Professional Documents

Culture Documents

Geneset Check Sheet - Qap

Uploaded by

ganeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geneset Check Sheet - Qap

Uploaded by

ganeshCopyright:

Available Formats

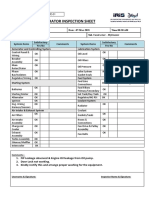

CC/QA-ED/F013/ Rev 009 DATE –18.08.

2016

GENSET FINAL CHECK

SHEET

Prepared by : QA engineer Approved by : HOD QA

Genset Model No Genset Sr. No. Engine Model No. Engine Sr. No. Alternator No. STAMFORD Date

MECCALTE

CR. GREAVES

Inspector Name Supervisor Name

Kva/phase:- A. Visual aspect (R009) :-

OK / REMARKS IF OK/N REMARK IF NOT

SPECIFICATION/DESIRE CHECK POINT

SPECIFICATIONS / DESIRE / CHECK POINTS NOK NOK OK OK

A. Fuel tank Assembly / Make - H. Electrical system –Wiring harness fitment

Check Connection of Engine & canopy

1 Foam fitment. 1

wiring harness

Fitment of fuel tank into base frame (Location & Connection of ECU ,Cam sensor, Crank

2 2

resting bolt fit) sensor,IMV Pump

Feed pump (with O-ring) & Fuel Gauge assembly Connection of T-Map sensor, Oil

3 3

with gasket, Assembly of Fuel filling hose pressure sensor & switch

Connection of Rail pressure, injector

4 Lekage test identification 4

sensor

Vent pipe, fuel lock, feed pump bracket with fuel Connection of Coolant temp Switch &

5 5

tank, Leak proof gasket use Sensor

Check fitment of engine, alternator, radiator Connection of Fuel feed pump, Starter,

6 6

mounting member Fuel gauge

Earthing Connection with body to Panel

B. Engine Alternator sub assembly fitment on Base frame 7

& Alternator

Engine mounting support bracket assembly Connection of Roof lamp, power cable,

1 8

(Intake side & Exhaust side) control panel fitment

9

2 Foundation bolts tightening by 60 Nm torque Battery serial no -

(7)

AVM selection (grade) & bolts tighten by 60 Nm &

3 I. Battery connection / Make -

50 Nm

Engine and Alternator coupling – fasteners

4 1 Battery mounting assembly

tightening torque 50 Nm

Connection Starter motor, Earthing to

C. Coolant system fitment by using Hose & clips 2

main body

Cooling system Assembly (Radiator Outlet to

1 Engine inlet) & (Engine outlet to radiator Inlet) – 2 J. Canopy Make:- (Regular or Compact)

Cyl. Genset

Thermostat to radiator Pipe & Hoses assembly-3,4 Canopy top fitment,lifting hook,coolant

2 1

& 6 Cyl. & oil filling caps

Coolant Manifold To Radiator Pipe& hose Canopy : No damage, dent, color

3 2

assembly - 3,4 & 6 Cyl. scratch, Peel off, Shades

D. Air intake & exhaust sytems assembly 3 Foam : Adequacy, Pasting

Position CAC pipe (intake side) with gasket on No uneven Doors gap, Top panels,

1 4

intake manifold & Exhaust side CAC Assembly Louvers, Side panel

Fastener tighten with spring washer to

2 Gas mixer Pipe to radiator assembly 5

canopy, Rat mesh

3 Turbocharger to CAC pipe assembly 6 Oil drain bolt & piping available

4 Air Filter Assembly 7 Working condition of Fuel & Door locks

E. Radiator mounting assembly , fan guard assembly K. Sticker

1 Fan assembly & fan gap check visualy 1 Engine & genset name plate

2 Auxiliary tank connections (tank to radiator) 2 Sticker : Cooper logo, Genset KVA

Sticker : Emergency stop, helpline &

F. Exhaust System Assembly checks 3

instruction label

Fastener fitment to Elbow, Expansion bellow, L-

1 Bend pipe, Tail Pipe,Silencer & Mounting Bkt. & L. Packing (rev 03: 11.7.2015)

insulation – 2 cyl.

