Professional Documents

Culture Documents

Special Provisions Appendix For Amendment To The 2020 Standard Specifications For Highway Construction Updated

Uploaded by

Rashedul KabirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Provisions Appendix For Amendment To The 2020 Standard Specifications For Highway Construction Updated

Uploaded by

Rashedul KabirCopyright:

Available Formats

SPECIAL PROVISIONS APPENDIX

FOR AMENDMENT TO THE 2020 STANDARD SPECIFICATIONS

FOR HIGHWAY CONSTRUCTION

Updated: January 1, 2021

The Amendments to the 2020 Standard Specifications for Highway Construction are as follows and take

precedence. New amendments within this Update are flagged as NEW. Others have been previously released on

the indicated “Issued Date” heading each provision. Italicized text is instructions; normal font is new text. Where

so marked, underlined text or grey-shaded table cells are insertions or amendments; strikeout text is deleted.

NEW SECTION 502 – ASPHALT PAVEMENT CONSTRUCTION (EPS)

Issued Date: January 1, 2021

SS 502.50 Payment Adjustments is amended by adding the following after the existing text.

(a) Rejection Limits: Notwithstanding any other provision of the Contract, including full or partial

waivers of payments adjustments for any or all of the following five rated characteristics:

(i) density;

(ii) AC content;

(iii) gradation;

(iv) application rate; and

(v) segregation,

the rejection limits for each of those characteristics will apply to the Work.

For smoothness, the payment adjustments and rejection limits shall apply as specified in

SS 502.57 Smoothness.

SS 502.53.04 Payment Adjustments is amended by adding the following after the existing text.

However, if a Lot contains any Sub-Lot that falls within the reject zone of Table 502-K:

(i) no bonus payment will be made for the Lot; and

(ii) any penalty for the Lot will be based on the average AC content of all Sub-Lots,

including those within the reject zone.

SS 502.57.04 Determination of Pavement Smoothness is amended by deleting the third

paragraph and replacing it with the following.

The profile shall be measured over the entire length of the pavement exclusive of structures

and shoulder areas. Acceleration, deceleration and turning lanes are considered part of the

driving lanes and shall be tested in accordance with this provision. The following areas will

be excluded from Smoothness EPS payment adjustments and reject limits:

• Areas with a speed limit less than 70km;

• Curb and gutter;

• Ramps, acceleration or deceleration lanes less than 300 m in length;

• Freeway cloverleafs;

• Turn lanes and storage lanes; and

UPDATE: January 1, 2021 Page 1 of 2

SP Appendix: SS 2020 Amendments

• Other areas as specified in the Contract.

The areas outlined above are not exempt from the requirements of SS 502.57.09 Smoothness

Deficiencies.

For the measuring process, the Contractor shall provide the Ministry Representative a chalk

guideline in the centre of the lane immediately prior to measurement.

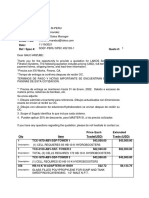

Tables 502-K and 502-M are deleted and replaced with the following.

Table 502-K: Payment Adjustments for Deviation Table 502-M: Payment Adjustments for Material

of Asphalt Content Application Rate

Differences of Actual AC Content Payment Adjustments $ per tonne

From Designed AC Content in JMF Actual Application of material in the Lot

(AC in %) Rate (Percent of (unless otherwise note)

