Professional Documents

Culture Documents

Natef Task Sheet - Section A.5 D9 (P-1) A5D9: Machine Front Brake Rotor ON Vehicle

Uploaded by

abul hussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natef Task Sheet - Section A.5 D9 (P-1) A5D9: Machine Front Brake Rotor ON Vehicle

Uploaded by

abul hussainCopyright:

Available Formats

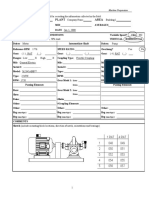

NATEF TASK SHEET --- SECTION A.

5 D9 (P-1)

A5D9: MACHINE FRONT BRAKE ROTOR ON VEHICLE

Student: __________________________ Date: ___________ Period: ____________

VIN: ___________________ Year: ______ Make: ________ Model: _________

Engine: __________ Transmission: __________ Production Date: _____________

OBJECTIVE: Student will evaluate and machine a rotor on the vehicle.

U U

.

MATERIALS: 1. EYE PROTECTION

2. Dial Indicator and Rotor Micrometer.

3. On-the-Car Brake Lathe

4. Vehicle (see instructor)

PROCEDURE: WEAR EYE PROTECTION! Remove front wheel and brake caliper.

Place brake lathe on vehicle (see procedure provided by on-the-car

lathe)(watch video if available). Attach magnetic mount dial indicator at

90 degree angle to rotor face. Rotate rotor assembly and measure lateral

run-out. Record measurement below. Measure rotor thickness with

micrometer and record measurement below. Look up vehicle in brake

specification booklet and record minimum thickness and maximum lateral

run-out specifications below. Machine rotor on vehicle. Measure rotor

thickness after machining and record measurement below. Do not to get

grease, dirt, or finger prints on rotor machined surface.

Record Measurements: Before Machining

0B After Machining Vehicle

1B

Specifications

4B Rotor Thickness 2B Minimum

Lateral Run-out

5B

Maximum

3B

YOUR RECOMMENDATIONS:______________________________________

(Does the rotor need to be replaced?)

PROBLEMS / CONCERNS:_________________________________________

INSTRUCTORS EVALUATION

LEVEL OF SKILL ATTAINED Initial OVERALL SKILL EVALUATION Points

DEMONSTRATES MASTERY (5) DOCUMENTATION COMPLETENESS (1)

PERFORMS SATISFACTORILY (4) SAFETY COMPLIANCE (1)

CAPABLE, NEEDS PRACTICE (3) W ORK PROFESSIONALISM (3)

ASSISTED IN PERFORMING (2) LEVEL OF SKILL ATTAINED (1-5)

EXPOSURE, OBSERVATION (1) TOTAL SCORE

INSTRUCTOR’S SIGNATURE:

A5D9 / Machine Rotor On Vehicle / 03-29-12 / vdb

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Bringing Words To LifeDocument23 pagesBringing Words To LifeKatarina Mijatovic100% (3)

- Schlumberger - Bit Running GuidelinesDocument38 pagesSchlumberger - Bit Running Guidelinesmanuelperdomot100% (1)

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- PDI Inspection Form July 2005Document4 pagesPDI Inspection Form July 2005Chris. B.No ratings yet

- Rotating Machinery AlignmentDocument61 pagesRotating Machinery AlignmentBesuidenhout Engineering Solutions and Consulting100% (1)

- Saudi Aramco: Drilling OptimizationDocument21 pagesSaudi Aramco: Drilling OptimizationBoukelia TahaNo ratings yet

- ES9-54 Fastener Installation Torque Values Rev GDocument34 pagesES9-54 Fastener Installation Torque Values Rev GIfran SierraNo ratings yet

- NCC Spherical Bearing Method Statement DraftDocument23 pagesNCC Spherical Bearing Method Statement Draftrohit67% (3)

- Yatak ResimleriDocument37 pagesYatak ResimleriŞansal Dikmener100% (1)

