Professional Documents

Culture Documents

PG Interface Card "OPC-PG3": Instruction Manual

Uploaded by

Hani KatanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PG Interface Card "OPC-PG3": Instruction Manual

Uploaded by

Hani KatanaCopyright:

Available Formats

3. Product Guarantee 5. Specifications 7.

Terminal Functions

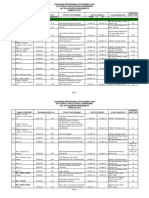

Instruction Manual The product guarantee term is one year after installation or two years after manufacturing on the nameplate, whichever expires first. 5-1. Specifications of applicable PG and PG interface card Table 3 lists terminal specifications.

However, the guarantee will not apply in the following cases, even if the guarantee term has not expired. Table 3 Terminal Specifications

Item Specifications

Terminal

PG Interface Card "OPC-PG3" (1) The cause includes incorrect usage or inappropriate repair or modification.

(2) The product is used outside the standard specified range. PG output pulse frequency

30 kHz max. (Open collector) symbol

Name Functions

100 kHz max. (Complementary) DC12V±10%, max.210mA (Factory default setting )

(3) The failure is caused by dropping, damage or breakage during transportation after the purchase.

[PO] Power supply for encoder *1 DC15V±10%, max.168mA

(4) The cause is earthquake, fire, storm or flood, lightening, excessive voltage, or other types of disaster or secondary disasters. Encoder pulse resolution 20 to 60000 P/R, A, B and Z phase (incremental)

DC24V±10%, max.100mA

Thank you for purchasing this PG interface card "OPC-PG3." Installing this card to your FRENIC-series enables to provide motor

control according to feedback signal from encoder (12V/15V/24V complementary or open-collector type). Open collector (Maximum cable length: 20 m) [CM] Common terminal of power supply DC0V (GND for power supply)

4. Wiring Pulse output circuit

Complementary (Maximum cable length: 100 m)

Connect this PG interface card to the C-port on control board of FRENIC-series. Do not connect it to any other port. [PA] Pulse input terminal A Input frequency max.30kHz (open-collector)

High level : 8V or more [PB] Pulse input terminal B Input frequency max.100kHz (Complementary)

Input pulse threshold

Low level : 3V or less

1. Check that: In general, the covers of the control signal wires are not specifically designed to withstand a high voltage (i.e., reinforced insulation is [PZ] Pulse input terminal Z Complementary or open-collector

not applied). Therefore, if a control signal wire comes into direct contact with a live conductor of the main circuit, the insulation of the 8 mA max. (+12Vdc, +15Vdc) [FA+] Pulse output terminal FA(+)

(1) A PG interface card and two screws (M3 8) are contained Pulse output current Line Driver output (RS422)

Model name cover might break down, which would expose the signal wire to a high voltage of the main circuit. Make sure that the control signal 20mA max. (+24Vdc)

[FA-] Pulse output terminal FA(-) Ratio of dividing frequency setting

in the package. CN1

wires will not come into contact with live conductors of the main circuit. +12Vdc±10% / 210mA or less 1/1, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128

(2) The PG interface card is not damaged during +15Vdc±10% / 168mA or less [FB+] Pulse output terminal FB(+)

PG power supply Wavy accuracy : refer to Figure 3

transportation--no defective devices, dents or warps. Failure to observe this precaution could cause electric shock or an accident. +24Vdc±10% / 100mA or less [FB-] Pulse output terminal FB(-)

(3) The model name "OPC-PG3 " is printed on the front of the [FZ+] Pulse output terminal FZ(+) Line Driver output (RS422)

PG interface card as shown in Figure 1. (The "PG" on the Terminal block TERM1 FZ single output the pulse signal same as PZ signal .FZ signal can’t divide by

6. Storage Environment [FZ-] Pulse output terminal FZ(-) SW1

front is a short name, as shown in Figure 1.) Noise may be emitted from the inverter, motor and wires.

If you suspect the product is not working properly or if you Option card Take appropriate measures to prevent the nearby sensors and devices from malfunctioning due to such noise. 6-1. Temporary Storage * 1 Turn the internal switch (SW2) to the proper position according to the PG power requirement.

have any questions about your product, contact the shop An accident could occur. Store the option card in an environment that satisfies the requirements listed in Table 2.

