Professional Documents

Culture Documents

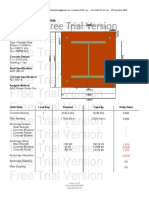

Purlin and Girth Design

Uploaded by

Rajveer SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purlin and Girth Design

Uploaded by

Rajveer SinghCopyright:

Available Formats

8.

1 PURLIN DESIGN

8.1.1 Design Data

a. Spacing of Purlin (S) : 1.40 m

b. Span of Purlin (L) : 8.00 m

c. Angle of Purlin (a) : 10.00 Degree

d. Yield Stress of Purlin : 250.0 N/mm2

e. Unbraced length of Purlin : 8.00 m

f. Type of Purlin : Single Span

g. Delfection Limit (L/delta) : 200

8.1.2 Design Load

a. Roof Dead Load

THK. 0.8mm metal Sheet. : 0.16 kN/m2

Purlin & Etc. : 0.26 kN/m2

0.42 kN/m2 (Conservatively)

b. Roof Live Load

Roof Live Load : 1.00 kN/m2

c. Wind Load ( As per ASCE -07- 05 Sec .6)

-Effective Wind Area ( A) for component (As per ASCE-07-05 Sec 6.2)

A1 = L x S = 11.20 m2

A2 = L xL /3= 21.33 m2 Governs

-Wind pressure coefficient Zone (a) (As per ASCE-07-05 Sec 6.3)

a = Min ( 10% of least horizontal dimension, 0.4h) > either 4% least horizontal dimension or 0.9m

h = 12.95 m Least Horizontal dimension = 14.00 m

a = 1.40 m > 0.90 m

a = 1.40 m Governs

-For Ɵ =10o , Values of GCP from Fig. 6-11C shall be used.

Zone

GCP GCP - ( +GCpi) GCP - ( -GCpi)

Roof

1~3 0.5 -0.05 1.05

1 -0.9 -1.45 -0.35

2 -1.7 -2.25 -1.15

3 -2.6 -3.15 -2.05

Where, +GCPi = + 0.55

-GCPi = - 0.55

hence, GCP - (+ GCpi) = -3.15 Outward

GCP - (- GCpi) = -2.05 Outward

-Velocity pressure at h = 17.40 m

qz = 1.08 kN/m2 (Refer to wind load calculation section 3 of this document)

-Wind load for component, W

W = qz x ( GCP - ( + GCpi) ) x S

= -4.76 kN/m -Outward

= -3.10 kN/m -Outward

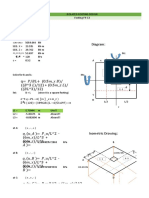

8.1.3 Maximum Moments

a. Dead + Live Load Case (Long Term load)

Total Dead Load = 0.59 kN/m Dead load (x) = 0.58 kN/m Dead load (y) = 0.10 kN/m

Total Live Load = 1.40 kN/m Live load (x) = 1.38 kN/m Live load (y) = 0.24 kN/m

Dead + Live (X-dir) = 1.96 kN/m Mx(max) = WL2 / 8 = 15.65 kN-m

Dead + Live (Y-dir) = 0.35 kN/m My(max) = WL2 / 8 = 2.76 kN-m

b. Dead + Wind Load Case (Short Term load)

Dead + Wind(X-dir) = -4.18 kN/m Mx(max) = WL2 / 8 = -33.48 kN-m

Dead (Y-dir) = 0.10 kN/m My(max) = WL2 / 8 = 0.82 kN-m

8.1.4 Member Selection

Using Member : ISMC 300x90

Member Properties:

Ix = 6420 cm4 Iy = 313 cm4 Weight= 36.3 kg/m

Sx = 428 cm3 Sy = 47.07 cm3 Ax = 46.24 cm2

8.1.5 Stress & Deflection

a. Allowable Flexure Strength ( Dead + Live Load Case is Critical )

Mnx = Mn / Ω = Sx Fy / Ω Ω = 1.67

= 64.07 kN-m

Mny = Mn / Ω = Sy Fy / Ω Ω = 1.67

= 7.05 kN-m

b. Governing Applied Moment

Mx(max) = 33.48 kN-m

My(max) = 2.76 kN-m

c. Flexure Strength Check

Mx + My

< 1

Mnx Mny

33.48 + 2.76

< 1

64.07 7.05

0.91 < 1 hence, OK.

d. Deflection Check ( Dead + Wind Load Case is Critical )

Delta x = 5 Wx L^4 = 17.38 mm

384 E Iy

Delta y = 5 Wy L^4 = 8.68 mm

384 E Ix

Delta total = 19.43 mm < 40.00 mm Hence, OK.

