Professional Documents

Culture Documents

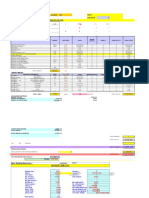

Transition Length Calculations

Uploaded by

Darshil ShahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transition Length Calculations

Uploaded by

Darshil ShahCopyright:

Available Formats

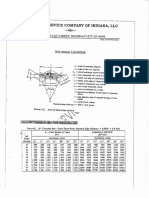

Useful Conveyor Design Data

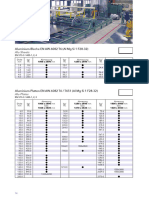

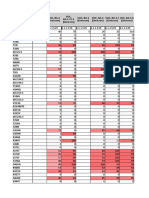

Transition Lengths

Table 1 indicates the recommended transition distance for half-troughed conveyor applications.

Table 2 indicates the recommended transition distance for full-troughed conveyor applications.

Table 3 indicates the number and location transition idlers.

Table 1 - Transition distance for half-trough depth.

TROUGH ANGLE (deg.) PERCENTAGE OF RATED TENSION FABRIC BELTS STEEL CABLE BELTS

MORE THAN 90 0,9w 2,0w

20 60 to 90 0,8w 1,6w

LESS THAN 60 0,6w 1,0w

MORE THAN 90 1,6w 3,4w

35 60 to 90 1,2w 2,6w

LESS THAN 60 0,9w 1,8w

MORE THAN 90 2,0w 4,0w

45 60 to 90 1,6w 3,2w

LESS THAN 60 1,2w 2,2w

Note:-

All conveyors using troughing idlers with angles greater than 20 adjacent to terminal pulleys shall have transition idlers between the given

terminal pulley and the nearest standard idler.

Table 2 - Transition distance for full-trough depth.

TROUGH ANGLE (deg.) PERCENTAGE OF RATED TENSION FABRIC BELTS STEEL CABLE BELTS

MORE THAN 90 1,8w 4,0w

20 60 to 90 1,6w 3,2w

LESS THAN 60 1,2w 2,0w

MORE THAN 90 3,2w 6,8w

35 60 to 90 2,4w 5,2w

LESS THAN 60 1,8w 3,6w

MORE THAN 90 4,0w 8,0w

45 60 to 90 3,2w 6,4w

LESS THAN 60 2,4w 4,4w

Note:-

All conveyors using troughing idlers with angles greater than 20 adjacent to terminal pulleys shall have transition idlers between the given

terminal pulley and the nearest standard idler.

Table 3 - Number and Location of transition idlers

NUMBER OF TRANSITION IDLERS FIRST SECOND THIRD FOURTH

1 0,33Y

2 0,17Y 0,50Y

3 0,10Y 0,30Y 0,60Y

4 0,07Y 0,20Y 0,40Y 0,67Y

You might also like

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Formed Metal - Round Bar UT2Document4 pagesFormed Metal - Round Bar UT2Siggy LaiNo ratings yet

- 12 - Determinations of Cut Off Vshale-Por-SwDocument26 pages12 - Determinations of Cut Off Vshale-Por-SwSyafrin Kultsum Naura AzzaNo ratings yet

- Costing Calculations:: Enquiry 588 (CS)Document10 pagesCosting Calculations:: Enquiry 588 (CS)Rakesh SharmaNo ratings yet

- Bus NumberDocument27 pagesBus NumberCristian GomezNo ratings yet

- Datasheet Highbay - 230328 - 152853Document3 pagesDatasheet Highbay - 230328 - 152853Ragin RamachandranNo ratings yet

- KN Calculation - Hull, Max STABILITY: Damage Case - IntactDocument1 pageKN Calculation - Hull, Max STABILITY: Damage Case - IntactSouravJenaNo ratings yet

- UL-142 Vertical Single-Wall IllustrationDocument1 pageUL-142 Vertical Single-Wall IllustrationRodrigoNo ratings yet

- Boq CabletrayDocument4 pagesBoq CabletrayLe HuyNo ratings yet

- SAE and ISO Viscosity ValuesDocument2 pagesSAE and ISO Viscosity ValuesadhyharmonypngNo ratings yet