Check S pipe , Exhaust bellow , Exhaust pipe,

2 M As per SOP

silencer & tail pipe assembly – 3,4,& 6 Cyl.

G. Fuel supply & return pipe Assembly

1 Fuel System assembly

Check Connection : Pump to fuel filter, Filter to

2 IMV, Venturi to Feed pump, Fuel return to

venturi connection

CC/QA-ED/F013/ Rev 009 DATE –18.08.2016

GENSET FINAL CHECK

SHEET

Prepared by : QA engineer Approved by : HOD QA

B. PERFORMANCE INSPECTION PARAMETERS

SR.N SPECIFICATIONS / DESIRE / CHECK OK /

ASPECT REMARKS IF NOK

o. POINTS NOK

01 Check engine oil level MAX / MIN dip stick -MAXIMUM LEVEL

02 Check coolant level Visual

03 White / black smoke no smoke allowed

04 If charging alternator use check the voltage output

C. FUNCTIONAL INSPECTION PARAMETERS

SR. SPECIFICATIONS / DESIRE / CHECK OK /

ASPECT REMARKS IF NOK

No. POINTS NOK

1 Genset on (start)/ off (stop) Check

2 Fuel leakages from joints Check all joints

2.1 IMV banjo bolt

2.2 All joints of hp pipes

2.3 Injector side

3 Oil leakages (visual)

3.1 Cam cover seal

3.2 Injector seal

Front cover seal inlet and exhaust

3.3

side

3.5

Oil filter 'o' ring

3.6 Oil pressure switch

3.7 Oil cooler 'o'ring

3.8 Filter head to block

3.9 Dipstick 'o' ring

Cyl.head gasket inlet side and

3.10

exhaust side

3.12 Oil pan gasket

3.13 Oil drain plug

3.14 Cyl. block to bed plate

3.15 Crank sensor

4 Coolant leakages Check all joints (visual)

4.1 From hoses

4.2 From water pump

Intake & Exhaust gas leakages

5 TC to radiator pipe both ends

(R006)

5.1 CAC to gas mixer pipe both ends

5.2 TC to bellow pipe both ends

5.3 Expansion Bellow joints

CC/QA-ED/F013/ Rev 009 DATE –18.08.2016

GENSET FINAL CHECK

SHEET

Prepared by : QA engineer Approved by : HOD QA

5.4 Silencer side pipe joints

6 Overhead lamp availability / functioning

write down the load ampere of

7 110 % load testing for % mints Ok/NOK = AMP

panel

Noise: Max 75 db (Standard Refer : IS 8528)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Avg

Vibration:

Above AVM on engine Below AVM at Engine Above AVM on Alternator Below AVM at Alternator

INTAKE TC INTAKE TC INTAKE TC INTAKE TC

D.CUSTOMER SPECIFIC REQUIREMENT : Caterpillar India Private Limited

OK / REMARKS SPECIFICATION/DESIRE CHECK OK/NO REMARK IF

SPECIFICATIONS / DESIRE / CHECK POINTS NOK IF NOK POINT K NOT OK

A) canopy aesthetic look C) No Cooper and Supplier branding allow

1 No dent (Small or Big) allow on canopy 1 Canopy sticker

2 No porous paint allow 2 Radiator sticker

3 Uneven paint thickness not allow 3 Control Panel sticker

4 No scratch mark allow 4 Controller

Main Alternator name plate

5 No uneven door gap allow for all canopy door 5

& sticker

6 Door hings should be inline with each other 6 AVM sticker

7 No rusty bolts allow 7 Air filter unit sticker

B) Sticker provision 8 Air filter element

1 Fgw name plate- 1 nos 9 Oil filter printing

2 Genset rating – 2 nos 10 Fuel filter printing

3 Fuel filling – 1 nos 11 Circuit Diagram (cooper)

4 Oil drain – 1 nos 12 Engine Ok sticker

Sticker electrical hazard & manual – 1 nos

5 13 Wiring harness sticker

6 Sticker hot surface – 1 nos 14 Power cable sticker

7 Sticker earthing – 2 nos 15 Battery cables sticker

8 Sticker lifting – 4 nos

9 Sticker fgw logo small -3 nos

10 Engine rocker cover plate – 1 nos

11 Sticker emergency – 1 nos

12 Sticker glycol mix coolant- 1 nos

CC/QA-ED/F013/ Rev 009 DATE –18.08.2016

GENSET FINAL CHECK

SHEET

Prepared by : QA engineer Approved by : HOD QA

All machining parts should be painted with black paint (rev 04)

