Professional Documents

Culture Documents

Magnesium Oxide: Product Data Sheet (PDS)

Uploaded by

Mannar1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnesium Oxide: Product Data Sheet (PDS)

Uploaded by

Mannar1Copyright:

Available Formats

Product Data Sheet (PDS)

FOR DRILLING FLUID SYSTEM

Egyptian Mud

Engineering & Chemicals Co.

MAGNESIUM OXIDE

DESCRIPTION TECHNICAL & ENGINEERING INFORMATION

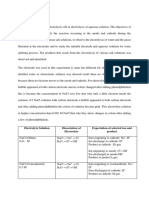

Magnesium Oxide is a buffering agent and Magnesium Oxide is a buffering agent used

polymer stabilizer that is used in water-based drilling in water-based drilling fluid and brine systems for

fluids and brine systems. controlling alkalinity up to 10.0 pH. MgO also helps

to slow down the rate of polymer degradation at

elevated temperatures.

PHYSICAL PROPERTIES MgO powder has a 10.0 pH alkalinity, so it does

not increase the pH of mud systems to levels which can

burn-up viscosifying polymers.

Appearance Powder

Some polymers are sensitive to the presence of Mg2+,

Colour White so rheology and fluid loss control may be affected if

Magnesium Oxide concentrations are too high.

Odor None

Specific Gravity 3.5

PACKAGING AND STORAGE

Flash Point Not flammable

M.gO is supplied in 25 kg sacks and should be

stored in a dry, safe location away from other products.

Solubility Insoluble in water

HSE

APPLICATION

MgO is not classified as hazardous, but it may be

MgO is an effective alternative to Caustic Soda for an irritant. The following safety wear, as recommended

controlling pH in polymer drilling fluid, completion and in the MSDS, should be used when mixing MgO:

work-over brine systems. MgO is much safer to - Standard PPE

handle than Caustic Soda, and can be added directly to - Dust Mask

the mud system through the mix hopper.

The recommended MgO treatment range is 0.3 ppb

to 0.5 ppb for improving polymer stability at elevated

temperatures, and around 8 ppb to 12 ppb for buffering.

Tel: +20 (2) 2673 2900

Head Office: Plot No. 196, 2nd City Center, Fifth Settlement, New Cairo, 11835, Egypt www.emec.com.eg

You might also like

- Fluid Loss Controller - Fluid Loss Control Polymer - Filtration Control AdditiveDocument3 pagesFluid Loss Controller - Fluid Loss Control Polymer - Filtration Control AdditiveManargudi mannarNo ratings yet

- KBR Gas Processing Mar 2016 Rev. 3 PDFDocument66 pagesKBR Gas Processing Mar 2016 Rev. 3 PDFCarolina Belen PadillaNo ratings yet

- EXAMINER TIPS For IGCSE Chemistry 0620 How To Use These TipsDocument6 pagesEXAMINER TIPS For IGCSE Chemistry 0620 How To Use These TipsAnand Kumar100% (1)

- Zinc PhosphateDocument3 pagesZinc PhosphateSandeep BNo ratings yet

- Basic Dental Materials: Factors Affecting SolubilityDocument9 pagesBasic Dental Materials: Factors Affecting SolubilityAlfina RizkaNo ratings yet

- Technical Report of Formic Acid PlantDocument6 pagesTechnical Report of Formic Acid PlantMuzzamilNo ratings yet

- Chemical Formula Writing WorksheetDocument4 pagesChemical Formula Writing Worksheetprabhu4321100% (1)

- Product Data Sheet (PDS) : For Drilling Fluid SystemDocument1 pageProduct Data Sheet (PDS) : For Drilling Fluid SystemMannar1No ratings yet

- Guar Gum: Product Data Sheet (PDS)Document1 pageGuar Gum: Product Data Sheet (PDS)Moatz HamedNo ratings yet

- Gypsum: Product Data Sheet (PDS)Document1 pageGypsum: Product Data Sheet (PDS)Mannar1No ratings yet

- Potassium Chloride (Powder) : Product Data Sheet (PDS)Document1 pagePotassium Chloride (Powder) : Product Data Sheet (PDS)Mannar1No ratings yet

- Citric Acid: Product Data Sheet (PDS)Document1 pageCitric Acid: Product Data Sheet (PDS)Mannar1No ratings yet

- Calcium Bromide Powder Product Data Sheet: Typ Pro Ical PertiesDocument1 pageCalcium Bromide Powder Product Data Sheet: Typ Pro Ical PertiespaimanNo ratings yet

