Professional Documents

Culture Documents

Bro SLV Imwx V20730

Uploaded by

ioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bro SLV Imwx V20730

Uploaded by

ioCopyright:

Available Formats

SLV

Shrink Bundler with Welding Bar

Side infeed and Vertical collator

Safe

Versatile

Easyy to use

Economical

Autopack SLV is a Bundle Shrink Wrapper specifically designed for stacking and shrink wrapping flat

rectangular shaped and/or stackable product such as pharmaceutical cartons, soap cakes, toothpaste

cartons, paper reams, and many others. It is available in single track or tandem operation.

Straight

h or Curve infeed

f d Single

l track

k or Tandem

d operation 90 d

degree or IInline

li outfeed

f d

The Autopack Package : Faster - Smaller - Better Pack - Less Energy

Standard Features Optional Features

• Quick & Easy changeover • Printed film registration device

• Stainless steel construction • Tear strip perforation device

• Speed up to 40 ppm (twin tracks) • Card / Leaflet inserter

• Line Control & Communication • Single track or Tandem operationn

• Integrated Control & User friendly HMI

• Better shrink through more efficient air circulation

Autopack designers pay particular attention to specifying materials and finishes that are

durable, do not affect the packaged product and remain serviceable for a long time.

Explore Shrink Wrapping and our range of Machines at

www. autopack.com

SLV

V20730

Side infeed and Vertical collator

Operation

Once the product leaves the carton machine, it is then transported As the welding bar ascends the pusher advances to transfer

into the Autopack wrapping unit, by means of a side mounted conveyor. the new collation into the welding position, at the same time

displacing the previously wrapped collation onto continuously

Here, the cartons accumulate until a full layer is counted, then the moving shrink tunnel conveyor. The wrapped collation soon enters

layer is elevated to the table level where it is supported by suitable the shrink tunnel chamber where recirculated hot air causes the

latches. This activates horizontal pusher which transfers the collation wrap to shrink, and tightly conform to the contours of the contents.

behind the welding bar where it undergoes the sleeve wrapping Once the pack is out of the hot chamber, forced air cooling is

operation. used to tighten the sleeve wrap to achieve a strong, secure pack

ready for stacking on a pallet or placing in a shipping carton.

SpecificaƟons 45SLV 60SLV 62SLV 82SLV

(All parameters in mm except “Film thickness”) L20 / M25 / M35 M25 / M35 M25 / H35 M25 / H35

Film Max roll width wf 430 580 2x270 2x350 Note:

Film thickness (μm) tf 35 < < 100

Max roll dia df 300 or max roll weight 25kg (whichever comes first) 1) Maximum stated pack width can only be

achieved if the pack depth and the height

Pack Size Min-Max pack width 1)

wp 90-370 90-510 90-220 90-310

are not at their maximum. In general as the

Min-Max pack depth 2) dp 60-240 60-240 60-210 60-210 pack depth or height goes up, then for a

Max pack height hp 150 / 200 / 300 200 / 300 200 / 300 200 - 300 given film size, width of the pack must

Min-Max carton depth dc 60-240 60-240 60-210 60-210 decrease.

Min-Max carton height hc 10-75 10-75 10-50 10-50

Min-Max carton width wc 20-370 20-510 20-220 20-310 2) The values specified are to satisfy most

Packing Speed Without colla on Packs/min 15-20 / 18-28 / 18-28 18-28 Up to 40 Up to 35 applications but if they don’t accommodate

With colla on 3) Packs/min 10-15 / 12-22 / 12-22 12-22 15-35 10-30 your product size please contact us as we

Electrical Supply Average power kW 8/8/9 9 / 10 10 / 20 11 / 24 may be able to vary some machine

Max power kW 11 / 12 / 13 13 / 15 14 / 28 16 / 35 parameters during the manufacturing

Available in 220/380/415, 3ph, N+E, 50/60Hz process.

Compressed Air Working pressure kPa 500 600 600 650

Consump on NL/Cycle 11 15 15 25 3) Stacking speed is much dependent on

collation pattern and carton size. On a

CFM 6 8 8 9

single track machine (45SLV or 60SLV),

typical speed will be 150 cartons/min for a

Dimensions 45SLV 60SLV 62SLV 82SLV

small carton stacked 4 wide x 3 high (12

(All parameters in mm) L20 / M25 / M35 M25 / M35 M25 / H35 M25 / H35

packs) collation.