- Format Barang Sendiri OSCARDocument3 pagesFormat Barang Sendiri OSCARHumaira RisandyNo ratings yet

- Jan 2022Document3 pagesJan 2022Dy Ju Arug ALNo ratings yet

- Nudo Coordenadas Barra Nudos L X Y N F F Pulg. Cos Q: Matriz de Rigidez BarraDocument4 pagesNudo Coordenadas Barra Nudos L X Y N F F Pulg. Cos Q: Matriz de Rigidez BarraAlex Pineda TinocoNo ratings yet

- Nudo Coordenadas Barra Nudos L X Y N F F Pulg. Cos Q: Matriz de Rigidez BarraDocument4 pagesNudo Coordenadas Barra Nudos L X Y N F F Pulg. Cos Q: Matriz de Rigidez BarraAlex Pineda TinocoNo ratings yet

- ExplotacionDocument2 pagesExplotacionKevin FernándezNo ratings yet

- K321-05041 A2 - Electrical Load AnalysisDocument4 pagesK321-05041 A2 - Electrical Load AnalysisJerome EugeneNo ratings yet

- Rpe 7139BDocument2 pagesRpe 7139BRADIOCOMUNICACIONES CAMPONo ratings yet

- FORA LED Flex High Power Flood Light Spec Sheet PDFDocument7 pagesFORA LED Flex High Power Flood Light Spec Sheet PDFRoberto AlladoNo ratings yet

- SPC Example 1Document5 pagesSPC Example 1christliu1024No ratings yet

- Wa0003Document1 pageWa0003Siphy MandlateNo ratings yet

- CDE (Radial Thru-Hole) 300-301 SeriesDocument11 pagesCDE (Radial Thru-Hole) 300-301 Seriesjghjkhgkh87No ratings yet

- Viscometer QuotationDocument2 pagesViscometer QuotationanushreechandakNo ratings yet

- ChromasterDocument18 pagesChromasterPrianurraufikachmadNo ratings yet

- Weight of Sample (GM) 11360: Sieve Size Weight PassingDocument17 pagesWeight of Sample (GM) 11360: Sieve Size Weight PassingMegdam Sameeh TarawnehNo ratings yet

- Examen ParcialDocument526 pagesExamen ParcialdarioNo ratings yet

- 2g-3g Sector Naming and Azimuth Analysis - Tanzania Network - 20120501Document10 pages2g-3g Sector Naming and Azimuth Analysis - Tanzania Network - 20120501ucsafmfukoNo ratings yet

- CANData For ToyotaDocument448 pagesCANData For ToyotajadsonsNo ratings yet

- Boy L PantDocument3 pagesBoy L PantHeny OllshopNo ratings yet

- ABU BATU ADOLANG OkDocument8 pagesABU BATU ADOLANG OkAbdullahNo ratings yet

- UntitledDocument18 pagesUntitledBrigitte Asenet Linares GarciaNo ratings yet

- Grua 14000Document6 pagesGrua 14000Miguel HernandezNo ratings yet

- Progress Works Pipe Hydrant: No Description Duration Quantity Unit Rate Total Amount Remarks (Day)Document2 pagesProgress Works Pipe Hydrant: No Description Duration Quantity Unit Rate Total Amount Remarks (Day)andhyirawanNo ratings yet

- Break Down Install ScaffoldingDocument2 pagesBreak Down Install ScaffoldingandhyirawanNo ratings yet

- Break Down WBL TANK REPAIR SHEEL 2020 Rev 3Document2 pagesBreak Down WBL TANK REPAIR SHEEL 2020 Rev 3andhyirawanNo ratings yet

- Biaya Vendor REPLACE DUCTING PLATE PARTIALLY OF Ducting IDF Going To Stack RBDocument3 pagesBiaya Vendor REPLACE DUCTING PLATE PARTIALLY OF Ducting IDF Going To Stack RBandhyirawanNo ratings yet

- First Year DrawingsDocument35 pagesFirst Year Drawingsapi-341200208No ratings yet

- Espectro Seudoaceleracion 3186Document4 pagesEspectro Seudoaceleracion 3186robinson simon villavaNo ratings yet

