Professional Documents

Culture Documents

Safe Work Method Statement

Uploaded by

Collen VhumisaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe Work Method Statement

Uploaded by

Collen VhumisaiCopyright:

Available Formats

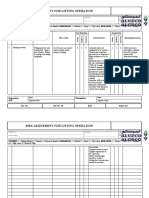

SAFE WORK METHOD STATEMENT

PROJECT- PRINCIPAL CONTRACTOR:

SITE ADDRESS-

TRADE ACTIVITY- Vinyl Installation

SCOPE OF WORK- Preparing floor and installation of Vinyl flooring

SWMS PREPARED BY: Ben Fitzgerald SIGNED: DATE: 4/1/2012

SWMS REVIEWED BY: SIGNED: DATE:

SUPERVISOR Ben Fitzgerald SIGNED: CONTACT: 0409 255 200

RESPONSIBILITY:

TO INSPECT ,APPROVE AND MONITOR ALL WORK AREAS, METHODS, TOOLS AND MATERIALS AND ENSURE THAT THE WORKS ARE

CARRIED OUT SAFELY AND TO CONSULT WITH ANY INSTALLERS PRIOR TO ANY CHANGES.

PERMITS TO WORK: ☐ Confined Space Hot Work

PPE: Hard Hat Hi- Visibility Garment Glasses

Safety Boots ☐ Gloves Mask

LEGISLATION: VICTORIA Occupational Health and Safety Act 2004

Occupational Health and Safety Regulations 2007

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

CODES OF PRACTISE: Electrical Safety on Construction Sites 2006

Manual Handling 2000

Control of hazardous Substances 1999

Mobile Plant on Constructions Sites 2008

AS 18845 Resilient Sheet and Tile Installation Practices 2004

QUALIFICATIONS:

PLANT & EQUIPMENT:

TYPE MAINTENANCE FREQUENCY

Floor Sander As per Kennard’s Hire To be tagged

Tools Tagged Monthly

ATTACH ANY RECORDS FOR POWERED MOBILE PLANT

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

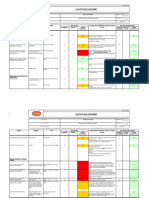

RISK ASSESSMENT MATRIX

CONSEQUENCE

How severely could someone be harmed?

LIKELIHOOD-

How likely could someone be CLASS 3 CLASS 2 CLASS 1

harmed? Medical Treatment or First Aid Lost Time Injury Permanent Disability or Death

Injury

Certain- Medium High High

Could happen frequently

Possible- Low Medium High

Could happen occasionally

Unlikely- May occur in extreme Low Low Medium

circumstances

HIERARCHY OF RISK CONTROL

Preferred Order to Eliminate or reduce the risk of injury

Elimination- Redesigning the job to design out risks altogether is the most effective method of risk control.

Substitution- Materials, chemicals, equipment or processes can be replaced with less hazardous ones.

Isolation- Enclosing or isolating the hazard from employees can eliminate or reduce the risk of injury or disease.

Engineering Control- If a hazard can not be eliminated, substituted or isolated, an engineering control is the next preferred measure.

Engineering controls may involve the provision of mechanical aids, barriers, guarding, ventilation or insulation to prevent employees

being exposed to a hazard.

Administrative Control- This may involve establishing policies, procedures and work practices designed to reduce an employee’s

exposure to a risk. It may also relate to the provision of specific training and supervisory practices.

Personal Protection Equipment- This may involve using appropriate protective clothing eg. Masks, respirators, fall arrest equipment.

This control should be considered when only other control measures are not practicable, or to increase protection from risk of injury.

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

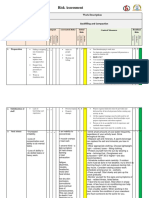

ITE JOB STEP POTENTIAL Inherent Risk CONTROLS PERSON

M (Break the job HAZARD (1 Low- 3High) (What are you going to do to make the (who will

down into steps) (What can harm job as safe as possible?) ensure this

you?) happens)

1 Site Induction Injury or Harm 1 (class 3 x possible = Low 1) Complete Site Induction before Site Manager/

entering site Installer

2 Unload tools and Traffic problems. 1 (class 3 x unlikely= Low 1) Unload from kerb side Installers

vinyl from vehicle Provide “warning signs” if unloading

from road

Move vehicles immediately after goods

are unloaded to car park.

