Professional Documents

Culture Documents

MODEL 150 SERIES (1969 - 1976) : Inspection Time Limits 1. Inspection Items Revi-Sion Status Task Interval Operation Zone

Uploaded by

Aero Diesel AviationOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MODEL 150 SERIES (1969 - 1976) : Inspection Time Limits 1. Inspection Items Revi-Sion Status Task Interval Operation Zone

Uploaded by

Aero Diesel AviationCopyright:

Available Formats

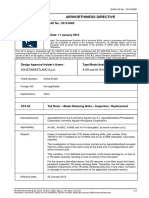

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

INSPECTION TIME LIMITS

1. Inspection Items

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

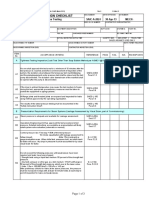

Inspect aircraft records to verify that all applicable Every 100 hours 1 -

Cessna Service Information Letters, Cessna Service or 12 months,

Bulletins and Supplier Service Bulletins are complied whichever occurs

with. first.

Inspect aircraft records to verify that all applicable Every 100 hours 1 -

Airworthiness Directives and Federal Aviation or 12 months,

regulations are complied with. whichever occurs

first.

Inspect aircraft records to verify that all logbook Every 100 hours 1 -

entries required by the Federal Aviation Regulations or 12 months,

are complied with. whichever occurs

first.

Inspect aircraft records to verify that all SID Every 100 hours 1 -

Inspections have been complied with as scheduled. or 12 months,

whichever occurs

first.

Inspect rudder pedal torque tube, shafts, support Initial: 10,000 7 211

brackets and cable attachment arms. Refer to hours or 20 years,

2A-14-01, Supplemental Inspection Document whichever occurs

27-20-01, for inspection procedure. first; Repeat: 3,000

hours or 5 years,

whichever occurs

first.

Elevator trim system. 1. Inspect elevator trim brackets Initial: 1,000 hours; 14 330,

and actuator support brackets. 2. Inspect pulleys, Repeat: 1,000 hours 340

attaching structure and fasteners. Refer to Section

2A-14-02, Supplemental Inspection Document

27-30-01, for inspection procedures.

This inspection is for mild/moderate corrosion Initial: 20 years; 11 730,

environment. Inspect main landing gear flat spring Repeat: 10 years 740

for rust or damage to finish. Inspect fittings and

entry step attachment. Refer to Section 2A-14-03,

Supplemental Inspection Document 32-13-01, for

inspection procedure.

This interval is for severe corrosion environment. Initial: 10 years; 13 730,

Inspect main landing gear flat spring for rust or Repeat: 5 years 740

damage to finish. Inspect fittings and entry step

attachment. Refer to Section 2A-14-03, Supplemental

Inspection Document 32-13-01, for inspection

procedure.

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 1

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

This inspection is for mild/moderate corrosion Initial: 20 years; 11 730,

environment. Inspect main landing gear tubular Repeat: 10 years 740

spring for rust or damage to finish. Inspect entry step

attachment. Refer to Section 2A-14-04, Supplemental

Inspection Document 32-13-02, for inspection

procedure.

This interval is for severe corrosion environment. Initial: 10 years; 13 730,

Inspect main landing gear tubular spring for rust or Repeat: 5 years 740

damage to finish. Inspect entry step attachment.

Refer to Section 2A-14-04, Supplemental Inspection

Document 32-13-02, for inspection procedure.

Inspect main landing gear fittings and attachment Initial: 3,000 hours or 15 210

of the fittings to the bulkheads. Refer to Section 5 years, whichever

2A-14-05, Supplemental Inspection Document occurs first; Repeat:

32-13-03, for inspection procedure. 1,000 hours or 5

years, whichever

occurs first.

Inspect nose landing gear torque links, bolts, bushings Initial: 3,000 hours or 8 720

and fork. Refer to Section 2A-14-06, Supplemental 5 years, whichever

Inspection Document 32-20-01, for inspection occurs first; Repeat:

procedure. 3,000 hours or 5

years, whichever

occurs first.

This inspection is for mild/moderate corrosion Initial: 20 years; 11 210

environment. Inspect carry-thru spar area, wing Repeat: 10 years

attach fittings, spar channel and lugs. Refer to Section

2A-14-07, Supplemental Inspection Document

53-11-01, for inspection procedure.