Engine Parts affected OK / NOT OK REMARKS IF NOT OK

Machining area near oil cooler

Core plug boss machining area

FIP mounting area (GCC)

Feed pump mtg.area

Above Intake Manifold

Engine Mounting bracket

All Machining bosses of cyl bock

Machined bosses on Cylinder head

Above Exhaust Manifold & bush

Starter Intermediate Plate

Engine and alternator coupling hub

Belt tensioner Bracket

Crank Pulley

Idler pulley

Water pump pulley

Fan pulley

EGR Valve body

Turbo housing

Exhaust Manifold

Alternator shaft rust trace mark

Spacer between EGR Valve & EGR Cooler

Charging alternator body(Alum)

Cover Oil Cooler body (Alum)

Punching area on Cyl block.

Canopy parts affected

Base frame Rusty

Door rusting

Rust below lifting hook

Rusty at canopy wall & corners

Lock pin rusty

Lock rusty

E- ADDITIONAL CHECKPOINTS (rev 08 Point. no. 7& 8 Added)

SR. NO. ASPECT/ CHECK POINT OK / NOT OK IF NOT OK ACTION TAKEN

1 Misalignment of cac piping & cooling pipe with radiator.

2 Misalignment of intake & exhaust system

3 Control panel door cracking at MCB pocket

CC/QA-ED/F013/ Rev 009 DATE –18.08.2016

GENSET FINAL CHECK

SHEET

Prepared by : QA engineer Approved by : HOD QA

4 Alternator shaft rusty check

5 Ensure Metallic pin used On -Off KEY switch to be fitted to Control Panel

Fuel float working / connection check (Compact-G25891507010 Regular-

6

G258007030002)

7 Transfer pipe Coolant Hose fouling with Exhaust Elbow 2 Cylinder

8 Water pump shaft failure , Fan pulley come out

9 Control panel door lock fitment/working

10 Coolant drops observed inside canopy (Near cooling system)

PARAMETER READINGS (SCOPE OF DG TESTING) (R007)

SR.NO. SPECIFICATIONS / DESIRE / CHECK POINTS VALUE REMARK IF NOT OK

FUEL LEVEL - If Applicable

1

(NOTE: LFL :-SHUT DOWN 5 %)

BATTERY VOLTAGE (at charging )-

2

(NOTE:12V BATTERY :-UPTO 14.2V MAX & 24 V :- 27.5 V MAX)

3 WORKING OF AMF FUNCTION - If Applicable

4 CONTACTORS WORKING- If Applicable

5 COLD ADVANCE SOLENOID OPERATION (UP TO 55°C) If Applicable

CHARGING ALTERNATOR OUPUT – DC VOLTAGE & ALT WL CONNECTIONS FOR CRG

6

ALTERNATOR

BATTERY CHARGER VOLTAGE – FOR 12 VOLT – REQUIRE 14.2 V & FOR 24 VOLT RE-

7

QUIRE 27.5 V

You might also like

- MTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistDocument1 pageMTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistabdiNo ratings yet

- AHU - With Recovery Fan Startup ChecklistDocument2 pagesAHU - With Recovery Fan Startup Checklisttekken123joNo ratings yet

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistKenneth JapsonNo ratings yet

- Scope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602Document6 pagesScope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602pathinathanNo ratings yet

- P1604 CodeDocument61 pagesP1604 CodeGeorgi Aleksiev100% (1)

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Win Progress.,Co - LTD (Pharkant Branch) : D13A Engine Receiving/Delivering Inspection FormDocument26 pagesWin Progress.,Co - LTD (Pharkant Branch) : D13A Engine Receiving/Delivering Inspection FormLinzaw OoNo ratings yet

- Engine ElectricalDocument4 pagesEngine ElectricalAndres Herland Balderas MirandaNo ratings yet

- Isuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFDocument50 pagesIsuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFVirgo100% (5)

