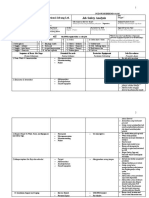

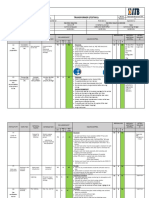

JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

1 Tools and prepation Defective tools/equipment Be careful when pick up tools

equipment Use hand gloves

Ensure tools ready and safe to use

1 Persiapan alat dan peralatan Pemakaian tool yang tidak tepat Berhati-hati ketika mengambil peralatan

Menggunakan sarung tangan

Memastikan semua peralatan siap digunakan

2 Pre-job safety tool box Miscommunication Ask per person about their task and responsibilities

meeting for personnel Misunderstanding Ask is there anyone do not understand about the topic

involved the activities or their responsibility

Ensure all of person understand about the topic

Ensure work instruction , JSA, and all supporting

document already communicate to personnel team

2 Pre –job safety tool box Miskomunikasi Tanyakan kepada personil apakah mereka paham

meeting untuk personnel dengan tugas dan tanggung jawabnya

yang terlibat dalam activitas Kesalahan pengertian Tanyakan apakah ada hal yang kurang jelas terkait

ini topic pembicaraan

Pastikan semua personil mengerti akan topic yang

1|Page

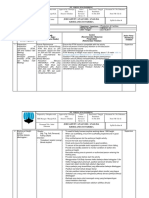

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

dibicarakan

Pastikan instruksi kerja, JSA dan semua dokumen

pendukung telah di komunikasikan

3 Lifting the object Dropped object Use approved procedure for lifting

Recognize the weight of load (to be in safe limit of SWL)

Crane’s boom is twist and broken Control and make sure that sling (s) and shackle (s)

installed under safe working load certification/check

Crane is tipped (tipping), loss color code

stability Ensure crane capacity is capable to lift material

Ensure that no body passing/ working under the lifted

object

Tag lines shall tied to any lifting object for control

Control movement of object during lifting

Crane is safe for use and certified

Operator crane & rigger certificate and experience

Lifting gear use must be certificate and proper color

code

Control movement of object during lifting with tag line

2|Page

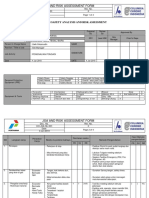

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

so that no over swaying and smooth crane operation

No lifting activity when strong wind (wind is less than

20 knots)

Principally, COG of lifted object must be under and in

line vertically to tip of crane boom so that no excessive

twist moment on crane boom

Therefore control and do adjustment if necessary to

keep vertically of hook sling line

Pre lift the object with gradual increase

Control/check and make sure that crane is sufficient to

lift the load radius, crane, track orientation is in

sccordance with the written procedure

Control during lifting operation so that there is no

condition causing twist on crane boom

Stable ground condition (check if reinforcement is

required)

Outrigger to be extended prior to start operation

3|Page

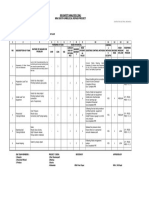

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

3 Pengangkatan Objek Benda terjatuh Menggunakan prosedur yang telah disahkan untuk

pengangkatan

Crane boom rusak Memastikan berat dari benda yang diangkat

Memastikan sling dan shackle yang dipasang sudah

Alat angkat kehilangan disertifikasi

keseimbangan Memastikan kapasitas alat angkat dapat mengangkat

material

Memastikan tidak ada yang melewati daerah kerja alat

angkat pada saat beroperasi

Tug line harus dipasang

Mengendalikan benda yang diangkat

Alat angkat aman untuk digunakan dan bersertifikasi

Lifting gear harus bersertifikasi dan mempunyai color

code

Mengendalikan pergerakan objek selama

pengangkatan dengan tug line

Tidak ada aktivitas ketika angina kencang

Pada prinsipnya, COG objek mengangkat harus berada

4|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

dibawah dan sejalan vertical ke ujung boom sehingga

ada momen sentuhan yang berlebihan pada derek

boom

Mengontrol dan melakukan penyesuaian untuk

menjaga vertical dan garis kail sling

Sebelum pengangkatan dengan kenaikan yang

signifikan

Mengontrol dan memastikan bahwa alat angkat cukup

diradius pengangkatan, alat angkat, orientasi track dan

sesuai dengan yang tertulis di dalam prosedur

Melalukan control pada saat pengangkatan sehingga

tidak ada kondisi yang mengakibatkan twist pada

boom alat angkat

Kondisi landasan yang stabil (melakukan pengecekan

penguatan landasan jika diperlukan)