This interval is for severe corrosion environment. Initial: 10 years; 13 210

Inspect carry-thru spar area, wing attach fittings, Repeat: 5 years

spar channel and lugs. Refer to Section 2A-14-07,

Supplemental Inspection Document 53-11-01, for

inspection procedure.

This interval is for mild/moderate corrosion Initial: 20 years; 11 210

environment. Inspect the cabin interior skin panels, Repeat: 10 years

frames and stringers. Refer to Section 2A-14-08,

Supplemental Inspection Document 53-30-01, for

inspection procedure.

This interval is for severe corrosion environment. Initial: 10 years; 13 210

Cabin interior skin panels. Inspect the cabin interior Repeat: 5 years

skin panels, frames and stringers. Refer to Section

2A-14-08, Supplemental Inspection Document

53-30-01, for inspection procedure.

This interval is for mild/moderate corrosion Initial: 10 years; 16 210

environment. Inspect seat rails for corrosion. Refer Repeat: 10 years

to Section 2A-14-09, Supplemental Inspection

Document 53-47-01, for inspection procedure.

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 2

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

This interval is for severe corrosion environment. Initial: 5 years; 17 210

Inspect seat rails for corrosion. Refer to Section Repeat: 5 years

2A-14-09, Supplemental Inspection Document

53-47-01, for inspection procedure.

Inspect horizontal stabilizer and elevator, including Initial: 10,000 20 330,

torque tube, spars, ribs, hinge bolts, hinge bearings, hours or 20 years, 340

brackets and attach fittings. Refer to Section whichever occurs

2A-14-10, Supplemental Inspection Document first; Repeat: 2,000

55-10-01, for inspection procedures. hours or 4 years,

whichever occurs

first.

Inspect horizontal stabilizer forward attachments. Initial: 100 hours or 22 330,

Refer to Section 2A-14-11, Supplemental Inspection 1 year, whichever 340

Document 55-11-01, for inspection procedure. occurs first; Repeat:

100 hours or 1 year,

whichever occurs

first.

Inspect vertical stabilizer attach bracket and horizontal Initial: 2,000 hours or 23 310,

stabilizer rear spar attachments. Refer to Section 4 years, whichever 320

2A-14-12, Supplemental Inspection Document occurs first; Repeat:

55-11-02, for inspection procedure. 2,000 hours or 4

years, whichever

occurs first.

Inspect vertical stabilizer and rudder, including spars, Initial: 10,000 7 320

ribs, hinge bolts, hinge bearings and attach fittings. hours or 20 years,

Refer to Section 2A-14-13, Supplemental Inspection whichever occurs

Document 55-30-01, for inspection procedure. first; Repeat: 3,000

hours or 5 years,

whichever occurs

first.

Inspect rudder spar. Refer to Section 2A-14-14, Initial: 100 hours or 22 320

Supplemental Inspection Document 55-41-01, for 1 year, whichever

inspection procedure. occurs first; Repeat:

100 hours or 1 year,

whichever occurs

first.

This interval is for typical usage environment. 1. Initial: 12,000 18 510,

Inspect inboard wing structure and wing attachment hours or 20 years, 610

to fuselage including working rivets. 2. Inspect flap whichever occurs

actuator support structure. Refer to Section 2A-14-15, first; Repeat: 2,000

Supplemental Inspection Document 57-11-01, for hours or 10 years,

inspection procedure. whichever occurs

first.

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 3

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

This interval is for severe usage environment. 1. Initial: 6,000 hours or 19 510,

Inspect inboard wing structure and wing attachment 10 years, whichever 610

to fuselage including working rivets. 2. Inspect flap occurs first; Repeat:

actuator support structure. Refer to Section 2A-14-15, 1,000 hours or 5

Supplemental Inspection Document 57-11-01, for years, whichever

inspection procedure. occurs first.

This interval is for mild/moderate corrosion Initial: 20 years; 11 510,

environment. Inspect wing for corrosion and missing Repeat: 10 years 520,

or loose fasteners. Refer to Section 2A-14-16, 610,

Supplemental Inspection Document 57-11-02, for 620

inspection procedure.

This interval is for severe corrosion environment. Initial: 10 years; 13 510,

Inspect wing for corrosion and missing or loose Repeat: 5 years 520,

fasteners. Refer to Section 2A-14-16, Supplemental 610,

Inspection Document 57-11-02, for inspection 620

procedure.

