Professional Documents

Culture Documents

HW - 3 ME308 - 201 Sol Updated

Uploaded by

Y7ya73Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HW - 3 ME308 - 201 Sol Updated

Uploaded by

Y7ya73Copyright:

Available Formats

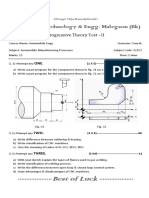

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

HW # 3 Due on Saturday Nov. 7 ,2020 (end of

Chapter 11: Rolling Contact Bearings

the day)

Student Name

Student ID#

Section#

Problem # 1 (35 pts)

A reverted compound gear train consists of two identical stages is to be

designed. The gearbox must be capable of transmitting 100kW at 225 rpm input

speed. The gear train increase the speed to achieve an output speed of 3600

rpm. You are requested to design the gear train for minimum size. The following

assumptions and limitations must apply during the design process.

1. The gear train is made of Spur gears.

2. Both pinion and gear are made from the same material and hardness.

3. To avoid interference, minimum pinion number of teeth is 36 teeth.

4. Material available is Carburirzed and hardened Grade 3

5. Minimum factor of safety against bending and pitting are 2 and √2,

respectively

6. Assuming the following:

Over load factor 1.25

Load distribution factor 1.3 (initial assumption)

Quality no. 8

Dynamic factor 1.1 (initial assumption)

Reliability is 0.999, and life is 109 cycles

Face width is assumed to be 12 times the module

a. Illustrate the gear train, show the input and output shafts, gears, and

indicate all parameters i.e speed and power. (3 pts)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

b. Determine the no. of teeth on the gear to achieve the required gear

ratio.(2

pts)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

c. Following AGMA standards and codes, determine the minimum pinion

diameter sufficient for transmitting the power considering above

assumptions. Use preferred sizes and dimensions (20 pts)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

d. Calculate the factor of safety against pitting and bending , then identify

the source of threat (note: initial assumed values for load distribution and

dynamic factor cannot be used) (10 pts)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

Problem # 2(35 pts)

A meat grinder gearbox is to be designed considering the following constrains:

a. The overall gearbox dimensions should not exceed 176 mm by 80 mm by 80 mm (see figure

1).

b. The central distances of the second and third stages are 47 mm and 52.5 mm, respectively (see

figure 2).

c. The meat grinder is driven by a 1800 watt motor at 1800 rpm (cw). The grinder must rotate at

16 rpm within 5% error.

d. Full depth tooth system is adopted.

e. Other geometrical and kinematics parameters are available in table 1

Figure 1 gearbox enclosure dimensions in mm (drawing not to scale)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

47

52.5

Figure 2 gear train (front view) dimensions in mm (drawing not to scale)

To complete the design, solve the following questions; show full work for full credit.

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

1. Why the meat grinder requires three-stage gear reducer? [2 points]

2. Determine the missing information in the table below; reflect the calculated dimensions on

figure 2. [10 marks]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

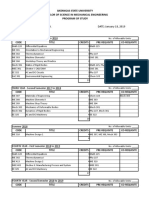

Table 1

Stage 1 Stage 2 Stage 3

Gear 2 Gear 3 Gear 4 Gear 5 Gear 6 Gear 7

Number

7 56 16 78 16 44

of teeth

Module 1 1 1 1 1.75 1.75

Pressure

25 25 20 20 20 20

angle

Pitch

7 56 16 78 28 77

diameter

Outer

9 58 18 80 31.5 80.5

diameter

Central

31.5 47 52.5

distance

Rotational

1800 225 225 46.15 46.15 16.7

speed

Gear

8 4.875 2.75

Ratio

3. Plot the side view of the gear train and show all diminsions; gears diameters and central

distance.

[2 marks]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

4. Based on evaluated dimensions in the table above, can the gear train fit in the enclosure, if no,

suggest what can be changed?

