Professional Documents

Culture Documents

MCS10 Multicomponent Sensor Data Sheet

Uploaded by

Tam NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCS10 Multicomponent Sensor Data Sheet

Uploaded by

Tam NguyenCopyright:

Available Formats

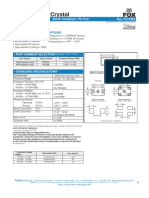

MCS10

Multicomponent sensor

Special features

- Compact multicomponent sensor

- Different nominal (rated) measuring

Data sheet

ranges

- Up to 6 components; each in every

direction: tension & compression,

clockwise & counterclockwise

- Can be adapted to many measurement

tasks by choosing the required

measurement outputs

- Flange connection with centering and pin

for positioning

- Degree of protection IP67

- TEDS

- Customization possible

Fx Fx

Mx

Mx

Mz

Fz

My Fy

B04439_09_E00_01 03.05.2021 HBM: public

Specifications

Size BG1 BG2 BG3

Type 005 010 025 050 100 200

Accuracy class 0.2 0.1 0.15

Nominal lateral force Fx & Fy Fx,nom ; Fy,nom kN 1 2 5 10 20 40

Nominal axial force Fz Fz,nom kN 5 10 25 50 100 200

Nominal bending moment Mx Mx,nom ; My,nom kN·m 0.05 0.15 0.35 0.7 2 3.5

& My

Nominal torsional moment Mz,nom kN·m 0.05 0.15 0.25 0.5 1.5 3

Mz

Nominal sensitivity Fx & Fy1) CFx,nom ; CFy,nom mV/V 1.5±0.3 1.3±0.3 1.2±0.3

Nominal sensitivity Fz 1) CFz,nom mV/V 1.4±0.3 1.3±0.3 1.2±0.3

Nominal sensitivity Mx & My 1) CMx,nom ; CMy,nom mV/V 1.8±0.3 1.5±0.3

Nominal sensitivity Mz1) CMz,nom mV/V 1.4±0.3 1.6±0.3 1.1±0.3 0.9±0.3

Relative zero signal error, dS,0 % ±1

related to nominal sensitivity

Temperature effect per 10K

in the nominal (rated) tem

perature range

On the output signal, related to TCc % <±0.2 <±0.1

the actual value

On the zero signal, related to TC0 % <±0.1

the nominal (rated) sensitivity

Linearity deviation, dlin % <±0.05

related to nominal sensitivity

Rel. reversibility error

(0.2Fnom to Fnom), related to

nominal sensitivity

Forces (Fx, Fy & Fz) % <±0.1

U (dhy)

Moments (Mx, My & Mz) % <±0.15 <±0.1 <±0.15

Rel. creep over 30 mins. dcrF+E % <±0.15

Rel. standard deviation of σrel % <±0.05

repeatability

per DIN 1319, related to the

variation of the output signal

Input and output resistance

3-component Fx/Fy Ω 350±20 700±20

Fz Ω 700±20 350±20

6-component Fx/Fy Ω 350±20 700±20

Ri; Ro

Fz Ω 700±20 700±20

Mx/My Ω 350±20 700±20

Mz Ω 700±20 350±20

Insulation resistance Ris Ω > 2x109

Reference excitation voltage Uref V 5

Operating range of the BU,G V 0.5 to 12

excitation voltage

Nominal temperature range Bt,nom °C -10 to +70

Operating temperature range Bt,G °C -10 to +85

Storage temperature range Bt,s °C -30 to +85

Reference temperature tref °C +23

1) The individual sensitivity can be found in the test certificate and is stored in the TEDS. This sensitivity has a maximum deviation of 0.5%

HBM 2 B04439_09_E00_01 03.05.2021 HBM: public

Specifications (continued)

Size BG1 BG2 BG3

Type 005 010 025 050 100 200

Crosstalk without matrix compensation

Determined at uniaxial load. With a smaller, interfering component, crosstalk is reduced by the same factor. Matrix compensa

tion can reduce the crosstalk.

