Professional Documents

Culture Documents

Manual de Operación y Mantenimiento 994 F

Uploaded by

Sujeiry RodriguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual de Operación y Mantenimiento 994 F

Uploaded by

Sujeiry RodriguezCopyright:

Available Formats

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Bienvenido: acaruajulca

Producto: NO SE HA ESCOGIDO NINGUN EQUIPO

Modelo: NO SE HA ESCOGIDO NINGUN EQUIPO

Configuración: NO SE HA ESCOGIDO NINGUN EQUIPO

Manual de Operación y Mantenimiento

994F Wheel Loader

Número de medio -SEBU7885-14 Fecha de publicación -01/07/2013 Fecha de actualización -01/07/2013

i04020405

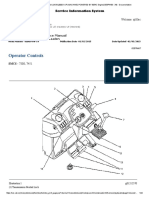

Operator Controls

SMCS - 7300; 7301; 7451

Note: Your machine may not be equipped with all of the controls that are discussed in this topic.

The operation section is a reference for the new operator and a refresher for the experienced operator. This

section includes descriptions of gauges, switches, machine controls, attachment controls, transportation, and

towing information.

Illustrations guide the operator through correct procedures of checking, starting, operating, and stopping the

machine. Operating techniques that are outlined in this publication are basic. Skill and techniques develop as

the operator gains knowledge of the machine and the capabilities of the machine.

1 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Illustration 1 g01134909

(1) Parking Brake Knob

(2) Left Brake Pedal and Impeller Clutch

(3) Right Brake Pedal

(4) Throttle Control

(5) STIC Control Lock

(6) STIC Steering Control

(7) Upshift Switch

(8) Downshift Switch

(9) Direction Control Switch

(10) Steering Console Adjustment

(11) Implement Console Adjustment Lever

(12) Implement Lockout Control

(13) Tilt Control

2 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

(14) Lift Control

(15) Set/Decel switch

(16) Resume/Accel switch

(17) Horn

(18) Store Button

(19) Armrest Adjustment Knobs

Illustration 2 g02175913

Right Side Instrument Panel

(20) Front window wiper switch

(21) Rear window wiper switch

(22) Heating and air conditioning switch

(23) Torque converter lockup switch

(24) Cigar lighter

(25) Front floodlight switch

(26) Beacon switch

(27) Rear floodlight switch

(28) Keypad for Payload Control System (PCS)

(29) Reduced rimpull selection switch

(30) Diagnostic connector

(31) 12 V power supply

(32) High intensity discharge lamp (HID) switch

(33) Stairway access light switch

(34) Running light switch

(35) Kickout set switch

3 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

(36) Throttle lock switch

(37) Starting aid switch

(38) Temperature control

(39) Quarter panel window wiper

(40) Engine start switch

Illustration 3 g01158334

Left side bumper

(41) Fuel Shutoff Switch

(42) Engine Enclosure Floodlight

(43) Stairway Access Light Switch

(44) Service Port and Service Switch

(45) Service Hour Meter

(46) Starter Lockout Switch

(47) Transmission Lockout Switch

4 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Illustration 4 g01158838

(48) Interior dome light

The following information briefly identifies the components of the cab.

Parking Brake (1)

Parking Brake - Engage the parking brake

after the machine has been stopped. Use the

parking brake if the service brakes fail to

stop the machine.

Pull the knob outward in order to apply the parking brake. Push the knob inward in order to release the

parking brake.

Left Brake Pedal and Impeller Clutch (2)

The left brake pedal controls both the brake pressure and the impeller clutch pressure. Partially depress the

left brake pedal in order to reduce the impeller clutch pressure. The brake pressure is increased as the

operator pushes down the pedal farther. This feature allows the operator to control the maximum drive train

torque. Lowering the maximum drive train torque supplies more engine power to the implements and to the

steering.

When the operator is digging, the left brake pedal can be used to stop any excessive tire slip.

Note: Calibration of the left brake pedal is necessary in order to compensate for normal mechanical wear.

ReferenceRefer to Systems Operation/Testing and Adjusting, SENR1372, "Transmission Electronic Control

System" for information about calibrating the left brake pedal.

Right Brake Pedal (3)

The right brake pedal decelerates the machine. Depress the brake pedal for normal braking of the machine.

Release the pedal in order to release the brake.

5 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Throttle Control (4)

The throttle control is mounted on the floor of the operator compartment. Depress the throttle control in order

to increase the engine speed. Release the throttle control in order to decrease the engine speed.

STIC Control Lock (5)

Move the lock lever to the left and to the rear in order to lock the STIC steering and transmission controls.

Return the lock lever to the original position in order to unlock the STIC steering and transmission controls.