(Resultant)

8.2 Girth Design (For Gable End Section)

8.2.1 Design Data

a. Spacing of Purlin (S) : 1.20 m

b. Span of Girth (L) : 8.00 m

c. Angle of Purlin (a) : 0.00 Degree

d. Yield Stress of Purlin : 250.0 N/mm2

e. Unbraced length of Purlin : 8.00 m

f. Type of Purlin : Single Span

g. Delfection Limit (L/delta) : 150

8.2.2 Design Load

a. Roof Dead Load

THK. 0.7mm metal Sheet. : 0.16 kN/m2

Girth & Gutter Etc. : 0.15 kN/m2

0.34 kN/m2 (Conservatively)

b. Roof Live Load

Roof Live Load : 1.00 kN/m2

c. Wind Load ( As per ASCE -07- 05 Sec .6)

-Effective Wind Area ( A) for component (As per ASCE-07-05 Sec 6.2)

A1 = L x S = 9.60 m2

A2 = L xL /3= 21.33 m2 Governs

-Wind pressure coefficient Zone (a) (As per ASCE-07-05 Sec 6.3)

a = Min ( 10% of least horizontal dimension, 0.4h) > either 4% least horizontal dimension or 0.9m

h = 14.50 m Least Horizontal dimension = 32.50 m

a = 3.25 m > 0.90 m

a = 3.25 m Governs

-For Ɵ >10o , Values of GCP from Fig. 6-11C shall be used.

Zone

GCP GCP - ( +GCpi) GCP - ( -GCpi)

Wall

5 -1.4 -1.95 -0.85

4 -1.1 -1.65 -0.55

5 1 0.45 1.55

4 1 0.45 1.55

Where, +GCPi = + 0.55

-GCPi = - 0.55

hence, GCP - (+ GCpi) = -1.95 Outward

GCP - (- GCpi) = 1.55 Inward

-Velocity pressure at h = 14.50 m

qz = 1.08 kN/m2 (Refer to wind load calcalation sec. 3.10.3 of this document)

-Wind load for component, W

W = qz x ( GCP - ( + GCpi) ) x S

= -2.53 kN/m -Outward

8.2.3 Maximum Moments

b. Dead + Wind Load Case (Short Term load)

Dead (Y-Dir) = 0.41 kN/m My(max) = WL2 / 8 = 3.26 kN-m

Wind (X-Dir) = -2.53 kN/m Mx(max) = WL2 / 8 = -20.22 kN-m

8.2.4 Member Selection

Using Member : ISMC 250x82

Member Properties :

Ix = 4080 cm4 Iy = 244 cm4 Weight = 30.6 kg/m

Sx = 326.4 cm3 Sy = 40.87 cm3 Ax = 38.98 cm2

8.2.5 Strss & Deflection

a. Allowable Flexure Strength ( Dead + Live Load Case id Critical )

Mnx = Mn / Ω = Sx Fy / Ω Ω = 1.67

= 48.86 kg-m

Mny = Mn / Ω = Sy Fy / Ω Ω = 1.67

= 6.12 kg-m

b. Governing Applied Moment

Mx(max) = 20.22 kN-m

My(max) = 3.26 kN-m

c. Flexure Strength Check

Mx + My

< 1

Mnx Mny

20.22 + 3.26

< 1

48.86 6.12

0.95 < 1 hence, OK.

d. Deflection Check ( Dead + Live Load Case is Critical )

Delta x = 5 Wx L^4 = 16.5 mm

384 E Iy

Delta y = 5 Wy L^4 = 45 mm

384 E Ix

Delta total = 47.55 cm < 53.33 mm Hence, OK.