This interval is for mild/moderate usage environment. Initial: 20 years; 11 510,

Inspect wing splice joint at strut attach. Refer to Repeat: 10 years 610

Section 2A-14-17, Supplemental Inspection Document

57-11-03, for inspection procedure.

This interval is for severe usage environment. Inspect Initial: 10 years; 13 510,

wing splice joint at strut attach. Refer to Section Repeat: 5 years 610

2A-14-17, Supplemental Inspection Document

57-11-03, for inspection procedure.

This interval is for mild/moderate corrosion Initial: 5 years; 12 510,

environment. Inspect wing root rib. Refer to Section Repeat: 5 years 610

2A-14-18, Supplemental Inspection Document

57-12-01, for inspection procedure.

This interval is for severe corrosion environment. Initial: 3 years; 21 510,

Inspect wing root rib. Refer to Section 2A-14-18, Repeat: 3 years 610

Supplemental Inspection Document 57-12-01, for

inspection procedure.

This interval is for typical usage environment. Inspect Initial: 12,000 18 510,

wing strut and strut tube. Refer to Section 2A-14-19, hours or 20 years, 610

Supplemental Inspection Document 57-40-01, for whichever occurs

inspection procedure. first; Repeat: 2,000

hours or 10 years,

whichever occurs

first.

This interval is for severe usage environment. Inspect Initial: 6,000 hours or 19 510,

wing strut and strut tube. Refer to Section 2A-14-19, 10 years, whichever 610

Supplemental Inspection Document 57-40-01, for occurs first; Repeat:

inspection procedure. 1,000 hours or 5

years, whichever

occurs first.

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 4

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

Inspect aileron hinges, hinge bolts, hinge bearings, Initial: 3,000 hours or 9 520,

hinge and pushrod attach fittings. Refer to Section 10 years, whichever 620

2A-14-20, Supplemental Inspection Document occurs first; Repeat:

57-51-01, for inspection procedure. 500 hours or 5 years,

whichever occurs

first.

This interval is for mild/moderate corrosion Initial: 20 years; 11 510,

environment. Inspect flap tracks for corrosion. Repeat: 10 years 610

Refer to Section 2A-14-21, Supplemental Inspection

Document 57-53-01, for inspection procedure.

This interval is for severe corrosion environment. Initial: 10 years; Re- 13 510,

Inspect flap tracks for corrosion. Refer to Section peat: 5 years 610

2A-14-21, Supplemental Inspection Document

57-53-01, for inspection procedure.

Inspect tubular engine mount. Refer to Section Initial: 5,000 hours or 10 120

2A-14-22, Supplemental Inspection Document 20 years, whichever

71-20-01, for inspection procedure. occurs first; Repeat:

At Engine Overhaul

Fuselage lower internal structure beneath the floor Every 60 months 6 210

panels. Make sure you inspect these areas: 1.

Cabin structure under floorboards. NOTE: Corrosion

Prevention and Control Program Inspection item

(baseline interval, refer to Section 2A-30-00 for

additional inspection information).

Fuselage internal structure in upper fuselage. Make Every 60 months 6 210

sure you inspect these areas: 1. Cabin bulkhead

corners. 2. Fuselage skin. NOTE: Corrosion

Prevention and Control Program Inspection item

(baseline interval, refer to Section 2A-30-00 for

additional inspection information).

Areas of the cabin structure. Make sure you inspect Every 60 months 6 210

these areas: 1. Firewall. 2. Firewall attachments.

NOTE: Corrosion Prevention and Control Program

Inspection item (baseline interval, refer to Section

2A-30-00 for additional inspection information).

Passenger/Crew door retention system. Make sure Every 48 months 5 210

you inspect these areas: 1. Bell cranks. 2. Pushrods.

3. Handle. 4. Pin retention. 5. Pins. 6. Lockplates

and guides. 7. Hinges. 8. Internal door framing.

NOTE: Corrosion Prevention and Control Program

Inspection item (baseline interval, refer to Section

2A-30-00 for additional inspection information). Note:

Remove interior panels for access.