Influencing component Affected component

XTFx->Fz

Lateral force (Fx,nom ; Fy,nom) % <±1 <±0.5

XTFy->Fz

Axial force

XTMx->Fz

Bending moment (Mx,nom ; My,nom) (Fz,nom) % <±1

XTMy->Fz

Torsional moment (Mz,nom) XTMz->Fz % <±3 <±1 <±0.5

XTFz->Fx

Axial force (Fz,nom) % <±3 <±1.5

XTFz->Fy

XTFx->Fy

Lateral force (Fx,nom ; Fy,nom) % <±1 <±0.5 <±0.3

XTFy->Fx

Lateral force XTMx->Fx

(Fx,nom ; Fy,nom) XTMx->Fy

Bending moment (Mx,nom ; My,nom) % <±2 <±1.5 <±1

XTMy->Fx

XTMy->Fy

XTMz->Fx

Torsional moment (Mz,nom) % <±3 <±1

XTMz->Fy

XTFz->Mx

Axial force (Fz,nom) % <±3 <±1.5

XTFz->My

XTFx->Mx

XTFx->My

Lateral force (Fx,nom ; Fy,nom) % <±1.5

Bending moment XTFy->Mx

(Mx,nom ; My,nom) XTFy->My

XTMx->My

Bending moment (Mx,nom ; My,nom) % <±1.5 <±1 <±0.5

XTMy->Mx

XTMz->Mx

Torsional moment (Mz,nom) % <±1.5 <±1

XTMz->My

Axial force (Fz,nom) XTFz->Mz % <±3 <±1.5

XTFx->Mz

Lateral force (Fx,nom ; Fy,nom) Torsional moment % <±3 <±1

XTFy->Mz

(Mz,nom)

XTMx->Mz

Bending moment (Mx,nom ; My,nom) % <±1.5 <±1

XTMy->Mz

B04439_09_E00_01 03.05.2021 HBM: public 3 HBM

Specifications (continued)

Size BG1 BG2 BG3

Type 005 010 025 050 100 200

Load limits

Load ratio sum at multiaxial load (theoretical value for calculating load ranges)

ȱ ǸFx2 ) Fy2 ǸMx ) My

2 2

ȳ

ȧ ȧ

|F z| |M z|

LRS + k 1 @ ) k2 @ ) k3 @ ) k4 @ @ 100%

Ȳ F x,nom F z,nom M x,nom M z,nom

ȴ

Correction factors

k1 0.7 0.7 1.3 1.6 1.2 1.4

k2 1.0 0.9 1.8 1.4 1.2 1.4

k3 0.6 0.6 1.1 1.1 1.1 1.1

k4 1.2 1.0 1.4 1.4 1.3 1.5

Criterion for the nominal (rated) measuring range to be met at % LRS<265 LRS<350

multiaxial load

(The load of each individual component must not exceed its maximum

capacity)

Criterion for the fatigue strength range to be met at multiaxial pul % LRS<250 LRS<325

sating load

(The load of each individual component must not exceed its maximum

capacity)

Criterion for the fatigue strength range to be met at multiaxial % LRS<175 LRS<250

alternating load

(The load of each individual component must not exceed its maximum

capacity)

Criterion for the static load range to be met at multiaxial load % LRS<340 LRS<450

(The load of each individual component must not exceed its limit load)

Lateral force limit (Fx, Fy), related to Fx,nom; Fy,nom2) Fx(y),L % 250 270 190 150 200 180

Axial force limit (Fz), related to Fz,nom 2) Fz,L % 170 200 140 190 200 180

Bending moment limit (Mx, My), related to Mx,nom; Mx(y),L %

310 240 230

My,nom2)

Torsional moment limit (Mz), related to Mz,nom2) Mz,L % 150 180 190 170

Criterion for the (static) range without break to be met at multiaxial % LRS<450 LRS<600

load

(The load of each individual component must not exceed its breaking

load)

Lateral force at break (Fx, Fy), related to Fx,nom; Fy,nom2) Fx(y),B % >490 >520 >340 >270 >370 >320

Axial force at break (Fz), related to Fz,nom 2) Fz,B % >330 >400 >250 >330 >360 >320

Bending moment at break (Mx, My), related to Mx,nom;

Mx(y),B % >600 >610 >430 >410

My,nom2)

Torsional moment at break (Mz), related to Mz,nom2) Mz,B % >280 >340 >320 >340 >300

2) At static load and uniaxial load

The load criteria apply to the sum of all simultaneously occurring loads, regardless of whether these are measured

or parasitic.

