Professional Documents

Culture Documents

Checking Lubricant For Water: Caution

Uploaded by

betabet GeorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checking Lubricant For Water: Caution

Uploaded by

betabet GeorgeCopyright:

Available Formats

MAINTENANCE SERVICE MANUAL NUMBER

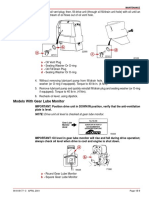

1. Fill gear lube monitor to “FULL” line on decal. Lubricate O-ring seal on gear lube monitor

neck with sterndrive oil, to ensure ease of installing and removing cap, and install gear

lube monitor cap. Do not overtighten cap - 1/4 turn, after cap contacts seal, is sufficient.

CAUTION

On models with Gear Lube Monitor, that have a dipstick in driveshaft housing cover:

DO NOT REMOVE DIPSTICK - DO NOT CHECK OIL LEVEL WITH DIPSTICK. Removal

of dipstick results in oil level raising/overfill condition, which can cause oil seal

damage; if left open, drive unit will overflow.

2. Check oil level in gear lube monitor.

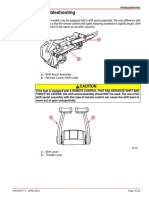

Checking Lubricant for Water

Periodically inspect lubricant for water to ensure that drive unit seals are not leaking.

MODELS WITHOUT DRIVE UNIT GEAR LUBE MONITOR

1. Trim drive unit to the full Trim UP/OUT position.

2. Remove fill/drain plug to take a sample of lubricant. If water is observed or if lubricant

appears discolored, drive unit is leaking and must be resealed.

b

a

22101 22103

a - Fill/Drain Plug

b - Sealing Washer Or O-ring

3. Reinstall fill/drain plug. Torque to 40 lb-in. (4.0 Nm).

Page 1B-10 90-818177--3 APRIL 2001

You might also like

- Holley Carburettor 4500 Ultra HP Dominator InstructionsDocument10 pagesHolley Carburettor 4500 Ultra HP Dominator InstructionsnicoseisNo ratings yet

- Chevrolet Transfer Case 231Document8 pagesChevrolet Transfer Case 231jorge antonio guillenNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- Carbtune PDFDocument22 pagesCarbtune PDFndmvillocilloNo ratings yet

- API Gate Valve - WKM Maintenance ManualDocument8 pagesAPI Gate Valve - WKM Maintenance ManualsambhajiNo ratings yet

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- LawnBoy D400 D600Document24 pagesLawnBoy D400 D600Frank BerrierNo ratings yet

- Wom ValvesDocument11 pagesWom ValvesRio IndokniveziaNo ratings yet

- Tubaexchange-Maint-Booklet 1Document12 pagesTubaexchange-Maint-Booklet 1api-267335331No ratings yet

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Transfer Case Overhaul 1988 Jeep CherokeeDocument9 pagesTransfer Case Overhaul 1988 Jeep CherokeeAhmat Juhairi AriffinNo ratings yet

- Cambio de Aceite de Transmisión Retroexcavadora 416cDocument2 pagesCambio de Aceite de Transmisión Retroexcavadora 416cPepe Alonzo100% (3)

- G.V. Manual (FC Type)Document20 pagesG.V. Manual (FC Type)sambhajiNo ratings yet

- TSP6630 Owner ManualDocument8 pagesTSP6630 Owner ManualRefamont SA CVNo ratings yet

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 pagesRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Gate Valve MaintenanceDocument8 pagesGate Valve Maintenancechar_lynNo ratings yet

- A B C D: Models With Gear Lube MonitorDocument1 pageA B C D: Models With Gear Lube Monitorbetabet GeorgeNo ratings yet

- A Part 21Document1 pageA Part 21betabet GeorgeNo ratings yet

- T A M 1000kg Manual v2Document9 pagesT A M 1000kg Manual v2Khabib MasrokhanNo ratings yet