- Microsoft Office 365 Customer Decision FrameworkDocument14 pagesMicrosoft Office 365 Customer Decision FrameworkthinkofdevilNo ratings yet

- Bit Running Guidelines PDFDocument39 pagesBit Running Guidelines PDFRyan LlanetaNo ratings yet

- STJLR 51 5254Document7 pagesSTJLR 51 5254akomocar100% (1)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- RKB Proper Lubricant Selection For Rolling Bearing Applications PDFDocument8 pagesRKB Proper Lubricant Selection For Rolling Bearing Applications PDFJako MishyNo ratings yet

- CompleteCatalog PDFDocument116 pagesCompleteCatalog PDFgume pesaNo ratings yet

- Tuning Solution V16.0.3.0Document16 pagesTuning Solution V16.0.3.0Amine HerbacheNo ratings yet

- The Triathlete's Training Bible: The World's Most Comprehensive Training Guide, 4th Ed. - TrainingDocument5 pagesThe Triathlete's Training Bible: The World's Most Comprehensive Training Guide, 4th Ed. - Trainingrenogodo0% (1)

- Bit Running GuidelinesDocument39 pagesBit Running GuidelinesEmad Zaki100% (1)

- Checklist For Rock Bolts PDFDocument4 pagesChecklist For Rock Bolts PDFImran FarooqNo ratings yet

- SFC FranchiseDocument10 pagesSFC FranchisecorinacretuNo ratings yet

- Static Var CompensatorDocument29 pagesStatic Var CompensatorCarlos Fabian GallardoNo ratings yet

- Three-Quater Face Schematics PDFDocument20 pagesThree-Quater Face Schematics PDFSchiteanu ClaudiuNo ratings yet

- Natef S A.5 D.1,7,8 (P 1) : Task SheetDocument1 pageNatef S A.5 D.1,7,8 (P 1) : Task Sheetabul hussainNo ratings yet

- B1 (2016) : D B I: Natef Task Sheet - Section A.5 D.3,6,8,10 P-1 ISC Rake NspectionDocument1 pageB1 (2016) : D B I: Natef Task Sheet - Section A.5 D.3,6,8,10 P-1 ISC Rake Nspectionabul hussainNo ratings yet

- Cylinder Block Inspection ReportDocument15 pagesCylinder Block Inspection Reportesa masivNo ratings yet

- Machine Plant AreaDocument5 pagesMachine Plant AreachocoteteNo ratings yet

- Annexure-1 (PG-3)Document16 pagesAnnexure-1 (PG-3)A A Mamun KhanNo ratings yet

- Brake Rotor Service: January & February 2010Document8 pagesBrake Rotor Service: January & February 2010BBNBGHNo ratings yet

- General Information: LWD LWT HWD HWT DWTDocument1 pageGeneral Information: LWD LWT HWD HWT DWTchenlixiong518No ratings yet

- Bit Running GuidelinesDocument48 pagesBit Running GuidelinesFernando CastelblancoNo ratings yet

- TurbineDocument12 pagesTurbineMMPAPNo ratings yet

- Korando SM SupplementDocument689 pagesKorando SM SupplementGerman Rosero M100% (1)

- 2021 Integration Manual: Tested - Proven - TrustedDocument28 pages2021 Integration Manual: Tested - Proven - TrustedSENTHIL NATHANNo ratings yet

- C30 2101 (Rev. - 2000.11) EN - AGRAFES CARACTERISTIQUES GENERALES (ENGLISH)Document16 pagesC30 2101 (Rev. - 2000.11) EN - AGRAFES CARACTERISTIQUES GENERALES (ENGLISH)Diego Camargo0% (1)

- 01 (Horizontal Drive Motor)Document40 pages01 (Horizontal Drive Motor)Thinh NguyenNo ratings yet

- Reduction Gear Cyclo - Maintenance Manual (SUMITOMO) CM2001Document39 pagesReduction Gear Cyclo - Maintenance Manual (SUMITOMO) CM2001OscarNo ratings yet

- Industrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedDocument23 pagesIndustrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedAnkush ChauhanNo ratings yet