Public interference. 1 (class 3 x unlikely= Low 1) Protect public while unloading by Installers

providing a barrier to area.

Use designated access areas

Trip hazards. 1 (class 3 x possible= Low 1) Do not store tools or carpet rolls etc on Installers

public footpath

Manual Handling 3 (class 2 x certain = high 3) Ensure materials are delivered in Installers

Injury smallest possible lengths.

Ensure proper manual handling

techniques are used.

Make sure there is enough help to

minimise weight lifted.

Use trolley

3 Run Leads Electric shock. 3 (class 1 x possible = High 3) Provide Earth Leakage breaker Installers

Do not use piggyback plugs

Ensure leads are tagged and valid

Trip Hazards 2 (class 3 x certain= medium 2) Suspend leads 1.8mm min. from Installers

ground if leads are being extended

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

across multiple work areas on hook

stands to keep leads off the ground.

Keep leads on floor area along walls

4 Establishment of Trip Hazards 1 (class 3 x possible= low 1) Principal contractor to provide open Installers

work area clear level work area.

Barrier off work areas to other trades

5 Establishment of Hand or body 1 (class 3 x unkiley= low 1) Wear correct P.P.E at all times Installers

personal damage, skin Consult and adhere to material safety

protective wear problems data sheets

6 Loading of Vinyl Trip Hazards 2 (class 2 x possible= Medium 2) Establish a storage area with site Installers

to work area manager

Keep walkways clear

Keep clear of props and “no go areas”

Manual handling e.g. 3 (class 2 x certain = High 3) Use correct manual handling Installers

back damage. procedures

7 Floor preparation Inhalation 2 (class 3 x certain= Medium 2) Wear correct P.P.E. Installers

installation Provide ventilation as required

Provide barrier to other trades

Consult and Adhere to MSDS

Back Injury 1 (class 3 x possible = Low 1) Use correct bending techniques Installers

Eye Injury 1 (class 3 x possible = Low 1) Wear gloves and glasses Installers

8 Spread of Vinyl Back injury 2 (class 2 x possible = Medium 2) Use correct bending techniques Installers

adhesive and Provide signs showing trip hazard

materials Provide barrier when laying close to

void

Provide signs showing trip hazard

Inhalation 3 (class 2 x certain = High 3) Provide ventilation as required Installers

Wear correct P.P.E.

Consult and Adhere to MSDS’s

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

Skin Contact 1 (class 3 x possible = Low 1) Wear correct P.P.E Installers

Clean Up any spills immediately

Barrier off areas to other trades.

9 Install Vinyl into Lacerations from 2(class 3 x certain= Medium 2) Wear gloves whenever necessary to Installers

Adhesive cutting tools avoid cuts from Stanley knives.

Keep work area tidy and practice good

housekeeping at all times.

Place all old blades in a safe container

for disposal.

Manual handling e.g. 3 (class 2 x certain = High 3) Use correct manual handling Installers

back damage. procedures

Cut vinyl into manageable sizes

Knee Injury 1(class 3 x unlikely= Low 1) Use correct bending techniques Installers

Wear Knee Pads

10 Welding of Vinyl Inhalation Problems 2(class 3 x certain= Medium 2) Wear correct PPE Installers

Joins Provide ventilation as required

Provide barrier to stop other trades

entering areas

Burns to Body 2(class 3 x certain= Medium 2) Trained personell only to use welder Installers

Wear gloves

Electrocution or 2 (class 1 x unlikely= Medium 2) Provide earth leakage breaker Installers

