Professional Documents

Culture Documents

Monitoring Gear Drives

Uploaded by

akhilsaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monitoring Gear Drives

Uploaded by

akhilsaCopyright:

Available Formats

Monitoring the Health

of Gear Drives

Predictive Maintenance Being The Best

Insurance Against Equipment Failure

Summary

Threat of equipment failure and unplanned downtime haunts all

maintenance supervisors. The best way to avoid costly repair,

rebuild or replacement jobs for any piece of equipment is to

prevent trouble before it occurs. Predictive maintenance, the

methodical analysis of the most likely sources of trouble,

provides the best insurance against equipment failures. In the

case of gear drives, this article will focus on predictive

maintenance and measured changes in vibration, noise,

temperature and oil.

Falk_RB03012

The Falk Corporation

4 pages

November 2003

SKF Reliability Systems

@ptitudeXchange

5271 Viewridge Court

San Diego, CA 92123

United States

tel. +1 858 496 3554

fax +1 858 496 3555

email: info@aptitudexchange.com

Internet: www.aptitudexchange.com

Use of this document is governed by the terms

and conditions contained in @ptitudeXchange.

Monitoring the Health of Gear Drives

Introduction equipment is used to better evaluate the need

for corrective action on specific components.

Threat of equipment failure and unplanned

downtime haunts all maintenance supervisors. Guidance for defining typical vibration levels

The best way to avoid costly repair, rebuild or for commercial gear drives is given in AGMA

replacement jobs for any piece of equipment is standards.

to prevent trouble before it occurs. Predictive

maintenance, the methodical analysis of the Sound

most likely sources of trouble, provides the

best insurance against equipment failures. Performing sound analysis is easier than

vibration analysis, but because it is one step

In the case of gear drives, predictive removed from the trouble source it should be

maintenance primarily concerns itself with part of a more extensive predictive

measured changes in vibration, noise, maintenance routine.

temperature and oil.

An operator who is familiar with a piece of

Vibration equipment may be able to detect a subtle

change in the level or type of noise coming

Vibration levels of new gear drives vary due from the gearbox. However, the use of

to the statistical nature of the factors that instruments helps quantify noise

influence the vibrations. The initial vibration characteristics and variance over time.

level tends to remain unchanged for a long

period of time. As components start to wear or Sound is accurately diagnosed through the use

fail, the vibration level rises. of frequency measurement devices. For

example, if a gear mesh is starting to wear the

Two methods used to determine vibration amplitude of the sound at the mesh frequency

performance of the equipment are trending tends to increase. An increase in gear mesh

and diagnostics. Both methods are widely frequency may indicate a wear problem. On

used in grain processing mills, refineries, the other hand, a bearing generates different

power plants and other process industries frequency and has its own signals to suggest

where continuous operation of gear drives is wear.

critical.

Sound by itself does not necessarily mean the

Trending monitors vibration over time using beginning of a failure pattern. The sound must

accelerometers or velocity pick-ups. Monitors be traced to a particular component and then

continuously measure vibration levels, while compared to its normal sound level.

hand-held instruments periodically analyze

vibration. As a safety precaution to avoid Temperature

catastrophic failure, continuous monitors

feature preset safety shutdown levels. Monitoring the operating temperature of gear

drives is common practice. Variations in

Diagnostic equipment measures the frequency operating temperature may indicate trouble.

content of vibration. The overall vibration To prevent temperature variations, set a

level is broken down into individual frequency maximum toleration temperature and have an

components. These separate readings are then alarm sound when the temperature reaches the

linked to specific pieces of equipment, such as threshold. It is not unusual for the alarm to

bearings or a pump. When trend readings sound because a bearing or the lubricant is

indicate increasing vibration levels, diagnostic failing.

© 2004 SKF Reliability Systems All Rights Reserved 2

Monitoring the Health of Gear Drives

Temperature fluctuations are diagnosed by shutting down the machine ensures freshly

sensors that are placed inside the gear housing circulate, evenly distributed oil. The plant or

and are connected to a gauge or other readout an independent testing laboratory then

apparatus on the outside of the gearbox. The analyzes the sample.

two types of sensors are Thermocouples and

Resistance Temperature Devices (RTD).

