Professional Documents

Culture Documents

Ds Ms54xx b2

Uploaded by

mecanderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds Ms54xx b2

Uploaded by

mecanderCopyright:

Available Formats

MS54XX

Miniature SMD Pressure Sensor

SPECIFICATIONS

1, 7, 12, and 70 bar absolute pressure range

Uncompensated

Piezoresistive silicon micromachined sensor

Miniature surface mount

Ceramic carrier

Low noise, high sensitivity, high linearity

The MS54XX SMD pressure sensor series is designed for

pressure sensor systems with highest demands on resolution and

accuracy. The device consists of a silicon micromachined

pressure sensor die mounted on a

6.2 x 6.4 mm ceramic carrier. The MS54XX can be delivered in a

high sensitivity version giving a maximal output voltage or in a

high linearity version. Both versions provide an output voltage

directly proportional to the applied pressure

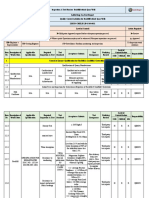

High Sensitivity Versions High Linearity Versions

Carrier Full scale Full Full

Product Product

pressure scale Linearity scale Linearity

code code

span span

1 bar MS5401-AM 240 mV ±0.20 % FS MS5401-BM 150 mV ±0.05 % FS

7 bar MS5407-AM 392 mV ±0.20 % FS

Ceramic

12 bar MS5412-BM 150 mV ±0.05 % FS

70 bar MS5470-AM 310 mV ±0.25 % FS

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 1

MS54XX

Miniature SMD Pressure Sensor

FEATURES

Low cost SMD package

Small size

High reliability, low drift

-40 °C to +125 °C operation range

Gel protection against humidity and water

APPLICATIONS

Brake systems

High resolution altimeters, variometers

Barometers

Engine management

Waterproof watches and diving computers

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 2

MS54XX

Miniature SMD Pressure Sensor

PIN CONFIGURATION

3: VS+

4: OUT+ 1: OUT-

2: GND

PIN DESCRIPTION

Pin Name Pin No Function

OUT- 1 Negative output voltage of Wheatstone bridge

GND 2 Ground

VS+ 3 Supply voltage of Wheatstone bridge

OUT+ 4 Positive output voltage of Wheatstone bridge

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Conditions Min Max Unit

Supply voltage VS+ Ta = 25 °C - 20 V

Storage temperature TS -40 +125 °C

Overpressure MS5401-AM

- 5

MS5401-BM (1) - 10

P Ta = 25 °C bar

MS5407-AM (2) - 21

MS5412-BM - 30

MS5470-AM - 180

NOTES

1) The MS5401-BM is qualified referring to ISO Standard 2281 and can withstand an absolute pressure of 11 bar

in salt water or 100 m water respectively.

2) The MS5407-AM is qualified referring to ISO Standard 2281 and can withstand an absolute pressure of 21 bar

in salt water or 200 m water specifically.

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 3

MS54XX

Miniature SMD Pressure Sensor

ELECTRICAL CHARACTERISTICS

HIGH SENSITIVITY VERSION

(Vs+ = 5 V; Ta = 25 °C)

Parameter Min Typ Max Unit Notes

Operating pressure range 0 - 1 bar

MS5401-AM Full-scale span (FS) 190 240 290 mV

Sensitivity 190 240 290 mV/bar

Linearity - ±0.15 ±0.40 % FS 1, 6

Operating pressure range 0 - 7 bar

Full-scale span (FS) 322 392 462 mV

MS5407-AM

Sensitivity 46 56 66 mV/bar

Linearity ±0.15 ±040 % FS 1, 6

Operating pressure range 0 - 70 bar

Full-scale span (FS) 250 310 370 mV

MS5470-AM

Sensitivity 3.6 4.4 5.3 mV/bar

Linearity ±0.25 ±0.50 % FS 1, 6

Operating temperature range -40 - 125 °C

Zero pressure offset -40 0 40 mV

Pressure hysteresis - - ±0.20 % FS 2, 6

Temperature hysteresis - 0.3 0.8 % FS 3, 6

All Ranges Repeatability - - ±0.20 % FS 4, 6

Bridge resistance 3.0 3.4 3.8 kΩ

Temperature coefficient of resistance +2'400 2'900 +3'300 ppm/°C 5, 6

Temperature coefficient of span -1'500 -1'900 -2'300 ppm/°C 5, 6

Temperature coefficient of offset -80 - +80 µV/°C 5, 6

NOTES

1) Deviation at one half full-scale pressure from the least squares best line fit over pressure range.