Outrigger harus dibuka sebelum pengankatan

dilakukan

5|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

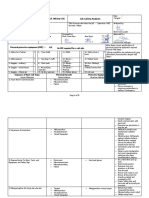

4 Moving the crane Crane is tipped (tipping), loss The precaution is the similar as described at point 1.3

stability Stop the movement then reduce travelling speed when

heaving of module is increasing load more than 5%.

Increasing load can be read from load indicator

Control movement with tag line

Flashing light with audible sign to alert personal around

the area

4 Pergerakan alat angkat Alat angkat kehilangan Untuk precaution sesuai dan sama seperti diatas

keseimbangan Stop pergerakan dan kemudian mengurangi kecepatan

perjalanan saat modul beban meningkat lebih dari 5%.

Kenaikan beban dan dilihat dari load indicator

Mengendalikan pergerakan dengan tug line

Menyalakan lampu dengan sirene untuk memperingati

personil yang berada di area yang sama

5 Personal hit by the object Keep safe distance with object, especially on

connection/splicing parts before releasing the object

Hit existing facilities Releasing action shall be announced to anybody before

execution

6|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

Ensure area is clear from unnecessary personnel

Rigging crews are not standing between load and

structure

Ensure rigging crews hands are not between slings and

shackles

Good communication to be established between rigger

& crane operator

Protect live facility (such as small bore piping, tubing) as

much as possible releasing the object

Plan the load path to final position

Electrical power lines within safe distance

5 Mengangkat dengan Personil dikenai oleh object Tetap menjaga jarak dengan objek yang akan diangkat,

keterbatasan terutama kekoneksi parts sebelum mengangkat dan

Membentur fasilitas existing melepas

Pelepasan objek harus di kamunikasikan kesetiap orang

sebelum melakukan pekerajaan

Memastikan area bebas dari orang yang tidak

berkepentingan

7|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

Personil rigging tidak berdiri diantara area pengankatan

Memastikan tangan personil rigging tidak berada

diantara sling dan shackle

Komunikasi yang baik antara rigger dan operator alat

berat

Melindungi fasilitas yangh live (seperti pipa yang

berukuran kecil, tubing)

Merencanakan posisi terakhir pengankatan

Jalur energy listrik harus dengan jarak yang aman

6 Housekeeping Bad housekeeping Ensure housekeeping implemented before and after

working hours.

All equipment and tools is stored in a safe place

6 Kebersihan Housekeeping yang buruk Pastikan housekeeping dilakukan sebelum dan sesudah

jam kerja

Semua peralatan dan alat-alat disimpan di tempat yang

aman.

8|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

9|Page

� JOB SAFETY ANALYSIS

Date / JSA No. 01042018/MEL/HSE/004 Department: (Bagian/fungsi) Construction

General Lifting/Loading & Supervisor: (Pengawas) Alwan

JOB (Perkerjaan)

Unloading Location: (Lokasi)

PERSONAL PROTECTIVE EQUIPMENT REQUIRED TO PERFORM THIS JOB ( ALAT PELINDUNG YANG DIPERLUKAN UNTUK MELAKUKAN PEKERJAAN).

□ Safety Helmet □ Ear Plug/Ear Muff □ Rubber Gloves □ Fire Extinguisher □ Other :

□ Safety Shoes □ Rubber Boat □ Full body Harness □ Lock out / Tag Out

□ Safety Glasses □ Face Shield □ Chemical coat □ Oil Spill Kit

□ Leather Gloves □ Apron □ Respirator / SCBA □ Work Permit Required

□ Cotton Gloves □ Dust / Gas Masker □ Goggles □ Barricade and/or Sign

No Sequence of Basic Steps Indentify Hazard RISK LEVEL Recommendation safe job procedures

(Urutan Langkah dasar pekerjaan) (Bahaya teridentifikasi) (Tingkat Resiko) (Rekomendasi prosedur kerja secara aman)

Pelaksana Pekerjaan Pengawas Pekerjaan Pemilik Asset

10 | P a g e