Professional Documents

Culture Documents

MM321 Lab 1

Uploaded by

Roshiv SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MM321 Lab 1

Uploaded by

Roshiv SharmaCopyright:

Available Formats

MM 321 Refrigeration and Air Conditioning

The University of the South Pacific

School of Engineering and Physics

MM 321 – Refrigeration and Air Conditioning

Lab 1: Study on an Automotive Cooling System

Lab Group: data set 1

Student Name: Shanil Sahai, Winji Tamata, Sahil Roshiv Sharma

Student ID#: S11173716, S11119842, S11171799

AIM

The aim of this experiment study and learn how an air-cooling system functions and find the compressor power and

Coefficient of performance (COP) of the system

INTRODUCTION

This experiment was conducted using a table-top air automotive cooling system. This air automotive system was

powered by motor gaining its source from a connected battery. The cycle begins when the refrigerant is compressed

adiabatically in the compressor. The pressure and temperature of the refrigerant will increase. Then refrigerant will

enter in the Condenser. Heat will be rejected from the refrigerant to the atmosphere in Condenser at constant

pressure. Then, the refrigerant will enter in expansion device where expansion takes place which result in reduction

of temperature and pressure of refrigerant. This low temperature refrigerant will enter into evaporator and by its

evaporation cooling will be produced at constant pressure. The heat absorbed in evaporator is termed as

Refrigeration effect. This low temperature refrigerant vapor enters in compressor and cycle is repeated. Different set

of data are collected, by the lab demo using the Vapor Compression Refrigeration Process and are assign for each

group respectively. It’s given row data variable are then analyzed on the Rw134a chart to find the enthalpies.

Hopefully the aided in achieving the overall aim is being achieved.

Air cooling is commonly defined as rejecting heat from an object by flowing air over the surface of the object,

through means of convection. At present, two major air conditioning systems are applied in the automobile industry-

the expansion valve system and the fixed orifice tube system. The main difference between these two is the type of

device that is used to lower the refrigerant pressure. When it comes to car cooling, many people think it’s a single

system working to regulate the temperature of both the engine and the cabin, but that actually isn’t the case. Your

car operates two different cooling systems, one to keep your engine cool and the other to keep you cool. A car air

conditioning system consists of a compact version of the components of the normal air conditioner that has an

evaporator, compressor, condenser, expansion device, and a fan which are fitted in a car to provide air condition

inside the passenger's compartment. Vehicles with air-conditioning are equipped with an air-conditioning (AC)

condenser mounted upstream of the radiator to transfer the waste heat fi-om the passenger compartment to the

airflow through the condenser.

Lab Report Page 1

MM 321 Refrigeration and Air Conditioning

(Fig : Car Air-conditioning Circuit Components)

Automotive air conditioning is now almost universal, and becomes as standard in almost all newly produced cars and

is a feature that most car owners have come to expect. Historically although it may not always seem like it, we sure

are likely to be drivers today when air conditioning comes standard on nearly every car, but it wasn’t always that

way. The development of automotive air conditioners began in earnest in 1930, when General Motors Research

Laboratories conceived the idea of the vapor compression system with R-12 refrigerant. They determined the

cooling capacity of the automotive air-conditioning (A/C) system to be 1 ton 200 Btu per minute. This estimate was

half of the cooling capacity of the present system. The work on automotive A/C culminated at General Motors with

the development of a prototype self-contained unit that was installed in the trunk of a 1939 Cadillac. Before World

War II, approximately 3,000 American cars were equipped with A/C. Most of the units were installed in expensive

luxury cars. Although it was ballyhooed as a great luxury item, drivers had two major complaints: First, there was not

provision for outside air. Smoking in the car made the air fetid and unbearable. Second, there were no interior

controls. Then by 20th century, the demand for AC units in cars increased rapidly and now all the manufacturers

provide AC units as standard facilities. Initially, its purpose was purely luxury, but now people use it as a safeguard

against heat, dust, cold and smoke.