2) Maximum difference of output voltage after 1 pressure cycle at any pressure within the operating pressure

range.

3) Maximum difference in offset after one thermal cycle from -40°C to +125°C.

4) Same as 2) after 10 pressure cycles.

5) Slope of the end-point straight line from 25°C to 60°C.

6) Not 100% tested.

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 4

MS54XX

Miniature SMD Pressure Sensor

ELECTRICAL CHARACTERISTICS (CONT.)

HIGH LINEARITY VERSIONS

(Vs+ = 5 V; Ta = 25 °C)

Parameter Min Typ Max Unit Notes

Operating pressure range 0 - 1 bar 8

MS5401-BM Full-scale span (FS) 120 150 180 mV

Sensitivity 120 150 180 mV/bar

Linearity - ±0.05 ±0.20 % FS 1, 6

Operating pressure range 0 - 12 bar 8

Full-scale span (FS) 120 150 180 mV

MS5412-BM

Sensitivity 10 12.5 15 mV/bar

Linearity ±0.05 ±0.15 % FS 1, 6

Operating temperature range -40 - 125 °C

Zero pressure offset -40 0 40 mV

Pressure hysteresis - - ±0.20 % FS 2, 6

Temperature hysteresis - 0.3 0.8 % FS 3, 6

All Ranges Repeatability - - ±0.20 % FS 4, 6, 7

Bridge resistance 3.0 3.4 3.8 kΩ

Temperature coefficient of resistance +2'400 2'900 +3'300 ppm/°C 5, 6

Temperature coefficient of span -1'500 -1'900 -2'300 ppm/°C 5, 6

Temperature coefficient of offset -80 - +80 µV/°C 5, 6

NOTES

1) Deviation at one half full-scale pressure from the least squares best line fit over pressure range.

2) Maximum difference of output voltage after 1 pressure cycle at any pressure within the operating pressure

range.

3) Maximum difference in offset after one thermal cycle from -40°C to +125°C.

4) Same as 2) after 10 pressure cycles.

5) Slope of the end-point straight line from 25°C to 60°C.

6) Not 100% tested.

7) MS5412-BM: Max. 0.3% FS

8) This sensor family is optimized for the linearity; it is suitable for applications with higher pressure where the

linearity requirement is less critical.

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 5

MS54XX

Miniature SMD Pressure Sensor

APPLICATION INFORMATION

GENERAL

The MS54XX is a miniaturized absolute pressure sensor series which has been designed as a surface mount device

(SMD). Its main advantages are the high performance of the semiconductor sensor and a design which makes it

suitable for applications requiring small dimensions and cost efficiency.

The sensor element of the MS54XX consists of a micromachined silicon membrane with borosilicate glass wafer-

bonded under vacuum to the back side for reference pressure. Implanted resistors make use of the piezo-resistive

effect to sense pressure applied to the membrane. The sensor is mounted using a special process allowing best

offset stability making the device suitable for direct PCB assembly.

Typical applications for this miniaturized pressure sensor MS54XX are altitude measurements and the

measurement of atmospheric reference pressure in medical and industrial equipment as well as in automotive and

household applications, consumer electronics and pneumatics.

