Professional Documents

Culture Documents

INVISTA U5101 PA66 Technical Data Sheet

Uploaded by

WARRAPONG THUNYAMANUKUL0 ratings0% found this document useful (0 votes)

100 views2 pagesData sheet PA66

Original Title

INVISTA U5101 PA66 technical data sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentData sheet PA66

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

100 views2 pagesINVISTA U5101 PA66 Technical Data Sheet

Uploaded by

WARRAPONG THUNYAMANUKULData sheet PA66

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

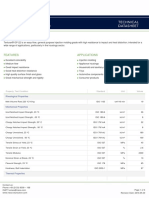

PRODUCT INFORMATION

INVISTA U5101

PA66 Resin

Product Description

INVISTA U5101 NC01 is a natural PA66 resin suitable for compounding, injection molding, and extrusion

applications where ease of processing, good color, and physical property retention are desired.

Properties (dry) Value Units Method

VISCOSITY

RV in formic acid, nominal 51 –– ASTM D789

VN at 0.5% in sulfuric acid, nominal 155 mL/g ISO 307

RV at 1% in sulfuric acid, nominal 2.8 –– ––

Density 1.14 g/cm3 ISO 1183

Mold Shrinkage, 2.0 mm, Parallel 1.6 % ISO 294-4

PHYSICAL

Mold Shrinkage, 2.0 mm, Transverse 1.9 % ISO 294-4

Water Absorption - 24 hours 1.6 % ISO 62

Water Absorption - Equilibrium @ 50% RH 2.6 % ISO 62

Tensile Strength at Yield 80 MPa ISO 527

Elongation at Yield 3.8 % ISO 527

Elongation at Break 30 % ISO 527

Tensile Modulus 2850 MPa ISO 527

MECHANICAL

Flexural Modulus 2900 MPa ISO 178

Flexural Strength 92 MPa ISO 178

Notched Charpy at 23°C 4.7 kJ/m2 ISO 179

Notched Charpy at -30°C 4.1 kJ/m2 ISO 179

Unnotched Charpy at 23°C NB kJ/m2 ISO 179

Unnotched Charpy at -30°C NB kJ/m2 ISO 179

Notched Izod at 23°C 4.8 kJ/m2 ISO 180

Melting Temperature, 10°C/min 262 °C ISO 11357

THERMAL

HDT at 0.45 MPa 207 °C ISO 75

HDT at 1.80 MPa 65 °C ISO 75

nylonpolymer.invista.com Issue date: April 2021

General Information Process Guidelines for Molding

Material Status Drying temperature 80 °C

Commercial: Active

Drying time* 6 - 10 hours

Availability Barrel temperatures

• North America Rear 250 - 270 °C

• South America Middle 270 - 290 °C

• Europe Front 270 - 290 °C

• Asia Nozzle 270 - 290 °C

Features Processing temperature (melt) 280 - 295 °C

• Good whiteness Mold temperature 50 - 90 °C

• Moderate-low viscosity Back pressure** 2 - 10 bar

RoHS Vent depth 0.007 - 0.04 mm

No intentional additives or ingredients used in Cushion (range) 4 - 6 mm

U5101 are among those in the European directive

Suggested moisture (max) 0.20 wt%

2011/65/EC (RoHs), as amended.

Suggested moisture (min) 0.10 wt%

Screw speed 75 - 180 rpm

* Initial moisture below 0.4 wt%. Use dehumidified air.

** Melt pressure

Product Data Sheet Disclaimer

This Product Data Sheet relates only to the identified product and any identified uses. It is based on information available as of April 2021. Additional information may be needed to evaluate

other uses of the product, including use of the product in combination with any materials or in any processes other than those specifically referenced. THIS PRODUCT DATA SHEET DOES NOT

CONTAIN A COMPLETE STATEMENT OF, AND DOES NOT CONSTITUTE A REPRESENTATION, WARRANTY OR GUARANTY WITH REGARD TO, A PRODUCT’S CHARACTERISTICS, USES, QUALITY,

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR THE SUITABILITY, SAFETY, EFFICACY, HAZARDS OR HEALTH EFFECTS OF THE PRODUCT, WHETHER USED SINGULARLY OR IN

