Professional Documents

Culture Documents

Weld Neck Flange Calculation: Asme Viii Div.1 Code: Hydrotest Condition

Uploaded by

anil pk0 ratings0% found this document useful (0 votes)

20 views1 pageOriginal Title

$RIEOK98

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageWeld Neck Flange Calculation: Asme Viii Div.1 Code: Hydrotest Condition

Uploaded by

anil pkCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

SHEET

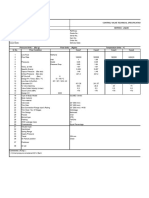

WELD NECK FLANGE CALCULATION

Code: ASME VIII Div.1 3/3

HYDROTEST CONDITION

Hydrotest temperature: 25 ºC

Hydrotest pressure: 7,2 MPa

Axial load at hydrotest: 814969,35 N

Bending moment at hydrotest: 2381755,63 N·m

Equivalent pressure: 9,33928696 MPa

Total hydrotest pressure: 16,539287 MPa

1

Flange material minimum yield stress at hydrotest temperature: 450,00 MPa

Bolting material minimum yield stress at hydrotest temperature: 724,00 MPa

Bolting at hydrotest:

Bolt load 19758334,46 N

Bolt stress 240,12 MPa

% of Yield 33,17 %

Flange stresses at hydrotest:

Stress % of Yield

Longitudinal hub stress 220,36 MPa 48,97 %

Radial flange stress 19,88 MPa 4,42 %

Tangential flange stress 200,09 MPa 44,47 %

Average of longitudinal & radial stress 120,12 MPa 26,69 %

Average of longitudinal & tangential stress 210,23 MPa 46,72 %

BOLT TENSIONING REQUIREMENTS

Required pretension load per bolt: 823,26 KN

Torque calculation (ASME PCC-1 2010)

Assumed thread friction 0,20

Assumed nut-flange friction 0,20

Required torque: 7533,00 N·m

NOTES

You might also like

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Maxon EC45 Flat 30wattDocument1 pageMaxon EC45 Flat 30wattElectromateNo ratings yet

- Report VN1931Document32 pagesReport VN1931Trung ĐứcNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- Riko DN10003 PN10 SZ40 22mayDocument5 pagesRiko DN10003 PN10 SZ40 22maystiven villanuevaNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- Model No.: 2200 30C 3.7V: Genspow Genspow Genspow Genspow GMBH GMBH GMBH GMBHDocument7 pagesModel No.: 2200 30C 3.7V: Genspow Genspow Genspow Genspow GMBH GMBH GMBH GMBHSophia RoseNo ratings yet

- Techn Spec B01052211.WDocument1 pageTechn Spec B01052211.WJOSE GARCIANo ratings yet

- Performance Summary For 42NH229FE - CA: 42NH Ductable in Room Fan Coil With Variable Speed MotorDocument28 pagesPerformance Summary For 42NH229FE - CA: 42NH Ductable in Room Fan Coil With Variable Speed MotorPlenum verde Plenum expansiónNo ratings yet

- Maxon EC90 Flat 90wattDocument1 pageMaxon EC90 Flat 90wattElectromateNo ratings yet

- Maxon EC-Max40 70wattDocument1 pageMaxon EC-Max40 70wattElectromateNo ratings yet

- Pump Sizing Fire Hydrant MojoDocument2 pagesPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhNo ratings yet

- 90mm EC Brushless MotorDocument1 page90mm EC Brushless MotorLucas SuplinoNo ratings yet

- Electrical Data P532 258 012 10 (Series) P532 258 004 10 (Series) P532 258 004 10 (Parallel) P532 258 0.7 10 (Parallel)Document1 pageElectrical Data P532 258 012 10 (Series) P532 258 004 10 (Series) P532 258 004 10 (Parallel) P532 258 0.7 10 (Parallel)Anas SharholiNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- MB325A Data SheetDocument3 pagesMB325A Data SheetammelinoNo ratings yet