EQUIPMENT

The equipment’s used within this bench top air automotive cooling system:

Battery

Motor

Compressor

Condenser

Evaporator

Thermal expansion valve

Receiver drier

Pressure and thermocouple gauge

Lab Report Page 2

MM 321 Refrigeration and Air Conditioning

METHODOLOGY

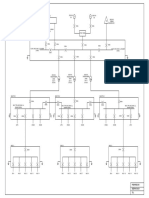

The bench top automotive cooling system was set up as demonstrated by the image below. Once the switch was

turned on, the power exerted from the battery, supplied energy to the motor to help in the cycle for compressor,

evaporator and condenser system. The refrigerant enters the compressor and is compressed thus result in the

increases of temperature and pressure. Once the refrigerant is pumped out of the discharge side of the compressor,

it flows into the thermocouple and pressure gauge where the reading was shown for pressure and temperature. It

then gradually, exits the gauges to the inlet of the condenser. Within the condenser the heat was exchanged so

basically the condenser rejects heat to its surrounding. As the refrigerant exits the outlet line of the condenser,

another set of thermocouple and pressure gauges were attached to alternated the readings again. The refrigerant

then flows though the receiver or refrigerant dryer, to filter and absorbed small amount of moisture present in the

refrigerant. It then travelled through the expansion valve, were its temperature and pressure are being reduced, and

flows directly to the evaporator and again heat was adding to the existing refrigerant. Out from the evaporator the

refrigerant does exit and enters the compressor and the cycle continues.

(Fig 2: Car Air-conditioning Circuit Works)

RESULTS

Given data from the experiment for set 1:

Evaporating pressure: 0.4MPa

Condenser pressure: 1MPa

Temperature at compressor outlet ¿ 65 ° C

Solution reading form the R-134a for h1, h2, h3=h4, h2s.

h 1=410 kJ /kg

h 2=451 kJ /kg

h 3=h 4=282 kJ /kg

h 2 s=436 kJ /kg

Sample Calculation :

Solving for heat

Q L=h1−h 4

q L =410−282=128 kJ /kg

Solving for work compressor

w c =h2 −h1

w c =451−410=41 kJ /kg

Lab Report Page 3

MM 321 Refrigeration and Air Conditioning

Solving for the COP (Coefficient of performance)

q L 128

formula: = =3.12 kJ /kg

wc 41

Solving for efficiency of the compressor.n c

h 2 s−h1 436−410 26

n c= = = =0.63 %

h2−h1 451−410 40

Table of raw and calculated results:

Values

h1 410 kJ /kg

h2 451 kJ /kg

h 3=h 4 282 kJ /kg

h2s 436 kJ /kg

qL 128 kJ /kg

wc 41 kJ /kg

COP 3.12 kJ /kg

nc 0.63 %

Ideal cycle graph from the P-h diagram.

DISCUSSION

Looking into the result of the experiment that is obtained, according to the calculations and the table of data

constructed. The solution reading for h1, h2, h3=h4 and h2s are obtain from the P-h diagram 134a.Basically the

result enthalpy acts as heat content, from which it measures how much heat a gas or liquid can hold and the amount

of heat that is needed to change the temperature. it contributes in the amount of internal energy within a system

combined with the product of its pressure and volume does making cooling system operational. However, Using the

Lab Report Page 4

MM 321 Refrigeration and Air Conditioning

enthalpy result that was obtained the heat input from low temperature medium QL by calculations was 128 kJ /kg .

And the work on compressor was 41 kJ /kg . This value has played an important role in the automotive cooling

system because of its two different ways of transferring energy from one system to another. The first law of

thermodynamics states that heat and work both contribute to the total internal energy of a system, but the second

law of thermodynamics limits the amount of heat that can be turned into work. Furthermore, in the extend our

calculations for the efficiency of the compressor for the system was extended to 0.63 % . To deeply look into this

value, it shows that system has lost much of its energy to heat resulting in a low efficiency percentage. However, the

aim of the experiment was achieved neglecting some errors which may have involved in calculations.