STIC Steering Control (6)

Note: The steering frame lock must be in the unlocked position in order to steer the machine.

Left Turn - Move the STIC

steering control to the left in order

to steer the machine to the left.

Moving the STIC steering control

farther to the left will cause the

machine to turn more quickly to

the left.

Right Turn - Move the STIC

steering control to the right in

order to steer the machine to the

right. Moving the STIC steering

control farther to the right will

cause the machine to turn more

quickly to the right.

Note: When you release the STIC steering control, the control will return to the center position. However,

the machine will maintain the current travel direction.

Upshift Switch (7)

Push the upshift switch in order to shift the machine into the next highest speed. The active speed range will

be shown on the speedometer.

"1" indicates First Speed.

"2" indicates Second Speed.

"3" indicates Third Speed.

Downshift Switch (8)

Push the downshift switch in order to shift the machine into the next lowest speed. The active speed range

will be shown on the speedometer.

Note: When the parking brake is engaged, the machine can only be shifted into second speed or into third

speed.

6 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Direction Control Switch (9)

The direction control switch for the STIC system is located on the steering control lever.

FORWARD - Move the bottom of trigger switch (9) to "F". This action will enable the machine to move in a

forward direction. "F" will be displayed on the speedometer.

NEUTRAL - Move the trigger switch to the MIDDLE position that is indicated by "N". This action will

disengage the transmission. "N" will be displayed on the speedometer.

REVERSE - Move the top of the trigger switch to "R". This action will enable the machine to move in a

reverse direction. "R" will be displayed on the speedometer.

Steering Console Adjustment (10)

Push the lever downward in order to slide the console forward or backward. Release the lever in order to lock

the console into position.

Implement Console Adjustment Lever (11)

Push the lever downward in order to slide the console forward or backward. Release the lever in order to lock

the console into position.

Implement Lockout Control (12)

Pull up the hydraulic lever lock in order to lock the implement control levers in position. Push down the

hydraulic lever lock in order to unlock the implement control levers.

Tilt Control (13)

Note: Do not use any lubricants on any part of the implement controls. The moving parts are self-lubricating.

Refer to Operation and Maintenance Manual, "Bucket Lift Control and Bucket Tilt Control - Clean" for the

maintenance procedure for the implement controls.

DUMP - Push the control lever

forward in order to dump a load

from the bucket.

HOLD - Release the control lever.

The bucket will remain in the

selected position.

TILT BACK - Pull the control

7 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

lever backward in order to tilt back

the bucket.

The control lever is detented in the full TILT BACK position. The control lever will stay detented and the

bucket will continue to tilt back until the bucket reaches the preset digging angle (bucket kickout position).

Then, the control lever returns to the HOLD position.

Note: The bucket rack back stops protect the tilt cylinders when the bucket is in the bank and when the

bucket is tilted back. The stops are designed to stay in contact with the lift arms when the lift arms are down

and the bucket is racked back. The stops will stay in contact with the lift arms until the bottom of the bucket

is approximately 2.1 m (6.89 ft) to 2.4 m (7.88 ft) off the ground. When the bucket is approximately 2.1 m

(6.89 ft) to 2.4 m (7.88 ft) off the ground, the bucket should not be in contact with material in the bank.

NOTICE

If the bucket is in contact with the bank and the rack back stops are

not contacting the lift arms, the tilt cylinder can be easily damaged by

over extending them.

ReferenceRefer to Service Magazine, SEPD0411, "Bucket Stops Provide Additional Protection For Tilt

Cylinder" for the service information.

Lift Control (14)

Note: Do not use any lubricants on any part of the implement controls. The moving parts are self-lubricating.

ReferenceRefer to Operation and Maintenance Manual, "Bucket Lift Control and Bucket Tilt Control -

Clean" for the maintenance procedure for the implement controls.

FLOAT - Push the control lever

forward into the detent. The bucket

will lower to the ground. The

bucket will float with the contour

of the ground.

The control lever will remain in the FLOAT position until the control lever is pulled out of the detent. The

control lever will return to the HOLD position when the control lever is released.

NOTICE

NEVER use FLOAT position to lower a loaded bucket.

Machine damage can result from bucket falling too fast.

8 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

LOWER - Push the control lever

forward in order to lower the

bucket. The control lever will

return to the HOLD position when

the control lever is released.

HOLD - The control lever will

return to the HOLD position when

the control lever is released from

the RAISE position or from the

LOWER position. The bucket will

remain in the selected position.

RAISE - Pull the control lever

backward in order to raise the

bucket. Release the control lever in

order to stop lifting the bucket. The

control lever will return to the

HOLD position when the control

lever is released.