COMBINATION WITH ANY OTHER PRODUCT, EXCEPT TO THE EXTENT REQUIRED BY THE RELEVANT LAW AND REGULATIONS. Nothing contained in this Product Data Sheet shall be construed to

modify any of the terms under which the product was sold by INVISTA. INVISTA and design are trademarks of INVISTA. ©2021 INVISTA.

www.nylonpolymer.INVISTA.com

nylonpolymer.invista.com Issue date: April 2021

You might also like

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Torzen® U4820lDocument1 pageTorzen® U4820lDiegoTierradentroNo ratings yet

- Eurotec® Tecomid® NA40 MR15 NL IL PA6.6, 15% Mineral Filled, Impact Modified, NaturalDocument1 pageEurotec® Tecomid® NA40 MR15 NL IL PA6.6, 15% Mineral Filled, Impact Modified, NaturalmuthuNo ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- Injection Molding Resins Brochure May 2017Document2 pagesInjection Molding Resins Brochure May 2017Lucas Valentim MendesNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- 300.056 Magnum 3416 SCDocument3 pages300.056 Magnum 3416 SCEnrique ChavezNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- 300.002 Abs3416naDocument3 pages300.002 Abs3416naEnriqueNo ratings yet

- Product PDF 102737Document5 pagesProduct PDF 102737vaibhav ShindeNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- L-QB 300 Heat Transfer OilDocument3 pagesL-QB 300 Heat Transfer OilYoong TanNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Tpo 0030 RTP 4920 1620 Uv IsoDocument2 pagesTpo 0030 RTP 4920 1620 Uv IsoVenkata ChadaNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Celstran® PA66-GF50-07Document1 pageCelstran® PA66-GF50-07Ankur PanwarNo ratings yet

- 2186 - Pc-Abs Pulse gx70Document3 pages2186 - Pc-Abs Pulse gx70mikeburnsthrowaccNo ratings yet

- Pulse GX50Document3 pagesPulse GX50Daniel Lack PendásNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- Abs Absolac 300Document2 pagesAbs Absolac 300ShrikantNo ratings yet

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SNo ratings yet

- TDS BorSafe ME3444 (E115026)Document2 pagesTDS BorSafe ME3444 (E115026)charlesNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- INVISTA U4630HSL PA66 Technical Data Sheetv2Document2 pagesINVISTA U4630HSL PA66 Technical Data Sheetv2Lucas Valentim MendesNo ratings yet

- TDS e 006Document2 pagesTDS e 006Paolo VelasquezNo ratings yet

- BioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection MoldingDocument1 pageBioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection Moldingpaolo.pradaNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 pageGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Econamid FL 6B30Document2 pagesEconamid FL 6B30Jagadeesh WaranNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Polyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)Document3 pagesPolyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)cir74636No ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- Styrolution PS 576H HIPSDocument3 pagesStyrolution PS 576H HIPSKevin AlvaradoNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- Technyl - A 218GV30 Natural - J20005Document6 pagesTechnyl - A 218GV30 Natural - J20005Leandro LacerdaNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- PC-ABS Bayblend FR3010Document4 pagesPC-ABS Bayblend FR3010countzeroaslNo ratings yet

- PA 6.6 Nylon 6.6Document2 pagesPA 6.6 Nylon 6.6Naeem KhanNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Absolac 300 Ineos AbsDocument2 pagesAbsolac 300 Ineos Absadrian4santanaNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- Sahara C 070baDocument2 pagesSahara C 070baNaren RawatNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Styron ATECH 1175 DatasheetDocument3 pagesStyron ATECH 1175 DatasheetbobNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Pet-G - UkDocument1 pagePet-G - UkamilcarbrrNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Astm 264 For Stainless Ateal CladDocument6 pagesAstm 264 For Stainless Ateal Cladsuraj kumarNo ratings yet

- Archive of SIDDocument9 pagesArchive of SIDFarhan RamadhanNo ratings yet

- Chemistry Air & Atmosphere Syllabus NotesDocument4 pagesChemistry Air & Atmosphere Syllabus NotesDavid Sutanto100% (6)