(Resultant)

1 2 3 4 5 6 7 8

Mass Depth Width Thickness Root

Section per of of of Radius Second Moment of Area

Designation metre Section Section Web Flange Axis

M H B s T r x-x

Kg/m mm mm mm mm mm cm4

PFC 430x100x64 64.44 430 100 11 19 15 21939

PFC 380x100x54 53.96 380 100 9.5 17.5 15 15034

PFC 300x100x46 45.53 300 100 9 16.5 15 8229

PFC 300x90x41 41.39 300 90 9 15.5 12 7218

PFC 260x90x35 34.84 260 90 8 14 12 4728

PFC 260x75x28 27.58 260 75 7 12 12 3619

PFC 230x90x32 32.16 230 90 7.5 14 12 3518

PFC 230x75x26 25.66 230 75 6.5 12.5 12 2748

PFC 200x90x30 29.72 200 90 7 14 12 2523

PFC 200x75x23 23.45 200 75 6 12.5 12 1963

PFC 180x90x26 26.06 180 90 6.5 12.5 12 1817

PFC 180x75x20 20.34 180 75 6 10.5 12 1370

PFC 150x90x24 23.87 150 90 6.5 12 12 1162

PFC 150x75x18 17.87 150 75 5.5 10 12 861

PFC 125x65x15 14.76 125 65 5.5 9.5 12 483

PFC 100x50x10 10.20 100 50 5 8.5 9 208

ISMC 75x40 7.14 75 40 4.8 7.5 8.5 78.5

ISMC 100x50 9.56 100 50 5.0 7.7 9.0 192.0

ISMC 125x65 13.1 125 65 5.3 8.2 9.5 425.0

ISMC 150x75 16.8 150 75 5.7 9.0 10.0 788.0

ISMC 175x75 19.6 175 75 6.0 10.2 10.5 1240.0

ISMC 200x75 22.3 200 75 6.2 11.4 11.0 1830.0

ISMC 250x80 26.1 250 80 7.2 14.1 12.0 3880.0

ISMC 250x82 30.6 250 82 9.0 14.1 12.0 4080.0

ISMC 300x90 36.3 300 90 7.8 13.6 13.0 6420.0

C12X30 44.64 304.80 80.52 12.95 12.73 28.58 6742.95

C12X25 37.20 304.80 77.47 9.83 12.73 28.58 5993.73

C12X20.7 30.80 304.80 74.68 7.16 12.73 28.58 5369.39

C10X30 44.64 254.00 76.96 17.09 11.07 25.40 4287.18

C10X25 37.20 254.00 73.41 13.36 11.07 25.40 3791.87

C10X20 29.76 254.00 69.60 9.63 11.07 25.40 3284.07

C10X15.3 22.77 254.00 66.04 6.10 11.07 25.40 2801.24

C9X20 29.76 228.60 67.31 11.38 10.49 25.40 2534.85

C9X15 22.32 228.60 63.25 7.24 10.49 25.40 2122.78

C9X13.4 19.94 228.60 61.72 5.92 10.49 25.40 1989.59

C8X18.5 27.53 203.20 64.26 12.37 9.91 23.81 1827.26

C8X13.7 20.39 203.20 59.44 7.70 9.91 23.81 1502.60

C8X11.5 17.11 203.20 57.40 5.59 9.91 23.81 1352.75

C7X14.7 21.88 177.80 58.42 10.64 9.30 22.23 1132.15

Air Products Internal Use Only

C7X12.2 18.16 177.80 55.63 7.98 9.30 22.23 1007.28

C7X9.8 14.58 177.80 53.09 5.33 9.30 22.23 882.41

MC12X50 74.41 304.80 105.16 21.21 17.78 33.34 11196.63

MC12X45 66.97 304.80 101.85 18.03 17.78 33.34 10447.41

MC12X40 59.53 304.80 98.81 14.99 17.78 33.34 9739.82

MC12X35 52.09 304.80 95.76 11.81 17.78 33.34 8990.60

MC12X31 46.13 304.80 93.22 9.40 17.78 33.34 8407.87

MC12X10.6 15.77 304.80 38.10 4.83 7.85 19.05 2301.76

MC10X41.1 61.16 254.00 109.73 20.22 14.61 33.34 6534.83

MC10X33.6 50.00 254.00 104.14 14.61 14.61 33.34 5785.62

MC10X28.5 42.41 254.00 100.33 10.80 14.61 33.34 5244.52

MC10X25 37.20 254.00 86.61 9.65 14.61 33.34 4578.55

MC10X22 32.74 254.00 84.33 7.37 14.61 33.34 4245.56

MC10X8.4 12.50 254.00 38.10 4.32 7.11 19.05 1327.78

MC10X6.5 9.67 254.00 29.72 3.86 5.13 14.29 953.17

MC9X25.4 37.80 228.60 88.90 11.43 13.97 31.75 3658.67