The origin of the sensor coordinates is in the geometric center (half the height of the sensor). In the application, the

bending moment generated by a lateral force must be taken into account when determining the maximum bending

moment that can occur. Please note that half the height of the sensor must be taken into account as an additional

lever arm.

HBM 4 B04439_09_E00_01 03.05.2021 HBM: public

Specifications (continued)

Size BG1 BG2 BG3

Type 005 010 025 050 100 200

Mechanical values

Nominal (rated) displacement at lateral force Fx & mm <0.03 <0.04 <0.05 <0.05 <0.05 <0.07

Fy

Nominal (rated) displacement at axial force Fz mm <0.02 <0.03 <0.03 <0.04 <0.04 <0.05

Tilt angle at Mx,nom; My,nom degrees <0.04 <0.05 <0.05 <0.06 <0.05 <0.05

Torsion angle at Mz,nom degrees <0.08 <0.08 <0.06 <0.07 <0.08 <0.07

Stiffness in the radial direction (x or y) kN/mm 37 54 117 202 452 659

Stiffness in the axial direction (z) kN/mm 353 471 993 1664 3018 4824

Stiffness during the bending moment round a kN·m/degrees 1.4 3.8 7.9 13.3 41.5 83.7

radial axis (x or y)

Stiffness during the torsional moment round the kN·m/degrees 0.7 2.1 4.6 7.6 27.4 44.5

axial axis (z)

Natural frequency3) in radial direction (x or y) 2.4 1.7 1.9 2.5 3.4

Natural frequency3) in axial direction (z) 7.4 5.2 5.6 7.2 6.4 7.9

kHz

Natural frequency3) around a radial axis (x or y) 8.5 6 6.5 8.4 7.8 9.9

Natural frequency3) around the axial axis (z) 3.8 2.8 3.1 4 5.1

General information

Weight (approx.) kg 0.5 1.0 1.8 3.8

Material: Measuring body Titanium alloy Stainless steel

Material: Housing Aluminum alloy, powder coated

Degree of protection per EN 60529 IP67

Maximum cable length (6-wire configuration) of the m 50

standard cable for multiple components

Transducer identification TEDS, per IEEE 1451.4

Emission (EME) (EN 61326‐1, Section 7)

RFI field strength Class B

Immunity to interference (EN 61326-1, Table 2;

EN 61326-2-3) V/m 10

Electromagnetic fields (AM) A/m 100

Power-frequency magnetic fields

Electrostatic discharge (ESD) kV 4

Contact discharge kV 8

Air discharge kV 1

Fast transients (burst) kV 1

Impulse voltages (surge) V 10

Conducted interference (AM)

Mechanical shock (EN 60068-2-27)

Number n 1000

Duration ms 3

Acceleration (half sine) m/s2 650

Vibration in 3 directions (EN 60068-2-6)

Frequency range Hz 10…2000

Duration h 2.5

Acceleration (amplitude) m/s2 150

3) The natural frequency in the specifications only takes into account the transducer, not the necessary loading fittings. The relevant natural

frequency of the overall setup changes naturally if additional masses are mounted on the transducer. Consequently, this is a recommended

value serving as a guide, which always requires consideration of the mounting conditions for a dynamic setup.

B04439_09_E00_01 03.05.2021 HBM: public 5 HBM

MCS10-005-3C

HBM 6 B04439_09_E00_01 03.05.2021 HBM: public

MCS10-005-6C

B04439_09_E00_01 03.05.2021 HBM: public 7 HBM

MCS10-010-3C / MCS10-025-3C / MCS10-050-3C

HBM 8 B04439_09_E00_01 03.05.2021 HBM: public

MCS10-010-6C / MCS10-025-6C / MCS10-050-6C

B04439_09_E00_01 03.05.2021 HBM: public 9 HBM

MCS10-100-3C

HBM 10 B04439_09_E00_01 03.05.2021 HBM: public

MCS10-100-6C

B04439_09_E00_01 03.05.2021 HBM: public 11 HBM

MCS10-200-3C

HBM 12 B04439_09_E00_01 03.05.2021 HBM: public

MCS10-200-6C

B04439_09_E00_01 03.05.2021 HBM: public 13 HBM

Pin assignment

Transducer assignment Amplifier assignment

6-pin Lemo

wh Free ends D-Sub D-Sub-HD

bu bk

gn gy

rd

PIN 1: Measurement signal (+) UA wh (white)

