Professional Documents

Culture Documents

AL 6XN General Properties

Uploaded by

ah1525Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AL 6XN General Properties

Uploaded by

ah1525Copyright:

Available Formats

AL-6XN® GENERAL PROPERTIES

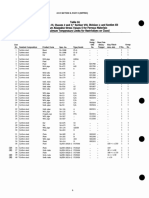

AL-6XN® (UNS N08367) is a 6 moly superaustenitic CHEMICAL REQUIREMENTS OF AL-6XN®

alloy containing higher levels of chromium, nickel, (UNS N08367); WT. %

molybdenum, and nitrogen than 316L stainless ELEMENT UNS N08367

steel. The alloying elements provide more corrosion Carbon 0.03*

resistance to acidic oxidizing chloride solutions,

Manganese 2.00*

making AL-6XN resistive to pitting and crevice

Phosphorous 0.04*

corrosion and stress corrosion cracking.

Sulfur 0.03*

AL-6XN outperforms 316L—and is a cost-effective

Silicon 1.00*

alternative to more expensive nickel-based alloys in

applications where excellent formability, weldability, Chromium 20.0–22.0

strength, and corrosion resistance are essential. Nickel 23.5–25.5

Molybdenum 6.0–7.0

Nitrogen 0.18–0.25

Copper 0.75*

Iron Balance (44)

*Maximum unless otherwise specified

Disclaimer: Always consult current standards.

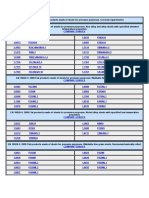

PRODUCT FORMS AND MATERIAL STANDARDS

Corrosion resistant alloys are COMMON SPECIFICATIONS FOR CORROSION RESISTANT ALLOYS

available in the most common AL-6XN AL-6XN

product forms: plate, sheet, strip, ALLOY FORM

ASME ASTM

bar, billet, wire, pipe, and tubing. The SA240 A240

table to the right shows applicable Plate, Sheet, and Strip

SB688 B688

ASME and ASTM material standards Rod, Bar, and Wire SB691 B691

associated with the various alloy Welded Pipe SB675 B675

products forms.

Heat Exchanger Tubing SA249 A249

Sanitary Tubing - A270

Welded Tubing B626

SB626

(General Applications) A269

Seamless Pipe and Tubing SB690 B690

Forged Pipe Flanges, Fittings, and Valves SB462 B462

Wrought Nickel Alloy Welded Fittings SB366 B366

Nickel Alloy Forgings SB564 B564

SA351

A743

Castings CN-3MN

A744

UNS J94651

Bare Welded ERNiCrMo-10

-

Rods and Wire UNS N06022

AL-6XN Properties/Specs REV 6/20

CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | + 1.417.831.1411

You might also like

- Aalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160Document3 pagesAalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160umar farooqNo ratings yet

- Dalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Document3 pagesDalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Zac Francis DaymondNo ratings yet

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesNo ratings yet

- Cast Carbon Steels in AWS D1.1 PDFDocument3 pagesCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNo ratings yet

- Asme Ii Part D Table 1a CSDocument20 pagesAsme Ii Part D Table 1a CSyar_nlNo ratings yet

- Alloy Steels - High - NickelDocument10 pagesAlloy Steels - High - NickelSureshNo ratings yet

- MS 01 147Document24 pagesMS 01 147Nabil ShaikhNo ratings yet

- Pipe Fittings - SwagelokDocument24 pagesPipe Fittings - SwagelokJagadish KumarNo ratings yet

- Swagelok Pipe FittingsDocument24 pagesSwagelok Pipe Fittingsgacm98100% (1)

- C12200 PD Copper - Austral Wright Metals - AustraliaDocument3 pagesC12200 PD Copper - Austral Wright Metals - Australiamohsen_267No ratings yet

- Stainless Steel: Product FormsDocument19 pagesStainless Steel: Product FormsDinalpinNo ratings yet

- F-7.2.1.5 Specification Revision ListDocument11 pagesF-7.2.1.5 Specification Revision ListRam ParimalamNo ratings yet

- Esfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFDocument643 pagesEsfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFChuy Ramos0% (1)

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Al-6xn Plus Tds en v2Document3 pagesAl-6xn Plus Tds en v2Sue EpicNo ratings yet