- TULI Linear Shafts and Ball Bushings 2021Document32 pagesTULI Linear Shafts and Ball Bushings 2021tranduc2058No ratings yet

- 3.sieve Analysis in Fine AggregateDocument1 page3.sieve Analysis in Fine AggregateLakshithaGonapinuwalaWithanageNo ratings yet

- Assignment QTDocument4 pagesAssignment QTmedhaNo ratings yet

- HP Catalog 6200 Series Power SuppliesDocument6 pagesHP Catalog 6200 Series Power SuppliesGregNo ratings yet

- With 21000 MAX-ER Swing and Travel Specifications: Manitowoc Cranes, IncDocument6 pagesWith 21000 MAX-ER Swing and Travel Specifications: Manitowoc Cranes, IncDavid FlemmingNo ratings yet

- HVLS Fan Performance at Industrial Shop-Graphic RepresentationDocument2 pagesHVLS Fan Performance at Industrial Shop-Graphic RepresentationSandeep AherNo ratings yet

- KN Calculation - Container Ship 4500teu: Damage Case - IntactDocument3 pagesKN Calculation - Container Ship 4500teu: Damage Case - IntactAdrian GilbyNo ratings yet

- San Ace 60A25 E PDFDocument3 pagesSan Ace 60A25 E PDFThi NguyễnNo ratings yet

- Bomba Bucher QXVDocument8 pagesBomba Bucher QXVمحمد متوليNo ratings yet

- Simulasi Modul 4Document4 pagesSimulasi Modul 4DMuhammad Yuar Wahyu MNo ratings yet

- SIP-Measurement Sheets-JhalawarDocument1,271 pagesSIP-Measurement Sheets-JhalawarPC Snehal Construction Pvt. Ltd. JhalawarNo ratings yet

- Second Order High Pass FilterDocument4 pagesSecond Order High Pass FilterPrasanna PaiNo ratings yet

- Wa0001Document1 pageWa0001Siphy MandlateNo ratings yet

- Madamme Roses S.A.S. Nit: 900.278.411-2 Invoice To Aca Trading IncDocument1 pageMadamme Roses S.A.S. Nit: 900.278.411-2 Invoice To Aca Trading Inckaren hurtadoNo ratings yet

- Pavement Materials: Module 2, Lecture 10 Aggregate Properties (Part 4)Document11 pagesPavement Materials: Module 2, Lecture 10 Aggregate Properties (Part 4)Rohit VasudevaNo ratings yet

- @ 60 Degc 100 WT % H2ODocument30 pages@ 60 Degc 100 WT % H2OMildoggNo ratings yet

- AMCO Lagerliste ENAW6082 Bleche PlattenDocument1 pageAMCO Lagerliste ENAW6082 Bleche PlattenReza PramataNo ratings yet

- San Ace 60A25 E-1283912 PDFDocument4 pagesSan Ace 60A25 E-1283912 PDFThi NguyễnNo ratings yet

- FefregDocument1 pageFefregarunNo ratings yet

- LHM 550 TerraDocument2 pagesLHM 550 Terralof29092017No ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- Tabelle VOC PCR FinderDocument30 pagesTabelle VOC PCR Findertama catNo ratings yet

- Simple AISC 2D Frame SkyCiv ReportDocument8 pagesSimple AISC 2D Frame SkyCiv ReportDarshil ShahNo ratings yet

- 215TR Series Shaft Mounted Gear DriveDocument2 pages215TR Series Shaft Mounted Gear DriveDarshil ShahNo ratings yet

- Beam GuruDocument27 pagesBeam GuruDarshil ShahNo ratings yet

- Belt Carrying Capacity TableDocument1 pageBelt Carrying Capacity TableDarshil ShahNo ratings yet

- Kathmandu Engineering College: Department of ArchitectureDocument1 pageKathmandu Engineering College: Department of ArchitectureSumee ShresthaNo ratings yet

- Part 7 SteelDocument14 pagesPart 7 SteelJaime Alberto Flores PeñaNo ratings yet

- Monitoring Alat November 2022-2Document4 pagesMonitoring Alat November 2022-2Candra KartikaNo ratings yet