Areas of the cabin structure for the passenger/crew Every 48 months 5 210

door. Make sure you inspect these areas: 1. Door

frames. 2. Door hinges. NOTE: Corrosion Prevention

and Control Program Inspection item (baseline

interval, refer to Section 2A-30-00 for additional

inspection information).

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 5

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

Areas of the cabin structure. Make sure you inspect Every 60 months 6 210

these areas: 1. Cabin door forward and aft frames.

2. Window frames with emphasis at stringers and

channel assemblies from aft of door frame to aft

bulkhead. 3. Seat attachment structure. 4. Aft

Cabin Bulkhead. NOTE: Corrosion Prevention and

Control Program Inspection item (baseline interval,

refer to Section 2A-30-00 for additional inspection

information).

Flaps. 1. Check flap travel cable tension, and travel Initial: 100 hours; 24 210,

time. 2. Check flap cable system, control cables, Repeat: every 600 510,

and pulleys, in accordance with the flight cable hours or 12 months, 610

inspection procedures in Section 2A-20-01, Expanded whichever occurs

Maintenance, Control Cables. first.

Aileron. 1. Check aileron travel and cable tension. Initial: 100 hours; 24 210,

2. Check aileron cable system, control cables, Repeat: every 600 510,

and pulleys, in accordance with the flight cable hours or 12 months, 520,

inspection procedures in Section 2A-20-01, Expanded whichever occurs 610,

Maintenance, Control Cables. first. 620

Elevator. 1. Check elevator travel and cable tension. Initial: 100 hours; 24 210,

2. Check elevator cable system, control cables, Repeat: every 600 310,

and pulleys, in accordance with the flight cable hours or 12 months, 330,

inspection procedures in Section 2A-20-01, Expanded whichever occurs 340

Maintenance, Control Cables. first.

Elevator Trim. 1. Check elevator trim travel and cable Initial: 100 hours; 24 210,

tension. 2. Check elevator trim cable system, control Repeat: every 600 310,

cables, and pulleys, in accordance with the flight cable hours or 12 months, 330,

inspection procedures in Section 2A-20-01, Expanded whichever occurs 340

Maintenance, Control Cables. first.

Rudder. 1. Check rudder travel and cable tension. Initial: 100 hours; 24 210,

2. Check rudder cable system, control cables, Repeat: every 600 310,

and pulleys, in accordance with the flight cable hours or 12 months, 320

inspection procedures in Section 2A-20-01, Expanded whichever occurs

Maintenance, Control Cables. first.

Wing structure internal. Make sure you inspect these Every 12 months 2 510,

areas: 1. Main spar upper and lower carry-thru fittings, 520,

2. Main spar upper and lower caps, 3. Main spar web. 610,

NOTE: Corrosion Prevention and Control Program 620

Inspection item (baseline interval, refer to Section

2A-30-00 for additional inspection information).

Wing structure internal. Make sure you inspect these Every 60 months 6 510,

areas: 1. Wing front spar and lower spar caps. 520,

2. Upper and lower wing attach spar fittings. 3. 610,

Wing lower skins. NOTE: Corrosion Prevention and 620

Control Program Inspection item (baseline interval,

refer to Section 2A-30-00 for additional inspection

information).

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 6

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

Wing structure external. Make sure you inspect these Every 60 months 6 510,

areas: 1. Skin with emphasis at skin overlaps and 520,

under access panels. 2. Rear spar upper and lower 610,

caps. 3. Rear spar web. NOTE: Corrosion Prevention 620

and Control Program Inspection item (baseline

interval, refer to Section 2A-30-00 for additional

inspection information).

Aileron attachments. Make sure you inspect these Every 24 months 3 520,

areas: 1. Aileron hinges. 2. Hinge bolts. 3. Hinge 620

bearings. 4. Hinge and pushrod support structure.

NOTE: Corrosion Prevention and Control Inspection

Item (baseline interval, refer to Section 2A-30-00

for additional inspection information). NOTE: Do

not apply LPS-3 Heavy Duty Rust Inhibitor on hinge

bearing.

Vertical stabilizer structure. Make sure you inspect Every 60 months 6 310,

these areas: 1. Forward spar attachment to tailcone 320

bulkhead. 2. Aft spar attachment to lower stabilizer

spar. 3. Front and rear spars. 4. Rear spar

rudder hinges. NOTE: Corrosion Prevention and

Control Program Inspection item (baseline interval,

refer to Section 2A-30-00 for additional inspection

information).