- Sa 36Document4 pagesSa 36edisson_barreraNo ratings yet

- Astm B366-04 PDFDocument9 pagesAstm B366-04 PDFromerobernaNo ratings yet

- USW ALLOY 357 DATA SHEETDocument1 pageUSW ALLOY 357 DATA SHEETbrunizzaNo ratings yet

- Astm B906Document16 pagesAstm B906Jamil SalmanNo ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- ASME SA240 316 Stainless Steel Plate - Stainless ProfileDocument2 pagesASME SA240 316 Stainless Steel Plate - Stainless ProfileHidden TruthNo ratings yet

- Ams 5596K PDFDocument8 pagesAms 5596K PDFadiNo ratings yet

- Lesson Plan: Brass PropertiesDocument7 pagesLesson Plan: Brass Propertiessurajit biswasNo ratings yet

- B 366 - 04 - QJM2NGDocument9 pagesB 366 - 04 - QJM2NGLemir LopezNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Tablas de Esfuerzos PDFDocument729 pagesTablas de Esfuerzos PDFSamuel PohezNo ratings yet

- 4-1. Hy-Lok Tube Fittings (2020)Document76 pages4-1. Hy-Lok Tube Fittings (2020)bernaNo ratings yet

- Data Sheet PSVDocument12 pagesData Sheet PSVDiego RuanoNo ratings yet

- PDFsam_B 366 - B 366M - 16Document9 pagesPDFsam_B 366 - B 366M - 16mike.jensen0581No ratings yet

- Sae Ams5659p (2014)Document9 pagesSae Ams5659p (2014)Yeonggeun Lee50% (2)

- AAAC Gulf Trading Co WLL Profile - Part8Document1 pageAAAC Gulf Trading Co WLL Profile - Part8rahman21420No ratings yet

- Bronze Stock ListDocument14 pagesBronze Stock ListFred Duarte Caldeira100% (1)

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument6 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification Forakib belNo ratings yet

- Esab 309cbDocument1 pageEsab 309cbGokul RajanNo ratings yet

- Aluminum SectionsDocument102 pagesAluminum SectionsDuy HaNo ratings yet

- B 366 - 01 Qjm2ni0wmuuxDocument6 pagesB 366 - 01 Qjm2ni0wmuuxHéctor NossaNo ratings yet

- Welding BrassDocument5 pagesWelding BrassMohammed NazeerNo ratings yet

- Tube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Document5 pagesTube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Jit BNo ratings yet

- Hy-Lok Tube Fittings Catalog No. H-200TFDocument76 pagesHy-Lok Tube Fittings Catalog No. H-200TFJit BNo ratings yet

- Factory-Made Wrought Nickel and Nickel Alloy Fittings: Standard Specification ForDocument9 pagesFactory-Made Wrought Nickel and Nickel Alloy Fittings: Standard Specification ForteaNo ratings yet

- Technical Specification Documents What Is Stainless Steel?Document1 pageTechnical Specification Documents What Is Stainless Steel?Mongia MoghiNo ratings yet

- Materials: For A Ins MusDocument7 pagesMaterials: For A Ins MusSoumya SameerNo ratings yet

- Equivalent Grade: Standard UNS Wnr. Afnor EN JIS OR Gost Hastelloy C276Document3 pagesEquivalent Grade: Standard UNS Wnr. Afnor EN JIS OR Gost Hastelloy C276RELIABLE PIPES & TUBESNo ratings yet

- SAW Content OnlyDocument19 pagesSAW Content OnlyIslam SahafayatNo ratings yet

- OK 67.70 ESAB 309moDocument1 pageOK 67.70 ESAB 309moSadashiva sahooNo ratings yet

- Npss Main Catalogue 05.10 PDFDocument57 pagesNpss Main Catalogue 05.10 PDFVEnt NoirNo ratings yet

- AstmDocument4 pagesAstmedisjdavNo ratings yet

- Copper Nickel Pipe Fittings CatalogDocument8 pagesCopper Nickel Pipe Fittings CatalogAli FarzadmaneshNo ratings yet

- Copper Pipe C12200Document1 pageCopper Pipe C12200Yowhannes TsehayeNo ratings yet

- Tensile Strength of CS & LTCS - BPVC - II - D - M-2021Document2 pagesTensile Strength of CS & LTCS - BPVC - II - D - M-2021shalinimanjunath2020No ratings yet

- Mil F 18870eDocument32 pagesMil F 18870eblissliNo ratings yet

- Channel Alloys LinecardDocument1 pageChannel Alloys LinecarddesignNo ratings yet