- Workshop-1 (Time & Work, Pipes & Cistern)Document4 pagesWorkshop-1 (Time & Work, Pipes & Cistern)ishika SharmaNo ratings yet

- ESTIMATION SPECIFICATIONS & CONTRACTS Sept 2020Document8 pagesESTIMATION SPECIFICATIONS & CONTRACTS Sept 2020Pothula SateeshNo ratings yet

- CV of Mahmood Ahmad 2022-1Document2 pagesCV of Mahmood Ahmad 2022-1Sahar RamzanNo ratings yet

- Checklist For Utility - Drainage, Fire and Electic DuctDocument2 pagesChecklist For Utility - Drainage, Fire and Electic DuctMridul HasanNo ratings yet

- 111 Slab Culvert Latest ProgressDocument104 pages111 Slab Culvert Latest ProgressSudip ShresthaNo ratings yet

- Watermark Structural Specification - Rev 02 EnglishDocument76 pagesWatermark Structural Specification - Rev 02 Englishloc khaNo ratings yet

- Cec 103 Workshop Technology 1 FT ExamDocument7 pagesCec 103 Workshop Technology 1 FT ExamIsrael Adegboyega100% (1)

- 3.6 Connection DrawingsDocument4 pages3.6 Connection DrawingsDurgeshwar TheenaNo ratings yet

- Reflection On Merdeka Tower - Fatima ShahidDocument2 pagesReflection On Merdeka Tower - Fatima ShahidFatima ShahidNo ratings yet

- Mega Project: Road Construction Division, FaisalabadDocument11 pagesMega Project: Road Construction Division, FaisalabadInfo TapeNo ratings yet

- Flakiness Index of Coarse Aggregate: Test DataDocument2 pagesFlakiness Index of Coarse Aggregate: Test DataRuwan Sampath WickramathilakaNo ratings yet

- Module 1 History of Civil Engineering-2Document6 pagesModule 1 History of Civil Engineering-2Adrian De GuzmanNo ratings yet

- Cec 315 Assignment IbehDocument2 pagesCec 315 Assignment IbehOji IfeanyiNo ratings yet

- Resumen GeneralDocument77 pagesResumen GeneralJanice SaenzNo ratings yet

- Manpower RequirementsDocument12 pagesManpower Requirementslinga2014No ratings yet

- RESUMEDocument2 pagesRESUMEElena CastroNo ratings yet

- Replacement of fm1 Mill, Trunions, and LinersDocument1 pageReplacement of fm1 Mill, Trunions, and Linerspinion gearNo ratings yet

- Fourth-Year-Civil-Engineering-Schedul - UpdatedDocument1 pageFourth-Year-Civil-Engineering-Schedul - UpdatedCharlene SisonNo ratings yet

- Fire Extinguisher Inspection 01Document1 pageFire Extinguisher Inspection 01PRIYESH . K. PRIYANNo ratings yet

- Mohammed Nasih Civil Engineer CVDocument3 pagesMohammed Nasih Civil Engineer CVMohammed Nasih VettathurNo ratings yet

- Avina Floor PlanDocument1 pageAvina Floor PlanCabal CabalierNo ratings yet

- Brochure - AJIYA Roofing SheetDocument2 pagesBrochure - AJIYA Roofing SheetAnonymous fE2l3DzlNo ratings yet

- Fly Ash 1Document9 pagesFly Ash 1Az AbqariNo ratings yet

- Brosur Box Culvert HD Custom DesignDocument1 pageBrosur Box Culvert HD Custom DesignDavid SiburianNo ratings yet

- Inspection Checklist (Icl) : Soil Protection and Control, Drainage and De-Watering Inspection CivilDocument3 pagesInspection Checklist (Icl) : Soil Protection and Control, Drainage and De-Watering Inspection Civilasif aziz khanNo ratings yet

- ACT - Assignments AllDocument4 pagesACT - Assignments AllKartik PandyaNo ratings yet

- Civ100-All Assignment Questions-RevisedDocument22 pagesCiv100-All Assignment Questions-RevisedgpacebonelloNo ratings yet