[2 marks]

Gear 7 is larger than the allowable limit (D out > 80 mm) ) a solution can be made by changing the

tooth system from full depth to stub tooth [D out = 77+ 2(0.8)(1.75)=79.8 mm]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

5. Does the gearbox provide required speed reduction? And why? Build the gear box on

https://geargenerator.com/ and show if the output speed was achieved [1 marks]

6. Can interference take place? If yes in which stage\stages. [2 marks]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

7. Why gear module in 3rd stage is larger than 1st and 2nd [1 marks]

In speed reducers, gears at the last stage will be exposed to maximum torque, therefore

maximum forces i.e stress. In order for the gear teeth to handle the high forces, the size of the

teeth must be large (larger module) as compared to first or second where the torque is smaller

8. Draw free body diagram of gear 6 and determine all forces. [5 marks]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

9. Select an economical material for the gears following AGMA standards and codes. Assuming

commercial quality and a minimum factor of safety against bending and wear 2, and 2^0.5

respectively. Face width 10 (m). Design the most critical stage only. [10 marks]

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

Problem # 3(20 pts)

A 26-tooth pinion rotating at a uniform 1800 rpm meshes with a 55-tooth gear in a helical gear

reducer. Both pinion and gear are manufactured to a quality level of 10. The transmitted tangential

load is 22 kN. Conditions are such that Km = 1.7. The teeth are standard 20-degree normal pressure

angle, and 30 helix, full-depth. The normal module is 5 and the face width 62 mm.

1. Determine the bending stress.

2. Determine the contact stresses.

3. Select a suitable material to insure bending factor of safety = 2

4. Calculating wear factor of safety.

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

Problem # 4 (10 pts)

Solve 14-24 in your textbook

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

King Fahd University of Petroleum & Minerals

College of Engineering Sciences

Mechanical Engineering Department

ME 308: Machine Design II Fall Semester 2020-2021 (201)

ME 308 Machine Design II Fall Semester 2020-2021 (201)

You might also like

- King Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentDocument2 pagesKing Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentOmar RefeNo ratings yet

- Best of Luck: Institute of Technology & Engg. Malegaon (BK)Document1 pageBest of Luck: Institute of Technology & Engg. Malegaon (BK)Pramod DhaigudeNo ratings yet

- Shri Shankaracharya Technical Campus, Bhilai: B.Tech. (Mechanical Engineering), Semester: 6Document19 pagesShri Shankaracharya Technical Campus, Bhilai: B.Tech. (Mechanical Engineering), Semester: 6Ashutosh girdharNo ratings yet

- Faculty of Engineering and TechnologyDocument1 pageFaculty of Engineering and TechnologyaeropaschalNo ratings yet

- Cad-Cam - Fba2 - 2020Document3 pagesCad-Cam - Fba2 - 2020Tafara DarangwaNo ratings yet

- Machine Design Assignment-1Document2 pagesMachine Design Assignment-1RAJAT RAJNo ratings yet

- CAD Assignments-2022Document15 pagesCAD Assignments-2022Glenn GatibaNo ratings yet

- MT Paper 2nd Mid TermDocument2 pagesMT Paper 2nd Mid Termanil chaudharyNo ratings yet

- Cad-Cam - Ittd2 - 2020Document3 pagesCad-Cam - Ittd2 - 2020Tafara DarangwaNo ratings yet

- Arba Minch University Assignment on Manufacturing ProcessesDocument2 pagesArba Minch University Assignment on Manufacturing ProcessesAlemNo ratings yet

- AUTOMOBILE COURSE STRUCTURE - FinalDocument41 pagesAUTOMOBILE COURSE STRUCTURE - FinalStephen AttaNo ratings yet

- Yeshwantrao Chavan College of Engineering: ESE Even Term 2021-22 Mechanical EnggDocument3 pagesYeshwantrao Chavan College of Engineering: ESE Even Term 2021-22 Mechanical EnggPurvesh RangariNo ratings yet

- Assignment Qb1 III Sem 150923Document1 pageAssignment Qb1 III Sem 150923Vasu 22No ratings yet