Inspect main landing gear axle assembly. Make sure Every 36 months 4 730,

you inspect these areas: 1. Main gear axle and attach 740

bolts. 2. Wheel halves. NOTE: Corrosion Prevention

and Control Program Inspection item (baseline

interval, refer to Section 2A-30-00 for additional

inspection information). NOTE: Do not apply LPS-3

Heavy-Duty Rust Inhibitor to the bearing. NOTE:

Coordinate with tire change.

Nose gear trunnion, steering assembly, torque link Every 36 months 4 720

assembly, nose gear fork and axle. Make sure you

inspect these areas: 1. Nose gear trunnion surface.

2. Steering collar and steering collar attach bolt. 3.

Torque link, torque link attach pin, and attach bolt. 4.

Nose gear fork. 5. Nose gear axle. NOTE: Corrosion

Prevention and Control Inspection Item (baseline

interval, refer to Section 2A-30-00 for additional

inspection information).

Inspect nose gear trunnion, torque link assembly, and Every 36 months 4 720

nose gear fork. Make sure you inspect these areas:

1. Nose gear trunnion upper and lower inner bore

surface and bearing. 2. Torque link bolt and attach pin

inner bore surface. 3. Nose gear fork lug inner bore

surface. NOTE: Corrosion Prevention and Control

Inspection Item (baseline interval, refer to Section

2A-30-00 for additional inspection information).

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 7

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

Nose landing gear outer barrel assembly. Make sure Every 36 months 4 720

you inspect these areas: 1. Outer barrel assembly. 2.

Upper strut end and lower collar assembly. NOTE:

Corrosion Prevention and Control Inspection Item

(baseline interval, refer to Section 2A-30-00 for

additional inspection information). NOTE: do not

apply LPS-3 Heavy-Duty Rust Inhibitor to the sliding

surfaces of the oleo strut.

Nose gear axle assembly. Make sure you inspect Every 60 months 6 720

these areas: 1. Nose gear axle and attach bolt. 2.

Wheel halves. NOTE: Corrosion Prevention and

Control Program Inspection item (baseline interval,

refer to Section 2A-30-00 for additional inspection

information). NOTE: Disassemble the nose gear strut

to get access. NOTE: Do not apply LPS-3 Heavy-Duty

Rust Inhibitor to the sliding surfaces of the oleo strut.

NOTE: Coordinate with tire change.

Horizontal stabilizer structure. Make sure you inspect Every 60 months 6 330,

these areas: 1. Stabilizer attachment to the tailcone 340

bulkhead, 2. Front and rear spars. NOTE: Corrosion

Prevention and Control Program Inspection item

(baseline interval, refer to Section 2A-30-00 for

additional inspection information).

Elevator trim system. Make sure you inspect these Every 24 months 3 330,

areas: 1. Elevator trim brackets, 2. Actuator support 340

brackets and bearings. 3. Pulleys and attaching

structure. NOTE: Corrosion Prevention and Control

Inspection Item (baseline interval, refer to Section

2A-30-00 for additional inspection information).

NOTE: Do not apply LPS-3 Heavy Duty Rust Inhibitor

on hinge bearing.

Rudder attachments. Make sure you inspect these Every 24 months 3 320

areas: 1. Hinge brackets. 2. Hinge bolts. 3. Hinge

bearings. NOTE: Corrosion Prevention and Control

Inspection Item (baseline interval, refer to Section

2A-30-00 for additional inspection information).

NOTE: Do not apply LPS-3 Heavy Duty Rust Inhibitor

on hinge bearing.

Rudder structure. Make sure you inspect these areas: Every 24 months 3 320

1. Skin. 2. Forward and aft spars at hinge locations.

NOTE: Corrosion Prevention and Control Inspection

Item (baseline interval, refer to Section 2A-30-00 for

additional inspection information).

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 8

© TEXTRON AVIATION INC. Jun 15/1975

CESSNA®

MODEL 150 SERIES (1969 - 1976)

SERVICE MANUAL

REVI- TASK INTERVAL OPERATION ZONE

SION

STATUS

Engine support structure. Make sure you inspect Every 12 months 2 120

these areas: 1. Engine truss. Pay particular attention

to vicinity of welds. NOTE: Corrosion Prevention and

Control Program Inspection item (refer to Section

2A-30-00 for additional inspection information).