The control lever is detented in the fully raised position. Until the lift kickout height is set, the control lever

is not detented. The control lever will stay in the detent and the bucket will continue to rise until the bucket

reaches the lift kickout height. Once the bucket reaches this height, the machine will perform a lower kickout

automatically. If the lever is not detented, the machine will not perform an automatic kickout.

Set/Decel Switch (15)

Set/Decel - Refer to Operation and

Maintenance Manual , "Throttle Lock

Switch (37)" for instructions on using the

Set/Decel switch.

Resume/Accel Switch (16)

Resume/Accel - Refer to Operation and

Maintenance Manual , "Throttle Lock

Switch (37)" for instructions on using the

Resume/Accel switch.

Horn (17)

Horn - Press the horn button in order to

activate the horn.

9 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Store Button (18)

The "STORE" key is used with the payload control system. Use the "STORE" key to store payload data. Use

the "STORE" key to make a selection from a menu. Use the "STORE" key to enter a number.

ReferenceSee this Operation and Maintenance Manual, "Payload Control System (PCS)" for information

about this switch.

Armrest Adjustment Knobs (19)

Turn the knobs counterclockwise in order to loosen the armrest. Pull up on the armrest in order to adjust to

the desired height. Turn the knobs counterclockwise in order to tighten the armrest at the desired height.

Front Window Wiper Switch (20)

Front Window Wiper and Window

Washer - Turn the knob clockwise in order

to turn on the intermittent wiper. Two

speeds are available. Push the knob in order

to activate the window washer. Spring force

will return the knob when the knob is

released.

Rear Window Wiper Switch (21)

Rear Window Wiper and Window

Washer - Turn the knob clockwise in order

to turn on the window wiper. Push the knob

in order to activate the window washer.

Spring force will return the knob when the

knob is released.

Heating and Air Conditioning Switch (22)

Fan Control

Heating and Air Conditioning Switch -

This switch controls the three-speed

heater/air conditioner fan.

OFF - Move the switch to this position in

order to stop the blower fan.

Move the switch clockwise in order to operate the heating system. Move the switch counterclockwise in

order to operate the air conditioning system.

Low Speed - Move the switch to this

10 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

symbol for the lowest fan speed.

Medium Speed - Move the switch to this

symbol for a medium fan speed.

High Speed - Move the switch to this

symbol for the highest fan speed.

Torque Converter Lockup Switch (23)

Torque Converter Lockup Clutch - This

feature allows the operator to engage the

lockup clutch, which prevents the torque

converter from operating. This switch

makes the power train direct drive. Push the

top of the switch in order to enable the

torque converter lockup clutch. When the

lockup clutch is enabled, the transmission

electronic control module (ECM) causes the

engagement of the lockup clutch.

This feature provides more efficient operation for high speeds and for carrying loads. The feature is available

in all speeds and directions except first speed forward for the 994F Wheel Loader.

Cigar Lighter (24)

Lighter - Push the lighter inward and

release the lighter. The lighter will move

outward slightly when the lighter is ready

for use.

NOTICE

The lighter outlet is part of a 24 volt circuit. Do not use this outlet to

operate 12 volt electrical components. Use of the lighter outlet to

operate 12 volt electrical components may result in damage to the

component and/or to the machine electrical system.

Rear Floodlight Switch (25)

Floodlights - Push the switch in order to set

the switch to the middle position. In the

11 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

middle position, the outer high intensity

discharge lamp (HID) that face forward are

on. Push the switch in order to set the

switch to the top position. In the top

position, all four HID lamps are on.

Beacon Switch (26)

Beacon Switch - Push the top of the switch

in order to turn on the beacon.

Floodlight Switch (27)

Floodlight - Push the switch in order to set

the switch to the middle position. In the

middle position, the rear HID lights are on.

Push the switch in order to set the switch to

the top position. In the top position, the

outside pair of rear facing ROPS lights are

on.

Keypad for Payload Control System (PCS) (28)

ReferenceFor information about the keypad for the PCS, refer to this Operation and Maintenance Manual,

"Payload Control System (PCS)".

Reduced Rimpull Selection Switch (29)

The reduced rimpull selection switch reduces the potential for wheel slippage without reducing the hydraulic

efficiency. The reduced rimpull selection switch is a four-position switch. Each setting corresponds to a

maximum allowable percentage of maximum rimpull.

ReferenceTo change the maximum allowable percentages for each setting of the rimpull selection switch,

refer to Testing and Adjusting, RENR6252, "Power Train ".

12 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Illustration 5 g00948240

Operating With Reduced Rimpull

In order to select a reduced rimpull setting, move the reduced rimpull selection switch to the desired setting.