Full Scale High Sensitivity Versions High Linearity Versions

Pressure (MS54XX-AX) (MS54XX-BX)

1 bar Variometer, Altimeter, Barometer High End Altimeter, Medical Instrumentation

7 bar Divers Watch, Tire Pressure, Electronic Scale High End Electronic Scale

12 bar Pneumatic Brake, Diving Computer

70 bar Engine Control, Diving Computer

HUMIDITY, WATER PROTECTION

MS54XX-XM WITH METAL CAP

The MS54XX-AM / - BMXXBA has an anticorrosive and antimagnetic metallic protection cap filled with silicone gel

for enhanced protection against humidity. The properties of this gel ensure function of the sensor even when in

direct water contact. This feature can be useful for waterproof watches or other applications, where direct water

contact cannot be avoided. Nevertheless the user should avoid drying of hard materials like for example salt

particles on the silicone gel surface. In this case it is advisable to rinse with clean water afterwards. Special care

has to be taken not to mechanically damage the gel. Damaged gel may lead to air entrapment and consequently to

unstable sensor signal, especially if the damage is close to the sensor surface.

The metal cap is fabricated of special anticorrosive alloy in order to avoid any galvanic effects within the end product.

The MS5401-BM is qualified referring to the ISO Standard 2281 and can withstand a pressure of 11 bar in salt

water. The concentration of the sea water used for the qualification is 41 g of sea salt per 1 litre of DI water. The

MS5407-BM satisfies salt-water testing with a pressure capability of 21 bar.

For underwater operations as specified in ISO Standard 2281 it is important to seal the sensor with a rubber O-ring

around the metal cap. Any salt water reaching the contact side (ceramic and pads) of the sensor could lead to

permanent damage. Especially for "water-resistant 100 m" watches and for diving computers, it is recommended

to provide a stable mechanical pusher from the backside of the sensor; otherwise the overpressure may push the

sensor backwards and even deform the electronic board on which the sensor is mounted.

LIGHT SENSITIVITY

The MS54XX is sensitive to sunlight (visible and near-infrared spectrum). This is due to the strong photo effect of

silicon. As the effect is reversible there will be no damage, but the user has to take care that in the final product the

sensor cannot be exposed to direct light during operation as it effects the measurement. This can be achieved for

instance by placing mechanical parts with holes in such that light cannot pass.

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 6

MS54XX

Miniature SMD Pressure Sensor

CONNECTION TO PCB

The package outline of the module enables the use of a flexible PCB to connect it. This can be important for

applications in watches and other special devices, and will also reduce mechanical stress on the device.

For applications subjected to mechanical shock, it is recommended to enhance the mechanical reliability of the

solder junctions by covering the rim or the corners of MS54XX ceramic substrate with glue or globtop-like material.

SOLDERING

Please refer to the application note AN808 for all soldering issues.

CLEANING

The MS54XX has been manufactured under clean-room conditions. Each device is inspected for homogeneity and

cleanness of the silicone gel. It is therefore recommended to assemble the sensor under class 10 000 or better

conditions. Should this not be possible, it is recommended to protect the sensor opening during assembly from

entering particles and dust. To avoid cleaning of the PCB, solder paste of type “no-clean” must be used. Cleaning

might damage the sensor.

RECOMMENDED PAD LAYOUT

Recommended pad layout for soldering of the MS54XX on a printed circuit board

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 7

MS54XX

Miniature SMD Pressure Sensor

PACKAGE OUTLINES

CERAMIC CARRIER AND METAL CAP

Device package outlines of MS54XX-AM and MS54XX-BM

(M = anticorrosive and antimagnetic stainless steel cap)

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 8

MS54XX

Miniature SMD Pressure Sensor

PACKING

The MS54XX is packed in 51 cm (20-inch) antistatic plastic tubes with rubber end-plugs of different colors: one

green and one black. The dot on the carrier next to Pin 1 is facing the green end-plug. Each tube contains 80

sensors. The tubes are marked "ANTISTATIC" and have an information label.

See the drawings below for more details.