MC9X23.9 35.57 228.60 87.63 10.16 13.97 31.75 3533.80

MC8X22.8 33.93 203.20 88.90 10.85 13.34 30.16 2655.56

MC8X21.4 31.85 203.20 87.63 9.53 13.34 30.16 2559.82

MC8X20 29.76 203.20 76.96 10.16 12.70 28.58 2264.30

MC8X18.7 27.83 203.20 75.69 8.97 12.70 28.58 2181.05

MC8X8.5 12.65 203.20 47.50 4.55 7.90 20.64 969.82

MC7X22.7 33.78 177.80 91.44 12.78 12.70 28.58 1972.94

MC7X19.1 28.42 177.80 87.63 8.94 12.70 28.58 1793.96

Air Products Internal Use Only

9 10 11 12 13 14 15 16

Elastic

Radius of Gyration Elastic Modulus Plastic Modulus

Second Moment of Area Neutral

Axis Axis Axis Axis Axis Axis Axis Axis

y-y x-x y-y x-x y-y cy x-x y-y

cm4 cm cm cm3 cm3 cm cm3 cm3

722 16.3 2.97 1020 97.9 2.62 1222 176

643 14.8 3.06 791 89.2 2.79 933 161

568 11.9 3.13 549 81.7 3.05 641 148

404 11.7 2.77 481 63.1 2.6 568 114

353 10.3 2.82 364 56.3 2.74 425 102

185 10.1 2.3 278 34.4 2.1 328 62

334 9.27 2.86 306 55 2.92 355 99.1

181 9.17 2.35 239 34.8 2.3 278 63.1

314 8.16 2.88 252 53.4 3.12 291 94.5

170 8.11 2.39 196 33.8 2.48 227 60.8

277 7.4 2.89 202 47.4 3.17 232 83.5

146 7.27 2.38 152 28.8 2.41 176 51.9

253 6.18 2.89 155 44.4 3.3 179 76.9

131 6.15 2.4 115 26.6 2.58 132 47.2

80 5.07 2.06 77.3 18.8 2.25 89.9 33.4

32.3 4 1.58 41.5 9.89 1.73 48.9 17.6

12.9 2.94 1.19 20.93 4.81 1.32 24.17 8.69

26.7 3.97 1.48 38.4 7.72 1.54 43.83 14.3

61.1 5.1 1.91 68 13.43 1.95 77.15 25.56

103.0 6.07 2.19 105.07 19.43 2.2 119.82 37.88

122.0 7.05 2.21 141.71 22.98 2.19 161.65 44.4

141.0 8.03 2.23 183 26.6 2.2 211.26 51.07

211.0 10.8 2.52 310.4 37.02 2.3 277.93 63.64

244.0 10.23 2.5 326.4 40.87 2.23 356.72 73.9

313.0 11.78 2.6 428 47.07 2.35 496.77 91.21

213.11 10.90 1.94 442.45 33.59 1.71 553.88 70.79

185.22 11.25 1.98 393.29 30.64 1.71 481.78 62.60

160.67 11.71 2.02 352.32 28.19 1.77 419.51 56.86

163.58 8.69 1.70 339.21 27.04 1.65 437.53 61.94

139.02 8.94 1.71 298.24 24.09 1.57 378.54 52.11

116.54 9.30 1.75 258.92 21.47 1.54 317.91 44.25

94.48 9.83 1.81 221.23 18.85 1.61 260.55 38.35

100.31 8.18 1.63 221.23 19.17 1.48 276.94 40.31

79.50 8.64 1.67 185.17 16.55 1.49 222.86 33.43

72.84 8.86 1.69 173.70 15.63 1.53 206.48 31.79

82.00 7.16 1.52 180.26 16.55 1.44 227.78 35.56

63.27 7.59 1.56 147.81 13.90 1.41 180.26 28.35

54.53 7.90 1.58 133.39 12.70 1.45 157.81 25.73

57.02 6.38 1.42 127.49 12.65 1.35 159.77 26.71

Air Products Internal Use Only

48.28 6.60 1.44 113.40 11.41 1.33 138.63 23.27

39.83 6.91 1.47 99.47 10.11 1.37 117.82 20.65

724.24 10.87 2.77 735.78 92.42 2.67 925.87 178.62

657.65 11.07 2.77 686.62 86.85 2.64 852.13 165.51

591.05 11.33 2.79 639.10 81.61 2.64 781.66 152.56

524.45 11.66 2.82 589.93 76.04 2.67 707.92 141.26

470.34 11.96 2.82 552.24 71.61 2.74 650.57 133.55

15.73 10.72 0.89 151.09 5.03 0.68 190.09 10.41

653.48 9.17 2.90 516.19 79.48 2.77 644.01 155.51

545.26 9.53 2.92 455.56 71.28 2.77 552.24 135.68