A Thermocouple contains two dissimilar wires

bonded together producing an electrical

current with temperature change. A RTD

relies on material that changes resistance with

temperature. As temperature changes, the

corresponding resistance change is sensed in

electrical readout circuits.

Both sensor systems measure the skin

temperature of the gear housing, the outer race

of bearing, bulk oil or other areas where

proper temperature is essential. Both systems

are reliable.

Figure 2 Oil samples are an excellent way to detect the

source of trouble before it affects the performance of

the equipment. Collect a sample from the top central

area of the oil reservoir immediately after shutting

down the machine.

Oil analysis targets three principal factors:

changes in viscosity, the amount of water in

the oil, and the presence of foreign particles.

An oil sample showing viscosity levels rising

about the proper range indicated deterioration.

Figure 1 Thermocouples and resistance temperature The presence of sludge denotes oil

devices (RTD) can measure the skin temperature of the breakdown. An excess amount of water

gear housing, the outer race of bearing, bulk oil or contributes to ruse, loss of lubrication, and

other areas where proper temperature is essential.

eventual component breakdown. The analysis

also takes a close look at contaminants in the

Oil Analysis oil. The composition of these help identify

Oil samples are an excellent way of detecting whether contaminants are entering the gearbox

trouble before it affects the performance of the from the outside, or if some part within the

equipment. Samples should be taken in gearbox is wearing out.

accordance with the equipment manufacturer's

recommendations and test results compared to Conclusion

the lube manufacturer's specifications. Machine wear is inevitable. But, by following

these predictive maintenance guidelines on a

Collecting oil samples from the top central

regular basis, wear can be monitored and

area of the oil reservoir immediately after

costly, unplanned downtime avoided.

© 2004 SKF Reliability Systems All Rights Reserved 3

Monitoring the Health of Gear Drives

About Falk

Falk is a world-leading manufacturer of

industrial mechanical power transmission

solutions. Falk leverages its legacy in power

transmission solutions - from standard and

custom gear drives, to couplings and

backstops, to unmatched service and support -

to provide the best customer experience and

the lowest total cost of ownership through its

reliability, leadership, and speed.

By Michael B. Antosiewicz, Manager-

Research & Technology, The Falk

Corporation

© 2004 SKF Reliability Systems All Rights Reserved 4

You might also like

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Vibration Monitoring: Envelope Signal ProcessingDocument14 pagesVibration Monitoring: Envelope Signal ProcessingDkdkkd100% (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- 237258Document14 pages237258Alberto Remolar100% (1)

- October 30, 2007 © SKF Group Slide 1Document23 pagesOctober 30, 2007 © SKF Group Slide 1AVNo ratings yet

- Analysis of Fan Excessive Vibration Using Operating Deflection Shape AnalysisDocument11 pagesAnalysis of Fan Excessive Vibration Using Operating Deflection Shape Analysisbudi_kamilNo ratings yet

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?From EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?No ratings yet

- SKF Bearing SelectDocument12 pagesSKF Bearing SelectMuhammed Aboul AzmNo ratings yet

- Case Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerFrom EverandCase Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Analysis of Gear Box.5-MilosprokoDocument3 pagesVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Extracto ISO 10816Document10 pagesExtracto ISO 10816clroyo9475No ratings yet

- WB - Bearings - Poster - FINAL - US SizeDocument1 pageWB - Bearings - Poster - FINAL - US SizeAditya Shiva AppallaNo ratings yet

- Case Studies #4: Gearbox DefectDocument13 pagesCase Studies #4: Gearbox DefectMiguel VillegasNo ratings yet

- Order Analysis ToolkitDocument16 pagesOrder Analysis ToolkitManuel Enrique Salas FernándezNo ratings yet