- Hyponic Operation and Maintenance ManualDocument56 pagesHyponic Operation and Maintenance ManualBenjamin SalgadoNo ratings yet

- GL-XX-Mobil-Vactra-Oil-Numbered-Series SDSDocument3 pagesGL-XX-Mobil-Vactra-Oil-Numbered-Series SDSSteffen Grønli KaroliussenNo ratings yet

- Body Structure Body Identification Body-In-White Mobile Access ElementsDocument4 pagesBody Structure Body Identification Body-In-White Mobile Access ElementsEngenharia APedroNo ratings yet

- Bearings Failures PDFDocument5 pagesBearings Failures PDFPàváñ RøçkzzNo ratings yet

- Quality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionDocument2 pagesQuality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionsourajpatelNo ratings yet

- Spherical Roller Bearings: DimensionsDocument4 pagesSpherical Roller Bearings: Dimensionskamal arabNo ratings yet

- Industrial Training Presentation-1 On Rajkot, Gujarat: ProtecDocument31 pagesIndustrial Training Presentation-1 On Rajkot, Gujarat: ProtecJAY KACHANo ratings yet

- Trailer Axles: Applications and Specifications GuideDocument70 pagesTrailer Axles: Applications and Specifications GuideRossman MejicanosNo ratings yet

- Taller 2 - Monoblock 2018-1Document5 pagesTaller 2 - Monoblock 2018-1Cristhian Joel Aquino BarzolaNo ratings yet

- Six Sigma Tata MotorsDocument37 pagesSix Sigma Tata MotorsAnamitra Chanda100% (1)

- NPD1 - Small Planetary Catalogue - Apr 2020Document39 pagesNPD1 - Small Planetary Catalogue - Apr 2020Shyam J VyasNo ratings yet

- Op-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For EngineersDocument4 pagesOp-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For Engineersjinwook75No ratings yet

- Rnu 306 - 20210211Document3 pagesRnu 306 - 20210211stalin63No ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Exploring The Latest Advancements in SPH Based Virtual Transmission DevelopmentDocument33 pagesExploring The Latest Advancements in SPH Based Virtual Transmission DevelopmentProvocateur SamaraNo ratings yet

- Six Sigma (Tata Motors)Document37 pagesSix Sigma (Tata Motors)ashuag29100% (1)

- Bridge Snooper TruckDocument32 pagesBridge Snooper TruckJasony PadasianNo ratings yet

- Bumper Car Manual Complete Dutch Revised 10 29 14 1Document47 pagesBumper Car Manual Complete Dutch Revised 10 29 14 1Soumajit SarkarNo ratings yet

- LAMP. 4. 4. Draft Lifting Plan ProcedureDocument12 pagesLAMP. 4. 4. Draft Lifting Plan ProcedureKONSULTAN RELOKASI RTGNo ratings yet

- Project Report: Nit KurukshetraDocument18 pagesProject Report: Nit Kurukshetrajatin virmaniNo ratings yet

- PWV2Document40 pagesPWV2Tony AppsNo ratings yet

- CHECK 11SHEET OF BOXNS - 2015 - REV - 2 - Amendment-01Document14 pagesCHECK 11SHEET OF BOXNS - 2015 - REV - 2 - Amendment-01PravinNo ratings yet

- Week14 - Kuliah RP Ke 10a - Pavement - Evaluation 2018Document54 pagesWeek14 - Kuliah RP Ke 10a - Pavement - Evaluation 2018Aulia Muhardi ArifinNo ratings yet

- GL XX Mobil Vactra Oil Numbered Series PDFDocument3 pagesGL XX Mobil Vactra Oil Numbered Series PDFmina riadNo ratings yet

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- Workshop MDocument69 pagesWorkshop MmanhNo ratings yet

- 2019 Notes To Remember AbdsDocument3 pages2019 Notes To Remember Abdsabul hussainNo ratings yet