470.34 9.88 2.95 414.59 65.38 2.84 491.61 124.38

301.77 9.83 2.52 360.52 48.51 2.42 429.34 92.59

266.39 10.13 2.53 335.93 45.06 2.51 391.65 86.69

13.57 9.17 0.92 104.71 4.39 0.72 129.79 8.98

5.54 8.71 0.67 75.22 2.25 0.49 96.68 4.65

315.09 8.71 2.57 319.55 49.00 2.46 385.10 93.41

297.19 8.84 2.57 309.72 47.36 2.49 368.71 90.29

291.78 7.85 2.59 260.55 46.05 2.57 312.99 88.00

273.88 7.95 2.59 252.36 44.41 2.59 298.24 84.88

183.97 7.72 2.20 222.86 33.10 2.13 268.75 63.25

172.74 7.85 2.20 214.67 31.95 2.16 255.64 60.96

25.97 7.75 1.27 95.37 7.06 1.09 113.89 14.34

301.35 6.78 2.64 221.23 46.38 2.64 268.75 88.16

252.24 7.04 2.64 201.56 41.79 2.74 237.61 79.48

Air Products Internal Use Only

17

Area

of

Section

A

cm2

82.1

68.7

58

52.7

44.4

35.1

41

32.7

British

37.9

29.9

33.2

25.9

30.4

22.8

18.8

13

9.1

12.18

16.69

21.4

24.97 Indian

28.41

33.25

38.98

46.24

56.84

47.35

39.23

56.84

47.35

37.87

28.90

37.87

28.45

25.42

35.55

26.06

21.74

27.94

Air Products Internal Use Only

23.23

18.52

94.84

85.16

76.13

American

66.45

58.84

20.00

78.06

63.68

54.00

47.42

41.61

15.87

12.58

48.19

45.29

43.23

40.52

37.94

35.48

16.13

43.03

36.19

Air Products Internal Use Only

Air Products Internal Use Only

You might also like

- Bouncing Ball Lab ReportDocument2 pagesBouncing Ball Lab ReportVivian Chuang33% (3)

- Anchors Reinforcement DesignDocument1 pageAnchors Reinforcement DesignManoj JaiswalNo ratings yet

- Procedure - Equivalent Diagonal StrutDocument5 pagesProcedure - Equivalent Diagonal StrutHemant SonawadekarNo ratings yet

- LowRiseBuilding (MBMA 2002) V2Document54 pagesLowRiseBuilding (MBMA 2002) V2Chea VannaiNo ratings yet

- Moment of Inertia of Compound Section Lip ChannelDocument7 pagesMoment of Inertia of Compound Section Lip Channelabhi aroteNo ratings yet

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FLenielle AmatosaNo ratings yet

- Ast For MomentDocument1 pageAst For MomenteramitdhanukaNo ratings yet

- Wind Load Calculation As Per Russia Code PDFDocument7 pagesWind Load Calculation As Per Russia Code PDFDušan ŠebekNo ratings yet

- Design Report of Lifting Spreader BeamDocument70 pagesDesign Report of Lifting Spreader BeamRajveer SinghNo ratings yet

- Chapter02 7 Study GuideDocument8 pagesChapter02 7 Study GuideKay Chan SothearaNo ratings yet

- Base PlateDocument15 pagesBase PlatemaheshbandhamNo ratings yet

- Hilti Analysis For Shear Resistance: Detail CalculationDocument4 pagesHilti Analysis For Shear Resistance: Detail Calculationinti lestariNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNo ratings yet

- BOLTED END PLATE ReportDocument19 pagesBOLTED END PLATE Reportmaheshbandham100% (1)

- Bsep SMFDocument6 pagesBsep SMFamirgholami1100% (1)

- Daniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FDocument2 pagesDaniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FvtalexNo ratings yet