Total System Overall Length 4) L 2470 / 2970 / 2970 2970 3890 2970 / 3890

Width W 650 800 970 1065 4) Depending on customer’s products

Infeed Height 5) Hi 730 730 730 730 range, different transfer tables may be used

Ou eed Height 5) Ho 830 830 830 830 between wrapper and tunnel. This will alter

Wrapper Height Hw 1690 1690 1690 1690 values of L.

Tunnel Height Ht 1720 / 1820 / 1920 1820 / 1920 1820 / 1870 1820 / 1920

5) Infeed / Outfeed height adjustable

Infeed Conveyor Length Li 730 730 1100 1100

+70mm. Extension possible on request.

Ouƞeed Roller Length Lo 750 1500 1500 1500

Width Wo 330 480 500 700

The above parameters are constantly reviewed and updated and may vary from project to project depending on customers requirements.

Lo

L

Li

Example with wf

4 x 2 x 3 collation

df

wp

W Wo

hp

Film

dp

Optional Curve Infeed

hc tf

dc wc

Hw Ht ks

rac

w i n t SLV

t /8 2

Hi Ho 62

Manufactured by: AUTOPACK CO., LTD. Distributed by:

98/50-51 Moo11, Phutthamonthon Sai 5 Rd,

Raikhing, Sampran, Nakornpathom, 73210, Thailand www. autopack.com

Tel: (66) 2 001-8940, Email: info@autopack.com

You might also like

- Affordability & Productivity: BasicDocument2 pagesAffordability & Productivity: BasicChandra NurikoNo ratings yet

- Specification Portable DP2 2 2018Document1 pageSpecification Portable DP2 2 2018NDNo ratings yet

- One Step Shrink Wrap SystemsDocument1 pageOne Step Shrink Wrap SystemsshrinkfilmNo ratings yet

- It's A Lantech!: Our Most Popular Stretch WrapperDocument2 pagesIt's A Lantech!: Our Most Popular Stretch WrapperWahyu UtomoNo ratings yet

- Hitachi Sumitomo Hydraulic Crawler Crane SCX900Document6 pagesHitachi Sumitomo Hydraulic Crawler Crane SCX900Nina JuliatiNo ratings yet

- PDF Lantech Q 300 Stretch Wrapper Shorr PackagingDocument2 pagesPDF Lantech Q 300 Stretch Wrapper Shorr PackagingBang JimyNo ratings yet

- ENMIN 3070 Conveyor BeltDocument56 pagesENMIN 3070 Conveyor BeltChaowalit BowkhuntodNo ratings yet

- Lewek Constellation: Ultra Deepwater Rigid & Flexible Pipelay/ Heavy Lift/Construction VesselDocument4 pagesLewek Constellation: Ultra Deepwater Rigid & Flexible Pipelay/ Heavy Lift/Construction Vesselgustavo adolfo almeida floresNo ratings yet

- Pulse Vacuum sterilizer-HG1-DMDocument4 pagesPulse Vacuum sterilizer-HG1-DMrachmonaaNo ratings yet

- Box Systems MGF Tech File 2019 NewDocument54 pagesBox Systems MGF Tech File 2019 NewmuthunayakeNo ratings yet

- Leaflet SMA Max LowDocument8 pagesLeaflet SMA Max LowCarlos Florencio UrbanoNo ratings yet

- STR40 STR45 STS45Document1 pageSTR40 STR45 STS45g665013100% (1)

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- Skid-Mate Shock AbsorberDocument2 pagesSkid-Mate Shock AbsorberAkshay GargNo ratings yet

- Industrial Injury Prevention: ISO 9002 Lic QEC13179Document8 pagesIndustrial Injury Prevention: ISO 9002 Lic QEC13179Jorge LuisNo ratings yet

- Delta / Delta DT: Roll-Bag ConvertingDocument2 pagesDelta / Delta DT: Roll-Bag Convertingmahfoud lazreugNo ratings yet

- Tapit SeriesDocument2 pagesTapit Seriespradatha_04No ratings yet

- Carrot Packaging Line PDF - Adobe Acrobat Pro ExtendedDocument10 pagesCarrot Packaging Line PDF - Adobe Acrobat Pro ExtendedadnankubilayNo ratings yet

- TSNZ Brochure March 2017Document24 pagesTSNZ Brochure March 2017arlene joy paredesNo ratings yet

- Palfinger 74002 PDFDocument8 pagesPalfinger 74002 PDFAnonymous mcCJYBoNo ratings yet

- 45 VVD eDocument2 pages45 VVD eماريا قراجةNo ratings yet

- 45 VVD eDocument2 pages45 VVD eماريا قراجةNo ratings yet

- HV CCV 2017-08 WebDocument4 pagesHV CCV 2017-08 WebHabib AliNo ratings yet

- Pavaflex: Flexible Woodfibre Insulation MaterialDocument1 pagePavaflex: Flexible Woodfibre Insulation MaterialNikola DragašNo ratings yet