- B 462 - 04 - QJQ2MGDocument5 pagesB 462 - 04 - QJQ2MGLemir LopezNo ratings yet

- Comparison A36 & SS400Document9 pagesComparison A36 & SS400massodiq100% (4)

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- AL 6XN Tube and Fittings SpecificationsDocument2 pagesAL 6XN Tube and Fittings Specificationsah1525No ratings yet

- THE WAY TO GO I S THE Anfi BI O!: New! New!Document6 pagesTHE WAY TO GO I S THE Anfi BI O!: New! New!ah1525No ratings yet

- THE WAY TO GO I S THE Anfi BI O!: New! New!Document6 pagesTHE WAY TO GO I S THE Anfi BI O!: New! New!ah1525No ratings yet

- Fracture Class Notes - Important PDFDocument34 pagesFracture Class Notes - Important PDFbathinsreenivasNo ratings yet

- Iso 11127 7Document7 pagesIso 11127 7ah1525No ratings yet

- AL 6XN Tube and Fittings SpecificationsDocument2 pagesAL 6XN Tube and Fittings Specificationsah1525No ratings yet

- AL 6XN General PropertiesDocument1 pageAL 6XN General Propertiesah1525No ratings yet

- The Corrosion of Superduplex SS in Different Types of SeawaterDocument9 pagesThe Corrosion of Superduplex SS in Different Types of SeawaterdevangmajithiaNo ratings yet

- Read Before Operating PulseDiveDocument12 pagesRead Before Operating PulseDiveah1525No ratings yet

- AL 6XN Tube and Fittings SpecificationsDocument2 pagesAL 6XN Tube and Fittings Specificationsah1525No ratings yet

- Iso 11127 6 PDFDocument7 pagesIso 11127 6 PDFah1525No ratings yet

- AL 6XN General PropertiesDocument1 pageAL 6XN General Propertiesah1525No ratings yet

- THE WAY TO GO I S THE Anfi BI O!: New! New!Document6 pagesTHE WAY TO GO I S THE Anfi BI O!: New! New!ah1525No ratings yet

- THE WAY TO GO I S THE Anfi BI O!: New! New!Document6 pagesTHE WAY TO GO I S THE Anfi BI O!: New! New!ah1525No ratings yet

- Iso 11127 6 PDFDocument7 pagesIso 11127 6 PDFah1525No ratings yet

- ENNI SpecificationDocument142 pagesENNI Specificationah1525No ratings yet

- Mechanical Integrity:: Fixed Equipment Standards & Recommended PracticesDocument36 pagesMechanical Integrity:: Fixed Equipment Standards & Recommended Practicesah1525No ratings yet

- Flyer Rosemount Wireless Permasense Corrosion Erosion Monitoring System For Refineries en 5390998Document2 pagesFlyer Rosemount Wireless Permasense Corrosion Erosion Monitoring System For Refineries en 5390998ah1525No ratings yet

- NORSOK-Systems-No1-March 2020 - tcm279-18016Document6 pagesNORSOK-Systems-No1-March 2020 - tcm279-18016ah1525No ratings yet

- NORSOK Systems No5 Oct 2016 - tcm279 106992 PDFDocument1 pageNORSOK Systems No5 Oct 2016 - tcm279 106992 PDFah1525No ratings yet

- API 510 exam questionsDocument16 pagesAPI 510 exam questionsSenthil Periyasamy100% (1)

- Bureau Veritas certificate for Ahmed HazemDocument2 pagesBureau Veritas certificate for Ahmed Hazemah1525No ratings yet

- NORSOK Systems No2 Nov 2012 - tcm279 18017 PDFDocument1 pageNORSOK Systems No2 Nov 2012 - tcm279 18017 PDFah1525No ratings yet

- NORSOK Systems No3 Nov 2012 - tcm279 106991 PDFDocument2 pagesNORSOK Systems No3 Nov 2012 - tcm279 106991 PDFah1525No ratings yet

- 580 09-07-2019 CertDocument1 page580 09-07-2019 Certah1525No ratings yet

- 580 09-07-2019 Cert PDFDocument1 page580 09-07-2019 Cert PDFah1525No ratings yet

- Norsok Standard M-501: Rev. 5, June 2004Document24 pagesNorsok Standard M-501: Rev. 5, June 2004Nelson Matos100% (1)