- BCF Type Local WF 400 (Full Weld)Document4 pagesBCF Type Local WF 400 (Full Weld)Puji KurniawanNo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Embeddedplate With StudsDocument78 pagesEmbeddedplate With StudsAkhil VNNo ratings yet

- Member DesignDocument25 pagesMember DesignPrima AdhiyasaNo ratings yet

- Bottom LugDocument7 pagesBottom LugAjiri IvoviNo ratings yet

- Brace Load CalculationDocument14 pagesBrace Load CalculationmaheshbandhamNo ratings yet

- Steel-Angle Bracing Design-1Document12 pagesSteel-Angle Bracing Design-1rohitbhagat005No ratings yet

- JEC Prog T BeamsDocument6 pagesJEC Prog T BeamsmakakkNo ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- AISC Connection-2nd Edition - (4+4) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (4+4) Anchor Rod-FixedTuấnThanhNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Anchor Bolt Design For Shear and TensionDocument2 pagesAnchor Bolt Design For Shear and Tensionsebastian90330% (1)

- Anchor Bolt Design As Per American CodeDocument1 pageAnchor Bolt Design As Per American CodeS A K ClostreNo ratings yet

- Bare Frame (Mbma-02)Document2 pagesBare Frame (Mbma-02)ansgcekNo ratings yet

- Hongo India PVT LTD (Frame-1) : Bolt Moment ConnectionDocument1 pageHongo India PVT LTD (Frame-1) : Bolt Moment Connection4geniecivilNo ratings yet

- LOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Document10 pagesLOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Aboalmaail AlaminNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectioncadsultanNo ratings yet

- JassimDocument29 pagesJassimZain Communication0% (1)

- Design Calculation For Lifting Hook Rev00Document29 pagesDesign Calculation For Lifting Hook Rev00layaljamal2No ratings yet

- Wind Loading Based On EC 1991-4Document4 pagesWind Loading Based On EC 1991-4janethNo ratings yet

- Seismic Load Analysis Per Asce 7-02 Aisc-08Document3 pagesSeismic Load Analysis Per Asce 7-02 Aisc-08intimate4lifeNo ratings yet

- Isolated Footing DesignDocument15 pagesIsolated Footing DesignAzzirrenNo ratings yet

- Compressor Shelter: Velocity of PressureDocument3 pagesCompressor Shelter: Velocity of PressurerohitnrgNo ratings yet

- Fixed Base Plate ExampleDocument5 pagesFixed Base Plate ExamplevtalexNo ratings yet

- RC Shear Wall 1.2Document13 pagesRC Shear Wall 1.2paras rahangdale100% (1)

- Section CapcityDocument16 pagesSection CapcityAnanthakrishna NageshNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Tata Projects Limited: 3. Wind Load CalculationDocument1 pageTata Projects Limited: 3. Wind Load CalculationSrinivas RegulavalasaNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- Column Design With ExcelDocument47 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- Shear Key DesignDocument2 pagesShear Key DesignmaheshbandhamNo ratings yet

- Bracing Connection - Rev EDocument32 pagesBracing Connection - Rev EHeberth SanchezNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- Wind Load Calculations On VesselsDocument3 pagesWind Load Calculations On VesselssudhakarebvnNo ratings yet

- M24 DIA Anchor Bolt ReinforcementDocument2 pagesM24 DIA Anchor Bolt ReinforcementYash SutharNo ratings yet

- ACI-350 P-M Interaction 1.1Document6 pagesACI-350 P-M Interaction 1.1ronpauccarNo ratings yet

- Rean Water Tech Pvt. LTD.: Isolated Footing DesignDocument5 pagesRean Water Tech Pvt. LTD.: Isolated Footing DesignSougata MondalNo ratings yet

- Purlin Design - Hat-Section@170 (r0)Document4 pagesPurlin Design - Hat-Section@170 (r0)Prince MittalNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- تصميم عمود 14 متر +مدونه الممارسةDocument27 pagesتصميم عمود 14 متر +مدونه الممارسةAhmed JaNo ratings yet

- Ref Drawing 2. Ref Code: 3. Design DatasDocument3 pagesRef Drawing 2. Ref Code: 3. Design Datasworkdata2223No ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- AtapDocument16 pagesAtapfebrianNo ratings yet

- Perhitungan GordingDocument15 pagesPerhitungan GordingFadila WulandariNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Cut Tee Plan Brace Connection On Beam JunctionDocument1 pageCut Tee Plan Brace Connection On Beam JunctionRajveer SinghNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- Transportation Plan 12-01-2022Document4 pagesTransportation Plan 12-01-2022Rajveer SinghNo ratings yet