Electric shock Do not piggy back leads

Ensure leads are tested and tagged

And valid

Fire Risk 1 (class 3 x unlikely= Low 1) Make sure fire extinguishers located Installers

nearby

Trip factor 1 (class 3 x unlikely = Low 1) Make sure leads around walls on floor Installers

area

11 Place rubbish, off Laceration by nail 1 (class 3 x unlikeyly= Low 1) Clean up Work area every hour. Installers

cuts and dust in and sharp objects Wear gloves

bins

Dust inhalation 1 (class 3 x possible = Low 1) Wear Dust Mask Installers

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

Safe Work Method Statement (Part 2)

Workers name, qualifications and

experience Workers duties and responsibilities Training required to complete work

Reviewed By: / /

Representative Position Signature Date

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

SAFE WORK METHOD STATEMENT

Safe Work Method Statement (Part 3)

The following people have read/had explained to them this safe work method statement and agree to abide

by it.

NAME SIGNATURE DATE NAME SIGNATURE DATE

This work method statement has been approved to be true and accurate by

…………………………………………………………………………………………………………………

Director of

……………………………………………………………………………………………………………………………………………………………………………………………………………

…………

Signed………………………………………………………………………….. Date……………………………………………………………

FloorCOM Pty Ltd 28-32 Bruce Street, Kensington Vic 3031

ABN 65 119 989 936 ACN 119 989 936

Phone: 03 9376 3444 Fax: 03 9372 6999

You might also like

- Electric Risk AssessmentDocument10 pagesElectric Risk AssessmentThandabantu MagengeleleNo ratings yet

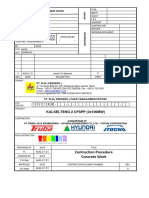

- SWP 003 Pouring ConcreteDocument1 pageSWP 003 Pouring ConcreteJICKNo ratings yet

- Risk Assessment For Laying of Pipes TextDocument3 pagesRisk Assessment For Laying of Pipes TextBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Risk Assessment GRP Tank InstallationDocument19 pagesRisk Assessment GRP Tank Installationanwer.ahmadNo ratings yet

- Critical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsDocument2 pagesCritical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsdnmuleNo ratings yet

- Tree of Qliphoth: Temple of Ascending FlameDocument30 pagesTree of Qliphoth: Temple of Ascending FlameGatuo Angel ToniNo ratings yet

- RA Bored Cast in Situ PileDocument38 pagesRA Bored Cast in Situ PileAnonymous zsBCtskz100% (1)

- Risk Assessment SurveyDocument2 pagesRisk Assessment Surveymohamed ghalyNo ratings yet

- Electrical Safety PlanDocument53 pagesElectrical Safety PlanLawrence adeleke OmisakinNo ratings yet

- Code of Practice - Construction Work - AUSDocument52 pagesCode of Practice - Construction Work - AUSAnonymous iWaBM6P9V6No ratings yet

- Risk Assessment For Lifting OperationDocument2 pagesRisk Assessment For Lifting OperationdsadasNo ratings yet

- 4-Final RA For Installation of Instalation Precast PDFDocument2 pages4-Final RA For Installation of Instalation Precast PDFeng mohamad husamNo ratings yet

- UCHA SWMS Safe Work Method Statement ExcavationDocument20 pagesUCHA SWMS Safe Work Method Statement Excavationyash shahNo ratings yet

- Welspun Enterprises Limited Project: Am2 Group Risk AssessmentDocument4 pagesWelspun Enterprises Limited Project: Am2 Group Risk AssessmentDwijendra ChanumoluNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- ESMPDocument62 pagesESMPMunir HussainNo ratings yet

- Risk Assessment-1 PDFDocument17 pagesRisk Assessment-1 PDFDayanandaNo ratings yet

- Excavation & Trenching PlanDocument37 pagesExcavation & Trenching PlanBogdan RaduNo ratings yet

- Risk Assessment of Flag PolesDocument5 pagesRisk Assessment of Flag Polesطارق رضوانNo ratings yet

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryAmit SinghNo ratings yet

- RA For Installation & Pressure Testing of Refrigerant PipingDocument9 pagesRA For Installation & Pressure Testing of Refrigerant PipingDong VanraNo ratings yet

- MOS FOR Plaster MetitoDocument7 pagesMOS FOR Plaster Metitoeng mohamad husamNo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim Esmat100% (1)