specified rate) Bottom Lift Top Lift

Payment Adjustments

Deviation from or Single Lift of Multiple Lifts

$ per tonne

Asphalt Mix Design - $7.00 for all

JMF Top Lift Lower Lifts material in the Lot - $7.00 for all

up to 110% and no material in the Lot

-0.56 or less REJECT REJECT ≥ 110 up to 106% and no

payment for

-0.55 to -0.51 REJECT -$9.00 payment for

product in excess

-0.50 to -0.46 -$8.00 -$8.00 of 110.0% product in excess

-0.45 to -0.41 -$7.00 -$7.00 of 106.0%

-0.40 to -0.36 -$5.00 -$5.00 ≥ 106.0 to <110.0

-$5.00

-0.35 to -0.26 -$3.00 -$3.00 ≥ 105.0 to <106.0 -$5.00

-0.25 to -0.16 -$1.00 -$1.00

≥ 103.0 to <105.0 -$2.00 -$2.00

-0.15 to -0.01 $0.00 $0.00

0.00 to +0.15 $2.00 $2.00 ≥ 102.0 to <103.0 $0.00 $0.00

+0.16 to +0.30 $1.50 $1.50 ≥ 97.0 to <102.0 $1.00 $1.00

+0.31 to +0.35 $0.00 $0.00 ≥ 94.0 to <97.0 -$2.00 -$2.00

+0.36 to +0.40 -$2.00 -$2.00

≥ 92.0 to <94.0 -$3.00 -$3.00

+0.41 to +0.45 -$3.00 -$3.00

≥ 90.0 to <92.0 -$4.00 -$4.00

+0.46 to +0.50 -$5.00 -$5.00

+0.51 to +0.55 REJECT -$6.50 ≥ 85.0 to <90.0 -$7.00 -$7.00

+0.56 or greater REJECT REJECT <85.0 REJECT REJECT

NEW SECTION 908 – PRESERVATIVE TREATMENT – WOOD PRODUCTS

Issued Date: January 1, 2021

SS 908 (Page 2 of 4) – The published page has a number for formatting issues, with SS 908.07.03,

SS 908.07.04, and SS 908.07.05 being out of sequential order and SS 908.07.05 list items (e) and

(f) incorrectly appearing under SS 908.07.02. SS 908 (page 2 of 4) is deleted and replaced with

the attached.

Attachments:

1. SS 908 (Page 2 of 4) – 1 page

UPDATE: January 1, 2021 Page 2 of 2

SECTION 908 PRESERVATIVE TREATMENT – WOOD PRODUCTS

908.07 Preservative Treatment – All treated wood conflict between any of these requirements, the following

materials shall be pressure treated in accordance with shall apply in the descending order of precedence:

CSA O80.

(a) Special Provisions;

The preservative treatment of laminated veneer lumber shall

(b) Drawings;

be in accordance with AWPA U1 and parallel strand

lumber shall be in accordance with AWPA U1 and (c) Related Standard Specifications as listed in SS 908.02;

AWPA T1. (d) SS 908 and; and lastly

908.07.01 Acceptable Preservatives – One of the (e) CSA O80, Table 2 “Use categories for specific

following preservatives shall be used: products, uses and exposures”.

(a) creosote; 908.07.06 Pre-cut or Field Treat – Cutting, framing, and

(b) pentachlorophenol in Type A hydrocarbon solvent; boring of timbers to receive preservative treatment shall be

done before treatment insofar as possible. In the event that

(c) copper naphthenate in Type A hydrocarbon solvent; cutting or drilling becomes necessary after treatment, a field

(d) chromated copper arsenate, Type C (CCA); treatment preservative specified in CSA O80 or the

AWPA M4 shall be used and applied in accordance to its

(e) ammoniacal copper zinc arsenate (ACZA); label. For bridge components, creosote and copper

(f) alkaline copper quaternary, Type A (ACQ-A); naphthenate shall be the only permitted field treatment

preservatives. At least two coats shall be applied and where

(g) alkaline copper quaternary, Type C (ACQ-C); possible, the colour of the preservative treatment used for

(h) alkaline copper quaternary, Type D (ACQ-D); or protecting field cuts shall match the original preservative

treatment colour.

(i) copper azole Type B (CA-B).