- Mid-Term Exam: Notes: Answer All Three QuestionsDocument2 pagesMid-Term Exam: Notes: Answer All Three Questionsseraj sersawiNo ratings yet

- PosDocument3 pagesPosAndre De VillaNo ratings yet

- Cad-Cam - Ittd3 - 2020Document3 pagesCad-Cam - Ittd3 - 2020Tafara DarangwaNo ratings yet

- BSC Progromme CoursesDocument9 pagesBSC Progromme Coursesaaronmking.r35No ratings yet

- CNC Lathe and Milling Machine Part Programs for Automobile ComponentsDocument1 pageCNC Lathe and Milling Machine Part Programs for Automobile ComponentsPramod DhaigudeNo ratings yet

- Savitribai Phule Pune University: Teaching SchemeDocument4 pagesSavitribai Phule Pune University: Teaching Schemesandeshs4No ratings yet

- Advt.-Recruitment of 249 Posts of MT (Tech.) in SAIL Utilizing GATE-2024Document1 pageAdvt.-Recruitment of 249 Posts of MT (Tech.) in SAIL Utilizing GATE-2024Sreeram DeekshitNo ratings yet

- DMS All Assignment & Exeracises (2019-2020)Document6 pagesDMS All Assignment & Exeracises (2019-2020)Nikhil BhosaleNo ratings yet

- JNTU Old Question Papers 2007Document10 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (5)

- Compulsory Sl. No. Questions Marks Co PoDocument1 pageCompulsory Sl. No. Questions Marks Co PoAll_regNo ratings yet

- Me 201 Dynamics: HW # 8 SolutionsDocument5 pagesMe 201 Dynamics: HW # 8 Solutionsنواف عبداللهNo ratings yet

- Training Details UpdatedDocument14 pagesTraining Details UpdatedPrasannaNo ratings yet

- Mae - PG SyallbusDocument16 pagesMae - PG Syallbusrudramuni tsNo ratings yet

- 2122 MTCC5055 S2 A2 Fa QPDocument10 pages2122 MTCC5055 S2 A2 Fa QPZoay7 I 6No ratings yet

- Cad-Cam - Ittd1 - 2020Document3 pagesCad-Cam - Ittd1 - 2020Tafara DarangwaNo ratings yet

- Q Paper TOM-I MSE-2 (B)Document1 pageQ Paper TOM-I MSE-2 (B)Surjit Kumar GandhiNo ratings yet

- Crankshaft DesignDocument8 pagesCrankshaft DesignDiego AvendañoNo ratings yet

- Auto 5th Sem-2902Document12 pagesAuto 5th Sem-2902Praveen NishadNo ratings yet

- RegisteredStudentBillReport (Generated On 16 - 12 - 2022 11 - 23 AM)Document2 pagesRegisteredStudentBillReport (Generated On 16 - 12 - 2022 11 - 23 AM)Irfan SalimNo ratings yet

- Meng 310 Exam 01 Spring 2011Document4 pagesMeng 310 Exam 01 Spring 2011Abdulrahman AlzahraniNo ratings yet

- CNC Lathe and Milling Programs for Automobile PartsDocument1 pageCNC Lathe and Milling Programs for Automobile PartsPramod DhaigudeNo ratings yet

- Mid Semester Test Date Sheet for Various ClassesDocument8 pagesMid Semester Test Date Sheet for Various ClassesyochanNo ratings yet

- End Sem PyqDocument5 pagesEnd Sem PyqJaspreet veeraNo ratings yet

- III B.tech Mechanical Course Structure and SyllabusDocument51 pagesIII B.tech Mechanical Course Structure and SyllabusN.S Achyuth AnandNo ratings yet

- Agenda 386AC Item-33Document1,225 pagesAgenda 386AC Item-33Lbw OutNo ratings yet

- COMSATS University Islamabad Wah Campus Assignment-IV (Spring 2022Document1 pageCOMSATS University Islamabad Wah Campus Assignment-IV (Spring 2022Raja HarisNo ratings yet