- 2013 02 DNT 044 LIDA RodDocument2 pages2013 02 DNT 044 LIDA RodKeny AnchanteNo ratings yet

- A New Nitration Product, 3-Nitro-4-Acetamidophenol, Obtained From Acetaminophen With Nitrous AcidDocument2 pagesA New Nitration Product, 3-Nitro-4-Acetamidophenol, Obtained From Acetaminophen With Nitrous AcidxcvNo ratings yet

- Section 3: Naming Compounds: Chapter 5: Molecules and CompoundsDocument21 pagesSection 3: Naming Compounds: Chapter 5: Molecules and CompoundsCheri BulahanNo ratings yet

- SikaWrap 231 C PDS PDFDocument4 pagesSikaWrap 231 C PDS PDFMohit KohliNo ratings yet

- Deuterated MoleculesDocument15 pagesDeuterated MoleculesRocío ConsueloNo ratings yet

- S 614v18 12Document66 pagesS 614v18 12Spyros Dimakis100% (1)

- Toxi Exp 10 ReviewerDocument2 pagesToxi Exp 10 ReviewerHannah Francesca PinedaNo ratings yet

- J Chroma 2017 05 035Document21 pagesJ Chroma 2017 05 035Fina Mustika SimanjuntakNo ratings yet

- E 697 - 96 Rty5ny05ngDocument13 pagesE 697 - 96 Rty5ny05ngBelazouz BoualemNo ratings yet

- Exp 2Document13 pagesExp 2Jasmine NguNo ratings yet

- STPM Trials 2009 Chemistry Paper 2 (Malacca)Document19 pagesSTPM Trials 2009 Chemistry Paper 2 (Malacca)sherry_christyNo ratings yet

- Thermostatic Control ValveDocument10 pagesThermostatic Control ValveAbu Yussif AlaboodiNo ratings yet

- Photomer 6210 SDS USDocument11 pagesPhotomer 6210 SDS USPrabhakar RamachandranNo ratings yet

- GMW14872 - Cyclic Corrosion Laboratory TestDocument22 pagesGMW14872 - Cyclic Corrosion Laboratory TestZAPSENo ratings yet

- E7215 2 11 16 - WHC KatalogversionDocument4 pagesE7215 2 11 16 - WHC KatalogversionQuy HoangNo ratings yet

- Anacardium Occidentale 5Document7 pagesAnacardium Occidentale 5Jesus Llorente MendozaNo ratings yet

- HVACDocument248 pagesHVACvictorinox dlcbNo ratings yet

- Lab 3: Solubility of Organic Compounds: ObjectivesDocument12 pagesLab 3: Solubility of Organic Compounds: ObjectivesJAN CAMILLE OLIVARESNo ratings yet

- Notes On Molecular Basis of Inheritance by ExamsRoadDocument8 pagesNotes On Molecular Basis of Inheritance by ExamsRoadVogolus machatteNo ratings yet

- SOP For Operating Procedure of Fogster - ULV Fogger Machine - PharmaguidelineDocument2 pagesSOP For Operating Procedure of Fogster - ULV Fogger Machine - PharmaguidelineMedicare Hygiene LimitedNo ratings yet

- FA - BiochemistryDocument62 pagesFA - BiochemistryMargaret GraceNo ratings yet

- Jurnal Markus Tanpa NamaDocument8 pagesJurnal Markus Tanpa NamaMarkus Koko Nur BudiantoNo ratings yet

- Presentation On DM PlantDocument16 pagesPresentation On DM PlantVenkat Dora100% (4)

- Osmosis Beaker KeyDocument2 pagesOsmosis Beaker Keyapi-26466818259% (44)

- O. Regulacion 558-00Document56 pagesO. Regulacion 558-00bernal saavedraNo ratings yet

- SSC CGL Model Paper - 17 Solution PDFDocument7 pagesSSC CGL Model Paper - 17 Solution PDFsandeep kumarNo ratings yet

- Company Profile Jai Baba Steel PVT LTDDocument14 pagesCompany Profile Jai Baba Steel PVT LTDShubham AgrawalNo ratings yet