- Install Shift KitDocument7 pagesInstall Shift Kithorsthorstson4No ratings yet

- Instruct For OperationDocument1 pageInstruct For OperationAriel Martinez NNo ratings yet

- Checking and Adding Sterndrive Oil: Models Without Drive Unit Gear Lube MonitorDocument1 pageChecking and Adding Sterndrive Oil: Models Without Drive Unit Gear Lube Monitorbetabet GeorgeNo ratings yet

- Service Bulletin: Landoll Corp. Warranty DepartmentDocument4 pagesService Bulletin: Landoll Corp. Warranty DepartmentChristian BedoyaNo ratings yet

- Instruction of Disassembly and Assembly of Low-Pressure Relief ValveDocument3 pagesInstruction of Disassembly and Assembly of Low-Pressure Relief ValvemohamedNo ratings yet

- Ford Festiva Brakes+Document12 pagesFord Festiva Brakes+SteveMateNo ratings yet

- Volvo Power SteeringDocument10 pagesVolvo Power SteeringFordiNo ratings yet

- Clutch: Precautions and Preparation Clutch Release Mechanism Clutch Disc and Clutch CoverDocument14 pagesClutch: Precautions and Preparation Clutch Release Mechanism Clutch Disc and Clutch CoveryangliNo ratings yet

- Service Instruction: LycomingDocument4 pagesService Instruction: LycomingGANo ratings yet

- 31733030Document28 pages31733030sunthron somchaiNo ratings yet

- Drill Head Inspectionand Oil LevelsDocument6 pagesDrill Head Inspectionand Oil LevelsSipa1109No ratings yet

- sm01b PDFDocument19 pagessm01b PDFvette512No ratings yet

- Calibracion de Motores Cummins 1Document2 pagesCalibracion de Motores Cummins 1joseNo ratings yet

- D08 26 Oil CylinderDocument3 pagesD08 26 Oil CylinderVăn Tuấn NguyễnNo ratings yet

- Front Driveshaft - V8 5.0L Petrol/V8 S/C 5.0L Petrol: RemovalDocument5 pagesFront Driveshaft - V8 5.0L Petrol/V8 S/C 5.0L Petrol: RemovalDerek L. SmithNo ratings yet

- Transfer CaseDocument6 pagesTransfer CaseTim SmithNo ratings yet

- Vac Pump Manual Jewelry CastingDocument12 pagesVac Pump Manual Jewelry CastingjfuentesemploymentNo ratings yet

- Grade 10 Automotive Tve q1wk5Document20 pagesGrade 10 Automotive Tve q1wk5Precious Dorothy TolentinoNo ratings yet

- GX100 Ajuste de MotorDocument1 pageGX100 Ajuste de MotorThu Naing TunNo ratings yet

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- 15 Evacuacion y Carga PDFDocument10 pages15 Evacuacion y Carga PDFAnel ValdesNo ratings yet

- Clu 1201Document1 pageClu 1201Aleix RamirezNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- Instruction Manual Handleiding en Gebruiksvoorschriften Mode D'emploi Et Instructions Pour L'utilisation Bedienungsanleitung Und Gebrauchsvorschriften Manual de Instrucciones Manuale Di IstruzioniDocument21 pagesInstruction Manual Handleiding en Gebruiksvoorschriften Mode D'emploi Et Instructions Pour L'utilisation Bedienungsanleitung Und Gebrauchsvorschriften Manual de Instrucciones Manuale Di IstruzioniAlain DefoeNo ratings yet

- Airboat - Operators ManualDocument11 pagesAirboat - Operators ManualMichael HallNo ratings yet

- 1998 Sec 7-Manual TransmissionDocument25 pages1998 Sec 7-Manual TransmissionAdal VeraNo ratings yet

- 2011 Maintenance Manual of Zoomlion Mixer(中英文)Document16 pages2011 Maintenance Manual of Zoomlion Mixer(中英文)Freddy AndresNo ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- Engine Tech Tip 10 0608 Dash Buzzer at Dot StopDocument10 pagesEngine Tech Tip 10 0608 Dash Buzzer at Dot Stopחנניה מוסNo ratings yet