If the machine is in first speed forward, the reduced rimpull selection switch will provide an impeller clutch

pressure which limits the rimpull to the desired level when the pedal is fully released.

Depressing the brake pedal will further reduce rimpull from the selected percentage. The rimpull that is

commanded by the fully released pedal will equal the reduced rimpull that is selected on the reduced rimpull

selection switch.

When a lower rimpull is selected, pedal travel will result in a more gradual decrease in rimpull.

If the machine is not in first speed forward, the impeller clutch pressure will remain at the maximum level

until the transmission is placed into first speed.

Returning to Maximum Rimpull

The reduced rimpull selection switch will continue to limit rimpull until the transmission is shifted out of

first speed. This reduction also continues until the reduced or maximum rimpull switch is placed in the

MAXIMUM position.

Diagnostic Connector (30)

The diagnostic connector is for the connection of service tools.

12 Volt Power Supply (31)

Power Receptacle (12 V) - This machine has a 12 V electrical outlet receptacle. This outlet supplies power

for auxiliary uses. Remove the cap before you use the outlet.

HID Floodlight Switch (32)

13 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

HID Floodlight switch - Push the top of

the switch in order to turn on the pair of

HID lamps that face reward. These HID

lamps are attached to the ROPS.

Stairway Access Light Switch (33)

Stairway Access Lights - Push the switch

in order to set the switch to the middle

position. In the middle position, the front

lights that face the bucket are on. Push the

switch in order to set the switch to the top

position. In the top position, all four front

ROPS floodlights are on and the lights on

the platform are on.

Note: An external switch for the stairway access lights (49) is located in the bumper on the left side of the

machine.

Running Light Switch (34)

Running Lights - Push the top of the

switch in order to turn on the running

lights. Move the switch to the center

position in order to turn on the panel lights.

The center position also turns on the rocker

switches that are equipped with indicator

lights. Push the bottom of the switch in

order to turn off the running lights.

Kickout Set Switch (35)

Lift Kickout Position and Lower

Kickout Position - To set the lift kickout,

raise the bucket to the desired position

above the midway point. Then depress the

bottom of the kickout set switch. The boom

will return to the programmed position

when the raise detent is activated and the

boom is below the kickout position.

To set the lower kickout, lower the bucket to the desired position below the midway point. Then depress the

bottom of the kickout set switch. The boom will return to the programmed position when the float detent is

activated. The boom must be at least a foot above the kickout position.

Note: If the boom is a foot or less above the lower kickout position, placing the lift control lever in the float

detent will cause the bucket to float. The bucket will hit the ground.

Bucket Kickout Position - To set the

bucket kickout position, tilt the bucket to

14 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

the desired digging angle and depress the

top of the kickout set switch. The bucket

will return to the programmed position

when the tilt control lever is placed in the

tilt back detent and the bucket is dumped

beyond the kickout.

Throttle Lock Switch (36)

Throttle Lock Switch - The throttle lock

switch is located on the right side of the

cab. Engage the switch in order to keep the

engine at the current rpm. When the throttle

lock is active, an indicator light will

illuminate on the front dash. Use the throttle

lock control on long hauls in order to avoid

driver fatigue. Fatigue may result from

depressing the throttle control for an

extended period.

On - Push the top of the switch in order to engage the throttle lock control.

Off - To release the throttle lock control, push the bottom of the switch or slightly depress the right brake

pedal.

Setting the Throttle Lock

The throttle lock can be set for a desired rpm.

1. Push the top of the on/off switch in order to turn on the throttle lock.

2. The indicator light for the throttle lock will illuminate when the on/off switch is in the ON position.

Refer to this Operation and Maintenance Manual, "Monitoring System" for the location of the

indicator light.

3. Depress the throttle control in order to achieve the desired engine rpm.

4. Depress "Set/Decel" switch (16) in order to set the throttle.

Canceling the Throttle Setting

The throttle setting may be canceled by depressing the right brake pedal or by moving the on/off switch to

the OFF position.

When the right brake pedal is used to cancel a throttle setting, press "Resume/Accel" switch (17) in order to

resume the throttle setting.

Accelerate or Decelerate

In order to accelerate to a higher rpm, continue pressing the Resume/Accel switch. Once the switch is

released, the previous setting will resume.

In order to decelerate to a lower rpm, continue pressing the Set/Decel switch. Once the switch is released, the

15 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

previous setting will resume.

Ether Starting Aid Switch (37)

Ether Starting Aid - Ether will

automatically be injected into the air intake

if the ambient temperature calls for starting

aid. Pressing the switch allows the operator

to inject an additional premeasured amount

of ether, if necessary.

ReferenceFor more information about using ether starting aid for cold starting purposes, refer to Operation

and Maintenance Manual, "Engine Starting with Ether Starting Aid".