908.08 Hardware, Fasteners and Metalwork

908.07.02 Certified Treatment Facilities – All pressure

treated material shall come from a treatment plant/facility 908.08.01 General – All hardware, fasteners and metal

that is certified under and in compliance with the Canadian work in contact with treated wood products used in

Wood Preservation Certification Authority (CWPCA) permanent structures shall be stainless steel or hot-dipped

program. galvanized in accordance with the ASTM A123,

ASTM A153 (Class D), or ASTM A653 (G90 coating class)

A copy of the CWPCA certificate and certification letter as applicable.

must be submitted to the Ministry Representative upon

request. 908.08.02 Wood Treated with CCA, ACZA, ACQ-A,

ACQ-C, ACQ-D, or CA-B – All hardware, fasteners and

908.07.03 Environmental Compliance – Preservatives metal work used in permanent structures shall be hot-dipped

shall comply with all required environmental regulations. galvanized in accordance with the ASTM A123,

Treated wood for use in bridges or for use near or in aquatic ASTM A153 (Class D) or ASTM A653 (G185 coating

environments shall be treated in accordance with the most class) as applicable. Nails, spikes and sheet metal

recent version of Best Management Practices for Use of fastenings shall be 304 or 316 stainless steel when specified.

Wood in Aquatic and Other Sensitive Environments,

published by Western Wood Preservers Institute et al 908.08.03 Galvanized fastenings – Galvanized nuts shall

(WWPI BMPs). be retapped to allow for the increased diameter of the bolt

due to galvanizing. Heat-treated alloy components and

908.07.04 Other Conditions – The type of preservative, fastenings that may be affected by the heat of the zinc bath

conditioning, treatment, penetration and retention for the shall have corrosion protection provided by an alternate

treated wood product shall be appropriate for the species, means as approved by the Designer and the Ministry

size, and end use of the product. Representative.

All sawn wood and glued-laminated members shall be 908.09 Handling of Treated Wood Products – All treated

incised before treatment in accordance with CSA O80. wood materials shall be handled with reasonable care to

All treated wood shall be substantially devoid of free prevent damage of the pressure-treated surface such as

surface preservative liquid and preservative deposits. puncture, cutting or crushing of fibre. Severely damaged

pieces will be rejected at the discretion of the Ministry

908.07.05 Use Category – The Use Category and the type Representative.

of preservative for treated wood materials shall be in

accordance with the following requirements. If there is any

BC MoTI SS 2020 908 (2 of 4)

You might also like

- Puzlled? Are You?lol...Document84 pagesPuzlled? Are You?lol...JohnJohn100% (3)

- Shop Manual PC400-7Document634 pagesShop Manual PC400-7EKO RANDI75% (4)

- Osm Cement Monitoring Form: Rockwell Business Center - Sheridan Superstructure PackageDocument8 pagesOsm Cement Monitoring Form: Rockwell Business Center - Sheridan Superstructure Packageaceboy_17No ratings yet

- Solution Manual For Managerial Economics Business Strategy 9th Edition by Baye PDFDocument7 pagesSolution Manual For Managerial Economics Business Strategy 9th Edition by Baye PDFa55278073479% (34)

- SampaSoln EXCELDocument4 pagesSampaSoln EXCELRasika Pawar-HaldankarNo ratings yet

- Billing Manager ProgressDocument1 pageBilling Manager Progressjesse celestialNo ratings yet

- J1123 - 16 - Leaf Springs For Motor Vehicle Suspension - SI PDFDocument14 pagesJ1123 - 16 - Leaf Springs For Motor Vehicle Suspension - SI PDFCamilo PachecoNo ratings yet

- Amnd No 2 IS 6911Document16 pagesAmnd No 2 IS 6911Rakesh Soti (JSHL-QUALITY)No ratings yet

- Chemistry - of - PETROCHEMICAL NEWDocument116 pagesChemistry - of - PETROCHEMICAL NEWvivaline AchiengNo ratings yet

- The Chemistry of PolymersDocument36 pagesThe Chemistry of PolymersKHANNo ratings yet

- Chemicals Used in Food ProcessingDocument317 pagesChemicals Used in Food Processingandriipopa75No ratings yet

- B53 3312 - Aço Soldavel Lam Frio (E275-335-390D)Document4 pagesB53 3312 - Aço Soldavel Lam Frio (E275-335-390D)Thiago SilvaNo ratings yet