PACKING TUBE OUTLINES

Information label

8.2

510

All measures in mm

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 9

MS54XX

Miniature SMD Pressure Sensor

ORDERING INFORMATION

Product code Product Art. No Package Delivery Form

325401001-00 Ceramic carrier Tube

325401001-50 Ceramic carrier Tape and Reel

Miniature pressure sensor 1 bar, High

MS5401-AM Ceramic carrier, Tube

sensitivity

325401006-00 without

transparent gel

325401000-00 Ceramic carrier Tube

325401000-50 Ceramic carrier Tape and Reel

MS5401-BM Pressure sensor 1 bar, High linearity Ceramic carrier, Tube

325401002-00 without

transparent gel

325407000-00 Ceramic carrier Tube

325407000-50 Ceramic carrier Tape and Reel

Miniature pressure sensor 7 bar, High

MS5407-AM Ceramic carrier, Tube

sensitivity

325407001-00 without

transparent gel

Tube

325412000-00 Ceramic carrier

MS5412-BM Pressure sensor 12 bar, High linearity

325412000-50 Ceramic carrier Tape and Reel

Miniature pressure sensor 70 bar, Tube

MS5470-AM 325470000-00 Ceramic carrier

High sensitivity

AX = high sensitivity

BX = high linearity

XM = anticorrosive and antimagnetic metallic cap

NORTH AMERICA EUROPE ASIA

Measurement Specialties, Inc., Measurement Specialties (Europe), Ltd., Measurement Specialties (China), Ltd.,

a TE Connectivity Company a TE Connectivity Company a TE Connectivity Company

Tel: 800-522-6752 Tel: 800-440-5100 Tel: 0400-820-6015

Email: customercare.frmt@te.com Email: customercare.lcsb@te.com Email: customercare.shzn@te.com

TE.com/sensorsolutions

Measurement Specialties, Inc., a TE Connectivity company.

Measurement Specialties, TE Connectivity, TE Connectivity (logo) and EVERY CONNECTION COUNTS are trademarks. All other logos, products and/or company names referred to herein

might be trademarks of their respective owners.

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes only, is believed to be reliable. However, TE Connectivity makes

no warranties as to its accuracy or completeness and disclaims any liability in connection with its use. TE Connectivity‘s obligations shall only be as set forth in TE Connectivity‘s Standard

Terms and Conditions of Sale for this product and in no case will TE Connectivity be liable for any incidental, indirect or consequential damages arising out of the sale, resale, use or misuse

of the product. Users of TE Connectivity products should make their own evaluation to determine the suitability of each such product for the specific application.

© 2015 TE Connectivity Ltd. family of companies All Rights Reserved.

SENSOR SOLUTIONS ///MS54XX 06/2017 Page 10

You might also like

- TST PM82 enDocument2 pagesTST PM82 endawitNo ratings yet

- Semiconductor Technical Data: 0 To 200 Kpa (0 - 29 Psi) 60 MV Full Scale Span (Typical)Document8 pagesSemiconductor Technical Data: 0 To 200 Kpa (0 - 29 Psi) 60 MV Full Scale Span (Typical)Phong DoNo ratings yet

- DB DMP331 eDocument5 pagesDB DMP331 egilad.leizerNo ratings yet

- Eng DS Ms5525dso D20-786470Document24 pagesEng DS Ms5525dso D20-786470ANo ratings yet

- Eng DS MS4525 B9 PDFDocument16 pagesEng DS MS4525 B9 PDFHichem MabroukiNo ratings yet

- DB DMP331 eDocument6 pagesDB DMP331 etouili majdiNo ratings yet

- Eng DS Ms4525do B10Document19 pagesEng DS Ms4525do B10Rene KurniadiNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- Screw-In Transmitter: Stainless Steel SensorDocument4 pagesScrew-In Transmitter: Stainless Steel SensorjOAONo ratings yet

- Max6070 Max6071 PDFDocument23 pagesMax6070 Max6071 PDFXan OVNo ratings yet

- Documento Met A NoDocument8 pagesDocumento Met A NoDayana BarahonaNo ratings yet