Temperature Control (38)

Setting the Temperature - Turn the knob

clockwise for warmer air. Turn the knob

counterclockwise for cooler air.

The heating and air conditioning system can be used for four functions:

Heating - Turn fan control switch (23)

clockwise to the desired speed. Adjust the

temperature control for the desired

temperature.

Cooling - Turn fan control switch (23)

counterclockwise to the desired speed.

Adjust the temperature control for the

desired temperature.

Pressurizing - Pressure inside the cab will help keep out dust. Close the door and the windows in order to

keep pressure in the cab.

Defogging - Turn fan control switch (23) counterclockwise in order to turn on the air conditioner. This action

will prevent moisture from forming on the windows. The volume of air that is needed to remove moisture

from the cab varies according to the speed of the fan. Adjust the temperature control so that the windows

remain free of moisture.

Quarter Panel Window Wiper Switch (39)

Quarter Panel Window Wiper and

Washer - Turn the knob clockwise in order

to turn on the window wiper. Push the knob

in order to activate the window washer.

Spring force will return the knob when the

knob is released.

Engine Start Switch (40)

16 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

OFF - When you insert the key and when

you remove the key, the engine start switch

must be in the OFF position. Turn the

engine start switch to the OFF position in

order to stop the engine. Also, turn the

engine start switch to the OFF position in

order to disconnect the power to the

electrical circuits in the cab.

ON - To activate the electrical

circuits in the cab, turn the engine

start switch clockwise to the ON

position.

START - To start the engine, turn

the engine start switch clockwise

to the START position. When the

key is released, the engine start

switch will return to the ON

position.

Note: If the engine fails to start, return the key to the OFF position. This action must be done before you

attempt to start the engine again.

Battery Disconnect Switch (41)

Disconnect Switch On - To

activate the electrical system,

insert the battery disconnect switch

key and turn the key clockwise.

The battery disconnect switch must

be in the ON position before the

engine can be started.

Disconnect Switch Off - To deactivate the

electrical system, turn the battery

disconnect switch key counterclockwise to

the OFF position.

The battery disconnect switch and the engine start switch perform different functions. The entire electrical

system is disabled when the battery disconnect switch is turned to the OFF position. The battery remains

connected to the electrical system when the engine start switch is turned to the OFF position.

Turn the battery disconnect switch to the OFF position. Remove the key when you service the electrical

system or any other machine components.

Turn the battery disconnect switch to the OFF position. Remove the key when the machine will not be used

for an extended period of a month or more. This procedure will prevent drainage of the battery.

17 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

NOTICE

Never move the battery disconnect switch to the OFF position while the

engine is operating. Serious damage to the electrical system could

result.

In order to prevent damage to the engine, verify that the engine is fully operational before cranking the

engine. Do not crank an engine that is not fully operational.

Perform the following procedure in order to check the battery disconnect switch for proper operation:

1. With the battery disconnect switch in the ON position, verify that electrical components in the operator

compartment are functioning. Verify that the hour meter is displaying information. Verify that the

engine will crank.

2. Turn the battery disconnect switch to the OFF position.

3. Verify that the following items are not functioning: electrical components in the operator compartment,

hour meter and engine cranking. If any of the items continue to function with the battery disconnect

switch in the OFF position, consult your Caterpillar dealer.

NOTICE

Never move the battery disconnect switch to the OFF position while the

engine is operating. Serious damage to the electrical system could

result.

Fuel Shutoff Switch (41)

Fuel System ON - Flip down the toggle

switch in order to activate the fuel system.

Fuel System OFF - Flip up the toggle

switch in order to deactivate the fuel

system.

Note: The engine will not shut off immediately. The fuel in the engine and the lines must first be exhausted

before the engine will stop.

Engine Enclosure Floodlight (42)

Engine Enclosure Floodlight - Flip up the

toggle switch in order to turn on the engine

enclosure floodlight. Flip down the toggle

18 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

switch in order to turn off the engine

enclosure floodlight. The light will come on

even if the machine is off.

Stairway Access Light Switch (43)

Stairway Access Light Switch - Flip up

the toggle switch in order to turn on the

stairway access lights. Flip down the toggle

switch in order to turn off the stairway

access lights. The light will come on even if

the machine is off.

Note: An internal switch for the stairway access lights (39) is located on the right side instrument panel in

the cab of the machine.

Service Port and Service Switch (44)

Service Port and Service Switch - This

service port connects a Caterpillar control

service tool. The control service tool

provides diagnostic access to the

Caterpillar monitoring system, the

electronic control module (ECM) for the

engine, and the electronic control module

(ECM) for the power train. This service

tool allows the technician to scroll through

display modes on the digital display

window and clear recorded faults. To use

the service port, the service switch must be

in the ON position.