- Gaither Gaither SB 2 2021 ThesisDocument30 pagesGaither Gaither SB 2 2021 ThesisMakwy GantengNo ratings yet

- Chandigarh University 1st Hourly Test DetailsDocument138 pagesChandigarh University 1st Hourly Test DetailsliniNo ratings yet

- Machine Drawing MID-I PAPERS - 2 SETS - AY 2020-2021 - II-IDocument2 pagesMachine Drawing MID-I PAPERS - 2 SETS - AY 2020-2021 - II-Ivenkee84No ratings yet

- Final - Mechanical - VI Semester - New - Syllabus PDFDocument18 pagesFinal - Mechanical - VI Semester - New - Syllabus PDFSrijan VermaNo ratings yet

- CUOnline - ReportsDocument2 pagesCUOnline - ReportsMuhammad Modood AbbasiNo ratings yet

- Cad Cam SyllabusDocument4 pagesCad Cam SyllabuskrishrathoreNo ratings yet

- MDP 2130 Tutorial 2Document4 pagesMDP 2130 Tutorial 2Khaled AbozaidNo ratings yet

- 6th - Sem MECH - CAD Lab ManualDocument38 pages6th - Sem MECH - CAD Lab ManualAssassin SmeltonNo ratings yet

- TIE 3213 Assignment 2 (2020) PDFDocument2 pagesTIE 3213 Assignment 2 (2020) PDFphillip chirongwe0% (1)

- Mech Eng SyllabusDocument101 pagesMech Eng SyllabusSaurav RaJNo ratings yet

- Semester: VIII: B. E. Mechanical Engineering (CBCS) Beme802T2: Computer Integrated ManufacturingDocument9 pagesSemester: VIII: B. E. Mechanical Engineering (CBCS) Beme802T2: Computer Integrated ManufacturingAmisha MankarNo ratings yet

- B.TECH-BCA-MCA Odd Semester Ist Sessional Exam Time Table-August 2020Document6 pagesB.TECH-BCA-MCA Odd Semester Ist Sessional Exam Time Table-August 2020harshbhagchandaniNo ratings yet

- Bachelor of Engineering in Mechanical Engineering (Automobile) CoursesDocument4 pagesBachelor of Engineering in Mechanical Engineering (Automobile) CoursesAaditya RamanNo ratings yet

- BtechaDocument104 pagesBtechamathewsivin5266No ratings yet

- Full SyllabusDocument409 pagesFull SyllabusSanthana BharathiNo ratings yet

- Machine Design 2 Lecture Midterm ExamDocument3 pagesMachine Design 2 Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- CAD Assessment Test QuestionsDocument2 pagesCAD Assessment Test QuestionskipseyNo ratings yet

- Guidelines For Sem VIII Choice R16 Regular ExaminationDocument5 pagesGuidelines For Sem VIII Choice R16 Regular ExaminationJvc NfuNo ratings yet

- Compulsory Sl. No. Questions Marks Co PoDocument1 pageCompulsory Sl. No. Questions Marks Co PoAll_regNo ratings yet

- HW6 201Document4 pagesHW6 201Y7ya73No ratings yet

- Mechanical Engineering Homework on StatisticsDocument5 pagesMechanical Engineering Homework on StatisticsY7ya73No ratings yet

- Mechanical Engineering Homework on StatisticsDocument5 pagesMechanical Engineering Homework on StatisticsY7ya73No ratings yet

- HW2 ME406 201 SolutionDocument6 pagesHW2 ME406 201 SolutionY7ya73No ratings yet

- Se Lab Da-2Document12 pagesSe Lab Da-2Anvesh PenkeNo ratings yet

- Sadie's Drawing Materials: Buy Your Supplies atDocument5 pagesSadie's Drawing Materials: Buy Your Supplies atAlison De Sando ManzoniNo ratings yet

- Macroeconomics QuestionnaireDocument5 pagesMacroeconomics Questionnairevikrant vardhanNo ratings yet