PIN 6: Bridge excitation voltage (-) UB bk (black)

TEDS chip

PIN 4: Measurement signal (-) UA rd (red)

PIN 2: Bridge excitation voltage (+) UB bu (blue)

PIN 3: Sense lead (+) gn (green)

PIN 5: Sense lead (-) TEDS chip gy (gray)

Cable shield, connected to the housing Shield Hsg. Hsg.

Cable

58

94

27.4

13.7

13.5

29

44.5

58

44.5

29

13.5

24.5

10.5

35

HBM 14 B04439_09_E00_01 03.05.2021 HBM: public

Ordering number MCS10

Ordering number

K‐MCS10

Code Measurement range

005 Fx=1 kN; Fy=1 kN; Fz=5 kN; Mx=0.05 kNm; My=0.05 kNm; Mz=0.05 kNm

010 Fx=2 kN; Fy=2 kN; Fz=10 kN; Mx=0.15 kNm; My=0.15 kNm; Mz=0.15 kNm

1 025 Fx=5 kN; Fy=5 kN; Fz=25 kN; Mx=0.35 kNm; My=0.35 kNm; Mz=0.25 kNm

050 Fx=10 kN; Fy=10 kN; Fz=50 kN; Mx=0.7 kNm; My=0.7 kNm; Mz=0.5 kNm

100 Fx=20 kN; Fy=20 kN; Fz=100 kN; Mx=2 kNm; My=2 kNm; Mz=1.5 kNm

200 Fx=40 kN; Fy=40 kN; Fz=200 kN; Mx=3,5 kNm; My=3,5 kNm; Mz=3 kNm

Code Version

2 3C Option for 3 components - only forces (Fx, Fy & Fz)

6C Option for 6 components - obligatory for moments

Code Component Fx

3 FX Measurement output Fx

00 No measurement output

Code Component Fy

4 FY Measurement output Fy

00 No measurement output

Code Component Fz

5 FZ Measurement output Fz

00 No measurement output

Code Component Mx

6 MX Measurement output Mx

00 No measurement output

Code Component My

7 MY Measurement output My

00 No measurement output

Code Component Mz

8 MZ Measurement output Mz

00 No measurement output

For example:

K-MCS10 - 0 1 0 - 6 C - F X - F Y - 0 0 - M X - 0 0 - M Z

1 2 3 4 5 6 7 8

Accessories (to be ordered separately)

Article Ordering number

Configurable connection cable K-KAB-M

Connection cable 6 m with free ends 1-KAB146-6

B04439_09_E00_01 03.05.2021 HBM: public 15 HBM

B04439_09_E00_01 03.05.2021 HBM: public

Subject to modifications. Hottinger Brüel & Kjaer GmbH

All product descriptions are for general information Im Tiefen See 45 ⋅ 64293 Darmstadt ⋅ Germany

only. They are not to be understood as a guarantee Tel. +49 6151 803‐0 ⋅ Fax +49 6151 803‐9100

of quality or durability. Email: info@hbm.com ⋅ www.hbm.com

measure and predict with confidence

HBM 16 B04439_09_E00_01 03.05.2021 HBM: public

You might also like

- Charter OCAP 4-Device Remote Control: Manufacturer'S CodesDocument2 pagesCharter OCAP 4-Device Remote Control: Manufacturer'S CodesDerek WebsterNo ratings yet

- Managerial Eco and Accounting FinalDocument16 pagesManagerial Eco and Accounting FinalMichael Paul GabrielNo ratings yet

- Completion Fluids BaroidDocument26 pagesCompletion Fluids Baroidcrown212No ratings yet