Service Hour Meter (45)

This display indicates the total operating hours of the machine. Use the display to determine the service hour

maintenance intervals.

Starter Lockout Switch (46)

Starter Lockout Switch - The starter

lockout switch prevents engine start-up.

This lockout is wired electrically. The

lockout is not controlled by an ECM. The

LED indicates when the starter lockout is

electrically active or inactive. Run a

diagnostic test by pushing in the LED.

The engine start key can turn the machine electrical power on and off. The engine cannot be started if the

starter lockout switch is in the ON position. The LED illuminates when the starter lockout is on. The LED

can be turned off by pushing in the light. If the light is pushed in and the starter lockout switch is in the OFF

19 de 20 03/11/2015 07:42 a.m.

Búsqueda del medio - SEBU7885 - 994F Wheel Loader https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

position, the LED will come on until you push the LED light.

Transmission Lockout Switch (47)

Transmission Lockout Switch - The

transmission lockout disables the

transmission while the engine is running.

This operation prevents machine

movement while taking fluid samples.

Maintenance can be done without machine

movement. The lockout and LED are

controlled by the transmission ECM, which

requires the machine electrical power to be

on.

The transmission is latched to neutral if the transmission lockout is switched on. The machine electrical

power is supplied when the transmission lockout is switched on. The LED illuminates. The horn sounds and

the ECM becomes powered if the engine start key is in the OFF position. Advisor indicates that the

transmission lockout is active. The engine start key turns off the engine. The engine start key cannot turn off

the machine electrical power. Only the transmission lockout or the electrical disconnect switches can turn off

the machine electrical power.

Interior Dome Light (48)

Push the switch in order to turn the dome light on and off.

Copyright 1993 - 2015 Caterpillar Inc. Tue Nov 03 2015 07:41:00 GMT-0430

Todos los derechos reservados.

acaruajulca

Red privada para licenciados del SIS.

20 de 20 03/11/2015 07:42 a.m.

You might also like

- Operator Controls: Operation and Maintenance ManualDocument17 pagesOperator Controls: Operation and Maintenance ManualAgus DaniNo ratings yet

- 428E Backhoe Loader Operator ControlsDocument22 pages428E Backhoe Loader Operator ControlsDaniel AmanorNo ratings yet

- Operator ControlsDocument9 pagesOperator ControlsRoberto Hernández DiegoNo ratings yet

- Operator Controls: Operation and Maintenance ManualDocument44 pagesOperator Controls: Operation and Maintenance ManualTaufik RizalNo ratings yet

- CAT CB 10 Vibratory Roller Operator ControlsDocument16 pagesCAT CB 10 Vibratory Roller Operator ControlsChalana UshanNo ratings yet

- 793FDocument26 pages793FHelar W. Cutipa MachacaNo ratings yet

- Testing and AdjustingDocument55 pagesTesting and Adjustingahmad sulaimanNo ratings yet

- Control de La TransmisionDocument8 pagesControl de La Transmisioniver_millan100% (1)

- Testeo TransmisionDocument53 pagesTesteo TransmisionTaller Pahr100% (1)

- Retro 13Document5 pagesRetro 13Henry MonteagudoNo ratings yet

- Presion Bomba Fija 994FDocument8 pagesPresion Bomba Fija 994FCarlos CevNo ratings yet

- Componentes de Maquina de Oruga D10RDocument152 pagesComponentes de Maquina de Oruga D10RJesús Abreu100% (1)

- 924f Wheel Loader 5nn00001-Up (Machine) Powered by 3114 Engine (Sebp2341 - 49) - DocumentationDocument49 pages924f Wheel Loader 5nn00001-Up (Machine) Powered by 3114 Engine (Sebp2341 - 49) - Documentationjulio cesar100% (2)

- Ajustes Trans 140GDocument13 pagesAjustes Trans 140GDomingo Cruz Garcia100% (3)

- Pacotes 12GDocument13 pagesPacotes 12GTatiano BrolloNo ratings yet

- Cat Transmission 938G 2 Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDocument5 pagesCat Transmission 938G 2 Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPMehdi Chakroune100% (1)

- Servo 769dDocument71 pagesServo 769dmiguel_catNo ratings yet

- Power Train Troubleshooting: Essai Et RéglageDocument15 pagesPower Train Troubleshooting: Essai Et RéglageAly AbdelhamedNo ratings yet

- Power Steering PumpDocument6 pagesPower Steering PumpDalton WiseNo ratings yet

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDocument5 pagesBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPNo ratings yet

- Transmission Pressures - Test and AdjustDocument8 pagesTransmission Pressures - Test and Adjustjuankielec100% (3)