Vertical Fin. Inspect the vertical fin attachment. Every 100 hours or 22 320

Refer to Section 2A-14-23, Supplemental Inspection 1 year, whichever

Document, 55-11-03 for inspection procedure. occurs first.

Aug 1/19 Inspect the rudder horn. Refer to Section 2A-14-24, Every 100 hours or 22 320

Supplemental Inspection Document 27-20-02 for 1 year, whichever

inspection procedure. occurs first; Repeat:

100 hours or 1 year,

whichever occurs

first.

D971-3-13 Temporary Revision Number 9 - Aug 1/2019 2A-10-01 Page 9

© TEXTRON AVIATION INC. Jun 15/1975

You might also like

- Temporary Revision 8Document38 pagesTemporary Revision 8Daniel Vásquez CabreraNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- INSP.TIME LIMITDocument8 pagesINSP.TIME LIMITjesus francoNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument35 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberJean Mark SilvestreNo ratings yet

- D2064 1TR8 PDFDocument36 pagesD2064 1TR8 PDFVIMAER Vidotti Manutenção Aeronáutica LTDANo ratings yet

- SM Cessna 152 Temporary Rev 9Document30 pagesSM Cessna 152 Temporary Rev 9technicmerpatipilotschoolNo ratings yet

- Inspection Time LimitsDocument10 pagesInspection Time LimitsPaola RabeloNo ratings yet

- 72.00.00 Engine - Inspection - CheckDocument83 pages72.00.00 Engine - Inspection - CheckTimoteo Molina RomeroNo ratings yet

- Operaciones de Mantenimiento c172Document5 pagesOperaciones de Mantenimiento c172Juan G Correa100% (1)

- 2a-14-00 Listing of Supplemental InspectionsDocument4 pages2a-14-00 Listing of Supplemental InspectionsAntonio BedoyaNo ratings yet

- Inspect Beechcraft Wings for CorrosionDocument5 pagesInspect Beechcraft Wings for CorrosionJ DaugNo ratings yet

- Lista de SidDocument4 pagesLista de SidPaola Rabelo0% (1)

- MODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. ScopeDocument5 pagesMODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. ScopesandyNo ratings yet

- Ssid Doc For 180Document60 pagesSsid Doc For 180Pankaj SharmaNo ratings yet

- Engine, Turboprop - InspectionDocument5 pagesEngine, Turboprop - InspectionSECCION TECNICANo ratings yet

- Inspection Time IntervalsDocument4 pagesInspection Time Intervalsmarcos torresNo ratings yet

- INSP. TIME LIMIT - STRUCDocument5 pagesINSP. TIME LIMIT - STRUCjesus francoNo ratings yet

- AAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017Document21 pagesAAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017jerome chaussonNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument54 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberRay MillsNo ratings yet

- MODEL 206 SERIES (1977 - 1986) : Listing of Supplemental Inspections 1. Supplemental Inspection ProceduresDocument4 pagesMODEL 206 SERIES (1977 - 1986) : Listing of Supplemental Inspections 1. Supplemental Inspection ProceduresAlejandro TorresNo ratings yet

- CPCP, Sid S Cessna Model 188 SeriesDocument155 pagesCPCP, Sid S Cessna Model 188 Seriesvilladazafabian713100% (1)

- Listing of Supplemental InspDocument4 pagesListing of Supplemental Inspjesus francoNo ratings yet

- Air Suspension System IntroductionDocument4 pagesAir Suspension System IntroductionArijitNandiNo ratings yet

- 35-590096 - Section 8Document8 pages35-590096 - Section 8Fábio FariaNo ratings yet

- MODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Document1 pageMODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Gabriel vieiraNo ratings yet

- Form 13Document4 pagesForm 13Jayendra NaiduNo ratings yet

- MccauleyDocument14 pagesMccauleyjose luis rocha marquezNo ratings yet

- MODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleDocument2 pagesMODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleRebeca SerranoNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Maintenance ManualDocument6 pagesMaintenance ManualHuda LestraNo ratings yet

- Maintenance 1800h, 12_24moDocument1 pageMaintenance 1800h, 12_24moTarek ElghazzalyNo ratings yet