CONCLUSION

To conclude, Air automotive cooling system, is a very important factor in automobile industries since it provides the

driver and the passengers a comfortable environment when driving. It’s designed to heat up the inside of a car

during the cold season and to provide cool air conditioning during the warm weathers. Finally, the experiment has

achieved its aim and was done successfully. This experiment has given students an inside understanding on how air

automotive cooling system works and the contributing materials and equipment that evolved in the process making

to have such influences in today’s automobile industries.

REFERENCE

Mikeduman.com. 2021. The Importance of Cooling Systems Checks | Mike Duman. [online] Available at:

<https://mikeduman.com/blog/importance-cooling-systems-checks> [Accessed 7 September 2021].

Lab Report Page 5

You might also like

- Rev Quiz All PDFDocument46 pagesRev Quiz All PDFNota Belz82% (17)

- USP Lab 4 SFEE Blower DuctDocument4 pagesUSP Lab 4 SFEE Blower DuctRoshiv Sharma0% (1)

- Refrigeration and Air ConditioningDocument263 pagesRefrigeration and Air ConditioningAjeet Verma92% (12)

- Vapor Compression Refrigeration CycleDocument44 pagesVapor Compression Refrigeration CycleJohnlloyd Barreto100% (1)

- The Macadamia Industry in MalawiDocument77 pagesThe Macadamia Industry in Malawiwarlord_ckNo ratings yet

- MM321 Lab 3Document5 pagesMM321 Lab 3Roshiv SharmaNo ratings yet

- MM 321 Refrigeration and Air Conditioning LabDocument5 pagesMM 321 Refrigeration and Air Conditioning LabRoshiv SharmaNo ratings yet

- MM321 Lab 1 Report 2020Document5 pagesMM321 Lab 1 Report 2020JnrNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsSiddhant Vishal ChandNo ratings yet

- Rey Experiment No. 5 Ref Training UnitDocument13 pagesRey Experiment No. 5 Ref Training UnitrickybobbyNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- H00413783LAB4Document8 pagesH00413783LAB4Huda AlkhouriNo ratings yet

- RevisionDocument19 pagesRevisionmenemNo ratings yet

- Air Conditioning Lab Final1Document20 pagesAir Conditioning Lab Final1haziqNo ratings yet

- Thermodynamics 1Document20 pagesThermodynamics 1ALFRED AKPONo ratings yet

- 16 Research PaperDocument7 pages16 Research Paperkhaja ziauddinNo ratings yet

- Air Conditioner Thermodynamics AnalysisDocument11 pagesAir Conditioner Thermodynamics AnalysisMohitNo ratings yet

- 2 - LEC 2 Refrigeration CyclesDocument52 pages2 - LEC 2 Refrigeration Cycleskolkolmohammed27No ratings yet

- LT4 GRP5Document17 pagesLT4 GRP5AegeeNo ratings yet

- Lab Heat PumpDocument9 pagesLab Heat PumpShahran IezzatNo ratings yet

- ME 2301 Thermal Engineering Short Questions and AnswersDocument67 pagesME 2301 Thermal Engineering Short Questions and AnswersBIBIN CHIDAMBARANATHAN100% (6)

- PH Number 1Document40 pagesPH Number 1DhduNo ratings yet

- University of The West Indies, St. Augustine.: FacultyDocument8 pagesUniversity of The West Indies, St. Augustine.: FacultyCharlotte BNo ratings yet

- Chapter 11 Refrigeration CyclesDocument20 pagesChapter 11 Refrigeration Cycleskalite123No ratings yet

- M.O Heat PumpDocument11 pagesM.O Heat PumpLawand RaufNo ratings yet

- ICE Theory of Cycle and Thermodynamic AnalysisDocument72 pagesICE Theory of Cycle and Thermodynamic AnalysisHoàng LongNo ratings yet