- Potassium Chloride (Powder) : Product Data Sheet (PDS)Document1 pagePotassium Chloride (Powder) : Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Potassium Hydroxide: Product Data Sheet (PDS)Document1 pagePotassium Hydroxide: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Potassium Hydroxide: Product Data Sheet (PDS)Document1 pagePotassium Hydroxide: Product Data Sheet (PDS)Mannar1No ratings yet

- Whitechem PPG 2000 TdsDocument1 pageWhitechem PPG 2000 TdsGİZEM DEMİRNo ratings yet

- CAUSTIC SODA (Powder/Beads) : Product Data Sheet (PDS)Document1 pageCAUSTIC SODA (Powder/Beads) : Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Zinc Bromide Brine: Product Data Sheet (PDS)Document1 pageZinc Bromide Brine: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Znco - 80: Guangzhou Longhi Rubber&Plastic Co., LTDDocument1 pageZnco - 80: Guangzhou Longhi Rubber&Plastic Co., LTDThanhNhựtNo ratings yet

- Citric Acid: Product Data Sheet (PDS)Document1 pageCitric Acid: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Flo ProDocument4 pagesFlo ProAhmet AyNo ratings yet

- Potassium Carbonate: Product Data Sheet (PDS)Document1 pagePotassium Carbonate: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- TDS Metabent Abe Q 550Document1 pageTDS Metabent Abe Q 550akbar100% (1)

- Soda Ash: Product Data Sheet (PDS)Document1 pageSoda Ash: Product Data Sheet (PDS)Mannar1No ratings yet

- Sodium Chloride: Product Data Sheet (PDS)Document1 pageSodium Chloride: Product Data Sheet (PDS)Mannar1No ratings yet

- Sodium Bicarbonate: Product Data Sheet (PDS)Document1 pageSodium Bicarbonate: Product Data Sheet (PDS)Mannar1No ratings yet

- Anti-Stripping AdditiveDocument16 pagesAnti-Stripping Additivenarendra rawatNo ratings yet

- Calcium Bromide Liquid Product Data SheetDocument1 pageCalcium Bromide Liquid Product Data SheetpaimanNo ratings yet

- AddBond LTWDocument1 pageAddBond LTWb3ry 17No ratings yet

- The Salt Pill™: Product Data Sheet (PDS)Document1 pageThe Salt Pill™: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Potassium Citrate PDSDocument1 pagePotassium Citrate PDSAndy KapNo ratings yet

- Magnesium Oxide (DIMET WASSER)Document1 pageMagnesium Oxide (DIMET WASSER)le quoc cuongNo ratings yet

- TDS - Zan HD Ot 20Document2 pagesTDS - Zan HD Ot 20fredNo ratings yet

- Glo Mica FMCDocument2 pagesGlo Mica FMCVikash KumarNo ratings yet

- Mica Medium: Product Data Sheet (PDS)Document1 pageMica Medium: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Milk of Magnesia, USP Antacid Cathartic Magnesium Hydroxide, Rolaids, Magnesia MagmaDocument3 pagesMilk of Magnesia, USP Antacid Cathartic Magnesium Hydroxide, Rolaids, Magnesia MagmaKate MendozaNo ratings yet

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Ground Gypsum Fg200-EnDocument3 pagesGround Gypsum Fg200-EnhadjinaumovaNo ratings yet

- KanCide 6902Document2 pagesKanCide 6902pavanirajesh193No ratings yet

- ID GelsmoothDocument1 pageID GelsmoothWael El EssawyNo ratings yet

- Decabromo Diphenyl OxideDocument1 pageDecabromo Diphenyl OxideHarshavardhanNo ratings yet

- Sized Marble: Product Data Sheet (PDS)Document1 pageSized Marble: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Zoldine Ms-Plus: Key Performance AdvantagesDocument6 pagesZoldine Ms-Plus: Key Performance AdvantagesPratik MehtaNo ratings yet

- Xanthan Gum (XC Polymer) PdsDocument1 pageXanthan Gum (XC Polymer) Pdsمحمد سعيد100% (1)

- Blastrite Sodium Bicarbonate - SodabradeDocument1 pageBlastrite Sodium Bicarbonate - SodabradeAsadNo ratings yet

- AEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDDocument1 pageAEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDeliteindustries.pkNo ratings yet

- Coatosil MP 200 Crosslinker WB Systems m8 PDFDocument8 pagesCoatosil MP 200 Crosslinker WB Systems m8 PDFjoseNo ratings yet

- DR ImtiazuddinsequesteringDocument3 pagesDR ImtiazuddinsequesteringAlan MedeirosNo ratings yet