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pages13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Method Statement Concrete WorkDocument5 pagesMethod Statement Concrete Workjherzel90No ratings yet

- Carpentry Risk Assessment WordDocument6 pagesCarpentry Risk Assessment WordPrince TeruyaNo ratings yet

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Document1 pageJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007No ratings yet

- Microsoft Office 365 Customer Decision FrameworkDocument14 pagesMicrosoft Office 365 Customer Decision FrameworkthinkofdevilNo ratings yet

- CIA Sec 3Document90 pagesCIA Sec 3Rock StarNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- Eskom Method StatementDocument6 pagesEskom Method StatementIsaac WamalaNo ratings yet

- Types of Malware and Importance of Malware AnalysisDocument10 pagesTypes of Malware and Importance of Malware AnalysisshaletNo ratings yet

- Report For Oil ProcessingDocument83 pagesReport For Oil ProcessingabhayNo ratings yet

- MOS 2x15T EOTC Robotic ShopDocument17 pagesMOS 2x15T EOTC Robotic ShopJohn Rey PerlasNo ratings yet

- WMS - Office FitoutsDocument30 pagesWMS - Office FitoutsPonraj MNo ratings yet

- 1 Excavations and TrenchesDocument2 pages1 Excavations and TrenchesAruNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- Risk - Assessment - TelehandlerDocument11 pagesRisk - Assessment - TelehandlerCiaraNo ratings yet

- Standard Activity Risk Assessment Facade Concrete Walls WF ADocument6 pagesStandard Activity Risk Assessment Facade Concrete Walls WF AChoubi ChoubacaNo ratings yet

- Tuning Solution V16.0.3.0Document16 pagesTuning Solution V16.0.3.0Amine HerbacheNo ratings yet

- Construction Procedure Reinforced Concrete WorkDocument8 pagesConstruction Procedure Reinforced Concrete WorkDimas DzununNo ratings yet

- Activity Risk Assessment Internal Concrete WallsA WFDocument6 pagesActivity Risk Assessment Internal Concrete WallsA WFChoubi ChoubacaNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- Oral Case Presentation Benchmarks - : Identifying Information & Chief ConcernDocument9 pagesOral Case Presentation Benchmarks - : Identifying Information & Chief ConcernManisanthosh KumarNo ratings yet

- Risk Assesssment-Vinyl & Tile Floor InstallationDocument2 pagesRisk Assesssment-Vinyl & Tile Floor InstallationMunaku TafadzwaNo ratings yet

- Eamcet 2013-2014 Opening and Closing RanksDocument201 pagesEamcet 2013-2014 Opening and Closing RanksCarolyn C. EyreNo ratings yet

- SUMMATIVE TEST NO 3. Aristotle Concept of MotionDocument2 pagesSUMMATIVE TEST NO 3. Aristotle Concept of MotionGeri Isabel Tampus0% (1)

- Hazard Identification and Risk AssessmentDocument7 pagesHazard Identification and Risk AssessmentRahulNo ratings yet

- Grating Decking and Floor Removal FormDocument2 pagesGrating Decking and Floor Removal FormMohamed Abd ElhaleemNo ratings yet

- DieselStorage Tank Refurbishment - MOSDocument6 pagesDieselStorage Tank Refurbishment - MOSSaran rasayaNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- Focus Audit Temp WorksDocument2 pagesFocus Audit Temp WorksArunKumar GanesanNo ratings yet

- Qcs 2010 Part 18.05 JoineryDocument5 pagesQcs 2010 Part 18.05 JoineryRotsapNayrbNo ratings yet

- Method Statement SandingDocument1 pageMethod Statement SandingShah AlamNo ratings yet

- Electrical Encasement Method StatementDocument2 pagesElectrical Encasement Method Statementsujith s pNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument12 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- 08 Hirarc Form (r02)Document2 pages08 Hirarc Form (r02)Aizat Sera SuwandiNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- Work Method Statement AtsDocument2 pagesWork Method Statement AtsYasirSwatiNo ratings yet

- Backfilling and CompactionDocument6 pagesBackfilling and CompactionAbbas iraqiNo ratings yet