- Isometric View Lifting Detail: NotesDocument2 pagesIsometric View Lifting Detail: NotesRajveer SinghNo ratings yet

- 2140 - Transportation Support - 01Document23 pages2140 - Transportation Support - 01Rajveer SinghNo ratings yet

- Double Cut Tee Plan Brace Connection On Beam WebDocument1 pageDouble Cut Tee Plan Brace Connection On Beam WebRajveer SinghNo ratings yet

- Cut Tee PB at Beam Junction Welded GussetDocument1 pageCut Tee PB at Beam Junction Welded GussetRajveer SinghNo ratings yet

- Mat Foundation Reinforcement DesignDocument1,094 pagesMat Foundation Reinforcement DesignRajveer SinghNo ratings yet

- B) 21 - 06 - 142B - SM - R0-OEx - CommentsDocument2 pagesB) 21 - 06 - 142B - SM - R0-OEx - CommentsRajveer SinghNo ratings yet

- 40 Ton Capacity COMPONENTS AND ADDITIONAL FEATURES DATADocument1 page40 Ton Capacity COMPONENTS AND ADDITIONAL FEATURES DATARajveer SinghNo ratings yet

- 40 Ton Capacity CRANE WHEEL LOAD DATADocument1 page40 Ton Capacity CRANE WHEEL LOAD DATARajveer SinghNo ratings yet

- Singh, Rajveer: From: Sent: To: Subject: AttachmentsDocument5 pagesSingh, Rajveer: From: Sent: To: Subject: AttachmentsRajveer SinghNo ratings yet

- 40 Ton Capacity Motor DataDocument2 pages40 Ton Capacity Motor DataRajveer SinghNo ratings yet

- C) Deviations and Clarifications-Hazardous Non-Hazardous Cranes - CommentsDocument2 pagesC) Deviations and Clarifications-Hazardous Non-Hazardous Cranes - CommentsRajveer SinghNo ratings yet

- Virtu: Virtual IT Drop inDocument22 pagesVirtu: Virtual IT Drop inRajveer SinghNo ratings yet

- Introduction To MS Team: Presentation By: Tech Support Client - InfrastructureDocument11 pagesIntroduction To MS Team: Presentation By: Tech Support Client - InfrastructureRajveer SinghNo ratings yet

- Jubail Industrial Gases Hub: Thursday, February 3, 2022 Air Products Internal Use OnlyDocument9 pagesJubail Industrial Gases Hub: Thursday, February 3, 2022 Air Products Internal Use OnlyRajveer SinghNo ratings yet

- Introduction To MS Edge: Presentation By: Tech Support Client - Infrastructure OperationsDocument9 pagesIntroduction To MS Edge: Presentation By: Tech Support Client - Infrastructure OperationsRajveer SinghNo ratings yet

- Visag - Part - 1 of 2Document25 pagesVisag - Part - 1 of 2Rajveer SinghNo ratings yet

- Lifting MethodologyDocument5 pagesLifting MethodologyRajveer SinghNo ratings yet

- Visag - Part - 2 of 2Document26 pagesVisag - Part - 2 of 2Rajveer SinghNo ratings yet

- Service Car - PDFDocument1 pageService Car - PDFRajveer SinghNo ratings yet

- Zoom For Government: Tech Support Client TeamDocument17 pagesZoom For Government: Tech Support Client TeamRajveer SinghNo ratings yet

- Load Combinations For Shelters - 0001Document104 pagesLoad Combinations For Shelters - 0001Rajveer SinghNo ratings yet

- Mobile Bill Receipts - RajveerDocument6 pagesMobile Bill Receipts - RajveerRajveer SinghNo ratings yet

- Covid Cases Rise With Delta Variant, But Deaths Don't Thanks To Vaccine - VoxDocument6 pagesCovid Cases Rise With Delta Variant, But Deaths Don't Thanks To Vaccine - VoxRajveer SinghNo ratings yet

- Specification For Plant Access Platforms, Stairs and Ladders Materials and FabricationDocument41 pagesSpecification For Plant Access Platforms, Stairs and Ladders Materials and FabricationRajveer SinghNo ratings yet