- Vcrs FinalDocument7 pagesVcrs Finalpradhansaurav61No ratings yet

- Chemical Engg Thermodynamics Lab List of ExperimentsDocument32 pagesChemical Engg Thermodynamics Lab List of ExperimentsGee DevilleNo ratings yet

- Compound Vapor Refrigeration System ExamplesDocument65 pagesCompound Vapor Refrigeration System Examplesm_alodat6144100% (1)

- Refrigeration SystemDocument30 pagesRefrigeration SystemMay Jade Genzola EsparesNo ratings yet

- Thermodynamics homework solutions for mechanical engineering courseDocument5 pagesThermodynamics homework solutions for mechanical engineering coursemuru0105No ratings yet

- Che325 Tutorial KitDocument10 pagesChe325 Tutorial KitCharles BaileyNo ratings yet

- 803 Rac (Me-803) Exp. ManualDocument47 pages803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToNo ratings yet

- ThermodynaDocument14 pagesThermodynaMostafa HamawandyNo ratings yet

- Air Cycle Refrigeration SystemDocument30 pagesAir Cycle Refrigeration SystemtsegayNo ratings yet

- Refrigeration Comp. LinkedDocument6 pagesRefrigeration Comp. LinkedDin TescoNo ratings yet

- Design A Solar Collector For VAR System With 1TR Capacity at Its Maximum COPDocument4 pagesDesign A Solar Collector For VAR System With 1TR Capacity at Its Maximum COPsadaaammm sadaaammmNo ratings yet

- Refrigeration Lab Report: Ali Rida Bachir SID 8104461Document4 pagesRefrigeration Lab Report: Ali Rida Bachir SID 8104461NARE EDMUNDNo ratings yet

- Thermo Prject 2-1Document20 pagesThermo Prject 2-1Syed AhmerNo ratings yet

- M 363 ContentDocument115 pagesM 363 Contentn.hartonoNo ratings yet

- Thermo 3 Cyclic ProcessesDocument13 pagesThermo 3 Cyclic ProcessesFebrian RomanNo ratings yet

- IntroductionDocument4 pagesIntroductionHazel AdoNo ratings yet

- Chapter 10: Refrigeration CyclesDocument14 pagesChapter 10: Refrigeration CyclesGhulam AbbasNo ratings yet

- Vapour Compression RefrigerationDocument38 pagesVapour Compression RefrigerationArvind75% (4)

- Carnot Cycle & Vapor Compression Refrigeration SystemsDocument2 pagesCarnot Cycle & Vapor Compression Refrigeration SystemsJom Ancheta BautistaNo ratings yet

- Heat Exchanger Performance PDFDocument18 pagesHeat Exchanger Performance PDFcynaiduNo ratings yet

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 pagesBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNo ratings yet

- HVACDocument17 pagesHVACashwini_kumar1984No ratings yet

- LS2 - Refrigeration Comp. Linked New PDFDocument6 pagesLS2 - Refrigeration Comp. Linked New PDFdildin01No ratings yet

- 4 Air Standared Cycles PDFDocument75 pages4 Air Standared Cycles PDFAli ZameerNo ratings yet

- The Effect of Eco-Friendly Refrigerants On Performance of Vapor Compression Refrigeration System With Dedicated Mechanical SubcoolinDocument12 pagesThe Effect of Eco-Friendly Refrigerants On Performance of Vapor Compression Refrigeration System With Dedicated Mechanical SubcoolinDr. Akhilesh AroraNo ratings yet

- Waste Heat from Diesel Gensets Run ACDocument6 pagesWaste Heat from Diesel Gensets Run ACsaliyarumesh2292No ratings yet

- Co2report PrimeDocument11 pagesCo2report PrimeNaveen AnnamalaiNo ratings yet

- Reversed Carnot & VCR Cycle Part IIDocument23 pagesReversed Carnot & VCR Cycle Part IISumran ShahidNo ratings yet