- Maxon EC22 50wattDocument1 pageMaxon EC22 50wattElectromateNo ratings yet

- Centrifugal Pump CalculationDocument8 pagesCentrifugal Pump CalculationLorenzoNo ratings yet

- Motores Maxon 2017Document1 pageMotores Maxon 2017--No ratings yet

- En 21 250Document1 pageEn 21 250compimagmaticNo ratings yet

- Espec. Tecnica Ic Alfa LavalDocument1 pageEspec. Tecnica Ic Alfa LavalAlejandro Luis LandaNo ratings yet

- Maxon RE30 Graphite Brushes 60wattDocument1 pageMaxon RE30 Graphite Brushes 60wattElectromateNo ratings yet

- CADANGAN MEMBINA DAN MENYIAPKAN SEBUAH STESEN MINYAK PETRONAS DI ATAS LOT 4Document1 pageCADANGAN MEMBINA DAN MENYIAPKAN SEBUAH STESEN MINYAK PETRONAS DI ATAS LOT 4NILRATAN SARKARNo ratings yet

- List of Documents For ApprovalDocument27 pagesList of Documents For ApprovalsitiNo ratings yet

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocument1 pageEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Pressure safety valve sizing for gas serviceDocument66 pagesPressure safety valve sizing for gas servicePROCESOS PROCESOSNo ratings yet

- ALIVIATORDocument14 pagesALIVIATORPROCESOS PROCESOSNo ratings yet

- T10-MFM Tech SpecDocument2 pagesT10-MFM Tech SpecMiltonNo ratings yet

- Case study of subsea piping systemDocument8 pagesCase study of subsea piping systemRaseuki MahadinaNo ratings yet

- Subsea piping case studyDocument16 pagesSubsea piping case studyRaseuki MahadinaNo ratings yet

- Microbox compressor datasheetDocument1 pageMicrobox compressor datasheetRober Marcial Apaza CaunaNo ratings yet

- E0805-220-V-903-120-3A (Latihan)Document65 pagesE0805-220-V-903-120-3A (Latihan)Sabrang LorNo ratings yet

- Chint 126kV sf6 Circuit Breaker TDSDocument2 pagesChint 126kV sf6 Circuit Breaker TDSJS EngineeringNo ratings yet

- 6kA 3-pole circuit breaker data sheetDocument3 pages6kA 3-pole circuit breaker data sheetDurakNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Flow Calculation: II. Constants I. Flow EquationDocument1 pageFlow Calculation: II. Constants I. Flow EquationAndrey Pachón FrancoNo ratings yet

- Euqw 4 YRk G1 ICTu Y2 U QQMDocument2 pagesEuqw 4 YRk G1 ICTu Y2 U QQMتكنو ليفتNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- En 21 251Document1 pageEn 21 251Froylan OchoaNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Maxon EC-Max30 40wattDocument1 pageMaxon EC-Max30 40wattElectromateNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- Sizing Trim BDocument1 pageSizing Trim Bachmad hermansyahNo ratings yet

- Review Topic 4Document51 pagesReview Topic 4AlteaAlNo ratings yet

- 12 149 enDocument1 page12 149 enLuka MadridNo ratings yet

- Ball Valve Specification and Sizing SheetsDocument2 pagesBall Valve Specification and Sizing SheetsEsteban ArguelloNo ratings yet

- Stress Analysis Report Stator Retarder Material's: MomentDocument2 pagesStress Analysis Report Stator Retarder Material's: MomentEngineering ProductionNo ratings yet

- NEOM OXAGON FUEL SYSTEM EXPANSION PROJECTDocument4 pagesNEOM OXAGON FUEL SYSTEM EXPANSION PROJECTsachin francisNo ratings yet

- AW5520EK-2P - TechemsehDocument2 pagesAW5520EK-2P - Techemsehuvaisul89No ratings yet