- B04439Document14 pagesB04439Eduardo Valentín Pérez HernándezNo ratings yet

- Short Description FFT01-P ENDocument2 pagesShort Description FFT01-P ENDiego CalvoNo ratings yet

- PW10 HBMDocument6 pagesPW10 HBMBogdan MoldovanNo ratings yet

- Eng Ds Xftc300 A5Document4 pagesEng Ds Xftc300 A5Zoltán SoósNo ratings yet

- Adxl202/Adxl210-Specifications: ADXL202/JQC/AQC ADXL210/JQC/AQC Parameter Conditions Min Typ Max Min Typ Max UnitsDocument1 pageAdxl202/Adxl210-Specifications: ADXL202/JQC/AQC ADXL210/JQC/AQC Parameter Conditions Min Typ Max Min Typ Max UnitsmhasansharifiNo ratings yet

- Press Force SensorDocument4 pagesPress Force SensortivakornNo ratings yet

- Ztt-12.00mt Resonador CeramicoDocument1 pageZtt-12.00mt Resonador CeramicoAramis PizzaNo ratings yet

- Danfoss Pressure Transducer 1-10 BarDocument5 pagesDanfoss Pressure Transducer 1-10 Barkathreen mae fabiana100% (1)

- Ceramic SMD Ultra Miniature Quartz Crystal Features and SpecificationsDocument2 pagesCeramic SMD Ultra Miniature Quartz Crystal Features and SpecificationspepeNo ratings yet

- 8.press SensorDocument10 pages8.press SensorGaurav MaithilNo ratings yet

- MBS 33Document5 pagesMBS 33NoelNo ratings yet

- Pressure Transmitter With Ratiometric Output Signal: AKS 32R and AKS 2050Document4 pagesPressure Transmitter With Ratiometric Output Signal: AKS 32R and AKS 2050benjaminfarfarNo ratings yet

- Karta Katalogowa 179999 Czujnik Optyczny Szczelinowy Omron Ee Sx1041 1 SZTDocument2 pagesKarta Katalogowa 179999 Czujnik Optyczny Szczelinowy Omron Ee Sx1041 1 SZTmarcinNo ratings yet

- Celda de Carga PWSE c3Document4 pagesCelda de Carga PWSE c3Marvin AlexanderNo ratings yet

- T935 Inclinometer: DC-Operated, Gravity-ReferencedDocument4 pagesT935 Inclinometer: DC-Operated, Gravity-ReferencedNicolasSuchNo ratings yet

- Eng Ds Xftc310 A4Document4 pagesEng Ds Xftc310 A4Zoltán SoósNo ratings yet

- Geotech CPT ProbesDocument2 pagesGeotech CPT ProbesIkhwansterNo ratings yet

- FX 532Document2 pagesFX 532giriprasadgoudNo ratings yet

- Alfa HealthcareDocument7 pagesAlfa HealthcareMOHIT PRADHANNo ratings yet

- Torque Transfer Standard: Special FeaturesDocument4 pagesTorque Transfer Standard: Special FeaturesdabafiNo ratings yet

- Mru Z: The Ideal Heave, Roll and Pitch SensorDocument2 pagesMru Z: The Ideal Heave, Roll and Pitch SensorAdi VNo ratings yet

- Load Cells: Special FeaturesDocument4 pagesLoad Cells: Special FeaturesanggaNo ratings yet

- Calibration Unit: Special FeaturesDocument2 pagesCalibration Unit: Special FeaturesAndres Camilo Salazar Latorre.No ratings yet

- Multicomponent Dynamometer: ForceDocument4 pagesMulticomponent Dynamometer: ForceIrina BancescuNo ratings yet

- Low Profile (Pancake) Load Cells: Universal Tension and Compression Load Cells For Industrial Force MeasurementsDocument3 pagesLow Profile (Pancake) Load Cells: Universal Tension and Compression Load Cells For Industrial Force MeasurementsshadyghanemNo ratings yet

- miniSVS - The Most Accurate Sound Velocity SensorDocument1 pageminiSVS - The Most Accurate Sound Velocity SensorEduardo GonzalezNo ratings yet