- 3.05 - Molecular Structure Lab Report: Determining PolarityDocument5 pages3.05 - Molecular Structure Lab Report: Determining PolarityMOBINA KOCHAK100% (2)

- CD110R 1Document384 pagesCD110R 1PooNo ratings yet

- Refining 101: Dennis Sutton March 2012Document45 pagesRefining 101: Dennis Sutton March 2012juan CarlosNo ratings yet

- Control of Vapor Recovery Units (VRU)Document8 pagesControl of Vapor Recovery Units (VRU)Yasmine ياسمينNo ratings yet

- Nano Nails - Pricing and Cream Formulation PDFDocument9 pagesNano Nails - Pricing and Cream Formulation PDFkamel100% (1)

- Finance Assignment Reviewed FinalDocument19 pagesFinance Assignment Reviewed FinalpranalraiNo ratings yet

- Master Si-Sdef-Spec 52105-1 - (2) Tcx-1670-Abv-Ss, (1) Tcx-3100-Abv-Ssf-Quote 11.19.21Document4 pagesMaster Si-Sdef-Spec 52105-1 - (2) Tcx-1670-Abv-Ss, (1) Tcx-3100-Abv-Ssf-Quote 11.19.21Rafael CalleNo ratings yet

- Administrative Delay During Post PO Placement ActivitiesDocument23 pagesAdministrative Delay During Post PO Placement Activitiesmahima sharmaNo ratings yet

- ANOF Fiorenza - STD P2 B24 L38Document4 pagesANOF Fiorenza - STD P2 B24 L38Allen MendozaNo ratings yet

- 4.2 - Cost of Equity - ExerciseDocument7 pages4.2 - Cost of Equity - ExerciseHTNo ratings yet

- Conversion Cost ExampleDocument62 pagesConversion Cost ExampleTamaraGarzaNo ratings yet

- Fair Price Gold CalculatorDocument8 pagesFair Price Gold CalculatorSacred MindNo ratings yet

- REF Price Approval FEB 11 2024 - 25 March 2024Document1 pageREF Price Approval FEB 11 2024 - 25 March 2024mahmoodrasel228No ratings yet

- Análisis de Modos y FrecuenciasDocument1 pageAnálisis de Modos y FrecuenciasIsabelNo ratings yet

- Exchange Rate, Real Adjustment and Monetary Policy: José de Gregorio Governor Central Bank of ChileDocument14 pagesExchange Rate, Real Adjustment and Monetary Policy: José de Gregorio Governor Central Bank of Chileapi-26091012No ratings yet

- Real Options Exercis - WeGig-2Document17 pagesReal Options Exercis - WeGig-2Anirudh SinghNo ratings yet

- Out Put SapDocument93 pagesOut Put SapAji ThesniperNo ratings yet

- 3.2 FCFE Exercise PartDocument4 pages3.2 FCFE Exercise PartHTNo ratings yet

- MTNL Delhi Dolphin: Final AmountDocument5 pagesMTNL Delhi Dolphin: Final AmountKushal SinhaNo ratings yet

- Usman Institute of TechnologyDocument4 pagesUsman Institute of TechnologyHafsa ParkerNo ratings yet

- New LAOD CALCULATION & DETAILSDocument10 pagesNew LAOD CALCULATION & DETAILSDessouki SamakNo ratings yet

- TAX Variance ClarificationDocument6 pagesTAX Variance ClarificationmaksudNo ratings yet

- Engsolutions RCB: Foundation Soil PropertiesDocument2 pagesEngsolutions RCB: Foundation Soil PropertiesReynaldo Tejada PiñerezNo ratings yet

- Group Assesment Part B 1,2,3Document7 pagesGroup Assesment Part B 1,2,3YajZaragozaNo ratings yet

- O-703 Edif. Lord Cochrane 3 - Ep.03 BañosDocument7 pagesO-703 Edif. Lord Cochrane 3 - Ep.03 BañosWilly FloresNo ratings yet