- KUKA Robots For High PayloadsDocument32 pagesKUKA Robots For High PayloadsNick RivieraNo ratings yet

- Capacity: 3000 KG Lift Height: 9.98 M Compact Stabilizers Load Place System (LPS) Torque Convertor TransmissionDocument4 pagesCapacity: 3000 KG Lift Height: 9.98 M Compact Stabilizers Load Place System (LPS) Torque Convertor Transmissionoscar el carevergaNo ratings yet

- Circular Track Meter (CTM) - : Astm: E-2157-01Document4 pagesCircular Track Meter (CTM) - : Astm: E-2157-01Ashish SharmaNo ratings yet

- Conveying & Palletizing: Harmony in MotionDocument32 pagesConveying & Palletizing: Harmony in MotionKien Nguyen TrungNo ratings yet

- Product Range: Trenching & ShoringDocument20 pagesProduct Range: Trenching & ShoringMarco Dos Santos NevesNo ratings yet

- IS 16.50 05.18 Enus-CompressedDocument2 pagesIS 16.50 05.18 Enus-CompressedvinandasanyotoNo ratings yet

- Kphpktrangem 2 enDocument12 pagesKphpktrangem 2 enGerald Leon FloresNo ratings yet

- Kphpktrangem 2 enDocument12 pagesKphpktrangem 2 enGerald Leon FloresNo ratings yet

- XT 558fdDocument1 pageXT 558fdASA PolyPlastNo ratings yet

- Kalmar DRT450 Reach Stacker SpecDocument4 pagesKalmar DRT450 Reach Stacker SpecFco JavierNo ratings yet

- ReclaimerDocument2 pagesReclaimerAan YunoNo ratings yet

- RP 405-435 05englDocument6 pagesRP 405-435 05englsaleNo ratings yet

- Sr-30 Eagle Standard Compressed 26ssnvtDocument16 pagesSr-30 Eagle Standard Compressed 26ssnvtjesusloera2384No ratings yet

- Kalmar Reach StackerDocument16 pagesKalmar Reach Stackerncthanhck100% (5)

- Double-Decking-System For Curtain-SiderDocument6 pagesDouble-Decking-System For Curtain-SiderAldair de Luis MoralesNo ratings yet

- Catalog Icanclave Serie DDocument8 pagesCatalog Icanclave Serie DSung Soon ChangNo ratings yet

- Qtkju1qud0ivf0sdpalfinger PK 50002 Eh B High Performance Knuckle Boom Crane NetworkDocument8 pagesQtkju1qud0ivf0sdpalfinger PK 50002 Eh B High Performance Knuckle Boom Crane NetworkpradewoNo ratings yet

- Raychem WPCT Heat Shrink SleevesDocument4 pagesRaychem WPCT Heat Shrink SleevesmngNo ratings yet

- Tts - Heavy Lift Cranes DK II Heavy - 2014Document2 pagesTts - Heavy Lift Cranes DK II Heavy - 2014Ruben Bartolome GarciaNo ratings yet

- 8026 TorqueMaster Technical SummaryDocument1 page8026 TorqueMaster Technical SummaryGabriela MotaNo ratings yet

- 11-1307 Budissa Image e LowDocument12 pages11-1307 Budissa Image e LowBin ZhangNo ratings yet

- TDS Tuffpaulin PVC TarpDocument4 pagesTDS Tuffpaulin PVC TarpmukulsareenNo ratings yet

- FRM 1120 Manual 2015 11 PDFDocument29 pagesFRM 1120 Manual 2015 11 PDFabi aufaNo ratings yet

- MCC Banda Modular - PG - 0150-0157Document8 pagesMCC Banda Modular - PG - 0150-0157Daniel MagallanesNo ratings yet

- GSG Me 104 27074 CaDocument4 pagesGSG Me 104 27074 CadajoelonceNo ratings yet

- Fiber Bundle & Blown Fiber Line: For Manufacturing FTTX ApplicationsDocument4 pagesFiber Bundle & Blown Fiber Line: For Manufacturing FTTX Applicationspagano mentalNo ratings yet

- Ozbesler-Katalog CompressedDocument80 pagesOzbesler-Katalog Compressedmohammad ghassanNo ratings yet

- WCD Viscotaq PE Outerwrap TDSDocument3 pagesWCD Viscotaq PE Outerwrap TDSvissupleNo ratings yet