- API 571 API 571 API 571 API 571 Corrosion and Materials Corrosion and Materials Certification CertificationDocument1 pageAPI 571 API 571 API 571 API 571 Corrosion and Materials Corrosion and Materials Certification Certificationah1525No ratings yet

- API 571 API 571 API 571 API 571 Corrosion and Materials Corrosion and Materials Certification CertificationDocument1 pageAPI 571 API 571 API 571 API 571 Corrosion and Materials Corrosion and Materials Certification Certificationah1525No ratings yet

- EN 10028 Steel Pressure StandardsDocument3 pagesEN 10028 Steel Pressure Standardsraduono100% (1)

- Alligation Sheet-2Document4 pagesAlligation Sheet-2baloj30838No ratings yet

- Multi - 1 Drills: YE-ML20Document2 pagesMulti - 1 Drills: YE-ML20Michel DominguesNo ratings yet

- Everything You Need to Know About Duplex and Super Duplex Cast Stainless SteelsDocument31 pagesEverything You Need to Know About Duplex and Super Duplex Cast Stainless SteelsAndy PhoenixNo ratings yet

- Material Equivalent 16-6-05Document7 pagesMaterial Equivalent 16-6-05Aan SharmaNo ratings yet

- FE410WWA - Equivalent Steel Grades QualitiesDocument6 pagesFE410WWA - Equivalent Steel Grades QualitiesbkprodhNo ratings yet

- Offshore & Structural Plate SizeDocument4 pagesOffshore & Structural Plate Sizelaleye_olumideNo ratings yet

- Copper Alloys in Ingot Form: Standard Specification ForDocument12 pagesCopper Alloys in Ingot Form: Standard Specification ForFierro Huerta Guillermo IsraelNo ratings yet

- ASME P & F Numbers GuideDocument4 pagesASME P & F Numbers GuideTanveer Rajput EngrNo ratings yet

- Manufacturing procedure for recommended filler materials and preheat temperaturesDocument5 pagesManufacturing procedure for recommended filler materials and preheat temperaturesMiguel Rodriguez100% (1)

- 11 Hi E P11 A I: N C R. Htihono, M, RipDocument3 pages11 Hi E P11 A I: N C R. Htihono, M, RipTarek AbuzeneNo ratings yet

- FS Corten-Crete FinishDocument10 pagesFS Corten-Crete FinishSUHANI VERMANo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Astm A286Document1 pageAstm A286akmlogaNo ratings yet

- Difference Between Austenitic, Ferritic, and MartensiticDocument3 pagesDifference Between Austenitic, Ferritic, and Martensitickihal zohirNo ratings yet

- GD KT Pro-0731-0418 Sus Abs V1Document6 pagesGD KT Pro-0731-0418 Sus Abs V1swami061009No ratings yet

- Stainless Steel Alloys Comparsion ChartDocument3 pagesStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Classification of Carbon and Low Alloy SteelsDocument4 pagesClassification of Carbon and Low Alloy SteelsmomoitachiNo ratings yet

- Steel Bar Product BroucherDocument16 pagesSteel Bar Product BroucherCREATIVE PIPING SOLUTIONS PVT. LTD.No ratings yet

- Range of Trim MaterialsDocument1 pageRange of Trim MaterialsAbu___AbdullahNo ratings yet

- Bolt and Nut Grade Identification GuideDocument7 pagesBolt and Nut Grade Identification GuideNor Azman JusofNo ratings yet

- JS Page Manhour Productivity (09-30-2019)Document335 pagesJS Page Manhour Productivity (09-30-2019)Rainier Gemuel TomNo ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Clasificacion Universal de Los MaterialesDocument24 pagesClasificacion Universal de Los MaterialesMateo100% (1)

- International Starch Institute. Stainless Steel TableDocument4 pagesInternational Starch Institute. Stainless Steel TableCesar Dominguez ParedesNo ratings yet

- P20 Tool Steel DescriptionDocument5 pagesP20 Tool Steel DescriptionJAFFERNo ratings yet

- Steel MillsDocument6 pagesSteel MillsMuhammad JunaidNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- ASTM A291-03 Standard Specification For Steel Forgings, Carbon and Alloy, For Pinions, Gears and ShaftsDocument4 pagesASTM A291-03 Standard Specification For Steel Forgings, Carbon and Alloy, For Pinions, Gears and Shaftsmedialeon0% (1)

- Norma Parte 1Document100 pagesNorma Parte 1Alejandra López100% (1)