- Switches: Systems OperationDocument5 pagesSwitches: Systems OperationMbahdiro KolenxNo ratings yet

- Sist de OperacionDocument64 pagesSist de OperacionMantenimiento Mecanico BiddleNo ratings yet

- Presion Bomba Variable 994FDocument8 pagesPresion Bomba Variable 994FCarlos CevNo ratings yet

- Transmission Pressures - Test and AdjustDocument9 pagesTransmission Pressures - Test and AdjustEver SaavedraNo ratings yet

- Check ListDocument155 pagesCheck Listahmad sulaimanNo ratings yet

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- Parking Brake - Test: Testing and AdjustingDocument3 pagesParking Brake - Test: Testing and AdjustingRajan MullappillyNo ratings yet

- Valvula de Control ParkingDocument5 pagesValvula de Control ParkingmartinaguilarespinoNo ratings yet

- Operator InputsDocument7 pagesOperator InputsJACOB MUDONHINo ratings yet

- Testing and AdjustingDocument58 pagesTesting and Adjustingrigoberto123456789No ratings yet

- 980g Wheel Loader 2kr00001-Up (Machine) Powered by 3406c Engine (Sebp2395 - 140) - Systems & ComponentsDocument7 pages980g Wheel Loader 2kr00001-Up (Machine) Powered by 3406c Engine (Sebp2395 - 140) - Systems & ComponentsHassan HamdyNo ratings yet

- Transmission and Torque Converter - TestDocument17 pagesTransmission and Torque Converter - Testshagu17100% (3)

- Test de Presiones de Transmision 938g2Document12 pagesTest de Presiones de Transmision 938g2cristian chuquicondor torres100% (2)

- Location of Pressure TapsDocument4 pagesLocation of Pressure TapsAbdellatef BakrNo ratings yet

- 938 Pressures - Test and AdjustDocument12 pages938 Pressures - Test and AdjustFaginawati CuteNo ratings yet

- Steering GeneralDocument10 pagesSteering GeneralpricopdanielNo ratings yet

- 980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED by 3406 Engine1212 - 57) - Systems & ComponentsDocument38 pages980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED by 3406 Engine1212 - 57) - Systems & ComponentsTransportation MaintananceNo ratings yet

- Secondary Stering Sys. Hmu SteringDocument7 pagesSecondary Stering Sys. Hmu SteringDidi PrawiraNo ratings yet

- CATERPILLAR Calibracion de TransmisionDocument6 pagesCATERPILLAR Calibracion de TransmisionJUAN CARLOS PAZ67% (3)

- Conveyor Drive Chain (Auger) - Check and AdjustDocument5 pagesConveyor Drive Chain (Auger) - Check and AdjustJefferson GomezNo ratings yet

- Nguyên lý làm việc hệ thống đi chuyển ủi d7gDocument70 pagesNguyên lý làm việc hệ thống đi chuyển ủi d7gDu TrầnNo ratings yet

- 315 D CaterpillarDocument4 pages315 D CaterpillarJose nildo lobato Mendes Mendes100% (1)

- Operacion de Sistemas 928F Contraeje PDFDocument43 pagesOperacion de Sistemas 928F Contraeje PDFBETOVN BETOVENNo ratings yet

- Ajuste RPM FanDocument9 pagesAjuste RPM Fandj danielilloNo ratings yet

- Switches: Systems OperationDocument5 pagesSwitches: Systems OperationEshop ManualNo ratings yet

- 140k Braek SystemDocument24 pages140k Braek SystemBINNo ratings yet

- CAT 769 C Especificaciones Transmision 1Document41 pagesCAT 769 C Especificaciones Transmision 1Taller PahrNo ratings yet

- 420 D Transmission TestDocument10 pages420 D Transmission TestShohan TaylorNo ratings yet

- 6020B Swing Hyd SystemDocument2 pages6020B Swing Hyd Systemzawmoe aungNo ratings yet

- Transmission 950gDocument17 pagesTransmission 950gAbi JithNo ratings yet

- Techdoc Print Page TEST TRANSMISSIONDocument11 pagesTechdoc Print Page TEST TRANSMISSIONtyok sajaNo ratings yet

- 4 Location of Hydraulic Components PDFDocument10 pages4 Location of Hydraulic Components PDFwesley candidoNo ratings yet

- 12g, 120g, 130g & 140g Motor Graders Power Shift TransmissioDocument13 pages12g, 120g, 130g & 140g Motor Graders Power Shift TransmissioJuan Gonzalez100% (1)

- Auto Lube RENR8396-00-01-ALL 777FDocument24 pagesAuto Lube RENR8396-00-01-ALL 777FemsonNo ratings yet