- 14 Electrical Section-N900 Series JMCDocument23 pages14 Electrical Section-N900 Series JMCRusonegro100% (1)

- Indmar Ignition Timing & AdjustmentsDocument6 pagesIndmar Ignition Timing & AdjustmentsrfffffNo ratings yet

- FK4219 - Electrical - Primary Protection Test - 61Document10 pagesFK4219 - Electrical - Primary Protection Test - 61Wagner GuimarãesNo ratings yet

- Comp No.5 (-10) PrestartchecklistDocument7 pagesComp No.5 (-10) PrestartchecklistEujan MejidanaNo ratings yet

- Startup Inspection ChecklistDocument2 pagesStartup Inspection ChecklistMouayed Zeadan100% (1)

- MGS Presentation Rev1 PDFDocument60 pagesMGS Presentation Rev1 PDFcspola50% (2)

- Código de Falla DD15 SPN 677 FMI 5Document7 pagesCódigo de Falla DD15 SPN 677 FMI 5sofiayniko86% (7)

- User's Manual of Terca R Electromagnetic RetarderDocument38 pagesUser's Manual of Terca R Electromagnetic RetarderАнтон ЧекмарёвNo ratings yet

- Oreda Volume 1 PDFDocument794 pagesOreda Volume 1 PDFdigeca100% (2)

- Engine Specification Sheet: de Pere, WI 54115 Curve Number: Revision DateDocument2 pagesEngine Specification Sheet: de Pere, WI 54115 Curve Number: Revision DateReynaldo MarianoNo ratings yet

- Materia-2006 Engine (1) - 005Document1 pageMateria-2006 Engine (1) - 005Ty ToyNo ratings yet

- Motor Cummins QSL9Document18 pagesMotor Cummins QSL9AndresPonceNo ratings yet

- Mma 152 MotorDocument101 pagesMma 152 Motoraviacion gnaNo ratings yet

- 3-CA4250P25K2T1E5A80-DY640-engine AccessoriesDocument24 pages3-CA4250P25K2T1E5A80-DY640-engine AccessoriesJesus gomez corvalanNo ratings yet

- (A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check SheetDocument3 pages(A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check Sheetyao nestorNo ratings yet

- Structure and Function Large Class CRI EngineDocument26 pagesStructure and Function Large Class CRI EngineTeguh Imam Adri100% (3)

- 07.2-110 Testing, Adjusting EngineDocument16 pages07.2-110 Testing, Adjusting EngineMariusz NowakowskiNo ratings yet

- Hydroserv Gen HS ELG 42Document2 pagesHydroserv Gen HS ELG 42rohit tiwariNo ratings yet

- Synch Motor ExcitationDocument17 pagesSynch Motor ExcitationwebdiegoNo ratings yet

- TMS800E Hyd Press Set ProcDocument20 pagesTMS800E Hyd Press Set ProcQike FlowersNo ratings yet

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- PL Starting 8B - 1Document8 pagesPL Starting 8B - 1Pelis CloneNo ratings yet

- IB-419 - All FI Models - Diagnostic Trouble Codes (DTC)Document6 pagesIB-419 - All FI Models - Diagnostic Trouble Codes (DTC)MotoEstudio MotoNo ratings yet

- 250 - V3 - Technical Service ManualDocument227 pages250 - V3 - Technical Service ManualBaldoNo ratings yet

- BC01C1 Loop Seal Blower Specn R00Document5 pagesBC01C1 Loop Seal Blower Specn R00JKKNo ratings yet

- MR1021Document5 pagesMR1021hazril azwaNo ratings yet

- Maintenance Interval Schedule GENSET 250KVADocument2 pagesMaintenance Interval Schedule GENSET 250KVARegi HermawanNo ratings yet

- FG Wilson India Operator (2 Cyl) PDFDocument69 pagesFG Wilson India Operator (2 Cyl) PDFviraj arjun ghadageNo ratings yet

- MC 10124184 9999 PDFDocument8 pagesMC 10124184 9999 PDFTracto Rescates de Occidente CtrlNo ratings yet