- Geraldez Vs Ca 230 Scra 329Document12 pagesGeraldez Vs Ca 230 Scra 329Cyrus Pural EboñaNo ratings yet

- Elitox PPT ENG CompressedDocument18 pagesElitox PPT ENG CompressedTom ArdiNo ratings yet

- A. Pawnshops 4. B. Pawner 5. C. Pawnee D. Pawn 6. E. Pawn Ticket 7. F. Property G. Stock H. Bulky Pawns 8. I. Service Charge 9. 10Document18 pagesA. Pawnshops 4. B. Pawner 5. C. Pawnee D. Pawn 6. E. Pawn Ticket 7. F. Property G. Stock H. Bulky Pawns 8. I. Service Charge 9. 10Darwin SolanoyNo ratings yet

- Lesson 5 Classifications of CommunicationDocument48 pagesLesson 5 Classifications of CommunicationRovenick SinggaNo ratings yet

- BATCH Bat Matrix OriginalDocument5 pagesBATCH Bat Matrix OriginalBarangay NandacanNo ratings yet

- Teresita Dio Versus STDocument2 pagesTeresita Dio Versus STmwaike100% (1)

- Target products to meet 20% demandDocument12 pagesTarget products to meet 20% demandAlma Dela PeñaNo ratings yet

- Climate Bogeyman3 PDFDocument199 pagesClimate Bogeyman3 PDFIonel Leon100% (1)

- Australian Securities and Investments Commission V KingDocument47 pagesAustralian Securities and Investments Commission V KingCourtni HolderNo ratings yet

- RetailMarketinginIndia 1Document158 pagesRetailMarketinginIndia 1RamanNo ratings yet

- Window On The Wetlands BrochureDocument2 pagesWindow On The Wetlands BrochureliquidityNo ratings yet

- Charles Henry Brendt (1862-1929)Document2 pagesCharles Henry Brendt (1862-1929)Everything newNo ratings yet

- A Ghost StoryDocument10 pagesA Ghost StoryTrần MạnhNo ratings yet

- How The Voice Works HandoutDocument7 pagesHow The Voice Works HandoutMatthew ColleyNo ratings yet

- How to Stop Overthinking and Make DecisionsDocument39 pagesHow to Stop Overthinking and Make DecisionsDeepak SinghNo ratings yet

- Lesson 1 Context CluesDocument33 pagesLesson 1 Context CluesRomnick BistayanNo ratings yet

- Newton's Laws of Motion: Problem SetDocument9 pagesNewton's Laws of Motion: Problem SetRoda Gayle RañadaNo ratings yet

- Titanium Plates and Screws For Open Wedge HtoDocument6 pagesTitanium Plates and Screws For Open Wedge HtoDaniel Quijada LucarioNo ratings yet

- Business Decision Making Assignment (July 2015)Document23 pagesBusiness Decision Making Assignment (July 2015)Michael Oppong100% (1)

- Indigo CaseDocument13 pagesIndigo Caseharsh sainiNo ratings yet

- HamletDocument37 pagesHamlethyan teodoroNo ratings yet

- CLASS 7B Result Software 2023-24Document266 pagesCLASS 7B Result Software 2023-24JNVG XIB BOYSNo ratings yet

- ACCT250-Auditing Course OutlineDocument7 pagesACCT250-Auditing Course OutlineammadNo ratings yet

- What Is MotivationDocument6 pagesWhat Is MotivationJohn Paul De GuzmanNo ratings yet

- L.G.B.T. Fiction: Book ReviewDocument4 pagesL.G.B.T. Fiction: Book ReviewDejana KosticNo ratings yet

- Test Bank For American Pageant Volume 1 16th EditionDocument36 pagesTest Bank For American Pageant Volume 1 16th Editionzoonwinkfoxyj8100% (48)

- SCM Software Selection and EvaluationDocument3 pagesSCM Software Selection and EvaluationBhuwneshwar PandayNo ratings yet