- General InformationDocument8 pagesGeneral InformationRichard ChuaNo ratings yet

- ReclaimerDocument6 pagesReclaimerMedo MedooNo ratings yet

- 938f TransmisiDocument23 pages938f TransmisiYudi setiawanNo ratings yet

- 785D Off-Highway Truck Hydraulic System Systems OperationDocument24 pages785D Off-Highway Truck Hydraulic System Systems Operation1No ratings yet

- 11 PJBUMI Digital Data Specialist DR NOOR AZLIZADocument7 pages11 PJBUMI Digital Data Specialist DR NOOR AZLIZAApexs GroupNo ratings yet

- High-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Document7 pagesHigh-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Dongxi LvNo ratings yet

- Building Envelop Design GuidDocument195 pagesBuilding Envelop Design GuidCarlos Iriondo100% (1)

- Lozada Vs MendozaDocument4 pagesLozada Vs MendozaHarold EstacioNo ratings yet

- Composition PsychologyDocument1 pageComposition PsychologymiguelbragadiazNo ratings yet

- Characteristics of Pop CultureDocument3 pagesCharacteristics of Pop Culturekhimamad02No ratings yet

- Principles of Marketing: Quarter 1 - Module 6: Marketing ResearchDocument17 pagesPrinciples of Marketing: Quarter 1 - Module 6: Marketing ResearchAmber Dela Cruz100% (1)

- PFASDocument8 pagesPFAS王子瑜No ratings yet

- Stdy RCD PDFDocument204 pagesStdy RCD PDFBol McSafeNo ratings yet

- Swimming (Sport) : Jump To Navigation Jump To Search Swimming Swimmer (Disambiguation)Document24 pagesSwimming (Sport) : Jump To Navigation Jump To Search Swimming Swimmer (Disambiguation)Teacher NhorNo ratings yet

- The Relationship Between Law and MoralityDocument12 pagesThe Relationship Between Law and MoralityAnthony JosephNo ratings yet

- History of Architecture VI: Unit 1Document20 pagesHistory of Architecture VI: Unit 1Srehari100% (1)

- (Nand Flash Memory) HY27 (U - S) S (08 - 16) 121M (Rev0.6)Document43 pages(Nand Flash Memory) HY27 (U - S) S (08 - 16) 121M (Rev0.6)jituelectNo ratings yet

- 5 L&D Challenges in 2024Document7 pages5 L&D Challenges in 2024vishuNo ratings yet

- Bekic (Ed) - Submerged Heritage 6 Web Final PDFDocument76 pagesBekic (Ed) - Submerged Heritage 6 Web Final PDFutvrdaNo ratings yet

- Discuss The Following Questions With Your Family Members Casually and Write The AnswersDocument2 pagesDiscuss The Following Questions With Your Family Members Casually and Write The AnswersVincent Stephen AmalrajNo ratings yet

- British Council IELTS Online Application SummaryDocument3 pagesBritish Council IELTS Online Application Summarys_asadeNo ratings yet

- Using JAXB For XML With Java - DZone JavaDocument20 pagesUsing JAXB For XML With Java - DZone JavajaehooNo ratings yet

- Federal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisDocument41 pagesFederal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisWaseem KhanNo ratings yet

- MigrationDocument6 pagesMigrationMaria Isabel PerezHernandezNo ratings yet

- Chapter 2 Demand (ECO415)Document28 pagesChapter 2 Demand (ECO415)hurin inaniNo ratings yet

- The Gift of ADHDDocument233 pagesThe Gift of ADHDGerman Rosales Vargas100% (3)

- Security Gap Analysis Template: in Place? RatingDocument6 pagesSecurity Gap Analysis Template: in Place? RatingVIbhishan0% (1)

- Easy Pork Schnitzel: With Apple Parmesan Salad & Smokey AioliDocument2 pagesEasy Pork Schnitzel: With Apple Parmesan Salad & Smokey Aioliclarkpd6No ratings yet

- Coaching Manual RTC 8Document1 pageCoaching Manual RTC 8You fitNo ratings yet

- Roger Dean Kiser Butterflies)Document4 pagesRoger Dean Kiser Butterflies)joitangNo ratings yet

- Rapidjson Library ManualDocument79 pagesRapidjson Library ManualSai Kumar KvNo ratings yet

- Block-1 Communication IGNOUDocument81 pagesBlock-1 Communication IGNOUr kumarNo ratings yet

- Assertiveness FinlandDocument2 pagesAssertiveness FinlandDivyanshi ThakurNo ratings yet

- Pedia Edited23 PDFDocument12 pagesPedia Edited23 PDFAnnJelicaAbonNo ratings yet