- MPM 573 01 52Document4 pagesMPM 573 01 52Mousa PetrolNo ratings yet

- TBM Gen GS09Document2 pagesTBM Gen GS09rohit tiwariNo ratings yet

- Engine Specification Sheet: Revision Date: de Pere, WI 54115 Curve NumberDocument26 pagesEngine Specification Sheet: Revision Date: de Pere, WI 54115 Curve Numberمصطفى الكوتNo ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- QSD Fuel SystemDocument58 pagesQSD Fuel SystemHendri Wiguno100% (3)

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- SpecSheetCFP11E F20Document2 pagesSpecSheetCFP11E F20abdelrhmangbr86No ratings yet

- Site Info:: 11TS01B0119: New - Redep017 Tsel: 2018-11-25: - 4.28123: 122.10905Document11 pagesSite Info:: 11TS01B0119: New - Redep017 Tsel: 2018-11-25: - 4.28123: 122.10905Naga AjiNo ratings yet

- Устройство PMS часть 1Document9 pagesУстройство PMS часть 1Achmad AminNo ratings yet

- 15 Air Metering-Acceleration SystemDocument17 pages15 Air Metering-Acceleration Systemapinya doungsoilNo ratings yet

- SM 67Document12 pagesSM 67eys.automotricesNo ratings yet

- Rav1 Feseau MoteurDocument3 pagesRav1 Feseau MoteurHirwa Jules KlutchNo ratings yet

- 309-00A Exhaust System - 1.5L EcoBoostDocument42 pages309-00A Exhaust System - 1.5L EcoBoostMohamed AdelNo ratings yet

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- 939Document5 pages939amir ghaznaviNo ratings yet

- MTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistDocument1 pageMTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistAfcade D'AgoueNo ratings yet

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 pagesAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadNo ratings yet

- SIS 2.0 Maintenance Interval Schedule - Standby (M0124697-02)Document2 pagesSIS 2.0 Maintenance Interval Schedule - Standby (M0124697-02)Carlos U. CallirgosNo ratings yet

- 2008 64 PCED - Pinpoint Test ME - Fuel Pump Control - High Pressure Fuel Injection PumpDocument8 pages2008 64 PCED - Pinpoint Test ME - Fuel Pump Control - High Pressure Fuel Injection PumpSta Teresita FC Ganaderia CharolaisNo ratings yet

- Fire Water Motor Engine PMDocument5 pagesFire Water Motor Engine PMShamsuddin SoomroNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Transformer&Reactor Protection PCS-978Document4 pagesTransformer&Reactor Protection PCS-978ganeshNo ratings yet

- Line Differential Protection PCS-931Document6 pagesLine Differential Protection PCS-931ganeshNo ratings yet

- PCS-9656 Arc ProtectionDocument3 pagesPCS-9656 Arc ProtectionganeshNo ratings yet

- Protocol Convert PCS-9794Document3 pagesProtocol Convert PCS-9794ganeshNo ratings yet

- GPS Synchronization Clock PCS-9785CDocument2 pagesGPS Synchronization Clock PCS-9785CganeshNo ratings yet

- Ethernet Switch PCS-9882Document3 pagesEthernet Switch PCS-9882ganeshNo ratings yet

- Instrument Transformers CatalogueDocument12 pagesInstrument Transformers CatalogueGanesh DuraisamyNo ratings yet

- Substation Automation SystemDocument5 pagesSubstation Automation SystemganeshNo ratings yet

- Instrument Transformers CatalogueDocument12 pagesInstrument Transformers CatalogueGanesh DuraisamyNo ratings yet

- PCS 9785CDocument3 pagesPCS 9785CganeshNo ratings yet

- PCS-9799 Station ManagerDocument4 pagesPCS-9799 Station ManagerganeshNo ratings yet

- Functions: Bay Control Unit (BCU)Document3 pagesFunctions: Bay Control Unit (BCU)ganeshNo ratings yet

- Ethernet Switch: ApplicationDocument2 pagesEthernet Switch: ApplicationganeshNo ratings yet

- PCS 915Document5 pagesPCS 915ganeshNo ratings yet

- Functions: Line Differential RelayDocument6 pagesFunctions: Line Differential RelayganeshNo ratings yet