- Climate Control System Operation, Diagnosis, and Repair 1Document90 pagesClimate Control System Operation, Diagnosis, and Repair 1abul hussainNo ratings yet

- Cayenne PDFDocument379 pagesCayenne PDFabul hussainNo ratings yet

- 2019 Gatesabdsadp Instructors Preso 71819 PDFDocument99 pages2019 Gatesabdsadp Instructors Preso 71819 PDFabul hussainNo ratings yet

- P65 Hard Roof & Body Systems PDFDocument116 pagesP65 Hard Roof & Body Systems PDFabul hussainNo ratings yet

- Natef Task Sheet - Section A1 D.6 P-1: WITH ENGINE COOL! Look Up and Print Out Directions For Removing andDocument1 pageNatef Task Sheet - Section A1 D.6 P-1: WITH ENGINE COOL! Look Up and Print Out Directions For Removing andabul hussainNo ratings yet

- A6/U10/L2 Vehicle Communications: JSA6H11 Anti-Theft System DiagnosisDocument3 pagesA6/U10/L2 Vehicle Communications: JSA6H11 Anti-Theft System Diagnosisabul hussainNo ratings yet

- A6G3Document2 pagesA6G3abul hussainNo ratings yet

- Circuit Control Devices: Read PDF File and Then Draw The Circuit Control Device in The Space ProvidedDocument1 pageCircuit Control Devices: Read PDF File and Then Draw The Circuit Control Device in The Space Providedabul hussainNo ratings yet

- A6/U14/L3 Vehicle Communications: Job SheetDocument3 pagesA6/U14/L3 Vehicle Communications: Job Sheetabul hussainNo ratings yet

- A6/U13/L3 Body Computer Systems: JOB SHEET A6H7 Radio Static DiagnosisDocument3 pagesA6/U13/L3 Body Computer Systems: JOB SHEET A6H7 Radio Static Diagnosisabul hussainNo ratings yet

- A6/U2/L1 Electromagnetic Devices: Job Sheet A6G1 Horn DiagnosisDocument3 pagesA6/U2/L1 Electromagnetic Devices: Job Sheet A6G1 Horn Diagnosisabul hussainNo ratings yet

- JOB SHEET A6H2 Heated Glass Diagnosis: A6/U10/L1 Miscellaneous Systems Diagnosis and RepairDocument3 pagesJOB SHEET A6H2 Heated Glass Diagnosis: A6/U10/L1 Miscellaneous Systems Diagnosis and Repairabul hussainNo ratings yet

- DecconvDocument2 pagesDecconvabul hussainNo ratings yet

- JOB SHEET A6F1 Gauge Testing & Inspection: A6/U9/L1 Gauges, Warning Devices, & Driver Information Systems DiagnosisDocument3 pagesJOB SHEET A6F1 Gauge Testing & Inspection: A6/U9/L1 Gauges, Warning Devices, & Driver Information Systems Diagnosisabul hussainNo ratings yet

- Using A Digital Volt-Ohm-Meter: Automotive TechnologyDocument2 pagesUsing A Digital Volt-Ohm-Meter: Automotive Technologyabul hussainNo ratings yet

- A6/U9/L1 Gauges, Warning Devices, & Driver Information Systems DiagnosisDocument3 pagesA6/U9/L1 Gauges, Warning Devices, & Driver Information Systems Diagnosisabul hussainNo ratings yet

- Natef Task Sheet - Section A.1, D.5 P-2 Cs3: Remove and Install Coolant HoseDocument1 pageNatef Task Sheet - Section A.1, D.5 P-2 Cs3: Remove and Install Coolant Hoseabul hussainNo ratings yet

- Customer Diagnostic WorksheetDocument3 pagesCustomer Diagnostic Worksheetabul hussainNo ratings yet

- Natef Task Sheet - Section A.1, D.3 (P-1) : Cs2: Cooling System Inspection, Pressure TestDocument1 pageNatef Task Sheet - Section A.1, D.3 (P-1) : Cs2: Cooling System Inspection, Pressure Testabul hussainNo ratings yet

