86% found this document useful (7 votes)

9K views9 pagesInstrument Loop Testing Procedure-1

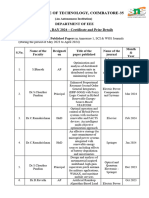

This document provides procedures for instrument loop and sequence testing for the APN-E/F New Field Development Project. It outlines common procedures for loop and sequence testing including requirements for calibration, communication during testing, manpower, and witnessing of tests. The document also describes detailed loop testing procedures and the sequence testing process. Attachments with additional information may be provided.

Uploaded by

Susanto PausinugrohoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

Topics covered

- Instrument loop testing,

- Testing procedure,

- Calibration requirements,

- Pre-commissioning tests,

- Pressure loop test,

- Level loop test,

- Flow loop test,

- Sequence testing,

- Control systems,

- Field instrumentation

86% found this document useful (7 votes)

9K views9 pagesInstrument Loop Testing Procedure-1

This document provides procedures for instrument loop and sequence testing for the APN-E/F New Field Development Project. It outlines common procedures for loop and sequence testing including requirements for calibration, communication during testing, manpower, and witnessing of tests. The document also describes detailed loop testing procedures and the sequence testing process. Attachments with additional information may be provided.

Uploaded by

Susanto PausinugrohoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

Topics covered

- Instrument loop testing,

- Testing procedure,

- Calibration requirements,

- Pre-commissioning tests,

- Pressure loop test,

- Level loop test,

- Flow loop test,

- Sequence testing,

- Control systems,

- Field instrumentation

- General

- Common Procedure

- General Loop Test Procedure

- Detailed Loop Test Procedure

- Sequence Test

- Attachments