pagesFarm Power and MachinarySushant YadavNo ratings yet

- Agri Engineering E-BookDocument9 pagesAgri Engineering E-Bookfarhanr.2023No ratings yet

- 1.0 Analysis of The ProductDocument23 pages1.0 Analysis of The ProductAre Riz ZalNo ratings yet

- OPERATION ON AGRICULTURAL MACHINERIES MARCH 14-18,2022Document146 pagesOPERATION ON AGRICULTURAL MACHINERIES MARCH 14-18,2022Rodwin Derick CatiisNo ratings yet

- 2021 - APES - Chap04 - Agricultural TractorsDocument31 pages2021 - APES - Chap04 - Agricultural TractorsKayra Myke VelascoNo ratings yet

- Design of Waste Shredder Machine to Reduce Agro-Waste and PollutionDocument5 pagesDesign of Waste Shredder Machine to Reduce Agro-Waste and PollutionRohan GadhveNo ratings yet

- Lesson 3 Agricultural Power and MachineryDocument23 pagesLesson 3 Agricultural Power and Machineryfaithmark ceriacoNo ratings yet

- PowerDocument9 pagesPowerfelixboridas23No ratings yet

- Coal MachineriesDocument7 pagesCoal Machineriesdudealok100% (2)

- Fabrication of Real Time Multi Purpose Agriculturalvehicle PDFDocument2 pagesFabrication of Real Time Multi Purpose Agriculturalvehicle PDFPriya Nanda ReddyNo ratings yet

- Training Report - Doc TanishDocument37 pagesTraining Report - Doc TanishDilraj ChahalNo ratings yet

- Designoftractorf00evan BWDocument99 pagesDesignoftractorf00evan BWashokkdesignNo ratings yet

- Lauching of TRACTOR in Rural MarketingDocument15 pagesLauching of TRACTOR in Rural Marketingsnoww100% (11)

- HARVESTING AND THRESHING MACHINERYDocument48 pagesHARVESTING AND THRESHING MACHINERYAnalinda SurilNo ratings yet

- Classification of Farm MachinesDocument6 pagesClassification of Farm MachinesPratibha shivNo ratings yet

- Abe 130 Laboratory Exercise 6Document8 pagesAbe 130 Laboratory Exercise 6Kailah BayangosNo ratings yet

- AMM - Chap 11 - Energy Efficiency in Ag EquipmentDocument22 pagesAMM - Chap 11 - Energy Efficiency in Ag EquipmentJohn CennaNo ratings yet

- Agri Engineering QuizDocument5 pagesAgri Engineering QuizJuleika S. SierraNo ratings yet

- 6Document242 pages6Ahmet KarakışNo ratings yet

- Farm Machinery and Equipment IDocument176 pagesFarm Machinery and Equipment IAzizrahman Abubakar100% (1)

- Farm Machinery and Equipment I (001 071)Document71 pagesFarm Machinery and Equipment I (001 071)essemon stebane daha100% (1)

- Farm Power and MachineryDocument168 pagesFarm Power and MachineryYogesh Chauhan100% (2)

- Mechanical Harvester ObservationsDocument3 pagesMechanical Harvester ObservationsHimanshu MogheNo ratings yet

- Purwanchal UnivirsityDocument34 pagesPurwanchal UnivirsitySushant YadavNo ratings yet

- Lecture 1Document27 pagesLecture 1khalid mustafaNo ratings yet

- The Operation, Care, and Repair of Farm MachineryFrom EverandThe Operation, Care, and Repair of Farm MachineryRating: 5 out of 5 stars5/5 (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Farm Electrification Guide for Efficient Irrigation and MechanizationDocument23 pagesFarm Electrification Guide for Efficient Irrigation and MechanizationSushant YadavNo ratings yet

- Harrow 1Document49 pagesHarrow 1Sushant YadavNo ratings yet

- Farm Tractor: Tractor Traction + Motor Machine Used To Pull or Push Agricultural Implements in The FieldsDocument44 pagesFarm Tractor: Tractor Traction + Motor Machine Used To Pull or Push Agricultural Implements in The FieldsSushant YadavNo ratings yet

- Farm Power and MachinaryDocument101 pagesFarm Power and MachinarySushant YadavNo ratings yet

- Transmission PT2509 Diagrama A40E Oil Pressure SpecificationsDocument3 pagesTransmission PT2509 Diagrama A40E Oil Pressure SpecificationsCEVegaONo ratings yet

- Ge12ti 950106-01168 PBDocument268 pagesGe12ti 950106-01168 PBKeron TrotzNo ratings yet

- Build Around The Industry'S Best.: Operating EfficiencyDocument2 pagesBuild Around The Industry'S Best.: Operating EfficiencynixonNo ratings yet

- Made in America Lifetime GuaranteeDocument4 pagesMade in America Lifetime GuaranteeGiandomenico BersanoNo ratings yet

- His Life's WorkDocument4 pagesHis Life's WorkAdds GiddyNo ratings yet

- B3 Intake System B3 Intake System: To IndexDocument4 pagesB3 Intake System B3 Intake System: To Indexwei fooNo ratings yet

- Edoc - Pub - Cs533e TJL Parts Book PDFDocument215 pagesEdoc - Pub - Cs533e TJL Parts Book PDFMarlon GeronimoNo ratings yet

- P100 Series Portable Hydrostatic TestersDocument8 pagesP100 Series Portable Hydrostatic TestersAwo Ni Orumila OsarosoNo ratings yet

- KINETROL Actuators 1180006.0.820.0157.4.00 - Spare Parts ListDocument2 pagesKINETROL Actuators 1180006.0.820.0157.4.00 - Spare Parts Listritchie_ardaniNo ratings yet

- Js200 Travel Gearbox New TypeDocument3 pagesJs200 Travel Gearbox New TypeManuel felipe PalmaNo ratings yet

- 8FBN15 30 Spec2018Document12 pages8FBN15 30 Spec2018Kristono HadiNo ratings yet

- 1993-94 All Model Parts Catalog PartsDocument378 pages1993-94 All Model Parts Catalog PartsStefano BellucciNo ratings yet

- Oil Pumps: Air-OperatedDocument25 pagesOil Pumps: Air-OperatedskyNo ratings yet

- 5126 Walk Behind Power Mower Fact SheetDocument3 pages5126 Walk Behind Power Mower Fact SheetjNo ratings yet

- 2001 Aprilia Pegaso 650 Owners ManualDocument112 pages2001 Aprilia Pegaso 650 Owners ManualKevin McCaigNo ratings yet

- Quantum Multiport PackerDocument1 pageQuantum Multiport Packersmithyry2014No ratings yet

- 385 - 95R25 MICHELIN X-CRANE+ 170F TL - HeuverDocument4 pages385 - 95R25 MICHELIN X-CRANE+ 170F TL - Heuversteven.sun.auNo ratings yet

- Specification Sheet FPRU19F8RFDocument4 pagesSpecification Sheet FPRU19F8RFgacnscNo ratings yet

- q2 Pricelist S LineDocument2 pagesq2 Pricelist S Linebengnoob333No ratings yet

- 1.1.4.A PulleyDrivesSprockets FinishedDocument4 pages1.1.4.A PulleyDrivesSprockets FinishedJacob DenkerNo ratings yet

- JCB TM320 & TM320S Brochure - Set248633215Document16 pagesJCB TM320 & TM320S Brochure - Set248633215Cabir ÇakmakNo ratings yet