- Natef Task Sheet - Section A.1, D.7 (P-1) : Cs 1B: Coolant Conductivity Test (For Dissolved Metals)Document1 pageNatef Task Sheet - Section A.1, D.7 (P-1) : Cs 1B: Coolant Conductivity Test (For Dissolved Metals)abul hussainNo ratings yet

- Natef Task Sheet - Engine A.1 D. 7 P-1: Cs1A: Check Condition and Concentration of CoolantDocument1 pageNatef Task Sheet - Engine A.1 D. 7 P-1: Cs1A: Check Condition and Concentration of Coolantabul hussainNo ratings yet

- Brake Warning Light System WSDocument2 pagesBrake Warning Light System WSabul hussainNo ratings yet

- Bulldog Repair Order Electrical-2019Document1 pageBulldog Repair Order Electrical-2019abul hussainNo ratings yet

- Circuit Control Device WSDocument1 pageCircuit Control Device WSabul hussainNo ratings yet

- Lab CPD-2Document35 pagesLab CPD-2Phu nguyen doanNo ratings yet

- Device Related Error in Patient Controlled.17Document6 pagesDevice Related Error in Patient Controlled.17Ali ÖzdemirNo ratings yet

- What's in Your BackpackDocument31 pagesWhat's in Your Backpackjohn ezekiel de asisNo ratings yet

- Project Charter.: Project Title:-A Google GlassesDocument3 pagesProject Charter.: Project Title:-A Google GlassesAliceNo ratings yet

- Natal Chart (Data Sheet) : Jul - Day 2442664.865117 TT, T 46.1 SecDocument1 pageNatal Chart (Data Sheet) : Jul - Day 2442664.865117 TT, T 46.1 SecДеан ВеселиновићNo ratings yet

- Lab Report Literature Review ExampleDocument5 pagesLab Report Literature Review ExampleafmzmqwdglhzexNo ratings yet

- DFX8 WebDocument2 pagesDFX8 Websamer8saifNo ratings yet

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Document23 pagesInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliNo ratings yet

- Energy and Buildings: F. AsdrubaliDocument9 pagesEnergy and Buildings: F. AsdrubaliBogdan BrieNo ratings yet

- C2-Forecasting Demand & SupplyDocument31 pagesC2-Forecasting Demand & SupplyPRITHIVI KUMAR A R 1522554No ratings yet

- Reading Comprehension Read The Article Below and Then Answer The Questions That FollowDocument4 pagesReading Comprehension Read The Article Below and Then Answer The Questions That Followjuan m isazaNo ratings yet

- Critical Thinking and EBPDocument31 pagesCritical Thinking and EBPEni SukmawatiNo ratings yet

- Media FillDocument13 pagesMedia FillraghuNo ratings yet

- Database Efficiency and TuningDocument22 pagesDatabase Efficiency and TuningJyothy SwaroopNo ratings yet

- Sekar KSP - Hypoglicemia Ec Tipe 2 DMDocument28 pagesSekar KSP - Hypoglicemia Ec Tipe 2 DMdianarahimmNo ratings yet

- Astm A 101Document3 pagesAstm A 101RECEP ÇETİNKAYANo ratings yet

- Experiment No.1. (Monograph)Document3 pagesExperiment No.1. (Monograph)ayeza.sarwar2021No ratings yet

- Deadlocks: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionDocument43 pagesDeadlocks: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionmigadNo ratings yet

- DOH Breast Cancer Guidelines FinalDocument123 pagesDOH Breast Cancer Guidelines Finalsupratimbiswas073380No ratings yet

- Project Charter and Stakeholder TemplateDocument15 pagesProject Charter and Stakeholder TemplateAtul PatilNo ratings yet

- Word 2016, Using Mail MergeDocument6 pagesWord 2016, Using Mail MergePelah Wowen DanielNo ratings yet

- Unit 7 Legal EthicalDocument22 pagesUnit 7 Legal Ethicalapi-462777064No ratings yet