- Investment CriteriaDocument15 pagesInvestment CriteriaGOWTHAM K KNo ratings yet

- Performance CheckDocument61 pagesPerformance CheckOscar LosadaNo ratings yet

- Dear Seller,: Use of ThisDocument15 pagesDear Seller,: Use of ThisSandeep KumarNo ratings yet

- Cdo V1093Document2 pagesCdo V1093Daisy E SolivaNo ratings yet

- Seplat Energy PLC: Ohaji South Flare Out ProjectDocument6 pagesSeplat Energy PLC: Ohaji South Flare Out ProjectELIJAH OKONNo ratings yet

- Fy2009budgetupdatedocument9b1 092408Document3 pagesFy2009budgetupdatedocument9b1 092408laurabrown63No ratings yet

- Convert Situacije BR BN SA PODLOGOM ModelDocument15 pagesConvert Situacije BR BN SA PODLOGOM ModelVladimir RisojevicNo ratings yet

- Truss MetalDocument9 pagesTruss MetalRia SusantiNo ratings yet

- Practice Q (Capital Budgeting)Document12 pagesPractice Q (Capital Budgeting)Divyam GargNo ratings yet

- Retaining Wall 21.9.21Document44 pagesRetaining Wall 21.9.21kamal kumar MallikarjunaNo ratings yet

- Reactive MaintenanceDocument8 pagesReactive MaintenanceAashutosh KarnaNo ratings yet

- 2010-2011 Preliminary Budget DiscussionDocument15 pages2010-2011 Preliminary Budget DiscussionCFBISDNo ratings yet

- R & D Converter: InputsDocument6 pagesR & D Converter: InputsKarthi KeyanNo ratings yet

- 250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Document9 pages250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Kai ZhaoNo ratings yet

- 10040-2563 Payment Certificate 01Document8 pages10040-2563 Payment Certificate 01Deepak DevNo ratings yet

- Tel: Fax: Tel: Fax:: Maître D'ouvrage Maître D'oeuvre Bureau de Contrôle Entreprise Générale ChantierDocument137 pagesTel: Fax: Tel: Fax:: Maître D'ouvrage Maître D'oeuvre Bureau de Contrôle Entreprise Générale ChantierHyeon-a KimNo ratings yet

- General Ledger (Summary) 9/1/1974 To 9/30/1974Document1 pageGeneral Ledger (Summary) 9/1/1974 To 9/30/1974Andre TuukNo ratings yet

- New Appraisal AnnextureDocument2 pagesNew Appraisal Annextureelangovan subashiniNo ratings yet

- Budget Single Project (Pend & App) : Project: RVS0104-Boston Medical CenterDocument2 pagesBudget Single Project (Pend & App) : Project: RVS0104-Boston Medical CenterPost Your FeedbackNo ratings yet

- Assignment-2: Prakash Steel 1) Sensitivity Analysis: Name: Divyansh Singh Roll Number: 18-MF-27Document1 pageAssignment-2: Prakash Steel 1) Sensitivity Analysis: Name: Divyansh Singh Roll Number: 18-MF-27Divyansh SinghNo ratings yet

- DSM Regulations 2022Document9 pagesDSM Regulations 2022bhupeshNo ratings yet

- Mis For Construction CoDocument1 pageMis For Construction CoShubham ChaudhariNo ratings yet

- Statement of Product ValueDocument2 pagesStatement of Product ValueveerendrareddyNo ratings yet

- Current Date: 11/19/2021 7:25:56 PM Units System: KN - M: Max B NT Top NB BottomDocument6 pagesCurrent Date: 11/19/2021 7:25:56 PM Units System: KN - M: Max B NT Top NB BottomArun KesbhatNo ratings yet

- Checking Weekly Dash BoardDocument15 pagesChecking Weekly Dash Boardjyothis_joy8315No ratings yet

- Profit and Loss Statement 31.12.20Document1 pageProfit and Loss Statement 31.12.20Si HadiNo ratings yet