- Acematt Ok 412Document1 pageAcematt Ok 412optimus_1404No ratings yet

- Soduim Salphite: Product Data Sheet (PDS)Document1 pageSoduim Salphite: Product Data Sheet (PDS)Mannar1No ratings yet

- Id FuryDocument2 pagesId FuryWael El EssawyNo ratings yet

- Sized Graphite: Product Data Sheet (PDS)Document1 pageSized Graphite: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- PDS Acetic AcidDocument1 pagePDS Acetic Acidrushikesh pandyaNo ratings yet

- Products ListDocument25 pagesProducts ListMin Thant MaungNo ratings yet

- TDS PAC SERIES PAC-031 BluwatDocument2 pagesTDS PAC SERIES PAC-031 BluwatAlfonso GarcíaNo ratings yet

- Id MMCPDocument1 pageId MMCPWael El EssawyNo ratings yet

- Lithium Complex Grease - 231114 - 210126 - 231114 - 210256Document2 pagesLithium Complex Grease - 231114 - 210126 - 231114 - 210256koppeck hernandezNo ratings yet

- Marble Fine: Product Data Sheet (PDS)Document1 pageMarble Fine: Product Data Sheet (PDS)Iqbal batchaNo ratings yet

- Fat Lime Putty: Product Data Sheet 1 of 1, Updated August 2020Document1 pageFat Lime Putty: Product Data Sheet 1 of 1, Updated August 2020Gopal MaheshwariNo ratings yet

- Modifications of GicDocument20 pagesModifications of GicDrShweta Saini67% (3)

- KOH Scrubbing of Acidic Gas Application Note B212035ENDocument2 pagesKOH Scrubbing of Acidic Gas Application Note B212035ENiyergvNo ratings yet

- Kurita Water Treatment Chemicals-ChemicalsDocument1 pageKurita Water Treatment Chemicals-Chemicalss.lakeb19No ratings yet

- CALCIUM CHLORIDE (Flakes/Granules) : Product Data Sheet (PDS)Document1 pageCALCIUM CHLORIDE (Flakes/Granules) : Product Data Sheet (PDS)Mannar1No ratings yet

- Soduim Salphite: Product Data Sheet (PDS)Document1 pageSoduim Salphite: Product Data Sheet (PDS)Mannar1No ratings yet

- Gypsum MSDSDocument4 pagesGypsum MSDSMannar10% (1)

- Sodium Bicarbonate: Product Data Sheet (PDS)Document1 pageSodium Bicarbonate: Product Data Sheet (PDS)Mannar1No ratings yet

- Calcium Chloride Powder PDSDocument1 pageCalcium Chloride Powder PDSMannar1No ratings yet

- Material Safety Data Sheet (MSDS) - Citric AcidDocument5 pagesMaterial Safety Data Sheet (MSDS) - Citric AcidMannar1No ratings yet

- Potassium Hydroxide: Product Data Sheet (PDS)Document1 pagePotassium Hydroxide: Product Data Sheet (PDS)Mannar1No ratings yet

- Diatomaceous Earth PDSDocument1 pageDiatomaceous Earth PDSMannar1No ratings yet

- Sodium Chloride: Product Data Sheet (PDS)Document1 pageSodium Chloride: Product Data Sheet (PDS)Mannar1No ratings yet

- Nut Shells: Lost Circulation MaterialDocument1 pageNut Shells: Lost Circulation MaterialMannar1No ratings yet

- Dispersant: Product DescriptionDocument1 pageDispersant: Product DescriptionMannar1No ratings yet

- Gypsum: Carbonate Contamination RemoverDocument1 pageGypsum: Carbonate Contamination RemoverMannar1No ratings yet

- Potassium Acetate PDSDocument1 pagePotassium Acetate PDSMannar1No ratings yet

- PH Control: Product DescriptionDocument1 pagePH Control: Product DescriptionMannar1No ratings yet

- Acidizing Solvent: Product DescriptionDocument1 pageAcidizing Solvent: Product DescriptionMannar1No ratings yet

- Ocma Bentonite PDSDocument1 pageOcma Bentonite PDSMannar1No ratings yet

- Soda Ash: Calcium Contamination RemoverDocument1 pageSoda Ash: Calcium Contamination RemoverMannar1No ratings yet

- Lost-Circulation Materials: Product DescriptionDocument1 pageLost-Circulation Materials: Product DescriptionMannar1No ratings yet

- Soda Ash: Product Data Sheet (PDS)Document1 pageSoda Ash: Product Data Sheet (PDS)Mannar1No ratings yet

- Sodium Bicarbonate: Product Data Sheet (PDS)Document1 pageSodium Bicarbonate: Product Data Sheet (PDS)Mannar1No ratings yet

- Sodium Chloride: Product Data Sheet (PDS)Document1 pageSodium Chloride: Product Data Sheet (PDS)Mannar1No ratings yet

- Potassium Hydroxide: Product Data Sheet (PDS)Document1 pagePotassium Hydroxide: Product Data Sheet (PDS)Mannar1No ratings yet

- Calcium Chloride Powder PDSDocument1 pageCalcium Chloride Powder PDSMannar1No ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- Structure and Bonding: John E. McmurryDocument49 pagesStructure and Bonding: John E. Mcmurry洪侊增No ratings yet

- IJDR Publication-AU Category B Publication 2023Document4 pagesIJDR Publication-AU Category B Publication 2023NARESHNo ratings yet

- Coordination Chemistry IIDocument77 pagesCoordination Chemistry IISOLeeNo ratings yet

- Ammonia: Acid Cleaners ADocument3 pagesAmmonia: Acid Cleaners AHyang Mi NitroNo ratings yet

- Syllabus of OMU - Final Complete 2022Document55 pagesSyllabus of OMU - Final Complete 2022Mohamed Babiker SulimanNo ratings yet

- Atoms, Molecules and Ions: Chapter 3 of General ChemistryDocument28 pagesAtoms, Molecules and Ions: Chapter 3 of General ChemistryPauline AdrinedaNo ratings yet

- Price Quotation: Chemline Scientific Corporation RB Chemodities Laboratory SuppliesDocument2 pagesPrice Quotation: Chemline Scientific Corporation RB Chemodities Laboratory Suppliesrsigue_1No ratings yet

- UNIFAC - Parámetros de Volumen y AreaDocument4 pagesUNIFAC - Parámetros de Volumen y Areaisabella MartinezNo ratings yet

- POCH Safety Data Sheet: MercuryDocument3 pagesPOCH Safety Data Sheet: MercuryRizkyNo ratings yet

- C F C G (LEL) S: Orrection Actors For Ombustible AS EnsorsDocument2 pagesC F C G (LEL) S: Orrection Actors For Ombustible AS EnsorsAli MehrpourNo ratings yet

- Chemistry Class 10 Meatals and NonmetalsDocument9 pagesChemistry Class 10 Meatals and NonmetalsGokulNo ratings yet

- Redox Equilibria: K. DonaldsonDocument83 pagesRedox Equilibria: K. DonaldsonEmily ZhengNo ratings yet

- Advanced Functional Materials From Nanopolysaccharides: Ning Lin Juntao Tang Alain Dufresne Michael K. C. Tam EditorsDocument434 pagesAdvanced Functional Materials From Nanopolysaccharides: Ning Lin Juntao Tang Alain Dufresne Michael K. C. Tam EditorsCARLOS ALBERTO RAMIREZ BARRAGANNo ratings yet

- USP-NF Aluminum MonostearateDocument3 pagesUSP-NF Aluminum MonostearateK.m. Ehsan Morshed RanaNo ratings yet

- Carbenes 3Document20 pagesCarbenes 3assquimicaNo ratings yet

- Thorplas Engineering ManualDocument32 pagesThorplas Engineering ManualNguyen JohnNo ratings yet

- Soil - Components, Properties and Processes (1Document12 pagesSoil - Components, Properties and Processes (1Tiffany RishiNo ratings yet

- Valdeviezo Micah Exp9Document8 pagesValdeviezo Micah Exp9BelenNo ratings yet

- Is 1367 8 2002Document24 pagesIs 1367 8 2002Palani JayaramanNo ratings yet

- Sae J1993 (Sep1996) PDFDocument4 pagesSae J1993 (Sep1996) PDFDiogoNo ratings yet

- Qi Lu: Professional ExperienceDocument4 pagesQi Lu: Professional ExperienceShiva DagalNo ratings yet

- Petrographic Examination of Hardened Concrete: Standard Practice ForDocument17 pagesPetrographic Examination of Hardened Concrete: Standard Practice ForJohn Royer Araúz FuentesNo ratings yet

- Engineering and The Environment: One Select Only OrganicDocument2 pagesEngineering and The Environment: One Select Only OrganicYazhou ZhouNo ratings yet

- Teknik PemisahanDocument77 pagesTeknik PemisahanAku AmelNo ratings yet

- Galata CFA Properties GuideDocument12 pagesGalata CFA Properties GuideToniHospitalerNo ratings yet