- Max 5407Document7 pagesMax 5407agifieldfoxNo ratings yet

- MS763Document4 pagesMS763Biosens BioNo ratings yet

- DB DMP333 eDocument6 pagesDB DMP333 eHossam A.MoneimNo ratings yet

- 24PC Pressure SensorsDocument4 pages24PC Pressure SensorsrngNo ratings yet

- Industrial Pressure Transmitter for High Pressure ApplicationsDocument5 pagesIndustrial Pressure Transmitter for High Pressure ApplicationspaulNo ratings yet

- OEM Pressure Transmitter Low Pressure: ApplicationsDocument3 pagesOEM Pressure Transmitter Low Pressure: ApplicationsVivian Daniela Velandia ViedaNo ratings yet

- DB LMP307 eDocument5 pagesDB LMP307 egilad.leizerNo ratings yet

- MS5837 07baDocument18 pagesMS5837 07baRene KurniadiNo ratings yet

- PC Board Mountable Pressure Sensor Features & SpecsDocument4 pagesPC Board Mountable Pressure Sensor Features & SpecsAsad AhmedNo ratings yet

- D O S O: Ifferential Utput Ilicon ScillatorDocument8 pagesD O S O: Ifferential Utput Ilicon ScillatorkynixNo ratings yet

- Smart DCM/SN Diff: WarningDocument24 pagesSmart DCM/SN Diff: WarningPiyapong ChianpimaiNo ratings yet

- DB LMK351 eDocument4 pagesDB LMK351 eJoaldo SantosNo ratings yet

- VRF2933 PDFDocument5 pagesVRF2933 PDFWalter Artur Artur MendesNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- ms1022 gp22 EquivalentDocument60 pagesms1022 gp22 Equivalentdbm100% (1)

- MS5837-02BA: Gel-Filled, Ultra-Compact, Water Resistant Digital Pressure and Temperature SensorDocument17 pagesMS5837-02BA: Gel-Filled, Ultra-Compact, Water Resistant Digital Pressure and Temperature SensorIdehen KelvinNo ratings yet

- MS5837 30baDocument16 pagesMS5837 30baAbdelaziz AbdelghanyNo ratings yet

- Bipolar Hall-Effect Position Sensor Technical OverviewDocument6 pagesBipolar Hall-Effect Position Sensor Technical OverviewJulioCesarMonteiroNo ratings yet

- Datasheet Hall SensorDocument6 pagesDatasheet Hall SensorPhong Nguyễn WindyNo ratings yet

- MST5350B MilestoneSemiconductorDocument10 pagesMST5350B MilestoneSemiconductorJR RegisNo ratings yet

- r5d PDFDocument30 pagesr5d PDFHưng HQ100% (1)

- ZR4040-4.1 Rev6-3 May2022Document5 pagesZR4040-4.1 Rev6-3 May2022daniel SNo ratings yet

- TESS - Pressure Sensors - SS TS TE100Document10 pagesTESS - Pressure Sensors - SS TS TE100halil ibrahim soysalNo ratings yet

- STMicroelectronics Webinar on Environmental SensorsDocument36 pagesSTMicroelectronics Webinar on Environmental SensorsDaniel MartinsNo ratings yet

- IR Receiver Modules For Remote Control Systems: Vishay SemiconductorsDocument7 pagesIR Receiver Modules For Remote Control Systems: Vishay SemiconductorsGautham HarinarayanNo ratings yet

- DTS Ks-Sil2 01-2019 Eng PDFDocument8 pagesDTS Ks-Sil2 01-2019 Eng PDFMiguel Ángel CenamorNo ratings yet

- Interactive Catalog Replaces Catalog PagesDocument5 pagesInteractive Catalog Replaces Catalog PagesDandy PrasetyoNo ratings yet

- LM4040, LM4041 Precision Micro-Power Shunt Voltage ReferencesDocument14 pagesLM4040, LM4041 Precision Micro-Power Shunt Voltage Referencesalvarogm10No ratings yet

- SS5080 Sensor Hall SeriesDocument4 pagesSS5080 Sensor Hall SeriesAnonymous ePW4IGwRWNo ratings yet