- TCI Composite Insulator CatalogueDocument16 pagesTCI Composite Insulator CatalogueganeshNo ratings yet

- PCS-978 Transformer ProtectionDocument6 pagesPCS-978 Transformer ProtectionganeshNo ratings yet

- Functions: Circuit Breaker ProtectionDocument4 pagesFunctions: Circuit Breaker ProtectionganeshNo ratings yet

- Functions: Line Distance RelayDocument5 pagesFunctions: Line Distance RelayganeshNo ratings yet

- Trackso Datalogger DatasheetDocument8 pagesTrackso Datalogger DatasheetganeshNo ratings yet

- Quizlet Table 7Document1 pageQuizlet Table 7JosielynNo ratings yet

- Thom22e ch03 FinalDocument44 pagesThom22e ch03 FinalDionisius AlvianNo ratings yet

- Van Daley - Leadership ResumeDocument1 pageVan Daley - Leadership Resumeapi-352146181No ratings yet

- Test Cases: Project Name: Virtual ClassroomDocument5 pagesTest Cases: Project Name: Virtual ClassroomTina HernandezNo ratings yet

- Ultimate Prime Sieve - Sieve of ZakiyaDocument23 pagesUltimate Prime Sieve - Sieve of ZakiyaJabari ZakiyaNo ratings yet

- Advanced Packaging Polymers: Product Selection GuideDocument12 pagesAdvanced Packaging Polymers: Product Selection GuideDKNo ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- DocumentationDocument44 pagesDocumentation19-512 Ratnala AshwiniNo ratings yet

- Appendicitis Case StudyDocument6 pagesAppendicitis Case StudyKimxi Chiu LimNo ratings yet

- Loan Agreement: Acceleration ClauseDocument2 pagesLoan Agreement: Acceleration ClauseSomething SuspiciousNo ratings yet

- Celestino vs. CIRDocument6 pagesCelestino vs. CIRchristopher d. balubayanNo ratings yet

- MT4 EA Installation Guide Digital - EnglishDocument7 pagesMT4 EA Installation Guide Digital - EnglishThe Trading PitNo ratings yet

- JAMB Syllabus For BiologyDocument27 pagesJAMB Syllabus For BiologyOluebube UchennaNo ratings yet

- Drill Bit Classifier 2004 PDFDocument15 pagesDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- Business English ExerciseDocument11 pagesBusiness English ExerciseAdeline KwanNo ratings yet

- Glossary of Terms 2nd PartDocument2 pagesGlossary of Terms 2nd Part2DJoyce D.N CapacieteNo ratings yet

- Theben Timer SUL 181DDocument2 pagesTheben Timer SUL 181DFerdiNo ratings yet

- Autodesk Design Review: About DWF and DWFXDocument7 pagesAutodesk Design Review: About DWF and DWFXNesreNo ratings yet

- Molecules of Life PDFDocument113 pagesMolecules of Life PDFArpit Pradhan100% (1)

- Corporate Profile of Multimode GroupDocument6 pagesCorporate Profile of Multimode GroupShaheen RahmanNo ratings yet

- E Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersDocument13 pagesE Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersRichard VillanuevaNo ratings yet

- L15 PDFDocument15 pagesL15 PDFlesNo ratings yet

- José Guadalupe PosadaDocument19 pagesJosé Guadalupe PosadaJudy Baca100% (1)

- Avanquest Perfect Image V.12 User GuideDocument174 pagesAvanquest Perfect Image V.12 User GuideShafiq-UR-Rehman Lodhi100% (1)

- Movie Review of THORDocument8 pagesMovie Review of THORSiva LetchumiNo ratings yet

- Nursing EnglishDocument139 pagesNursing EnglishSara Williams100% (3)

- 7 ApportionmentDocument46 pages7 Apportionmentsass sofNo ratings yet

- Panel Hospital List IGIDocument6 pagesPanel Hospital List IGIAbdul RahmanNo ratings yet

- Hilti TE 804 and 905avr PartsDocument13 pagesHilti TE 804 and 905avr PartsAqui Solo100% (1)

- 28 ESL Discussion Topics Adult StudentsDocument14 pages28 ESL Discussion Topics Adult StudentsniallNo ratings yet