- Gear InspectionDocument2 pagesGear InspectiontaghdirimNo ratings yet

- Advanced Turbomachinery Diagnostics - Online Course W2Document8 pagesAdvanced Turbomachinery Diagnostics - Online Course W2ali shetaNo ratings yet

- Full SpectraDocument19 pagesFull SpectraBharath Chandra ReddyNo ratings yet

- Signal Processing Dan Analisis Vibrasi: Januari 2021Document19 pagesSignal Processing Dan Analisis Vibrasi: Januari 2021Fifth AnalistNo ratings yet

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Document7 pages5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC ANo ratings yet

- Report On Prognosis of Faulty GearDocument20 pagesReport On Prognosis of Faulty GearShashi Bhushan GunjanNo ratings yet

- Don't Get Soft: Cover Series: Installation Best PracticesDocument6 pagesDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Sideband Energy Ratio Gea19501aDocument1 pageSideband Energy Ratio Gea19501azeroseyaNo ratings yet

- Vibxpert Manual English PDFDocument86 pagesVibxpert Manual English PDFRizki A-fNo ratings yet

- High Vibration at Main Gear Box of Gas TurbineDocument9 pagesHigh Vibration at Main Gear Box of Gas TurbineJJNo ratings yet

- Timebase Plots ExplainedDocument18 pagesTimebase Plots ExplainedManuel L LombarderoNo ratings yet

- Low Freq. Meas & gSEDocument13 pagesLow Freq. Meas & gSEsatya_chagantiNo ratings yet

- Fallas de Rodamientos (Ingles)Document44 pagesFallas de Rodamientos (Ingles)Weimar G. SalazarNo ratings yet

- Vib Screen - Vib Analysis PDFDocument16 pagesVib Screen - Vib Analysis PDFAngka SubaronNo ratings yet

- FAG Bearing DamageDocument91 pagesFAG Bearing Damagesamir8albinoNo ratings yet

- Online TextbookDocument6 pagesOnline TextbookYanuar KrisnahadiNo ratings yet

- Using PeakVue Plus Technology For Detecting Anti Friction Bearing FaultsDocument11 pagesUsing PeakVue Plus Technology For Detecting Anti Friction Bearing Faultseko bagus sunaryo100% (1)

- Time Waveform Analysis TechniquesDocument2 pagesTime Waveform Analysis TechniquesManel Montesinos100% (1)

- VACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10Document1 pageVACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10ho-faNo ratings yet

- Vibration Analysis For GearsDocument5 pagesVibration Analysis For GearsJaime Berry100% (1)

- Vibra K Cmva 2006 Spike Energy Paper 430kb PDFDocument22 pagesVibra K Cmva 2006 Spike Energy Paper 430kb PDFmarvin17No ratings yet

- Vibrasyon Electrical ProblemsDocument4 pagesVibrasyon Electrical ProblemsbbulutmmNo ratings yet

- Sleeve Bearing Diagnostics R1Document75 pagesSleeve Bearing Diagnostics R1Daniel_Ali_bNo ratings yet

- FFT Windowing TutorialDocument10 pagesFFT Windowing TutorialPradeep LoboNo ratings yet

- Seminario de Vibraciones PrufftechnikDocument114 pagesSeminario de Vibraciones PrufftechnikOdlanier José MendozaNo ratings yet

- Lube SelectDocument7 pagesLube SelectLLNo ratings yet

- Balance VibrationDocument4 pagesBalance VibrationZaidiNo ratings yet

- Clean Oil GuideDocument28 pagesClean Oil GuideAlex VulpeNo ratings yet

- 2130 - Advanced Fast Balance - 97059 - 1CD PDFDocument432 pages2130 - Advanced Fast Balance - 97059 - 1CD PDFLuisSilva100% (1)

- ANALEX PQL Datasheet PDFDocument2 pagesANALEX PQL Datasheet PDFmaye palominoNo ratings yet

- Rev.0 CSI 2600 PDFDocument170 pagesRev.0 CSI 2600 PDFAnonymous srwHCpANo ratings yet