- MS5611 01BA03 AMSYS DatasheetDocument22 pagesMS5611 01BA03 AMSYS DatasheetDanil StefanovNo ratings yet

- DIM20Document2 pagesDIM20merikNo ratings yet

- MS5803-05BA: Miniature Altimeter and Diving ModuleDocument19 pagesMS5803-05BA: Miniature Altimeter and Diving ModuleBirendra KumarNo ratings yet

- DCBD AY1415-Bai Tap On Thi Cuoi KyDocument4 pagesDCBD AY1415-Bai Tap On Thi Cuoi KyErik ChanNo ratings yet

- LM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionDocument7 pagesLM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionAndrés Cely AgudeloNo ratings yet

- Product Profile: 60 V, 360 Ma N-Channel Trench MOSFETDocument15 pagesProduct Profile: 60 V, 360 Ma N-Channel Trench MOSFETmhemaraNo ratings yet

- Product Profile: 60 V, 360 Ma N-Channel Trench MOSFETDocument15 pagesProduct Profile: 60 V, 360 Ma N-Channel Trench MOSFETFelixChoqueNo ratings yet

- PWM Constant-Current Control Stepper Motor Driver: Bi-Cmos IcDocument22 pagesPWM Constant-Current Control Stepper Motor Driver: Bi-Cmos IcMari FlorentinaNo ratings yet

- MP3V5050 70736 PDFDocument12 pagesMP3V5050 70736 PDFAngel BlancasNo ratings yet

- cảm biến chân ty 2Document5 pagescảm biến chân ty 2Trần Quốc ĐôngNo ratings yet

- Explosion-Proof Magnetostrictive Liquid Level SensorDocument5 pagesExplosion-Proof Magnetostrictive Liquid Level SensoribilalashrafNo ratings yet

- Piezorresistive Transmitters: Model: 21R - 21 SR / MRDocument2 pagesPiezorresistive Transmitters: Model: 21R - 21 SR / MRMarcelo PellizzaNo ratings yet

- Ultra-Low Pressure Digital Sensor: SM9333/SM9336 Series Differential Pressure SensorsDocument19 pagesUltra-Low Pressure Digital Sensor: SM9333/SM9336 Series Differential Pressure SensorsBiswajit SinghNo ratings yet

- HBM P3 Top ClassDocument10 pagesHBM P3 Top ClasslgustavolucaNo ratings yet

- PN2293 01 - en GBDocument5 pagesPN2293 01 - en GBpunietNo ratings yet

- Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument9 pagesIntegrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedFaisalNo ratings yet

- MPXV5050VC6T1-R3 2018Document9 pagesMPXV5050VC6T1-R3 2018leonardoviolimNo ratings yet

- High-pressure sensors measurement up to 25 MPaDocument3 pagesHigh-pressure sensors measurement up to 25 MPaX'mix ĐreamerNo ratings yet

- Newnes Electronics Engineers Pocket BookFrom EverandNewnes Electronics Engineers Pocket BookRating: 4.5 out of 5 stars4.5/5 (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Manual Lavadora Indesit PDFDocument72 pagesManual Lavadora Indesit PDFcasperllNo ratings yet

- Shell Technology Liner Technology: Foot Segmentation Liner ConstructionsDocument2 pagesShell Technology Liner Technology: Foot Segmentation Liner ConstructionsmecanderNo ratings yet

- Hagan Product Range 2015/16: FeaturesDocument24 pagesHagan Product Range 2015/16: FeaturesmecanderNo ratings yet

- Hagan-Katalog2015-16 EN LowDocument19 pagesHagan-Katalog2015-16 EN LowmecanderNo ratings yet

- Catalogo Dolomite Outdoor SS16 Mid Res (CalzadoOutdoor)Document68 pagesCatalogo Dolomite Outdoor SS16 Mid Res (CalzadoOutdoor)mecanderNo ratings yet

- Ds Ms54xx b2Document10 pagesDs Ms54xx b2mecanderNo ratings yet

- OS Buyers Guide FC7H344965Document18 pagesOS Buyers Guide FC7H344965mecanderNo ratings yet