- Boson India Ventures: Pressure Safety Valve Calculation - Valve Sizing Based On Known Flow RateDocument3 pagesBoson India Ventures: Pressure Safety Valve Calculation - Valve Sizing Based On Known Flow RateRahul AdityaNo ratings yet

- Circuit Breaker Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document3 pagesCircuit Breaker Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PNo ratings yet

- Li̇nz Kaynak Maki̇nasi 02-Prow18 - 400DC2Document5 pagesLi̇nz Kaynak Maki̇nasi 02-Prow18 - 400DC2Aliksan TasdemirNo ratings yet

- Weblink For Calculation: Pressure Drop Calculation R 1.0Document1 pageWeblink For Calculation: Pressure Drop Calculation R 1.0Sumit WaghmareNo ratings yet

- InstruCalc Control Valve Sizing PCV-3060 17.11.22Document1 pageInstruCalc Control Valve Sizing PCV-3060 17.11.22aszrol ponimanNo ratings yet

- Scantling CalculationDocument16 pagesScantling Calculationfadelrifqi8No ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document67 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Manufacturer Record Book Index for Ball Check and Globe ValvesDocument17 pagesManufacturer Record Book Index for Ball Check and Globe Valvesanil pkNo ratings yet

- Weld Neck Flange Calculation: Asme Viii Div.1 Code: Hydrotest ConditionDocument1 pageWeld Neck Flange Calculation: Asme Viii Div.1 Code: Hydrotest Conditionanil pkNo ratings yet

- Apple ChatDocument1 pageApple Chatanil pkNo ratings yet

- LAL-CHM-Q21090836 - China Petroleum Pipeline (Water)Document2 pagesLAL-CHM-Q21090836 - China Petroleum Pipeline (Water)anil pkNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document67 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- General notes on water intake well constructionDocument4 pagesGeneral notes on water intake well constructionanil pkNo ratings yet

- General notes on water intake well constructionDocument4 pagesGeneral notes on water intake well constructionanil pkNo ratings yet

- Preservation NORSOK Std.Document20 pagesPreservation NORSOK Std.KARTHIGEYAN.RNo ratings yet

- General notes on water intake well constructionDocument4 pagesGeneral notes on water intake well constructionanil pkNo ratings yet

- RAS MARKAZ CRUDE OIL PARK EARTHWORKS SPECIFICATIONDocument41 pagesRAS MARKAZ CRUDE OIL PARK EARTHWORKS SPECIFICATIONanil pkNo ratings yet

- Instrument Support and Installation DetailsDocument44 pagesInstrument Support and Installation Detailsanil pkNo ratings yet

- EDistrict Portal Receipt Page3Document1 pageEDistrict Portal Receipt Page3anil pkNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document41 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- EDistrict Portal Receipt PageDocument2 pagesEDistrict Portal Receipt Pageanil pkNo ratings yet

- Sanoj Dossier PDFDocument1 pageSanoj Dossier PDFanil pkNo ratings yet

- ITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFDocument9 pagesITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFanil pk100% (1)

- XYZABCDocument1 pageXYZABCanil pkNo ratings yet

- Kerala eDistrict Portal Receipt Payment RecordDocument1 pageKerala eDistrict Portal Receipt Payment Recordanil pkNo ratings yet

- Anu PDFDocument1 pageAnu PDFanil pkNo ratings yet

- A N U PDFDocument1 pageA N U PDFanil pkNo ratings yet

- ANUDocument1 pageANUanil pkNo ratings yet

- Manu PDFDocument1 pageManu PDFanil pkNo ratings yet

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Document34 pages9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- 9686 Ot NCR 0009 Closed NCRDocument6 pages9686 Ot NCR 0009 Closed NCRanil pkNo ratings yet

- VINUDocument1 pageVINUanil pkNo ratings yet

- NCR - 001Document1 pageNCR - 001anil pkNo ratings yet

- Daniel Fast Recipes A Couple CooksDocument12 pagesDaniel Fast Recipes A Couple CooksmariamNo ratings yet