- Bobby Mayo Tear Off and Reinstall 34 PanelDocument4 pagesBobby Mayo Tear Off and Reinstall 34 PanelnickroofenerNo ratings yet

- Assignment 3.1 FARDocument11 pagesAssignment 3.1 FARJames Brian F PoserioNo ratings yet

- Trial Balance As at 31 May, 2022Document10 pagesTrial Balance As at 31 May, 2022Mae Ann AguilaNo ratings yet

- DummyDocument5 pagesDummysatishNo ratings yet

- Komatsu Pc210 210lc 210nlc 240lc 240nlc 7k Shop ManualDocument20 pagesKomatsu Pc210 210lc 210nlc 240lc 240nlc 7k Shop Manuallawrence100% (46)

- Summary of Current Charges (RS) : Talk To Us SMSDocument13 pagesSummary of Current Charges (RS) : Talk To Us SMSBrandon FloresNo ratings yet

- Motilal Oswal Specialty Chemicals Sector UpdateDocument6 pagesMotilal Oswal Specialty Chemicals Sector UpdateKrishna Raj KNo ratings yet

- Assessment of Ground Water Quality in and Around Gobichettipalayam Town Erode District, TamilnaduDocument6 pagesAssessment of Ground Water Quality in and Around Gobichettipalayam Town Erode District, TamilnadufosterbalaNo ratings yet

- Supergene Metal DepositsDocument6 pagesSupergene Metal DepositsRalph Carlo EvidenteNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument8 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification Foranurag yadavNo ratings yet

- Ingredient For Anti-Pollution PDFDocument131 pagesIngredient For Anti-Pollution PDFAkash SharmaNo ratings yet

- G 02 01 02 Specification Fuel OilDocument1 pageG 02 01 02 Specification Fuel OilJahurul IslamNo ratings yet

- Alkaline Activation of Clays For The Consolidation of Earthen ArchitectureDocument350 pagesAlkaline Activation of Clays For The Consolidation of Earthen ArchitectureSiham BelhajNo ratings yet

- Hydrazoic AcidDocument2 pagesHydrazoic AcidahmadammarhassanNo ratings yet

- Ammonia SpiritDocument12 pagesAmmonia Spiritseecktskatrina03No ratings yet

- Format: Proforma For Submission of Monthly Environmental Data (For Coal/Lignite Thermal Power Plants)Document4 pagesFormat: Proforma For Submission of Monthly Environmental Data (For Coal/Lignite Thermal Power Plants)owngauravNo ratings yet

- Review Ruthenium Pincer Complexes Ligand Design and Complex SynthesisDocument41 pagesReview Ruthenium Pincer Complexes Ligand Design and Complex Synthesisxuyijing2007comNo ratings yet

- TDS - Mulcoa - 60 - Rev 1Document1 pageTDS - Mulcoa - 60 - Rev 1유유재하No ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Regeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based ModelDocument6 pagesRegeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based Modeltrilok corporationNo ratings yet

- Analysis of Elements in An Alloy by ColorimetryDocument4 pagesAnalysis of Elements in An Alloy by ColorimetryScop KushaalNo ratings yet

- Method For Measuring Degreasing On Different SubstratesDocument42 pagesMethod For Measuring Degreasing On Different SubstratesFra FraNo ratings yet

- Give Correct Formulas For These Type I Binary CompoundsDocument5 pagesGive Correct Formulas For These Type I Binary CompoundsJeanette HernandezNo ratings yet

- Incoming JR Chemistry Worksheet-5 (Day-5) : KOH CO O CO NDocument5 pagesIncoming JR Chemistry Worksheet-5 (Day-5) : KOH CO O CO NantNo ratings yet

- Haloalkanes and HaloarenesDocument2 pagesHaloalkanes and HaloarenesVisakh Suku SNo ratings yet

- Explain The Relationship Between Soil Clay and Cation Exchange CapacityDocument3 pagesExplain The Relationship Between Soil Clay and Cation Exchange CapacityZahilah SamatNo ratings yet