- Caching, Queries, Entity Framework ReferencesDocument13 pagesCaching, Queries, Entity Framework ReferencesmecanderNo ratings yet

- Catalogo Dolomite Outdoor SS16 Mid Res (CalzadoOutdoor)Document68 pagesCatalogo Dolomite Outdoor SS16 Mid Res (CalzadoOutdoor)mecanderNo ratings yet

- Quick Reference Guide: Dell™ Optiplex™ Gx620Document144 pagesQuick Reference Guide: Dell™ Optiplex™ Gx620Dan VasiliuNo ratings yet

- NAV2009 03 Multipile LocationsDocument42 pagesNAV2009 03 Multipile LocationsmecanderNo ratings yet

- Quick Reference Guide: Dell™ Optiplex™ Gx620Document144 pagesQuick Reference Guide: Dell™ Optiplex™ Gx620Dan VasiliuNo ratings yet

- Manage Data With Transact-SQL: Skill 1.2: Query Multiple Tables by Using JoinsDocument21 pagesManage Data With Transact-SQL: Skill 1.2: Query Multiple Tables by Using JoinsmecanderNo ratings yet

- 4 SSLinIISDocument10 pages4 SSLinIISmecanderNo ratings yet

- Developer Updates For. Microsoft Dynamics NAV PDFDocument43 pagesDeveloper Updates For. Microsoft Dynamics NAV PDFgasif2000No ratings yet

- GettingStarted 3741Document62 pagesGettingStarted 3741mecanderNo ratings yet

- 008 - Accessing Your Model's Data From A Controller - Microsoft DocsDocument13 pages008 - Accessing Your Model's Data From A Controller - Microsoft DocsmecanderNo ratings yet

- Microsoft Excel 2007-Tips & Tricks: Absolute ValueDocument27 pagesMicrosoft Excel 2007-Tips & Tricks: Absolute ValuemecanderNo ratings yet

- Accelerating OpenAPI Design Development With Next Level MockingDocument18 pagesAccelerating OpenAPI Design Development With Next Level MockingmecanderNo ratings yet

- 0006 - Adding A Model - Microsoft DocsDocument4 pages0006 - Adding A Model - Microsoft DocsmecanderNo ratings yet

- Dell EMC Ready Bundle For Microsoft SQL ServerDocument27 pagesDell EMC Ready Bundle For Microsoft SQL ServermecanderNo ratings yet

- 016 - Implementing Basic CRUD Functionality With The Entity Framework in ASP PDFDocument20 pages016 - Implementing Basic CRUD Functionality With The Entity Framework in ASP PDFmecanderNo ratings yet

- 008 - Accessing Your Model's Data From A Controller - Microsoft DocsDocument13 pages008 - Accessing Your Model's Data From A Controller - Microsoft DocsmecanderNo ratings yet

- 015 - Getting Started With Entity Framework 6 Code First Using MVC 5 - Microsoft Docs PDFDocument25 pages015 - Getting Started With Entity Framework 6 Code First Using MVC 5 - Microsoft Docs PDFmecanderNo ratings yet

- 013 - Examining The Details and Delete Methods - Microsoft Docs PDFDocument4 pages013 - Examining The Details and Delete Methods - Microsoft Docs PDFmecanderNo ratings yet

- 011 - Adding A New Field - Microsoft Docs PDFDocument14 pages011 - Adding A New Field - Microsoft Docs PDFmecanderNo ratings yet

- 016 - Implementing Basic CRUD Functionality With The Entity Framework in ASP PDFDocument20 pages016 - Implementing Basic CRUD Functionality With The Entity Framework in ASP PDFmecanderNo ratings yet

- 012 - Adding Validation - Microsoft Docs PDFDocument11 pages012 - Adding Validation - Microsoft Docs PDFmecanderNo ratings yet

- 014 - Getting Started With Entity Framework 6 Code First Using MVC 5 - Microsoft Docs PDFDocument1 page014 - Getting Started With Entity Framework 6 Code First Using MVC 5 - Microsoft Docs PDFmecanderNo ratings yet