- Contractor base list in UsaDocument8 pagesContractor base list in Usamytech206No ratings yet

- Mccsemi: 8050 SS-C 8050 SS-DDocument2 pagesMccsemi: 8050 SS-C 8050 SS-DLeonardo IñiguezNo ratings yet

- Final Class 8 Science 20230828084415550Document5 pagesFinal Class 8 Science 20230828084415550aryantomar5112No ratings yet

- Training ReportDocument56 pagesTraining ReportRavimini100% (2)

- Biografia Buerkli-ZieglerDocument7 pagesBiografia Buerkli-ZieglerJesús Ángel Ortiz OrdazNo ratings yet

- Principle Principle PrincipleDocument12 pagesPrinciple Principle PrincipleDarshana JuvekarNo ratings yet

- BSBPMG531 - Assessment Task 2 v2Document26 pagesBSBPMG531 - Assessment Task 2 v2Paulo Dizon100% (2)

- BA Mckesson Interview 2Document3 pagesBA Mckesson Interview 2Vikram hostNo ratings yet

- Ruminations by Other PeopleDocument31 pagesRuminations by Other PeopledhultstromNo ratings yet

- Ec6303 Signals and SystemsDocument2 pagesEc6303 Signals and SystemsSam PaulNo ratings yet

- Fire and Ice by Robert FrostDocument2 pagesFire and Ice by Robert Frostapi-561976496No ratings yet

- Sbi KukkatpallyDocument2 pagesSbi KukkatpallyRavi Babu KonkatiNo ratings yet

- BukuDocument39 pagesBukusimon sembiringNo ratings yet

- Ancient India CoinageDocument18 pagesAncient India Coinagemangala kalaiselviNo ratings yet

- Circuit Breaker Analyzer & Timer CAT126D: DescriptionDocument7 pagesCircuit Breaker Analyzer & Timer CAT126D: Descriptionkenlavie2No ratings yet

- Remote Access Portal User GuideDocument3 pagesRemote Access Portal User GuidezeljavaNo ratings yet

- Air Ticket Booking - Book Flight Tickets - Cheap Air Fare - LTC Fare - IRCTC AIRDocument2 pagesAir Ticket Booking - Book Flight Tickets - Cheap Air Fare - LTC Fare - IRCTC AIRMohitSharmaNo ratings yet

- Grade 10 - Module 1Document3 pagesGrade 10 - Module 1Dypsy Pearl A. PantinopleNo ratings yet

- 6.4 Qualitative Quantitative AnalysisDocument6 pages6.4 Qualitative Quantitative AnalysisAndrea PagsuguironNo ratings yet

- CA ruling on fertilizer disputeDocument16 pagesCA ruling on fertilizer disputeRuby Anna TorresNo ratings yet

- Ansi C 136.20Document16 pagesAnsi C 136.20Amit Kumar Mishra100% (1)

- Sources of Subject of ArtDocument32 pagesSources of Subject of ArtAlaina De GuzmanNo ratings yet

- Case 26 Star River Electronics - Group Thạch Trung Chương HiểnDocument12 pagesCase 26 Star River Electronics - Group Thạch Trung Chương HiểnTrương ThạchNo ratings yet

- Lubricated Coupling TrainingDocument47 pagesLubricated Coupling TrainingTheerayootNo ratings yet

- Currency DerivativesDocument16 pagesCurrency DerivativesAdityaNandaNo ratings yet

- Quality Control and Assurance Processes for Coffee ProductionDocument5 pagesQuality Control and Assurance Processes for Coffee ProductionSharifah NuruljannahNo ratings yet

- Insurance - Unit 3&4Document20 pagesInsurance - Unit 3&4Dhruv GandhiNo ratings yet

- ZEOLITEDocument13 pagesZEOLITEShubham Yele100% (1)

- Parts List of Engine Assy Ofdz-00536Document1 pageParts List of Engine Assy Ofdz-00536CwsNo ratings yet