- Service Bulletin 239CDocument14 pagesService Bulletin 239CoscarNo ratings yet

- (Beechcraft) Annual Inspection - 100-Hour Inspection ChecklistDocument19 pages(Beechcraft) Annual Inspection - 100-Hour Inspection ChecklistRobertNo ratings yet

- Enmienda A MSC.1-Circ.1432 (En Vigor A Día 10-05-2017)Document7 pagesEnmienda A MSC.1-Circ.1432 (En Vigor A Día 10-05-2017)AbianNo ratings yet

- Engine - Inspection - CheckDocument2 pagesEngine - Inspection - CheckSECCION TECNICANo ratings yet

- Qa LHB Air BrakeDocument4 pagesQa LHB Air BrakeSriram SubramanianNo ratings yet

- T12833-Purge Air CHK VLVDocument6 pagesT12833-Purge Air CHK VLVJEORJENo ratings yet

- Service Bulletin: TitleDocument13 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Installation, Maintenance, & Repair Series 909 and LF909: Reduced Pressure Zone AssembliesDocument8 pagesInstallation, Maintenance, & Repair Series 909 and LF909: Reduced Pressure Zone AssembliesPrabath KNo ratings yet

- N-Series High Speed Gear Long-Term Maintenance PlanDocument8 pagesN-Series High Speed Gear Long-Term Maintenance PlanErnani MesquitaNo ratings yet

- Operating & Maintenance Procedure For Air Cooler Heat ExchangerDocument10 pagesOperating & Maintenance Procedure For Air Cooler Heat Exchangerrahim_33516285675% (8)

- Easa Ad 2013-0009 1Document3 pagesEasa Ad 2013-0009 1Yuri SilvaNo ratings yet

- Braden - Service BulletinDocument5 pagesBraden - Service BulletinRafael MonteiroNo ratings yet

- Gestion Mantenimiento Puente GruaDocument11 pagesGestion Mantenimiento Puente GruaBryan Esteban Casas ZapataNo ratings yet

- Model FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Document226 pagesModel FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Paul100% (1)

- Pneumatic TestDocument6 pagesPneumatic TestShrichand G. BathvNo ratings yet

- Time Limits/Maintenance Checks Time Limits Inspection/CheckDocument7 pagesTime Limits/Maintenance Checks Time Limits Inspection/CheckWalter TorenaNo ratings yet

- CmentDocument2 pagesCmentTariqNo ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- Subsea Decommissioning: Casey Kavanaugh Workover/Decommissioning Coordinator February 10, 2015Document17 pagesSubsea Decommissioning: Casey Kavanaugh Workover/Decommissioning Coordinator February 10, 2015Mohammed adelNo ratings yet

- Kidde Nitrogen Time Delay K-85-9130 ABDocument5 pagesKidde Nitrogen Time Delay K-85-9130 ABElemsa InstalacionesNo ratings yet

- Cessna InspectionDocument4 pagesCessna InspectionsandyNo ratings yet

- SSE/Air brake super check plan (40Document2 pagesSSE/Air brake super check plan (40srdme tkdNo ratings yet

- Ata ChaptersDocument40 pagesAta Chaptersflippy.ryghtsNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- 7 Scheduled Inspection Program Lj1073 and AfterDocument5 pages7 Scheduled Inspection Program Lj1073 and AfterWilly GrNo ratings yet

- MODEL 150 SERIES (1969 - 1976) : Inspection Time Limits - Structure 1. ScopeDocument5 pagesMODEL 150 SERIES (1969 - 1976) : Inspection Time Limits - Structure 1. ScopeAero Diesel AviationNo ratings yet

- ML C 100 70 D97117Document33 pagesML C 100 70 D97117Aero Diesel AviationNo ratings yet

- MODEL 150 SERIES (1969 - 1976) : Inspection Operation 1Document1 pageMODEL 150 SERIES (1969 - 1976) : Inspection Operation 1Aero Diesel AviationNo ratings yet

- ML C 100 70 D97115Document5 pagesML C 100 70 D97115Aero Diesel AviationNo ratings yet

- Ata 34Document492 pagesAta 34Geovanni Riquelme LooNo ratings yet

- Montes Claros Airport ChartDocument3 pagesMontes Claros Airport ChartThaynanNo ratings yet

- Bangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Document3 pagesBangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Swarupendra BhattacharyyaNo ratings yet