- NIC Components NEXM SeriesDocument1 pageNIC Components NEXM SeriesNICCompNo ratings yet

- ACC 5011B Charge AmplifierDocument6 pagesACC 5011B Charge AmplifierNguyen Danh HuyNo ratings yet

- SkyCiv Structural 3D ReportDocument15 pagesSkyCiv Structural 3D ReportAlexandreNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- Light Touch SMD Switches SpecificationsDocument3 pagesLight Touch SMD Switches SpecificationsThomas SabuNo ratings yet

- SP8 Pesaje Dinamico - B04504 PDFDocument4 pagesSP8 Pesaje Dinamico - B04504 PDFFernando PastorNo ratings yet

- Honeywell Sensing Force Sensors FSG Product Sheet 008028 2 ENDocument4 pagesHoneywell Sensing Force Sensors FSG Product Sheet 008028 2 ENYiğit Taylan DasNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputGopal HegdeNo ratings yet

- HBM P3 Top ClassDocument10 pagesHBM P3 Top ClasslgustavolucaNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputNilesh WableNo ratings yet

- DTS MN 07-2017 Eng PDFDocument4 pagesDTS MN 07-2017 Eng PDFvipul patelNo ratings yet

- Célula Z7ADocument6 pagesCélula Z7AJoaquimNo ratings yet

- EMV 1025S-0 1: Single Hole Mounting MeterDocument2 pagesEMV 1025S-0 1: Single Hole Mounting Meterdenbigh1974No ratings yet

- AI309145930291en 000301Document6 pagesAI309145930291en 000301Aicky IkrackNo ratings yet

- 3-Axis Compass With Algorithms HMC6343: Features BenefitsDocument13 pages3-Axis Compass With Algorithms HMC6343: Features BenefitsrajNo ratings yet

- SMD Clipped Sine Wave 6 Pads 11.4 X 9.6 X 2.5 MM: VM62S SeriesDocument1 pageSMD Clipped Sine Wave 6 Pads 11.4 X 9.6 X 2.5 MM: VM62S SeriessergioNo ratings yet

- HC49S & HC49SS Low Profile Quartz Crystal ResonatorsDocument1 pageHC49S & HC49SS Low Profile Quartz Crystal ResonatorsPeter MossNo ratings yet

- Atc0000ce20 49490Document3 pagesAtc0000ce20 49490xowanob534No ratings yet

- csacspacedatasheet1614799407951Document3 pagescsacspacedatasheet1614799407951daniel.esquivel.trujilloNo ratings yet

- High-accuracy USB inclinometer with PC softwareDocument6 pagesHigh-accuracy USB inclinometer with PC softwarebasconesjoseNo ratings yet

- MD 9060 Digital MultimeterDocument2 pagesMD 9060 Digital MultimetertemporayNo ratings yet

- Data Sheet Series KTN ZD NeuesLayout2021Document12 pagesData Sheet Series KTN ZD NeuesLayout2021kohij64471No ratings yet

- Siemens SRD 00514Document4 pagesSiemens SRD 00514accessmodyfierNo ratings yet

- DFB Laser Diodes Specs & AppsDocument34 pagesDFB Laser Diodes Specs & AppsAqua BlueNo ratings yet

- DS Standard-CTE-CTU7000 E 11507-1Document6 pagesDS Standard-CTE-CTU7000 E 11507-1marioni_a1No ratings yet

- Transmisor de Presion - de El Tratamiento de Aguas 060g2418 mbs4510Document5 pagesTransmisor de Presion - de El Tratamiento de Aguas 060g2418 mbs4510josue alvarez vargasNo ratings yet

- Series PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracyDocument7 pagesSeries PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracymuhammetnaberNo ratings yet

- Single-Ended Beam Load Cell Single-Ended Beam Load Cell: Model 5123Document3 pagesSingle-Ended Beam Load Cell Single-Ended Beam Load Cell: Model 5123Juan Carlos BallinariNo ratings yet

- Leader LDC-823A - ManualDocument16 pagesLeader LDC-823A - Manual김박사No ratings yet

- Torque Reference Transducer: Special FeaturesDocument6 pagesTorque Reference Transducer: Special FeaturesdabafiNo ratings yet