- Catalog Appleton PLG Close Up Plugs BR Reducers en Us 190422Document2 pagesCatalog Appleton PLG Close Up Plugs BR Reducers en Us 190422maygomezNo ratings yet

- ITP of Backfill Behind Quay Wall C01Document6 pagesITP of Backfill Behind Quay Wall C01魏利强No ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Formulation Fundamentals Across IndustriesDocument7 pagesFormulation Fundamentals Across IndustriesAdil Anwar0% (1)

- Cyclic TriaxialDocument2 pagesCyclic TriaxialnkotiaNo ratings yet

- Calorimetry SheetDocument26 pagesCalorimetry SheetAbdullahNo ratings yet

- 3.3 BleachingDocument28 pages3.3 Bleachingshym hjrNo ratings yet

- The Profesional's Advisor On ProceedureDocument136 pagesThe Profesional's Advisor On ProceedureINSTECH ConsultingNo ratings yet

- Importance and Methods of Enhancing MetalDocument56 pagesImportance and Methods of Enhancing MetalJoan F. Malig75% (20)

- Comparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteDocument9 pagesComparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteIJRASETPublicationsNo ratings yet

- Koyo Ceramic Catb1013exDocument17 pagesKoyo Ceramic Catb1013exJose DonaireNo ratings yet

- ASTM C-865-2002 Standard Practice For Firing of Refractory Concrete SpecimenDocument3 pagesASTM C-865-2002 Standard Practice For Firing of Refractory Concrete SpecimenGajendra PandeyNo ratings yet

- Advance Engineering Classes: Mob.: +917879930147, PH.: 0755-4916240Document33 pagesAdvance Engineering Classes: Mob.: +917879930147, PH.: 0755-4916240swaparnikaNo ratings yet

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- A Review On Nano Uids: Preparation, Stability Mechanisms, and ApplicationsDocument18 pagesA Review On Nano Uids: Preparation, Stability Mechanisms, and ApplicationsdasdasNo ratings yet

- PENGARUH SUHU DAN WAKTU PEMANASANDocument8 pagesPENGARUH SUHU DAN WAKTU PEMANASANFebi Azizah Permata SariNo ratings yet

- Dissolution Apparatus - USPDocument6 pagesDissolution Apparatus - USPkakak zeaNo ratings yet

- Modulation of The Band Gap of Graphene Oxide-The Role of AA-stackingDocument8 pagesModulation of The Band Gap of Graphene Oxide-The Role of AA-stackingcbs78No ratings yet

- FINITE ELEMENT 18ME73 ASSIGNMENTSDocument10 pagesFINITE ELEMENT 18ME73 ASSIGNMENTSFOODIE USNo ratings yet

- Chemical Reaction Unit Test - QuizizzDocument4 pagesChemical Reaction Unit Test - QuizizzAngkita KiranaNo ratings yet

- ProgrammeDocument78 pagesProgrammedileep mNo ratings yet

- Agitator Manual Chemineer PDFDocument102 pagesAgitator Manual Chemineer PDFArunkumar100% (2)

- Ulma Offer Summary 32011 GarlandsDocument47 pagesUlma Offer Summary 32011 GarlandsSarah Layadi100% (1)

- Skema Halus Persamaan Kimia - PDFDocument9 pagesSkema Halus Persamaan Kimia - PDFIza MohdSabri33% (3)

- Min. Requirements For Retaining Wall/Sloping BackfillDocument6 pagesMin. Requirements For Retaining Wall/Sloping Backfillfostbarr0% (1)

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- Ballistic Resistance of Novel Amorphous-Alloy-Reinforced Perforated ArmorDocument15 pagesBallistic Resistance of Novel Amorphous-Alloy-Reinforced Perforated ArmoraamirmubNo ratings yet

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Document1 pageEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- BS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General IntroductionDocument18 pagesBS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General Introductionssebastian8177100% (7)