- Instruction Manual For 2way & 3way Cylinder Valve: Section TitleDocument10 pagesInstruction Manual For 2way & 3way Cylinder Valve: Section TitleFlo MarineNo ratings yet

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocument36 pagesRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNo ratings yet

- Rack and Pinion Installation Instructions: Technical ServiceDocument2 pagesRack and Pinion Installation Instructions: Technical ServiceneozerokNo ratings yet

- Pages From Rescue Boat Engine Mercury 25Document11 pagesPages From Rescue Boat Engine Mercury 25Prajesh T VNo ratings yet

- Sonnax 77701-076-InDocument2 pagesSonnax 77701-076-InmiguelNo ratings yet

- Er 105 8Document4 pagesEr 105 8cesar coronadoNo ratings yet

- Ultra Dominator Instructions 199R10501Document10 pagesUltra Dominator Instructions 199R10501xeron71260% (1)

- Land Rover V8: and ToolDocument56 pagesLand Rover V8: and ToolAntonio OliveiraNo ratings yet

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- A Part 66Document1 pageA Part 66betabet GeorgeNo ratings yet

- A Part 57Document1 pageA Part 57betabet GeorgeNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

- A Part 56Document1 pageA Part 56betabet GeorgeNo ratings yet

- A Part 65Document1 pageA Part 65betabet GeorgeNo ratings yet

- A Part 60Document1 pageA Part 60betabet GeorgeNo ratings yet

- A Part 52Document1 pageA Part 52betabet GeorgeNo ratings yet

- A Part 53Document1 pageA Part 53betabet GeorgeNo ratings yet

- A Part 63Document1 pageA Part 63betabet GeorgeNo ratings yet

- A Part 61Document1 pageA Part 61betabet GeorgeNo ratings yet

- Power Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- A Part 55Document1 pageA Part 55betabet GeorgeNo ratings yet

- A Part 62Document1 pageA Part 62betabet GeorgeNo ratings yet

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- A - Part - 59 AdsfasfDocument1 pageA - Part - 59 Adsfasfbetabet GeorgeNo ratings yet

- A Part 64Document1 pageA Part 64betabet GeorgeNo ratings yet

- Trim Control OUT/UP Trim Switch InoperativeDocument1 pageTrim Control OUT/UP Trim Switch Inoperativebetabet GeorgeNo ratings yet

- Power Trim System Wiring Diagram: Troubleshooting Service Manual Number 14Document1 pagePower Trim System Wiring Diagram: Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Oil Foams Out of Pump Fill/Vent Screw: Cause Special InstructionsDocument1 pageOil Foams Out of Pump Fill/Vent Screw: Cause Special Instructionsbetabet GeorgeNo ratings yet

- Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- Hard Steering (Engine Running) - Power Steering System: Cause Special InstructionsDocument1 pageHard Steering (Engine Running) - Power Steering System: Cause Special Instructionsbetabet GeorgeNo ratings yet

- Power Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too HighDocument1 pagePower Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too Highbetabet GeorgeNo ratings yet

- A Part 54Document1 pageA Part 54betabet GeorgeNo ratings yet

- In/Down Solenoid Clicks: Cause Special Instructions - Clean And/orDocument1 pageIn/Down Solenoid Clicks: Cause Special Instructions - Clean And/orbetabet GeorgeNo ratings yet

- Performance Troubleshooting: Low WOT Engine RPMDocument1 pagePerformance Troubleshooting: Low WOT Engine RPMbetabet GeorgeNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- Troubleshooting: Sterndrive Unit Will Not Slide Into Bell HousingDocument1 pageTroubleshooting: Sterndrive Unit Will Not Slide Into Bell Housingbetabet GeorgeNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- Important Information: Section 1C - TroubleshootingDocument1 pageImportant Information: Section 1C - Troubleshootingbetabet GeorgeNo ratings yet