- DiscussionDocument14 pagesDiscussionYousif OthmanNo ratings yet

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument7 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- MM222 Lab 1 (S)Document3 pagesMM222 Lab 1 (S)Roshiv SharmaNo ratings yet

- Development of Automatic Mini Fan with PIR SensorDocument8 pagesDevelopment of Automatic Mini Fan with PIR SensorToheebdareNo ratings yet

- Science Report - Stem CellsDocument7 pagesScience Report - Stem CellsKay NeethlingNo ratings yet

- LIST of Tools-BartenderDocument5 pagesLIST of Tools-BartenderLegal DepartmentNo ratings yet

- Plant Coordination and ControlDocument13 pagesPlant Coordination and ControlMarilyn GumeyiNo ratings yet

- 6035 - L2u203 - PPT - Outcome1 2Document104 pages6035 - L2u203 - PPT - Outcome1 2shahin.noktehdan4102No ratings yet

- Upper Gastro Intestinal BleedingDocument13 pagesUpper Gastro Intestinal BleedingmuniningmicanNo ratings yet

- Determination of AzadirachtinDocument6 pagesDetermination of AzadirachtinPrathamesh BolajNo ratings yet

- Zonal RegulationsDocument146 pagesZonal RegulationsBasavarajaCM50% (2)

- Chiller Maintenance Service 2015Document29 pagesChiller Maintenance Service 2015Huong Ban MaiNo ratings yet

- Axial SpA Guideline 2019 ACRDocument15 pagesAxial SpA Guideline 2019 ACRTurboNo ratings yet

- Cascade Control: 25.1 Master and Slave LoopsDocument10 pagesCascade Control: 25.1 Master and Slave Loopsdeepak pandeyNo ratings yet

- Basic CourseDocument97 pagesBasic CourseAhmed KhairyNo ratings yet

- High Efficiency 2.45 GHZ Low Power Hybrid Junction Rectifier For RF Energy HarvestingDocument4 pagesHigh Efficiency 2.45 GHZ Low Power Hybrid Junction Rectifier For RF Energy HarvestingPrakash SunnyNo ratings yet

- Rohail Hassan: ObjectiveDocument3 pagesRohail Hassan: ObjectiveNoumanKhanNo ratings yet

- Mintek Ar 2011Document76 pagesMintek Ar 2011Algradi MosheerNo ratings yet

- Guidelines For Dengue Surveillance Edition2.PDF WHODocument115 pagesGuidelines For Dengue Surveillance Edition2.PDF WHOFebyan Kuan Lu Hap100% (1)

- Conceptual SLDDocument1 pageConceptual SLDakhilNo ratings yet

- "Fragile" - StingDocument4 pages"Fragile" - StingFabián ReinosoNo ratings yet

- KFS Ut U3Document5 pagesKFS Ut U3Ana DuarteNo ratings yet

- Vehicon (Prime) - Transformers WikiDocument13 pagesVehicon (Prime) - Transformers Wikiamos_evaNo ratings yet

- ICH Guidelines: Prsented By: Manish Shankarpure M.Pharm (Quality Assurances and Techniques)Document17 pagesICH Guidelines: Prsented By: Manish Shankarpure M.Pharm (Quality Assurances and Techniques)Manish shankarpureNo ratings yet

- Ece-Research Work 1Document10 pagesEce-Research Work 1Peale ObiedoNo ratings yet

- Building Schedule 050721Document6 pagesBuilding Schedule 050721Parth DaxiniNo ratings yet

- Specifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Document7 pagesSpecifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Marek WyszatyckiNo ratings yet

- 09a50205 PowerelectronicsDocument8 pages09a50205 PowerelectronicsPaone KalyanNo ratings yet

- Prog 4534543Document559 pagesProg 4534543Vasile TroianNo ratings yet

- Food DirectoryDocument20 pagesFood Directoryyugam kakaNo ratings yet

- Noun Form Answers PDFDocument11 pagesNoun Form Answers PDFChinna LingamNo ratings yet