- Orbit V33N3 2013 Q3Document64 pagesOrbit V33N3 2013 Q3Adhitya DwijayanthoNo ratings yet

- Machinery VibrationsDocument33 pagesMachinery VibrationsDanish AfrozNo ratings yet

- FAG - An Overview of Bearing Vibration AnalysisDocument12 pagesFAG - An Overview of Bearing Vibration AnalysisVirgilio100% (1)

- Resolving Oil Whirl Issues in a Gas Compressor Case StudyDocument42 pagesResolving Oil Whirl Issues in a Gas Compressor Case StudyChristian Santillan100% (1)

- Gearbox White PaperDocument13 pagesGearbox White PaperRony MartínezNo ratings yet

- James I. Taylor - The Vibration Analysis Handbook (2003, VCI) - Libgen - lc-1-5Document5 pagesJames I. Taylor - The Vibration Analysis Handbook (2003, VCI) - Libgen - lc-1-5Khemiri Houssem EddineNo ratings yet

- Unbalance IdentificationDocument22 pagesUnbalance IdentificationAV100% (1)

- Nova-PeakVue Rev B2 PDFDocument2 pagesNova-PeakVue Rev B2 PDFAlejandro José Poveda GuevaraNo ratings yet

- General Instructions 700 & 800 Series Models: LightninDocument12 pagesGeneral Instructions 700 & 800 Series Models: LightninsamukubunavanuaNo ratings yet

- Redictive Aintenance: Predictive Maintenance 99Document4 pagesRedictive Aintenance: Predictive Maintenance 99COE201No ratings yet

- What Is Condition Monitoring?Document15 pagesWhat Is Condition Monitoring?ajmalNo ratings yet

- MiniLab Series BrochureDocument16 pagesMiniLab Series BrochureAlexander Rodriguez SarmientoNo ratings yet

- Basic Mechanical Maintenance Training: Predictive Maintenance TechniquesDocument39 pagesBasic Mechanical Maintenance Training: Predictive Maintenance Techniquesolyax100% (4)

- Centrifugal Pump Set Failure ModesDocument70 pagesCentrifugal Pump Set Failure ModesArif WidyatamaNo ratings yet

- 3-2 Shaft Alignment Method Exercis Rev-2.1Document9 pages3-2 Shaft Alignment Method Exercis Rev-2.1akhilsaNo ratings yet

- SKF DesignationDocument7 pagesSKF DesignationakhilsaNo ratings yet

- Understand Phase GuideDocument2 pagesUnderstand Phase GuideakhilsaNo ratings yet

- Understand PhaseDocument4 pagesUnderstand PhaseakhilsaNo ratings yet

- Shaft Alignment: Calculations For Horizontal Shaft AlignmentDocument38 pagesShaft Alignment: Calculations For Horizontal Shaft Alignmentakhilsa100% (1)

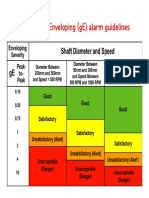

- gE alarm guidelines for acceleration envelopingDocument1 pagegE alarm guidelines for acceleration envelopingakhilsaNo ratings yet

- Fundamentals of Lub OilDocument8 pagesFundamentals of Lub OilakhilsaNo ratings yet

- Gas Turbine Components SGT400 SiemensDocument131 pagesGas Turbine Components SGT400 SiemensAmmar Altamimy89% (9)

- Gas Turbine Components SGT400 SiemensDocument131 pagesGas Turbine Components SGT400 SiemensAmmar Altamimy89% (9)

- Pte Academic Test Practice Repeat SentenceDocument3 pagesPte Academic Test Practice Repeat SentenceJackAziz100% (7)

- Cultural Understanding Impacts Consumer BehaviorDocument10 pagesCultural Understanding Impacts Consumer BehaviorNguyễn Hữu Thảo NguyênNo ratings yet

- CBSE Class 10 Maths Sample Paper Set 6Document4 pagesCBSE Class 10 Maths Sample Paper Set 6darshilsinghgharwarNo ratings yet