- Moisture Separator - Brochure - 1521101259Document16 pagesMoisture Separator - Brochure - 1521101259Hanhan Subhan UmbaraNo ratings yet

- P2800 Series 201508Document2 pagesP2800 Series 201508TRIINETNo ratings yet

- Python Compac 35 (P)Document3 pagesPython Compac 35 (P)Konstantinos SynodinosNo ratings yet

- BrochureDocument100 pagesBrochurewahbyNo ratings yet

- Rev. Flat Bottom Silos - Solution No.2Document43 pagesRev. Flat Bottom Silos - Solution No.2nu.arabiaNo ratings yet

- Grupuri Pompare Apa Menajera - LowaraDocument48 pagesGrupuri Pompare Apa Menajera - LowaraAvram FlorinNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Advanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsFrom EverandAdvanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsDuixian LiuNo ratings yet

- Scavenging BlowersDocument15 pagesScavenging BlowersGargee ChavanNo ratings yet

- Method Statement Epoxy FloorDocument8 pagesMethod Statement Epoxy Floorbeshnu garanaik67% (3)

- Pigging Training Course Mod 5 Rev 1Document46 pagesPigging Training Course Mod 5 Rev 1Suparerk SirivedinNo ratings yet

- Assesment bct554 Draft PDFDocument14 pagesAssesment bct554 Draft PDFsharifah atiqahNo ratings yet

- BIS0418 C1L2P1 Technical Guide Bending Rolling Shearing Punching WEB SIN...Document6 pagesBIS0418 C1L2P1 Technical Guide Bending Rolling Shearing Punching WEB SIN...MarcoNo ratings yet

- EthedcoDocument98 pagesEthedcosherifelbayoumy266No ratings yet

- Heat InputDocument1 pageHeat InputArul Edwin VijayNo ratings yet

- Form 2 W1 Lesson 3Document5 pagesForm 2 W1 Lesson 3meow meow100% (1)

- ChemicalDocument2 pagesChemicaldalton2004No ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- National Gypsum Company - Levels of Gypsum Board FinishDocument3 pagesNational Gypsum Company - Levels of Gypsum Board FinishStephen PoppeNo ratings yet

- Hombre Pared ManualDocument11 pagesHombre Pared ManualjosetecoNo ratings yet

- Carbozinc 11Document2 pagesCarbozinc 11Victor A. Claure Manzoni100% (1)

- Fitup (2019!06!01) Report-91 OfficialDocument2 pagesFitup (2019!06!01) Report-91 OfficialCarlosNo ratings yet

- Head and Flanges Sums NptelDocument18 pagesHead and Flanges Sums NptelRADHE GRAPHICSNo ratings yet

- Deterioration of ConcreteDocument18 pagesDeterioration of ConcreteMohammed AwfNo ratings yet

- Nylock Nut TDocument2 pagesNylock Nut Taiyubi2No ratings yet

- Donaldson FiltersDocument2 pagesDonaldson FiltersYorkistNo ratings yet

- H 3159Document58 pagesH 3159Alex GigenaNo ratings yet

- Practical PipeDocument11 pagesPractical PipeMohd Effiezool Yaser100% (1)

- #0000, #000 and #00 Thread DimensionsDocument1 page#0000, #000 and #00 Thread DimensionsTheodor EikeNo ratings yet

- Mid2 Objective PaperDocument2 pagesMid2 Objective PaperChilla DivyaNo ratings yet

- Paints and VarnishDocument46 pagesPaints and VarnishnasirNo ratings yet

- NORSOK Structural Steel Fabrication M-101Document67 pagesNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- Ferrous Welding MetallurgyDocument12 pagesFerrous Welding Metallurgymrigesh vermaNo ratings yet

- Comparison of Austempering and Quench-And-Tempering Processes ForDocument103 pagesComparison of Austempering and Quench-And-Tempering Processes FornihalsinghNo ratings yet

- ISO 2063 2005 en PreviewDocument8 pagesISO 2063 2005 en PreviewBussborg33% (3)

- Seal Assemblies Web FPRDocument3 pagesSeal Assemblies Web FPRVictor Flores ResendizNo ratings yet

- Mpaps G-20Document6 pagesMpaps G-20PANKAJ CHAUHANNo ratings yet

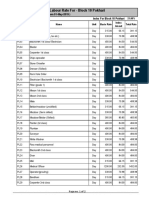

- Block 10 Pokhari - ResourceRate - LabourDocument2 pagesBlock 10 Pokhari - ResourceRate - LabourManojNo ratings yet