- Aluminum Electrolytic Capacitors: SpecificationsDocument1 pageAluminum Electrolytic Capacitors: SpecificationsMichael KovalNo ratings yet

- Rs Pro p40 WW PotmetersDocument1 pageRs Pro p40 WW PotmetersMartien BakkerNo ratings yet

- Cond-Usb: Strain-Gauge Bridge To Usb ConverterDocument2 pagesCond-Usb: Strain-Gauge Bridge To Usb ConverterTecnoquality EquiposNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesDocument3 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesMANUALES100% (1)

- Dengue Fever PresentationDocument11 pagesDengue Fever Presentationhira khanNo ratings yet

- Computer Organization and ArchitectureDocument173 pagesComputer Organization and ArchitecturesalithakkNo ratings yet

- These Are The Top 10 Machine Learning Languages On GitHubDocument3 pagesThese Are The Top 10 Machine Learning Languages On GitHubAbeer UlfatNo ratings yet

- MikroTik Course Outline UpdatedDocument2 pagesMikroTik Course Outline UpdatedAbdul KuddusNo ratings yet

- 3hac13347 1Document18 pages3hac13347 1CJ MallickNo ratings yet

- Resolve Error in FI Document Parking WorkflowDocument4 pagesResolve Error in FI Document Parking WorkflowManohar G ShankarNo ratings yet

- Perspective View: This SiteDocument1 pagePerspective View: This SiteRose Lind TubogNo ratings yet

- A Review of Bring Your Own Device OnDocument11 pagesA Review of Bring Your Own Device OnNurrul JannathulNo ratings yet

- Section A-A: PLUNGER, LGA, 7X7, G3Document1 pageSection A-A: PLUNGER, LGA, 7X7, G3Ericson. TatlongmariaNo ratings yet

- Ch3.2 - HomeworkDocument2 pagesCh3.2 - HomeworkArcherDash Love GeometrydashNo ratings yet

- iC60L Circuit Breakers (Curve B, C, K, Z)Document1 pageiC60L Circuit Breakers (Curve B, C, K, Z)Diego PeñaNo ratings yet

- Hershey's Milk Shake ProjectDocument20 pagesHershey's Milk Shake ProjectSarvesh MundhadaNo ratings yet

- Sustainable Development & Environmental Assessment QuizDocument2 pagesSustainable Development & Environmental Assessment QuizramananNo ratings yet

- Lancaster Paint Monthly Specials April-May 31, 2011Document16 pagesLancaster Paint Monthly Specials April-May 31, 2011SteveNo ratings yet

- Well BlowdownDocument47 pagesWell BlowdownMask BlackNo ratings yet

- Business Description: Executive SummaryDocument4 pagesBusiness Description: Executive SummaryYudhi SugataNo ratings yet

- 2nd National Biosafety Conference Programme and AbstractsDocument56 pages2nd National Biosafety Conference Programme and AbstractsDaddie InyasisNo ratings yet

- 9) - Stategy Formulation at Corporate LevelDocument34 pages9) - Stategy Formulation at Corporate Leveldulshan jeewanthaNo ratings yet

- Resume - Savannah RodriguezDocument1 pageResume - Savannah Rodriguezapi-634086166No ratings yet

- Quick Start Guide: Before You BeginDocument13 pagesQuick Start Guide: Before You Beginfrinsa noroesteNo ratings yet

- Omron DSDocument1 pageOmron DSematnNo ratings yet

- 5197-Car Hire 04 Dates-Ltr 157 DT 23.04.19Document1 page5197-Car Hire 04 Dates-Ltr 157 DT 23.04.19arpannathNo ratings yet

- MOBISEC 2020 - 15 - Mobile MalwareDocument64 pagesMOBISEC 2020 - 15 - Mobile MalwareBobbylovesvickieNo ratings yet

- Isolating Antagonistic BacteriaDocument12 pagesIsolating Antagonistic BacteriaDesy rianitaNo ratings yet

- ResumeDocument2 pagesResumeCameron Bracken100% (3)

- HR Workflows in TOPdeskDocument2 pagesHR Workflows in TOPdeskTOPdesk0% (1)