- TLC Visualization SolutionsDocument3 pagesTLC Visualization SolutionseraborNo ratings yet

- Transcricao How To Be Happy (Before Success) - by Earl NightingaleDocument62 pagesTranscricao How To Be Happy (Before Success) - by Earl NightingalepauloalaraNo ratings yet

- Is The Sustainable Development Goals (SDG) Index An Adequate Framework To Measure The Progress of The 2030 Agenda?Document9 pagesIs The Sustainable Development Goals (SDG) Index An Adequate Framework To Measure The Progress of The 2030 Agenda?hadi_friendNo ratings yet

- ENGLISH CONTENT UNIT 4 2022 5tos.Document9 pagesENGLISH CONTENT UNIT 4 2022 5tos.Dylan QuiñónezNo ratings yet

- Basic Life Support Checklist CSLLFIDocument1 pageBasic Life Support Checklist CSLLFIShane Frances SaborridoNo ratings yet

- Lean Healthy Raw Food Winter RecipesDocument60 pagesLean Healthy Raw Food Winter RecipesKaio Sol100% (6)

- Emebet Kebede FINALDocument65 pagesEmebet Kebede FINALTefeNo ratings yet

- Vergara, Valerie G. Drug Study (Ma'Am Dean)Document3 pagesVergara, Valerie G. Drug Study (Ma'Am Dean)Valerie VergaraNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- 14 Ways To Acquire KnowledgeDocument4 pages14 Ways To Acquire KnowledgeRenato MiguelNo ratings yet

- Sidhil - ICT Design EngineerDocument3 pagesSidhil - ICT Design Engineeratif_aman123No ratings yet

- HZVDocument6 pagesHZVnurrozaqNo ratings yet

- Growatt Warranty Procedure - 07-09-2020Document9 pagesGrowatt Warranty Procedure - 07-09-2020Design TeamNo ratings yet

- Muhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Document19 pagesMuhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Rana Muhammad Ashfaq Khan0% (1)

- Emd MPC 543Document25 pagesEmd MPC 543jaskaran singhNo ratings yet

- Ricoh Aficio SP c830dn-c831dn AP-p3 (m124-m125) FSMDocument1,064 pagesRicoh Aficio SP c830dn-c831dn AP-p3 (m124-m125) FSMDương Minh Phụng100% (1)

- Combustion ChemistryDocument17 pagesCombustion Chemistryrajeev50588No ratings yet

- Balanced Scorecard ThesisDocument59 pagesBalanced Scorecard Thesisapi-3825626100% (5)

- Of Our TimesDocument84 pagesOf Our TimesThe Journal of Music100% (1)

- Medical Education For Healthcare Professionals: Certificate / Postgraduate Diploma / Master of Science inDocument4 pagesMedical Education For Healthcare Professionals: Certificate / Postgraduate Diploma / Master of Science inDana MihutNo ratings yet

- RTR - Nonmetallic Pipng ProcedureDocument16 pagesRTR - Nonmetallic Pipng Proceduremoytabura96100% (1)

- Practical File ON Programming For Problem Solving Lab (: 21BTCS181)Document15 pagesPractical File ON Programming For Problem Solving Lab (: 21BTCS181)Vaibhavi SinghNo ratings yet

- 1Document5 pages1qweqweNo ratings yet

- Quotation SS20230308 100KVAR APFC PANEL VIDHYA WIRESDocument4 pagesQuotation SS20230308 100KVAR APFC PANEL VIDHYA WIRESsunil halvadiyaNo ratings yet

- Epiroc MTH46BDocument8 pagesEpiroc MTH46BGalo DoloresNo ratings yet

- Las 4.4 - Hope 4 - Mountaineering (Hiking, Trekking, Camping, Orienteering)Document5 pagesLas 4.4 - Hope 4 - Mountaineering (Hiking, Trekking, Camping, Orienteering)Maricel EsperatNo ratings yet

- Taeka HaileleulDocument167 pagesTaeka HaileleulBini100% (1)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet