Professional Documents

Culture Documents

Course Agenda: Body Electrical Diagnosis Course L652

Uploaded by

Long HàOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Agenda: Body Electrical Diagnosis Course L652

Uploaded by

Long HàCopyright:

Available Formats

BODY ELECTRICAL DIAGNOSIS COURSE - AGENDA

Body Electrical Diagnosis Course L652

Course Agenda

Lesson Time Duration Description

Day 1

1.00 9:00 10 Introduction

1.10 9:10 60 Review of Basic Electrical Theory

10:10 15 Break

1.20 10:25 60 Introduction to EWD

Worksheets 2-1 and 2-2

1.30 11:25 60 Following Current Flow in a Circuit

12:25 60 Lunch

1.40 1:25 30 Using Electrical Diagnosis Tools

1.49 1:55 30 The Six-Step Diagnosis Troubleshooting Plan

1.50 2:25 60 Using Repair Manual

3:25 90 Worksheets

Day 2

2.10 8:30 90 Open Circuit Diagnosis

Worksheet 2-4 Right Hand Mirror Does Not Go UP or DOWN

2.20 10:00 60 Short Circuit/Parasitic Load Diagnosis

2.25 11:00 60 On-Car/Simulator Short & Parasitic Load Diagnosis

12:00 60 Lunch

2.30 1:00 60 High Circuit Resistance Diagnosis

2.35 2:00 60 On-Car/Simulator High Resistance Diagnosis

2.40 3:00 60 Feedback Problem Diagnosis

4:00 60 Review

Day 3

5.00 8:30 120 Rotations/Body Electrical

6.00 10:30 30 Multiplexing Introduction

6.00 11:00 60 Rotations/Multiplexing Worksheets

12:00 60 Lunch

6.00 1:00 60 Rotation/Body Electrical or Multiplexing Worksheets

6.00 2:00 90 Rotation/Body Electrical or Multiplexing Worksheets

3:30 15 Break

6.00 3:45 75 Review and Final Test

LEXUS Course L 652 - Body Electrical Diagnosis 1

OVERVIEW

ES 300 Body Electrical Simulator Instructor Information

Overview

The ES 300 Body Electrical Simulator is a TMC produced training aid designed for use in body electrical courses.

Nearly all body electrical systems from an ES 300 are fully operational, and can be used to teach both system

operation theory and diagnosis.

The relative position of all parts (including wire harness routing) are approximately the same as on an actual ve-

hicle.

Fault Switches

• For convenience in the classroom, a set of twenty fault switches are provided. Sixteen of the switches are

pre-programmed with faults.

The following circuits have built-in “fault switches” for in-class practice of troubleshooting techniques:

Interior Light

Heater Blower Motor

Horn

CD / Radio

Headlight

Taillight

Power Window

Combination Meter

Remote Control Mirror

Turn Signals

Wireless Door Lock

• These circuits illustrate the 4 major types of electrical problems encountered on the vehicle: Open, short-to-

ground/parasitic load, high resistance, and feedback, with varying difficulty levels for each problem (see

table). The fault for each circuit is activated by moving the appropriate fault switch to the UP position.

LEXUS Course L 652 - Body Electrical Diagnosis 2

LEXUS BODY ELECTRICAL SIMULATOR INFORMATION

LEXUS Course L 652 - Body Electrical Diagnosis 3

LEXUS BODY ELECTRICAL SIMULATOR INFORMATION

LEXUS Course L 652 - Body Electrical Diagnosis 4

LEXUS BODY ELECTRICAL SIMULATOR INFORMATION

LEXUS Course L 652 - Body Electrical Diagnosis 5

LEXUS BODY ELECTRICAL SIMULATOR INFORMATION

LEXUS Course L 652 - Body Electrical Diagnosis 6

LESSON OBJECTIVES SUMMARY

Body Electrical Diagnosis Course L 652

Summary of Lesson Objectives

Lesson 1.00 Objectives

1. Instructor introduction to technicians

2. Complete attendance records

3. Introduce technicians to program goals, and objectives

4. Familiarize technicians with technician handbook

Lesson 1.10 Objectives

1. Technician will know what subjects the L 652 course will be covering.

2. Through this review of L 622 course materials, the technician will be able to demonstrate an

understanding of the following concepts:

• Voltage

• Amperage

• Resistance

• An electrical circuit

• Series circuit theory

• Parallel circuit theory

3. Familiarize the technicians with EWD wiring diagram symbols.

Lesson 1.20 Objectives

After completing this section, the technician will be able to:

1. Find and use each of the sections of the EWD

2. Given a system circuit diagram in the EWD:

• Identify each of the symbols used on the system diagram.

• Understand the meaning of the labels that are used with those symbols.

• Apply basic current flow theory to diagram the path of current flow through the circuit.

3. Know how to apply the information in the EWD within the 6-step troubleshooting plan.

Lesson 1.25 Objectives

After completing this worksheet:

1. The technician will have demonstrated the use of all the sections of the EWD during a "typical"

diagnostic process.

2. Applied the concepts covered in lesson 1.1 on an actual system circuit diagram.

3. Demonstrated an understanding of the symbols used on the system circuit diagram.

Lesson 1.30 Objectives

After completing this section, the technician will be able to:

1. Use the System Outline section of the EWD when available.

2. Configure the switches/relays to the appropriate position for the operating condition.

3. Follow the current flow path from the B+ source to ground in example EWD circuits.

4. Apply "what-if" problem simulation scenarios to the circuit.

LEXUS Course L 652 - Body Electrical Diagnosis 7

LESSON OBJECTIVES SUMMARY

Lesson 1.40 Objectives

In this section the technician will demonstrate the ability to:

1. Use the system outline section of the EWD.

2. Configure the switches/relays to the appropriate position for the operating condition.

3. Follow the current flow path from the B+ source to ground.

4. Determine the amount voltage that should be measured at given test points.

5. Apply "what-if" problem simulation scenarios to the circuit.

After completing this section, the technician will be able to:

1. Use a voltmeter and measure voltage drops and open circuit voltage in a circuit.

• Understand what an acceptable voltage drop is

• Understand the concept of what creates a voltage drop

• Understand the proper way to connect a voltmeter in a circuit

• Know how to use a voltmeter for continuity check only

• Understand the voltmeter's application in diagnostics

2. Use an ammeter to measure current flow.

• Use a series type ammeter

• Use a inductive type ammeter

• Understand the concept of parasitic load

• Be able to apply parallel circuit current rules

• Understand the ammeter's application in diagnostics

3. Use an ohmmeter to measure the resistance of a component.

• Understand the need for circuit isolation when using an ohmmeter

• Understand the ohmmeter's application in diagnostics

4. Use a jumper wire properly for circuit diagnosis.

5. Apply basic circuit theory concepts with the use of an EWD on vehicle circuits.

Lesson 1.49 Objectives

After completing this section, the technician will be able to:

1. Implement the 6-step diagnostic process on a typical body electrical problem.

2. Properly verify an electrical problem.

3. Use defined techniques to analyze the related symptoms.

4. Isolate and correct the trouble using the EWD and electrical diagnostic tools.

5. Perform wire, connector, and harness repairs according to proper procedures.

LEXUS Course L 652 - Body Electrical Diagnosis 8

LESSON OBJECTIVES SUMMARY

Lesson 2.10 Objectives

After completing this section, the technician will be able to:

1. Successfully diagnose an open circuit problem in an electrical circuit.

2. Apply the 6 step diagnostic process.

3. Learn the diagnostic strategy for diagnosing an open circuit problem in which the entire circuit is

inoperative.

4. Learn the diagnostic strategy for diagnosing an open circuit problem in which part of the circuit is

still functional.

5. Apply basic circuit theory concepts with the use of an EWD on vehicle circuits.

Lesson 2.20 Objectives

After completing this section, the technician will be able to:

1. Successfully diagnose a high resistance electrical circuit problem.

2. Apply the 6 step diagnostic process for this type of problem.

3. Locate a high resistance problem in the ground circuit.

4. Locate a high resistance problem in the B+ circuit.

5. Apply basic circuit theory concepts with the use of an EWD on vehicle circuits.

Lesson 2.25 Objectives

After completing this section, the technician will have:

1. Successfully diagnosed 3 high circuit resistance problems.

2. Practiced and applied the 6 step diagnostic process on these problems.

3. Extensively used the EWD support sections to locate electrical/wiring components and determine

power flow from the fuses and junction blocks.

4. Used the EWD System Circuit Diagrams to trace the path of current flow through circuits.

Lesson 2.30 Objectives

After completing this section, the technician will be able to:

1. Diagnose a short-to-ground in an electrical circuit.

2. Diagnose an unwanted parasitic load problem.

3. Apply the 6 step diagnostic process for each of these problems.

4. Use the EWD to determine circuit power distribution through the various junction blocks and junction

connectors.

5. Apply basic circuit theory concepts with the use of an EWD on vehicle circuits.

Lesson 2.35 Objectives

After completing this section, the technician will have:

1. Successfully diagnosed 3 short-to-ground/excessive parasitic load circuit problems.

2. Practiced and applied the 6 step diagnostic process on these problems.

3. Extensively used the EWD support sections to locate electrical/wiring components and determine

power flow from the fuses and junction blocks.

4. Used the EWD System Circuit Diagrams to trace the path of current flow through circuits.

LEXUS Course L 652 - Body Electrical Diagnosis 9

LESSON OBJECTIVES SUMMARY

Lesson 2.40 Objectives

After completing this section, the technician will be able to:

1. Successfully diagnose an electrical feedback circuit problem.

2. Apply the 6 step diagnostic process for this type of problem.

3. Diagnose a feedback problem in a lighting circuit.

4. Diagnose a feedback problem in a general body electrical circuit.

5. Apply basic circuit theory concepts with the use of an EWD on vehicle circuits.

Lesson 5.00 Objectives

After completing this section, the technician will be able to:

1. Accurately diagnose open circuit problems.

2. Diagnose parasitic load problems.

3. Diagnose short to ground problems.

4. Diagnose high resistance problems.

5. Diagnose feedback problems.

This section will also:

1. Provide feedback on what the technician has learned from the course.

2. Enhance the technicians' confidence in their electrical diagnostic ability.

Lesson 6.00 Objectives

After completing this section, the technician will be able to:

1. Define multiplexing and serial data.

2. Explain the need for standard.

3. Retrieve trouble codes (DTCs) from a multiplexing system.

4. Diagnose a simple system fault in a multiplexing system.

LEXUS Course L 652 - Body Electrical Diagnosis 10

MATERIAL REQUIREMENTS AND APPROACH TO INSTRUCTION

Body Electrical Diagnosis

Course L652

Material Requirements and Approach to Instruction

Materials

• Instructor Guide

• Multimedia Presentation

• LCD Projector and Screen

• L 652 Technician Handbook

• L 622 Experiment Suitcase (Optional)

• Digital Multimeters

• ES 300 Body Electrical Simulator (Should be located in the front of the classroom)

• Assorted jumper wires

• L 652 Technician Handbook

• 1998 ES 300 EWD (1 per technician)

• Spare body/engine wiring harness

• Assorted Lexus vehicles *

* The concept regarding vehicle usage is that any vehicle in the Lexus lineup can be used to teach these electri-

cal concepts. However, some of the bugs cannot be placed on all vehicles because of limitations regarding ac-

cess to bugged areas and/or the possible damage to related components. The ES 300 simulator should always

be considered as an extra vehicle and included in rotations whenever practical. In every case where the electri-

cal problem is not "system specific" an attempt has been made to make the bug generic. Instructors are encour-

aged to look at the concept of the bug (what the bug is designed to teach) and then try to install the bug on avail-

able vehicles with the least amount of time and trouble.

Approach

The course is built around the simulator as a means of showing how the theory of electrical trouble-

shooting can be applied to an automotive system. The multimedia presentation has been designed to

assist the instructor in the transition between theory and real world applications. Just as the instruc-

tor is free to use additional relevant examples to relate a concept during his presentation, he is also

encouraged to go beyond the confines of the outline to produce bugs and diagnostic scenarios which

work for him and his group of technicians. Another important consideration is the concept of "volt-

age drop" which has been used in a number of examples as a diagnostic approach that works and is

very useful. It is recommended that the instructor become familiar with this concept and make every

effort to convey this knowledge to the technicians.

LEXUS Course L 652 - Body Electrical Diagnosis 11

ENROLLMENT AND INTRODUCTION 1.00

Lesson Title Enrollment and Introduction 1.00

Day Number One

Time Period 9:00 - 9:10 a.m.

Total Time 10 min.

Instructional Objectives

1. Instructor introduction to technicians

2. Complete attendance records

3. Introduce technicians to program goals, and objectives

4. Familiarize technicians with technician handbook

Lesson Key Points

• Use this time to take attendance and orient the technicians to the topics which will be covered each day of

the course. By using the time and topic, technicians will get a feel for what is to be covered throughout

the day.

• Discuss the technician incentive program depending on the make-up of the class.

• This is also a time to “break the ice” so the class gets to know each other. Have technicians introduce

themselves and hobbies they enjoy.

• Depending on your area policy you may wish to discuss technical problems and fixes at this time.

Required Material

• Multimedia presentation

• LCD Projector and Screen

LEXUS Course L 652 - Body Electrical Diagnosis 12

ENROLLMENT AND INTRODUCTION 1.00

Slide / Activities / Ref.

I. Enrollment

A. Complete Attendance Record as indicated on back of form

B. Have each technician enroll with appropriate information on Atten-

dance Record

II. Introduction

A. Introduce yourself as instructor

B. Introduce course: Lexus Body Electrical Diagnosis L652

C. Prerequisites

1. Course L 622 - Electrical Fundamentals

D. Have technicians introduce themselves

1. Name

2. Dealership

3. Number of years as Lexus technician

4. Hobbies or interests

III. Problems (Optional)

A. Discuss Technician Incentive Program

B. Discuss recent technical problems and fixes

LEXUS Course L 652 - Body Electrical Diagnosis 13

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Lesson Title Review of Electrical Circuit Theory and Concepts 1.10

Day Number One

Time Period 9:10 - 10:10 a.m.

Total Time 60 min.

Instructional Objectives

1. Familiarize the technician with the subjects to be covered during the course.

2. Through a review of L 622 course materials, the technician will be able to demonstrate an understanding of the

following concepts:

• Voltage

• Amperage

• Resistance

• An electrical circuit

• Series circuit theory

• Parallel circuit theory

3. Familiarize the technicians with EWD wiring diagram symbols.

Lesson Key Points

Use this section to review the materials that were covered in L 622. Heavily emphasize the practical on-car

applications of electrical theory, with less emphasis on concepts that are “nice to know.”

During the review of the concepts, try to get a “feel” for the knowledge and skill level of the technicians, and tailor

your instruction to fit their needs as much as possible.

Required Materials

• L 652 Technician Handbook

• Computer Presentation

• L 622 Experiment Suitcase (Optional)

• Digital Multimeter

• ES 300 Body Electrical Simulator (Should be located in the front of the classroom)

LEXUS Course L 652 - Body Electrical Diagnosis 14

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

After the general introduction/attendance matters have been finished,

proceed with the following.

NOTE: The instructor may feel the need to Assign Worksheet 1-1 and

go to the Worksheet 1-1 Presentation materials for review, or continue

forward with Slide 2. If students need a review of L622 this option

may be valuable.

Slide 1

LEXUS Course L 652 - Body Electrical Diagnosis 15

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

I. Introduction to L 652 Course

A. Course Objectives

1. Solidify the concepts taught in L 622

a. L 622 concentrates on the theory aspects of electricity

and electronics

2. How to diagnose electrical circuits on the vehicle

Slide 2 a. Repairing body electrical problems can take too long, not

very profitable

b. Have a lot of guesswork and parts changing

3. “Real World” electrical

a. Some electrical problems are difficult to diagnose

b. Using proper techniques will eliminate any unnecessary

checks

c. The techniques in the course will make you faster and

more profitable

B. Sections of the L 622 course

1. Review

a. Concepts taught in L 622, emphasizing real world appli-

cations

Explain to the technicians that the review will be brief; later in this

course we will be applying the concepts covered in L 622 on an

actual body electrical troubleshooting.

2. Tools of Electrical Diagnosis

a. Explanation and practice with major tools for electrical di-

agnosis:

1) Electrical Wiring Diagrams

2) Digital Multimeters

3) BE section of the Repair Manual

b. Extensive lab/worksheet exercises for each of these

LEXUS Course L 652 - Body Electrical Diagnosis 16

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

3. Electrical Troubleshooting

a. Explanation of the 6-step troubleshooting method

b. Diagnostic techniques for:

1) Open circuit problems

2) Short/parasitic load circuit problems

3) High resistance problems

4) Feedback problems

c. Extensive hands-on lab worksheets for each of these

problems

4. Final exam

a. 20 multiple choice questions, open book

b. Hands-on diagnostic problem

C. ES 300 Body Electrical Simulator

1. Nearly all of the body electrical systems of a 1998 ES 300

2. Systems are operational.

3. The location of components, harnesses, and connectors/

splices are in the approximate locations as they would be on

the car.

4. A set of bug switches will be used to create electrical prob-

lems for class case studies and worksheets

II. Basic Electrical Terms

A. Voltage

1. Definition

a. Electrical pressure differential

b. Pressure differential causes current flow if a complete

path is present.

2) Other terms

Demonstrate each of these voltage concepts on the Simulator using

the Dome Light circuit.

Slide 3

LEXUS Course L 652 - Body Electrical Diagnosis 17

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

c. Open Circuit Voltage

1) Measured at any point in the circuit when there is no

current flow present

2) Used when diagnosing an inoperative or open circuit.

If you placed the negative probe of the DMM on the opposite side of

the connector, it should also read about 12.6 V if the ground path of

the circuit has continuity.

Slide 4

d. Voltage Drop

1) Measurement made with voltmeter connected in par-

allel to circuit or portion of a circuit that has current

flow through it:

2) Can measure exactly how much voltage the load is

getting.

a) Almost all body electrical components should

be receiving full battery voltage.

Slide 5

3) Used to track down high resistance problems.

Figure 1-8 illustrates a 0.1V drop across all the connections.

An additional explanation of voltage drop is to also call it an “I R”

drop. This application of Ohm's law can help the technician remem-

ber that for a voltage drop to occur, you need to have amperage and

resistance. If you are missing one of these components, you can’t

have a voltage drop.

B. Amperage or current flow

1. The rate of flow or “how much” electricity.

2. Multiplied by voltage tells you the amount of power being used.

3. Measured with meter in series or with accessory inductive

clamp.

4. Watts = electrical horsepower.

Slide 6

5. Knowing source voltage is key.

LEXUS Course L 652 - Body Electrical Diagnosis 18

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

Slide 7

LEXUS Course L 652 - Body Electrical Diagnosis 19

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

Fig. 1-10 illustrates the amount of power the light bulb is using: 650

ma X 12.5V drop (not the battery voltage) = 8.125 watts.

C. Resistance

1. Opposition to current flow.

2. Regulates the amount of current flow in a circuit.

3. Problems occur when resistance is excessive.

Slide 8

4. Measured in Ohms

a. When using an ohmmeter, isolate the component being

measured from parallel connections.

b. When using an ohmmeter, be sure the power is

disconnected.

Slide 9

D. Ohm’s Law

1. Allows you to predict how an electrical circuit will behave.

a. States that current flow in a circuit will always be propor-

tional to the voltage and resistance in a circuit.

1) E, I, and R in a circuit are always proportional and

maintain a fixed ratio with each other.

a) If you know the value any two of those compo-

nents, you can mathematically determine

what the third one is.

2. Because we deal with predominately 12 V only circuits, the rule

to remember is that when there is more resistance in a cir-

cuit, there is always less current flow.

3. On car applications of Ohm’s law.

Demonstrate each of these conditions on the Simulator as you talk

about them.

a. If a circuit is inoperative: infinite resistance or open

circuit.

b. Partially operative: excessive series resistance.

c. Fuse is blown: excessive current flow from too little

resistance.

Slide 10

LEXUS Course L 652 - Body Electrical Diagnosis 20

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

1) Short-to-ground before the load

2) Too low circuit resistance from over-loading

Be sure to stress to the technician how these principles are time sav-

ers in the diagnostic process. Ohm's law allows them to eliminate

unnecessary checks and component changes. Application of Ohm's

Law allows you to quickly identify the type of problem (Open, short,

high resistance), and using the EWD, you can eliminate any guess-

work involved in identifying the potential problem areas.

NOTES ARE ON EACH SLIDE

Slide 11

Slide 12

Slide 13

LEXUS Course L 652 - Body Electrical Diagnosis 21

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

III. Series Circuits

A. “True” definition has multiple loads with a single path of current flow

1. Example circuit is Lexus cooling fan circuit on most models.

Slide 14 EWD pg. 264

B. Resistance

1. Resistances add up to the total circuit resistance.

C. Current Flow

1. Same at any point in the circuit.

2. On-car application

a. A resistor either before or after the load still has the

same effect on current flow.

Use the inductive ammeter on the Simulator and measure the current

flow at the Blower Motor, and relay block. You can also measure the

current flow at the battery and have the class tell you the relationship

between that amperage and the amperage that is being used by the

fan.

Slide 15

D. Voltage

1. Divides proportionately between all the resistances.

2. The sum of the voltage drops will equal the source voltage.

You will always encounter a situation in class where the voltage

drops DO NOT add up EXACTLY to the source voltage. Small differ-

ences (usually less than 0.10 volt) can be attributed to meter inaccura-

cy, meter lead resistance, fluctuations in source voltage, and round-

ing error in the DMM.

3. On-car application

a. Because of connections, the load usually receives a little

less than source voltage.

1) Max 0.2V drop across any switch, connection or re-

lay point.

Slide 16

LEXUS Course L 652 - Body Electrical Diagnosis 22

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

b. High resistance problems can be identified by the voltage

drop. There should only be a voltage drop of significance

at the load.

c. The excessive resistance can be located anywhere in the

circuit and still have the same effect.

Demonstrate this using a wire wound resistor in series with the dome

light on the ES 300 BE simulator.

IV. Parallel Circuits

A. Defined as a circuit with multiple loads, but also multiple paths to

ground.

Never use the phrase “Current flow takes the path of least resistance!”

If you have a parallel circuit with a 2 and 4W resistor, current flow

does not just take the 2W path, the path of least resistance. If the

phrase was changed to “Current flow will always take a path of no re-

sistance and by-pass (short out) the rest of the circuit,” then it would

be correct.

Slide 17

B. Term “parallel” is also used to describe the connection of a voltmeter

when making a voltage drop check.

C. Voltage

Slide 18

1. Voltage to each branch will be the same as source voltage.

2. On-car application

a. Everything that receives “12V” is connected in parallel to

the battery.

b. Number of parallel branches does not affect the voltage

(although the total load on the voltage source will).

c. If problem occurred in series to a set of power/grounds

that are connected in parallel, it will affect all of the cir-

cuits.

Slide 19

LEXUS Course L 652 - Body Electrical Diagnosis 23

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

D. Resistance

1. Total resistance is less than the smallest resistor.

2. On-car application

a. We tend to look at parallel circuits in terms of amperage.

b. The more components in parallel, more amperage flows.

c. (With voltage constant) If amperage is increased, Ohm’s

law says that it can only happen if there is a decrease in

resistance.

Most technicians find this concept very confusing to understand. As

long as they can see that current flow is increased when a branch is

added, that is all they need to know for this class.

Slide 20

E. Current Flow

1. Total current flow is equal to the sum of the current flow in

each branch.

2. On-car application

a. Each branch works independently of each other.

b. The amperage that each accessory “draws” adds up to

total load on the charging system or fuse.

Slide 21

c. You can determine the amount of amperage a component

draws by measuring the change in amperage at the bat-

tery when the accessory is turned ON.

LEXUS Course L 652 - Body Electrical Diagnosis 24

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

V. Series Parallel Circuits

A. Combination of elements of both series and parallel circuits together

in a single circuit.

B. Applications

1. Circuit control

a. A single switch in series can control a set of 12 V lamps

that are connected to it in parallel.

Slide 22

2. Power/ground distribution

a. Many unrelated circuits with many parallel branches are

connected to the same fuse/junction block or to the

same ground point.

b. If problem occurred in series to a set of power/grounds

that are connected in parallel, it will affect all of the cir-

cuits.

3. Connectors

a. Junction connectors in series with a fuse distribute

power to multiple circuits.

b. Series power supply

c. Parallel power connections at J12/J13

d. Parallel grounds at J5/J6

e. Series control through R5 rheostat.

Slide 23 EWD pg. 113

VI. Electrical Circuit Concepts

This section is meant to provide a review of the basic EWD schematic

symbols as well as a theory review.

A. Components in a basic circuit

Emphasize that for the circuit to function properly, you need all of

these conditions present.

Slide 24 EWD pg. 130

1. Load

a. What gets the work done in the circuit (the reason why

the circuit was built)!

b. Most loads typically require “12 V,” it is always the circuit

resistance which determines the amount of current flow.

Slide 25

LEXUS Course L 652 - Body Electrical Diagnosis 25

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

2. Voltage source (power and ground)

a. Provided by the battery and alternator

b. Altenator provides AC

c. Battery provides DC

Slide 26

d. Other sources found on car:

1) Sensors (speed sensor)

2) Capacitors

3) Ignition Coils

Slide 27

3. Over-current protection

a. Prevent circuit damage from a short to ground or exces-

sive current flow condition.

1) Fuse

a) circuits are designed to carry only certain

amount of cuurents

2) Circuit breaker

a) Some types have a hole at the top to reset

Slide 28

the breaker.

3) Fusible link

How to examine a fuse to help diagnose a problem is discussed in

section 5, short-to-ground diagnosis.

4. Control device

a. Switch

1) Blower speeds change as resistance is added or

subtracted

2) Broken wires impact switch

b. Resistors

c. Transistors

Slide 29

1) Acts as a non-mechanical switch with “logic” fea-

tures

LEXUS Course L 652 - Body Electrical Diagnosis 26

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

5. Conductor

a. A low resistance pathway for the current or amperage to

flow.

1) Items which affect the amount of resistance in a

conductor are

a) Diameter

b) Length

c) Material

Slide 30

d) Temperature

e) Physical condition

b. The amperage or electron flow occurs whenever there is

a complete pathway to ground.

6. Connectors

According to Field Technical Product Report Summaries, connector

and terminal problems are the #1 electrical problem, and account for

up to 75% of all electrical problems, depending on the model.

a. Aids in assembly and service of the vehicle

b. Typical problems

1) Disconnected

Slide 31 2) Terminal backed out

3) Terminal corroded

4) Terminal spread too wide

5) Improperly made splice

These terminal/connector problems can be illustrated on a scrap har-

ness. Demonstration of a terminal with too wide a spread can be use-

ful to illustrate how to inspect a terminal for this condition. Also,

show the Lexus Wire Repair SST to the class.

In L 652, we will not be discussing a lot of the theoretical aspects of

electricity such as the 2 current flow theories. This course will always

assume the use of the conventional theory of current flow (+ to -).

B. Requirements for current flow

1. A complete connection between the + and - sides of the volt-

age source.

a. The pressure differential causes the current to flow

through the conductor.

b. Using a voltmeter in parallel to the load, the voltage drop

should be about the same as the voltage drop at the

source.

2. The resistance in the load and in the control device

a. Regulates the amount of current flow.

b. When it will occur.

LEXUS Course L 652 - Body Electrical Diagnosis 27

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

C. In actual application, voltage drop at the load is approximately the

same as the source voltage.

1. It will never be exactly the same because of the series resis-

tances that uses some of the pressure that is available to

push current through the load.

VII. Basic Diagnostic Tools

A. Electrical Wiring Diagram

Show the EWD/point out the actual EWD to the class.

1. The EWD is your #1 source for information to make repairs to

the electrical system.

2. You must know your basic circuit theory and all the concepts

talked about in L 622 in order to be able to use the EWD to fix

Slide 32 a problem.

a. Little information in it to guide you through problems.

b. You must be able to follow the paths of current flow in the

circuit:

1) If you cannot follow those current flow paths, you

will not know where to perform checks with a volt-

meter, or know what to look for (possible open,

short, or high resistance problem).

In short, using the EWD to diagnose and successfully repair the cir-

cuits brings all the L 622 concepts together!

B. Repair Manual

1. The BE section of the Repair Manual has some information

that is not contained in the EWD.

a. ECU controlled circuits

1) Look in the Repair Manual FIRST before using the

EWD.

2) The RM and NCF have information about the self di-

agnosis systems that are used in circuits such as

SRS, ABS, and the Cruise Control System.

2. Use the RM when

a. Diagnosing ECU controlled circuits.

b. You need guidance as to how to diagnose the circuit.

c. You need verification of something listed in the EWD that

does not match the actual vehicle.

C. Introduction to the RM Body Electrical Section

1. This is the last of the tools that will be covered in this course.

2. Very useful, especially in conjunction with the EWD.

LEXUS Course L 652 - Body Electrical Diagnosis 28

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

3. Advantages over the EWD

a. Has information about the self-diagnostic systems

1). Trouble code system is not mentioned in the EWD

a) Code definition

b) How to access codes

c) How to clear codes

b. Diagnostic Assistance

1). Clear set of procedures for dealing with trouble

codes

2). Individual component inspection procedures

3). Tables which explain where each switch should be

under a given condition

a) Power door lock system “sensors”

4). Troubleshooting matrices

a) Direct you to check, given a particular

symptom, specific components in a spe-

cific order.

5). Troubleshooting “trees”

a) Tell you exactly what to do to test sys-

tem.

Explain to the class that this “laundry list” of possible causes is the

same thing that they would come up with while diagnosing using the

EWD. However, with the EWD, the order that you would make your

checks would be up to the technician's discretion.

The matrices in the RM may not take into account the accessibility of

components, or even the past history of failures, like the technician

would while diagnosing with the EWD alone. However, for a situation

where the technician is totally “lost”, it would be the resource to use.

(Although, after completing this course, that situation should not oc-

cur!)

c. Additional Specifications

1). Various resistance and voltage values

4. Disadvantages to using the RM Body Electrical Materials

a. Black and White only

b. Does not use the connector/component ID system used

in the EWD

1). Slowly is being integrated into the RM.

2). 1998 ES 300 BE section uses the EWD connector/

component ID system.

LEXUS Course L 652 - Body Electrical Diagnosis 29

REVIEW OF ELECTRICAL CIRCUIT THEORY AND CONCEPTS 1.10

Slide / Activities / Ref.

D. Digital Multimeter

1. This course concentrates on the DMM only. Analog meters

have their place, but in general, the DMM provides many ad-

vantages:

a. Highly accurate

b. Additional features such as min-max, peak hold

c. Low cost models available

Slide 33

d. Good models are highly durable

e. Many meters provide an analog bar graph to view volt-

ages that are changing rapidly (acts like a mini-oscillo-

scope)

f. Can be used with confidence on solid state ECU con-

trolled circuits.

1) Some older or inexpensive analog meters have

voltmeters with a low internal impedance.

a) The meter itself loads (uses power from) the

circuit you are testing.

b) The additional current flow demand on an

ECU’s power supply can artificially “pull down”

the circuit voltage.

c) Leads to an inaccurate measurement.

E. Test Lights

1. Not emphasized in this class

2. have limited usefulness

3. can cause a number of problems

a. ECUs

Slide 34 4. If hooked up in parallel becomes a load

5. Logic probe better for voltage testing

F. Fused Jumper Wire

1. Should be used in place of straight jumper

2. Need to know the current before hookup.

LEXUS Course L 652 - Body Electrical Diagnosis 30

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Lesson Title Using the Electrical Wiring Diagram 1.20

Day Number One

Time Period 10:25 - 11:25 a.m.

Total Time 60 min.

Instructional Objectives

After completing this section, the technician will be able to:

1. Find and use each of the sections of the EWD.

2. Given a system circuit diagram in the EWD:

• Identify each of the symbols used on the system diagram.

• Understand the meaning of the labels that are used with those symbols.

• Apply basic current flow theory to diagram the path of current flow through the circuit.

Lesson Key Points

Use the EWD to walk the technician through each of the sections thoroughly. Answer any questions that they

may have about each of the sections, and add any additional information that you have about your experiences

in using the book.

Although the sections of the EWD are illustrated in the Technician Handbook, it is recommended that you simply

use the 1998 ES 300 EWD while talking about each of the Sections. In this way, the technician will get practice

in using the actual tool that he has to work with in the shop.

Component and parts location, and other information that is included with the system circuit diagrams will be

discussed later. In this section, keep the technician focused on the schematic only.

Use the ES 300 Body Electrical Simulator’s electrical circuits to illustrate what is being shown in the EWD.

Required Materials

• L652 Technician Handbook

• Multimedia presentation

• 1998 ES 300 EWD (1 per technician)

• Spare body/engine wiring harness

• ES 300 Body Electrical Simulator

LEXUS Course L 652 - Body Electrical Diagnosis 31

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

Although each of these sections is illustrated in the Technician Hand-

book, it is recommended that you have the technicians find and exam-

ine each of these sections directly in the 1998 ES 300 EWD.

I. Using the EWD

Slide 35

A. Sections of the EWD

1. Section A: Introduction

a. Defines what is in each section

2. Section B: How to use this manual

a. Small explanation of diagnosis using the manual

b. Definition of symbols and labels that are used on the

system circuit diagram

c. Explanation of each of the auxiliary sections of the sys-

tem circuit diagram

3. Troubleshooting

a. Techniques for measuring voltage

b. Continuity and resistance checks

c. Finding a short circuit

d. Disconnecting male and female connectors

Slide 36

e. Terminal removal techniques

4. Section D: Abbreviations

a. A short list of some of the abbreviations that are used

on the system schematic

5. Section E: Glossary of terms and symbols

a. Defines many of the schematic symbols that are used

on the system circuit diagrams

6. Section F: Relay Locations

a. The first section that deals with the specific vehicle the

EWD was written for

b. Physical location of relay blocks and relays

c. Junction Block diagrams and schematics

d. Junction block connector and fuse information

e. Relay block fuse and connector information

1) Relay and junction blocks are grouped together and

numbered consecutively

LEXUS Course L 652 - Body Electrical Diagnosis 32

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

7. Section G: Electrical Wiring Routing

a. Component location

b. Wire harness routing

c. Connector locations

d. Wire harness to wire harness connector pin information

e. Wire harness to wire harness connector locations

f. Splice points

g. Ground points

8. Section H: Power Source (Current Flow Chart)

a. Power distribution to the each of the fuses and some

major components

1) Not all components are covered. Not entirely helpful

for short-to-ground diagnosis

b. Power distribution from each of the fuses

1) Helpful in diagnosing short-to-ground or parasitic

load problems

2) Gives page number of schematic, part name, and

location code

9. Section I: System Circuit Diagrams

a. Color schematics and additional information that is the

heart of the EWD

10. Section J: Ground Point

a. Gives ground point schematics and location tables

b. Use to help find circuits that are connected to each other

through shared ground points

11. Section K: Overall Electrical Wiring Diagram

a. Condensed version of “map” style wiring schematic

b. Still useful to some technicians because “you can see

everything at once”.

c. Because of increased circuit complexity, seeing every-

thing at once is not necessarily an advantage anymore.

d. The new style circuit diagrams are easier to follow.

The type of schematic a technician prefers many times depends on

the type of schematic that he learned first. For some technicians who

have been in the business a long time, there may be some resistance

to the EWD schematics. They are not used to turning pages to find

the (power/fuse, ground, location) circuit information that is covered

in the different sections of the EWD.

LEXUS Course L 652 - Body Electrical Diagnosis 33

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

II. System Circuit Diagram Features

A. Breaks the vehicle electrical system into individual system circuits.

B. Provides identification code numbers for cross referencing to Service

Hints and location charts.

C. Lists all splices in harness wiring.

1. Older versions of the EWD did not do this.

Slide 37 EWD p. 264 D. Provides references to circuits which share common wiring/compo-

nents.

E. Provides all wires in color for easy identification.

F. Uses colors and grey shading to identify different components.

G. Fuses (power) are at the top, ground at the bottom.

1. When a battery or fusible link is used in the circuit, it is located

on the lower left of the schematic.

III. Parts of the System Circuit Diagram Section I

Recommend to the technicians to use the table of contents at the front

of the EWD to help locate the system circuit diagram that they are

looking for. It definitely helps speed up the process of finding the

right circuit.

A. System Title

1. Always at the top corner of the page.

2. Power Source, Starting/Charging circuits are always first.

3. The easiest way to find the circuit you need is to use the table

of contents either at the front of the book, or at the beginning

of section I.

Slide 38 EWD p. 98 & 118 4. Asterisks * / Parenthesis ( )

a. Indicates different wiring and connector for different mod-

els or equipment specification (S/D) = Sedan, etc.

LEXUS Course L 652 - Body Electrical Diagnosis 34

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

B. Wire Color

1. Wire colors are indicated by abbreviation of the wire color:

a. B=Black

b. BR=Brown

c. G=Green

d. GR=Gray

Slide 39 EWD p. 160

e. L=Blue *

f. LG=Light Green

g. O=Orange

h. P=Pink

i. R=Red

j. V=Violet

k. W=White

l. Y=Yellow

m. SB=Sky Blue

* This is different from other manufacturers

2. If the wire has a stripe or “tracer” on the wire, the color is rep-

resented by a dash (-) and a second letter.

LEXUS Course L 652 - Body Electrical Diagnosis 35

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

C. Junction Block

Using the spare body/engine wiring harness, show an actual Junction

Block and Junction Connector. If possible, disassemble a Junction

Block to show how it is constructed.

This slide is taken from the Moon Roof circuit on page 238 of the

1998 ES 300 EWD.

1. Always shaded grey

2. Different shading to differentiate the different junction blocks

3. ID number is always in an oval

a. Number indicates the J/B number

b. Letter indicates a specific connector

c. Number next to the oval indicates the pin number in the

connector.

Slide 40 EWD p. 238

Many times, you need to look at 2 or more different system circuit

schematics to find a specific component, wire or connector. An exam-

ple of this would be all the schematics that have the Integration Relay

in it. In order to know about all the terminals at the Integration Relay

on a 1998 ES 300, you need to look at the headlight, tailight, Illumina-

tion, Interior Light, and Tail Light wiring diagrams.

Slide 41 EWD p. 25

LEXUS Course L 652 - Body Electrical Diagnosis 36

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

D. Relay Block

Using a Body or Engine harness, show the technicians an actual Re-

lay Block. If that is unavailable, use the ES 300 Body Electrical Simu-

lator.

1. Relay blocks are not shaded.

2. ID numbers in an oval symbol indicate which relay block the

component is located in.

This slide is from the Headlight (Canada) schematic page 98 of the

1998 ES300 EWD

Slide 42 EWD p. 98

LEXUS Course L 652 - Body Electrical Diagnosis 37

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

E. Components/Parts

1. Parts are always shaded Blue.

2. ID numbers usuaully begin with the first letter of the name of

the component.

3. Use the parts location table found in the support section usu-

ally found behind the system circuit diagram to locate compo-

nents.

Slide 43 EWD p. 126

4. Component ID number corresponds to the ID number on the

schematic

a. Pin numbering system is different for male or female ter-

minals:

1) Female - left to right, with #1 in the upper left corner.

2) Male - right to left, with #1 in the upper right corner.

Slide 44 b. View of the connector is from the terminal side of the

connector lock tab up.

5. Explains cavities that are not used in the particular circuit

have a “•” in them, and those cavities that are left empty and

marked by an X.

It is usually helpful to match the wire color on the schematic to verify

the correct pin on the connector when doing any pin/voltage inspec-

tion.

LEXUS Course L 652 - Body Electrical Diagnosis 38

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

F. Multiple Connectors

1. Letter in a circle is used to designate which connector.

2. ID Numbers

a. E for Engine.

b. I for Instrument Panels. B for Body.

The Integration Relay on the headlight, tail light, interior light, and

auto shut-off circuit schematics is shown in varying degrees of detail

on each system circuit diagram.

G. Parts label

1. All parts are labeled and are colored sky blue.

Slide 45 EWD p. 114

H. Wire harness to wire harness connectors

1. On harness-to-harness connectors, the connector symbol indi-

cates which terminal is the male or female terminal.

2. Most connectors are white in color. If the connector is a differ-

ent color, the color will be noted above the illustration.

3. Harness-to-harness connectors use an I, E, or B as the first

digit in the ID number to indicate approximate location.

Slide 46 EWD p. 126

a. I = Instrument panel

b. E= Engine

c. B= Body

Use an appropriate engine or body harness to illustrate all of these

points about connectors.

LEXUS Course L 652 - Body Electrical Diagnosis 39

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

I. Locating a Harness to Harness Connector

1. Use ID number on the location table.

2. Column to the right of number gives page number.

3. Find location of connector on designated page.

Slide 47 EWD p. 36

J. Switches and Relays

1. Switches shown in Normal position.

2. Multi-pole switches (Combo Switch, Heater Fan, etc.)

a. Circle and line show connections at various switch posi-

tions.

b. Gang type switch has dotted line inside switch connect-

ing the arms.

Slide 48

Optional: Go to worksheet 2.1

K. Shielded Cable

1. Dotted line around a section of the wire indicates a wire that is

shielded

a. A shielded wire is a wire that has a grounded wire sur-

rounding the insulation of the wire to absorb electro mag-

netic interference.

b. Used on low current flow ECU sensor circuits.

Slide 49 EWD p. 74 2. Intermittent or erratic operation of ECU controlled systems

could be caused by the failure of the shielding.

L. Splice point

1. Uses same ID codes as the harness to harness connector in

an octagon.

a. E=Engine Room

b. I=Instrument panel

c. B=Body

2. Splice points connect additional wires and systems together in

Slide 50 EWD p. 109

parallel.

a. When diagnosing problems where a number of different

circuits are not working, a splice (or power feed to a

splice or ground side splice) could be a cause.

LEXUS Course L 652 - Body Electrical Diagnosis 40

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

b. Section G gives the general location of the splice.

M. Power and Ground Distribution

1. Shows entire circuit with fuses and grounds.

2. Section K contains Power Source.

N. Section H Shows Current Flow

1. Use to find other components that use same fuse.

Slide 51 EWD p. 40

2. If no B+ is available trace back to fusible links.

3. Lists every load on the vehicle

a. Good for diagnosing parasitic draw

b. Also good for feedback issues

Slide 52 EWD p. 126

O. Ground Point

1. Represented by a triangle.

2. Which lights are affected if BN ground is lost?

a. license plate

b. rear side marker, etc.

Slide 53 EWD p. 109

LEXUS Course L 652 - Body Electrical Diagnosis 41

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

c. Section J shows shared grounds.

2. Use support section and ID number to locate ground on

vehicle.

3. Grounds always located at the bottom of the schematic.

4. Uses the I, E, and B location designations that were used for

harness to harness connectors, and for the splice points.

Slide 54 EWD p. 278

P. System Outline

1. Gives path of current flow

2. Describes operation of circuit

3. Found after individual system circuit

4. Some circuits do not have system outline

Slide 55 EWD p. 127

Q. Service Hints

1. Contains information not found in RM.

2. Provides pin voltages and resistance values.

3. Larger diagrams may replace “System Outline” with “Service

Hints.”

Slide 56 EWD p. 76

R. Overall Wiring Diagram (Section K)

1. Can be used as a back up for other diagrams.

a. Helps to verify possible errors.

b. Sometimes faster to use.

Slide 57 EWD p. 282

LEXUS Course L 652 - Body Electrical Diagnosis 42

USING THE ELECTRICAL WIRING DIAGRAM 1.20

Slide / Activities / Ref.

S. Troubleshooting (Section C)

1. Gives general hints in diagnostics.

Slide 58 EWD p. 10

T. Section L

1. Contains part numbers of connectors in newer vehicles.

2. Consult parts department for availability.

a. some connectors not available.

3. Power source section moved to back of book in newer

manuals.

Slide 59

Slide 60

** Introduce Worksheet 2-2 Tracing Current Flow. Use multime-

dia presentation to demonstrate how the tracing should be

done and to introduce the concept of Voltage Drop.

LEXUS Course L 652 - Body Electrical Diagnosis 43

FOLLOWING CURRENT FLOW IN A CIRCUIT 1.30

Lesson Title Following Current Flow in a Circuit 1.30

Day Number One

Time Period 11:25 am - 12:25 pm

Total Time 60 min

Instructional Objectives

After completing this section, the technician will be able to:

1. Given a system circuit diagram in the EWD:

• Understand the usage of the system outline section of the EWD when available

• Be able to configure the switches/relays to the appropriate position for the operating condition

• Follow the current flow path from the B+ source to ground in example EWD circuits

Lesson Key Points

Use the Technicain Handbook to walk the technician through the process of tracing current flow using the supplied

example circuits. Illustrate the current flow tracing with the use of the circuit on the ES 300 Body Electrical

Simulator.

Integrate what-if problem scenarios with the two example circuits.

Perform the 2 worksheets on Radiator fan and Remote Control Mirror Circuits. Integrate the problem switches on the

Simulator with what-if problem scenarios.

Required Materials

• L 652 Technician Handbook

• Multimedia presentation

• 1998 ES 300 EWD (1 per technician)

• ES 300 Body Electrical Simulator

• 2 Different Color Highlighters for each Technician

LEXUS Course L 652 - Body Electrical Diagnosis 44

FOLLOWING CURRENT FLOW IN A CICUIT 1.30

Slide / Activities / Ref.

NOTE: Do the students understand the following concepts which are

used in subsequent exercises?

I. The importance of being able to trace the path of current flow

through a circuit diagram

A. The EWD does not tell you a procedure to diagnose a circuit.

1. Relies on the technician’s ability to use the EWD

B. The EWD is useless without this skill.

1. You will mis-diagnose everything unless you know where cur-

rent flow is going.

II. Procedure for tracing current flow

A. Determine which fuses are “hot” and at what times.

B. Move the switches into the proper open or closed position.

1. The system outline tells you a terminal-by-terminal description

of the current flow.

2. If the circuit does not use an ECU or an electronic control de-

vice, there will not be a system outline in the EWD.

a. An example of this would be the Remote Control Mirror

Circuit, Turn Signal Circuit, or Horn Circuit.

C. Starting from the fuse at top of the page, apply the series and par-

allel circuit laws to determine all the paths to ground in the circuit.

D. Break the circuit up into separate individual circuits.

1. Just about all the systems on the vehicle are made up of a

combination of separate, individual circuits.

a. This is important because in diagnosisng a circuit, you

want to identify the portions that are working and those

that are not.

II. Hints on finding all the paths to ground

A. Current flow will take any path to ground it can get.

1. Current does not necessarily flow “down” (it goes up and side-

ways, too) the page, but will find as many paths to ground as

possible.

a. Visually on the page, it will flow up, down and sideways

b. With all of the splices, especially on the ground side of

most circuits, the current flow can find a ground through

circuits that don’t seem to be related.

1) This is a feedback type problem.

The feedback problem can be demonstrated with the use of switch 27

on the simulator.

LEXUS Course L 652 - Body Electrical Diagnosis 45

FOLLOWING CURRENT FLOW IN A CICUIT 1.30

Slide / Activities / Ref.

B. Current flow will bypass a load or resistance only if it can go directly

to ground.

1. This is a statement to replace that misconception of “Current

flow takes the path of least resistance.”

C. There is a difference between where there is voltage present and

where there is current flow.

1. Current flows only when there is a complete connection or cir-

cuit between the B+ source and ground.

2. Voltage will be present anywhere there is an unbroken connec-

tion between a location and the B+ source.

The measurement of voltage at certain locations can be of help in de-

termining CONTINUITY in circuit while diagnosing a problem. How-

ever later in the course, we will try to explain the difference between

making a voltmeter in series measurement and making an actual

VOLTAGE DROP measurement in a LIVE circuit, with current flow go-

ing through it.

D. Use a highlighter on a photocopy of the wiring diagram.

1. Drawing the paths to ground is one of the best ways of visually

seeing where the possible trouble areas are.

a. In the diagnostic process, based upon your operational

checks, you can draw in all the parts of the circuit that

you have observed to be operating.

b. The areas that you have not marked then become the

areas that you need to check. It is here that you can

apply the split-half methodology to help locate the prob-

lem.

2. In the beginning, it is possible to be a little confused in drawing

the lines; Therefore in this class, use one highlighter for

drawing and the other highlighter for making corrections only.

3. Add arrows if necessary for clarity.

4. For effective diagnostics, you must become CONFIDENT at

doing this.

III. First Example: The Horn Circuit

A. Found on Page 250 of the 1998 ES 300 EWD

While working on this circuit, a test light may be substituted for a

horn to make the noise level more tolerable.

Point out to the techncians that on simple schematics such as this,

there is no system outline section given in the manual.

B. Use the copy of the diagram in the Technician handbook.

C. This circuit does not have a system outline in the EWD.

D. Sample questions.

LEXUS Course L 652 - Body Electrical Diagnosis 46

FOLLOWING CURRENT FLOW IN A CICUIT 1.30

Slide / Activities / Ref.

Even if the answer may seem easy, it is a good introductory use of the

EWD features. Make the student find the answers out.

1. When is the Haz-horn fuse “hot?” All times

2. What should the positions of the Horn Relay contact and Horn

Switch be? Both Open, until the Horn is depressed by the

driver; Normally Open.

Normally open means the switch position when the vehicle is parked,

all the doors closed.

3. In what sequence does this circuit operate? The Horn Switch

is depressed, completing the circuit for the relay coil; B+ is

then applied to the horns. The horns are connected in parallel;

Both receive 12V and provide ground from their housing.

4. Have the techicians trace the current flow in the two circuits

that are involved in making the horns work.

Other questions can be asked in conjunction with the ES 300 Body

Electrical Simulator.

What is the location of the horn relay, horn fuse?

What are the J/B connector numbers?

What would happen if there was an open in the G-B wire?

What would happen if there was an open in the G-W wire?

Proceed to the TRACING CURRENT FLOW worksheets.

LEXUS Course L 652 - Body Electrical Diagnosis 47

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Lesson Title Using the Electrical Diagnostic Tools Section 1.40

Day Number One

Time Period 1:25 - 1:55 p.m.

Total Time 30 min.

Instructional Objectives

After completing this section, the technician will be able to:

1. Use the System Outline to determine system operation.

2. Locate and use the diagnosis information to check connectors.

3. Perform a wire harness inspection.

4. Use jumper wires to aid in diagnosis.

5. Use DVOM to diagnose a circuit.

6. Use a digital ammeter to diagnose a circuit.

Lesson Key Points

The primary goal of this module is to familiarize the technician with the information available in the EWD.

Required Materials

• L 652 Technician Handbook

• Multimedia presentation

• 1998 ES 300 EWD (1 per technician)

• ES 300 Body Electrical Simulator

• 1 DMM

• 1 1998 ES 300 RM

LEXUS Course L 652 - Body Electrical Diagnosis 48

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

I. Introduction to the EWD System Outline

Slide 61

A. Shows how the system operates

B. Very useful diagnostic aid

C. Helps narrow down on paper the problem on the vehicle

Slide 62 EWD p. 137

1. Connectors are critical element

a. Typical Problems

1) connectors not locked

2) terminal pins backed out

3) terminals spread

Slide 63

2. Harness Inspections

a. wire chafing or rubbing

b. harness stretched too tightly

c. abnormal kinks or bends

3. Visual Inspections

a. Know how the system operates.

Slide 64 b. Check the easiest items first.

c. Use your experiences from the past to judge what should

be looked at first.

1) Tell you exactly what to do to test system.

LEXUS Course L 652 - Body Electrical Diagnosis 49

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

4. Jumper Wires

a. Help to bypass certain sections of wiring harness

b. Should use only a fused jumper wire

c. Never by-pass a load

Slide 65

II. Digital Multimeters

A. Features of Multimeters

1. Accurate

2. Not sensitive to polarity

3. Durabale

Slide 66

4. Batteries last long time

5. Other features are min-max

6. Analog bar graph

Slide 67

B. Digital Voltmeter

1. Connect negative probe to ground

2. Connect positive probe to pin (source voltage)

Slide 68

LEXUS Course L 652 - Body Electrical Diagnosis 50

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

C. Voltage Drop

1. Turn circuit ON

2. Connect leads

3. Measurement of 0 volts can mean two things

4. circuit is OFF or Open

Slide 69 5. There is vitually no resistance (load) in that part of circuit.

D. Digital Ammeter

1. Used in checking the starting and charging systems.

2. Used in diagnosing parasitic load problems.

3. Fuel pump check shown

a. Normal = 4.0A

b. Excessive = 6.0A

c. Warm pump = 3.0A or less

Slide 70

LEXUS Course L 652 - Body Electrical Diagnosis 51

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

4. Types of Digital Ammeters

a. Series (Fluke)

b. Clamp (VAT40/60)

c. Maximum ECU draw 50mA

d. Battery generally rated at 50AH

e. Below 12V on battery is unacceptable for load test

must change

Slide 71

LEXUS Course L 652 - Body Electrical Diagnosis 52

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

E. Digital Ohmmeter

1. Measures Resistance

Slide 72

2. Diode Check

a. Diode check is a separate function

b. Determines resistance one way and then the other

Slide 73

3. Continuity beep 0 - 100W

a. Only checks continuity

b. Does not determine resistance

c. Good for checking a wire from one end to the other

Slide 74

4. Ohmmeter checks

a. Highly accurate

b. Good for limited checks

c. Voltage checks still most accurate

Slide 75

LEXUS Course L 652 - Body Electrical Diagnosis 53

USING THE ELECTRICAL DIAGNOSTIC TOOLS SECTION 1.40

Slide / Activities / Ref.

III. Worksheets for Section Three

A. Worksheet 3-1 / Voltage Drop

1. Trace current flow when door is opened using markers.

2. Use voltmeter to determine current at fuse.

B. Worksheet 3-2 / Measuring Amperage

1. Section 2 / use clamp attachment or series to measure

seats

2. Section 3 / Inductive type or series

C. Measuring Resistance

1. Use this to measure resistance in relays.

LEXUS Course L 652 - Body Electrical Diagnosis 54

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Lesson Title The Six-Step Diagnostic Process 1.49

Day Number One

Time Period 1:55 - 2:25 p.m.

Total Time 30 min.

Instructional Objectives

After completing this section, the technician will be able to:

1. Implement the 6-step diagnostic process on a typical body electrical problem.

2. Properly verify an electrical problem.

3. Use defined techniques to analyze the related symptoms.

4. Isolate and correct the trouble using the EWD and electrical diagnostic tools.

5. Perform wire, connector, and harness repairs according to proper procedures.

Lesson Key Points

This section applies the skills developed in Day 1 to diagnose and successfully pinpoint electrical problems.

The six-step troubleshooting plan applies to all electrical problems in general. Each of the six steps is broken into

specific actions that should be performed. Specialized techniques for troubleshooting opens, short-to-grounds,

parasitic loads, high resistance, and feedback problems are covered in the lessons which follow.

Have the technicians think strategically about the problem through the use of the six-step plan. Show him/her

that they can save a lot of time by working on paper first before going to the vehicle.

Work to build the Technician's confidence in the use of the diagnostic tools, and in his/her own abilities.

Stress that these techniques will help them to repair electrical problems faster, and make electrical problems

more profitable overall.

Required Materials

• L 652 Technician Handbook

• Multimedia presentation

• 1998 ES 300 EWD

• Lexus Body Electrical Simulator

• 1 DMM for every 2 technicians minimum; 1 DMM per technician optimal

LEXUS Course L 652 - Body Electrical Diagnosis 55

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Slide / Activities / Ref.

I. Introduction

A. You have now covered all the necessary “tools” to perform the diag-

nostic process.

1. Use of the EWD

2. Being able to follow the current flow in a circuit

3. Use of the DMM/Jumper wires

Slide 76

B. Some problems can be fixed quickly without any wasted effort.

1. Repeatedly seen problem on certain model

2. Therefore you can go to the problem area immediately

C. Problems where there is no trend to follow are not as easy.

1. Need to follow a six-step troubleshooting plan

a. Provides a structured approach

b. Will help you to fix problem in the least amount of time

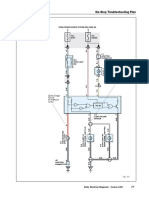

II. Six-step Troubleshooting Plan

A. Verify the Complaint

Slide 77

B. Determine the Related Symptoms

C. Analyze the Symptoms

D. Isolate the Trouble

E. Correct the Trouble

F. Check for proper operation

G. These steps will minimize diagnosis time.

1. You will make only the checks that you need to make.

2. Emphasis on those checks that are the easiest to make.

3. Organizes the all of your checks.

H. Finding the cause of an electrical problem will depend on your skills

and not luck.

The definitions of each of these steps are a little different than the

definitions that are found in the L 622 course. In general, we are

trying to define each of these steps a little more clearly than in the

L 622 book. The diagnostic worksheets that you will be using will

follow these revised definitions.

LEXUS Course L 652 - Body Electrical Diagnosis 56

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Slide / Activities / Ref.

III. Verify the complaint

A. Identify the problem.

1. Must understand what the customer is talking about.

a. Customer is not technically oriented.

b. Technician usually does not interface with customer.

The example that is used to illustrate this process is a Stop Light

Slide 78

problem on 1998 ES300. The stop light wiring diagram is found on

page 126 of the ES300 EWD.

2. Does a problem actually exist?

a. Must know how the circuit is supposed to operate.

1) Use the System Outline, New Car Features or

Owner's manual as reference.

Slide 79

Show the Technicians a copy of an owner’s manual, and how the in-

formation can be used with a customer.

b. May not be a problem.

1) Not being operated properly.

2) Operating condition that the customer is not aware

of causing the system to go into a "fail-safe" mode.

A good example of this would be to demonstrate the operation of

Slide 80 the Cruise Controls System on the ES300 Body Electrical Simulator

with the parking brake only slightly engaged.

c. Characteristic of the vehicle

1) No fix possible for a non-problem

2) Compare vehicle to a known good vehicle.

B. Intermittent or Continuous

1. If problem is intermittent

a. Duplicate exact conditions which caused problem to oc-

cur.

1) May require additional customer input.

b. Typical Causes (triggers)

Slide 81 1) temperature/weather

2) vibration

3) type of driving

4) How it is operated by customer

LEXUS Course L 652 - Body Electrical Diagnosis 57

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Slide / Activities / Ref.

c. If you cannot duplicate problem

1) Perform thorough visual inspection.

a) Pay attention to terminal spread problems.

2) Simulate vibrations on harness.

a) Keep in mind that disconnecting and moving

the harness can temporarily “fix” a problem.

3) Never consider a vehicle’s problem fixed if it hap-

pens to “magically” fix itself.

4) If the situation warrants it, call Technical Assistance.

d. Repair Manual Troubleshooting section has inspection

procedures for tracking down intermittents.

B. Only if a problem exists should you go on to the next step.

1. You cannot accurately fix a problem that you cannot duplicate.

IV. Determine the Related Symptoms

A. After problem is verified

B. Operational check to determine

1. How much of circuit is affected?

2. Find clues to the location of the problem by operating other cir-

cuits which have parallel connections to the problem area.

Slide 82

C. Circuits are “related” through Parallel connections

1. Two or more loads connected in parallel within a single circuit

2. Entirely different circuits that are related through a shared

power source or ground point

3. Shared switches/sensors

a. For example, the door courtesy light switches are

Slide 83 EWD Pg. 126 shared by both the interior light circuit and the key

buzzer circuit.

LEXUS Course L 652 - Body Electrical Diagnosis 58

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Slide / Activities / Ref.

To do this requires a strong general knowledge about the different

systems which share the same sensors or switches.

D. How much of the circuit is affected

1. Entire system is dead.

a. Possible power or ground problem.

b. Load or component is bad.

E. If the whole circuit is inoperative

1. Check for a blown fuse.

2. This can be done by checking the operation of other circuits

which use the same fuse or ground point.

a. This information is in Section H, Power Source Current

Flow Chart, and in Section J, Ground Point Information.

b. If the circuit works, it proves that the fuse or ground

point is OK.

c. If the circuit doesn't work, it means that a fuse or ground

point needs to be checked.

Slide 84 EWD Pg. 126 1) This check then becomes a time saver to help de-

fine the exact problem you are dealing with.

3. Part of the circuit operates

a. You can assume that the main power and main ground

are OK.

1) Not 100% true, especially in circuits with multiple

fuses and multiple ground points.

2) But the odds are in your favor—need to play the

odds if speed is a concern.

Slide 85 EWD Pg. 126

LEXUS Course L 652 - Body Electrical Diagnosis 59

THE SIX-STEP DIAGNOSTIC PROCESS 1.49

Slide / Activities / Ref.

F. If part of the circuit is still operating

1. Because part of the circuit works, it tells you that:

a. The power source to those parts of the circuit are OK.

b. The ground point to those parts of the circuit are OK.

c. The conductors and connections in that part of the circuit

are OK.

Slide 86 EWD Pg. 126 2. If you know which parts of the circuit are OK, you can then

only concentrate on the parts of the circuit that could be

causing the problem.

a. No wasted time on unnecessary checks.

b. More profitable.

G. If the circuit has an ECU with self diagnostic ability:

1. The New Car Features and BE section of the RM are the best

places to look for information.

a. The EWD can help you to locate and understand the type

of problem better as a supplement to the RM.

b. RM has information on using the self diagnostic system.

c. Guides you to specific inspections to make for a given

Slide 87 code.

d. Symptoms matrix for driveability problems that do not set

trouble codes.

H. Using Diagnostic Trouble Codes (DTC)

1. Always check for codes first, and write them down.

a. If there are no codes, use the symptoms table.

2. Clear code to see if the problem occurs continuously or is

intermittent

a. If intermittent, you may need to simulate the conditions