- Safety Moment: Five Major Safety Tips To Avoid Fire Mishaps at Industrial SitesDocument3 pagesSafety Moment: Five Major Safety Tips To Avoid Fire Mishaps at Industrial SitesRajveer SinghNo ratings yet

- Design of Members For Compression: Chapter EDocument3 pagesDesign of Members For Compression: Chapter ELemark R.No ratings yet

- Frictionproblems PDFDocument16 pagesFrictionproblems PDFJannel PaetNo ratings yet

- CN3135 Process Safety and Environment Consequence Modeling PDFDocument10 pagesCN3135 Process Safety and Environment Consequence Modeling PDFVincent ChongNo ratings yet

- Mechanization of Berth-6 at Adani Krishnapatnam Port LimitedDocument43 pagesMechanization of Berth-6 at Adani Krishnapatnam Port LimitedVignesh VenkatasubramanianNo ratings yet

- Aci 350.3-06 PDFDocument67 pagesAci 350.3-06 PDFManuel Restrepo100% (1)

- Chemical Engineering Thermodynamics: Custodio, Keyzel B. Paña, Kimberly Anne HDocument12 pagesChemical Engineering Thermodynamics: Custodio, Keyzel B. Paña, Kimberly Anne HMark William Almero GeronNo ratings yet

- IAL - Mechanics 1 - FinalDocument25 pagesIAL - Mechanics 1 - FinalasifshahanaNo ratings yet

- Precast Balanced Cantilever BridgeDocument139 pagesPrecast Balanced Cantilever Bridgeوائل محمد محمودNo ratings yet

- Motion Along A Straight LineDocument6 pagesMotion Along A Straight LineSin YeeNo ratings yet

- Static MixersDocument5 pagesStatic Mixershwang2No ratings yet

- International Journal of Multiphase Flow: D.P. Schmidt, S. Gopalakrishnan, H. JasakDocument9 pagesInternational Journal of Multiphase Flow: D.P. Schmidt, S. Gopalakrishnan, H. JasakThamil ThedalNo ratings yet

- Useful Solutions For Standard ProblemsDocument2 pagesUseful Solutions For Standard ProblemsAmjad Khan BanuzaiNo ratings yet

- What Is Specific Heat Capacity: EquationDocument3 pagesWhat Is Specific Heat Capacity: Equationmikayla bryanNo ratings yet

- Chapter 5 Work and EnergyDocument68 pagesChapter 5 Work and EnergyDylan HNo ratings yet

- Observer's Frame Is ImportantDocument17 pagesObserver's Frame Is ImportantMASUD RAIHANNo ratings yet

- Basic Principles of Electromagnetic Theory by SamuelDocument4 pagesBasic Principles of Electromagnetic Theory by SamuelKhajavali ShaikNo ratings yet

- Chapter 4 - Efficiency of ColumnsDocument38 pagesChapter 4 - Efficiency of ColumnsAnonymous vRU4VlNo ratings yet

- Geo ChecklistDocument3 pagesGeo ChecklistJo AlvarezNo ratings yet

- BICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiDocument3 pagesBICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiSri DNo ratings yet

- Cold Formed Purlin - CDocument12 pagesCold Formed Purlin - CHarjasa AdhiNo ratings yet

- Statics 13esi Solutions-Manual c01-180896Document16 pagesStatics 13esi Solutions-Manual c01-180896Sana'a Aamir0% (1)

- Week 02 Supports and Reactions (P1)Document15 pagesWeek 02 Supports and Reactions (P1)EdwardNo ratings yet

- Determining The Viscosity of A Liquid Using A Simple PendulumDocument5 pagesDetermining The Viscosity of A Liquid Using A Simple PendulumklljNo ratings yet

- 1.1 Prob Sheet Energy Analysis of Closed SystemsDocument3 pages1.1 Prob Sheet Energy Analysis of Closed SystemsAnonymous mXicTi8hBNo ratings yet

- Grain Size StudyDocument14 pagesGrain Size StudyiyamNo ratings yet

- Gas/Liquid Separators: Quantifying Separation Performance - Part 1Document10 pagesGas/Liquid Separators: Quantifying Separation Performance - Part 1sara25dec689288No ratings yet

- Energy PDFDocument5 pagesEnergy PDFNajmus SaherNo ratings yet

- Science 8 Q1 Summative TestDocument10 pagesScience 8 Q1 Summative TestJessah Chris Eve Valle100% (4)