- BasicsonairfoilsandliftgenerationDocument10 pagesBasicsonairfoilsandliftgenerationazamataufiqNo ratings yet

- SCRIPT For News ReportDocument2 pagesSCRIPT For News ReportRosenelle Andrea MoloniasNo ratings yet

- Legge Letter JuneDocument15 pagesLegge Letter JuneAlicia RomeroNo ratings yet

- Aircraft Maint ProgramsDocument44 pagesAircraft Maint ProgramsAtiesh MishraNo ratings yet

- Airbus Aerodynamic DeteriorationsDocument172 pagesAirbus Aerodynamic Deteriorationspontoo100% (6)

- Mel-A320 LanDocument1,330 pagesMel-A320 LanSantiagoNo ratings yet

- Section 3 - Emergency Procedures: Z 242 L Flight ManualDocument18 pagesSection 3 - Emergency Procedures: Z 242 L Flight ManualJuan Carlos Sanchez MaldonadoNo ratings yet

- Structure Question BankDocument16 pagesStructure Question BankMinh Ngọc LêNo ratings yet

- SURVEY OF UAV APPLICATIONS IN CIVIL MARKETS (June 2001)Document11 pagesSURVEY OF UAV APPLICATIONS IN CIVIL MARKETS (June 2001)indrawantanjungNo ratings yet

- GIC 405/20 JUN/KGS-JMK: - Not For Real World NavigationDocument38 pagesGIC 405/20 JUN/KGS-JMK: - Not For Real World NavigationEmerald GrNo ratings yet

- Load FactorDocument5 pagesLoad FactorNouman NadeemNo ratings yet

- SKCG/CTG Cartagena, Colombia: Eskab 1A (Eska1A) Ilmik 1A (Ilmi1A) (RWY 01) Rnav DeparturesDocument1 pageSKCG/CTG Cartagena, Colombia: Eskab 1A (Eska1A) Ilmik 1A (Ilmi1A) (RWY 01) Rnav DeparturesAlexandra DiazNo ratings yet

- Flight Briefing VFR LSGL (Lausanne) - LSZB (Bern) : RouteDocument3 pagesFlight Briefing VFR LSGL (Lausanne) - LSZB (Bern) : RouteReljaNo ratings yet

- Study Case of Drone ZiplineDocument9 pagesStudy Case of Drone ZiplineMinh Hương Lê100% (1)

- Aviation Questionnaire: Image Not Found or Type UnknownDocument3 pagesAviation Questionnaire: Image Not Found or Type UnknownVadim TsaplinNo ratings yet

- Study of Blended Wing Body Design (BWBDocument36 pagesStudy of Blended Wing Body Design (BWBchanrixsoni100% (2)

- PAVE Checklist P A: Ilot IrcraftDocument2 pagesPAVE Checklist P A: Ilot IrcraftjonNo ratings yet

- Boarding PassDocument1 pageBoarding PassKaivalya EkhandeNo ratings yet

- Dsmuey: Lion Air Eticket Itinerary / ReceiptDocument4 pagesDsmuey: Lion Air Eticket Itinerary / Receiptdenstar silalahiNo ratings yet

- LFLB PDFDocument18 pagesLFLB PDFAnonymous scqhkCPxJFNo ratings yet

- High-Tech Warfare by Bill Gunston, Doug Richardson, Ian HoggDocument184 pagesHigh-Tech Warfare by Bill Gunston, Doug Richardson, Ian HoggRicardo Lopez100% (2)

- Flight International - August 5 2014 UKDocument44 pagesFlight International - August 5 2014 UKRohan MahajanNo ratings yet

- UNIVAIR CessnaDocument13 pagesUNIVAIR CessnaJessie Bechayda100% (1)

- First Flight Test CardDocument21 pagesFirst Flight Test Cardapi-1649387No ratings yet

- Book Colombia Flight MDE to BOGDocument8 pagesBook Colombia Flight MDE to BOGLina LacorazzaNo ratings yet

- Air France v. Saks, 470 U.S. 392 (1985)Document13 pagesAir France v. Saks, 470 U.S. 392 (1985)Scribd Government DocsNo ratings yet

- Endorsement Cheat Sheet by BriDocument9 pagesEndorsement Cheat Sheet by BriPatrick StoneNo ratings yet