- SAIC-X-3003 Rev 3Document2 pagesSAIC-X-3003 Rev 3Imran khanNo ratings yet

- Risk Assessment For Sewerage Piping Installation: 1. Hazard Identification 2. Risk Evaluation 3. Risk ControlDocument2 pagesRisk Assessment For Sewerage Piping Installation: 1. Hazard Identification 2. Risk Evaluation 3. Risk Controlmd_rehan_20% (1)

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- Imb SH Hse 0009 01Document64 pagesImb SH Hse 0009 0101095902062ahmedNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- JHA For Mobile Crane 1 PDFDocument6 pagesJHA For Mobile Crane 1 PDFSethu MathanNo ratings yet

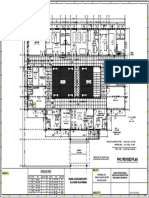

- PHC Revised Plan: Roads & Buildings Dept. M.G. Road VijayawadaDocument1 pagePHC Revised Plan: Roads & Buildings Dept. M.G. Road VijayawadaTirupathi RajaNo ratings yet

- It Didn't Snow On Saturday. It Rained On SaturdayDocument1 pageIt Didn't Snow On Saturday. It Rained On SaturdayAnna Talhammer100% (1)

- HAL S3201 - Brochure 2011 - NopricesDocument6 pagesHAL S3201 - Brochure 2011 - NopricesOmar García MuñozNo ratings yet

- NevirapineDocument2 pagesNevirapineمحمد عريف حكيمNo ratings yet

- Sales Order Demo PolicyDocument4 pagesSales Order Demo Policysindhura2258No ratings yet

- Stroke - Wikipedia, The Free EncyclopediaDocument31 pagesStroke - Wikipedia, The Free EncyclopediaRhonskiiNo ratings yet

- Critical Thinking and EBPDocument31 pagesCritical Thinking and EBPEni SukmawatiNo ratings yet

- 01-PPS SMOI User Manual BodyDocument93 pages01-PPS SMOI User Manual BodyGuelahourou Joel SossieNo ratings yet

- Partners Case CCMNDocument4 pagesPartners Case CCMNapi-314349758No ratings yet

- Kafka and NiFIDocument8 pagesKafka and NiFIabhimanyu thakurNo ratings yet

- DLL - July 15 - Idiomatic ExpressionsDocument2 pagesDLL - July 15 - Idiomatic ExpressionsLenlen Santos Catinoy100% (1)

- EMPOWERMENT TECHNOLOGIES QUARTER 1 MODULE 3 Final 2 PDFDocument13 pagesEMPOWERMENT TECHNOLOGIES QUARTER 1 MODULE 3 Final 2 PDFJason GullaNo ratings yet

- GRP 1Document2 pagesGRP 1Yuva RaniNo ratings yet

- Quiet Healing CentreDocument12 pagesQuiet Healing CentredoliamahakNo ratings yet

- Social Customer Relationship Management (SCRM) - Application and TechnologyDocument9 pagesSocial Customer Relationship Management (SCRM) - Application and TechnologyThu TrangNo ratings yet

- Piyush Mulkar: Cleveland, OHDocument6 pagesPiyush Mulkar: Cleveland, OHRadha RamineniNo ratings yet

- Carob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsDocument7 pagesCarob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsMonica BotaNo ratings yet

- Vis DK 25 Programming GuideDocument210 pagesVis DK 25 Programming GuideshrihnNo ratings yet

- Uponor v. Sioux Chief Mfg.Document5 pagesUponor v. Sioux Chief Mfg.PriorSmartNo ratings yet

- 7 How To Build The Super-Parasol Part IDocument6 pages7 How To Build The Super-Parasol Part IkroitorNo ratings yet

- Gene KnockDocument5 pagesGene KnockAnne Marian JosephNo ratings yet

- Small Business Management Entrepreneurship and Beyond 6th Edition Hatten Solutions ManualDocument36 pagesSmall Business Management Entrepreneurship and Beyond 6th Edition Hatten Solutions ManualketmieoilstoneqjdnwqNo ratings yet