Figure 1 Product Appearance. The factory default position is "12V."

where you bought the product or your local Fuji branch office.

Table 2 Environmental Requirements for Storage and Transportation

2. Installation Procedure Perform wiring properly, referring to the "Terminal Allocation and Symbol Diagram," "Terminal Specifications," and "Internal Block Item Requirements

Diagram" shown below. Storage

-25 to 70C

Temperature * 1 Location where the option card is not subject to abrupt changes in temperature

Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with a capacity of 22 kW or that would result in the formation of condensation or ice.

FA+ FA- FB+ FB- FZ+ FZ- PO CM PA PB PZ Relative humidity 5 to 95% * 2

below, or at least ten minutes for inverters with a capacity of 30 kW or above. Make sure that the LED monitor and charging lamp are

turned OFF. Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+) The inverter must not be exposed to dust, direct sunlight, corrosive or flammable gases, oil mist, vapor, water drops or

and N(-) has dropped to the safe level (+25 VDC or below). Atmosphere vibration. The atmosphere must contain only a low level of salt.

Figure 2 Terminal Allocation and Symbol Diagram of OPC-PG3 (0.01 mg/cm2 or less per year)

Otherwise, electric shock could occur.

Atmospheric 86 to 106 kPa (in storage)

pressure 70 to 106 kPa (during transportation)

(1) Perform wiring on the PG interface card. Table 1 Terminal Specifications

*

Refer to Section 4 "Wiring." 1 Assuming a comparatively short storage period (e.g., during transportation or the like)

Terminal Size M2 *

2 Even if the humidity is within the specified requirements, avoid such places where the option card will be subjected to sudden

TERM1 is the removable terminal. Use it with below precautions. changes in temperature that will cause condensation to form.

Tightening Torque 0.22 to 0.25 N·m

Precautions for temporary storage

- Remove and connect the removable terminal after PG interface card is removed from inverter.

- Remove the removable terminal from the PG interface card by the tool (e.g. the straight slot screwdriver).

TERM1

Recommended Wire Gauge* AWG16 to 26

(1) Do not leave the inverter directly on the floor.

t1

TH n 3us n:Division ratio

Wire strip length 5 mm 2

(2) If the environment does not satisfy the specified requirements, wrap the option card in an airtight vinyl sheet or the like for

Otherwise, injuries could occur. * Insulated wires with allowable temperature of 105ºC storage. Figure 3 Accuracy of line driver output.

(UL-listed) are recommended.

Failure may occur the PG interface card (3) If the option card is to be stored in an environment with a high level of humidity, put a drying agent (such as silica gel) in the

airtight package described in item (2).

Straight slot screwdriver

(2) Remove the front cover from the inverter and expose the control printed circuit board (control PCB). The PG interface card 6-2. Long-term Storage

can be connected to the C-port only. The long-term storage methods for the inverter vary largely according to the environment of the storage site. General storage methods

are described below.

To remove the front cover, refer to the FRENIC-series Instruction Manual. For inverters with a capacity of 30 kW or above,

open also the keypad enclosure. (1) The storage site must satisfy the requirements specified for temporary storage.

(2) The inverter must be stored in a package that is airtight to protect it from moisture. Include a drying agent inside the package

(3) Insert connector CN1 on the back of the PG interface card into the C-port on the inverter's control PCB. Then tighten the two to maintain the relative humidity inside the package to within 70%.

screws that come with the card. (3) If the option card has been installed in the equipment or control board at a construction site where it may be subjected to

Check that the positioning cutout is fitted on the tab and connector CN1 is fully inserted. Do not connect the PG interface humidity, dust or dirt, then remove the option card and store it in a suitable environment specified in Table 2.

card to the ports other than C-port. Doing so may damage the card.

(4) If necessary, Please set change of the divided output with disconnection detection.

Refer to Section 8 "Setting."

(5) Put the front cover back into place.

To put back the front cover, refer to the FRENIC-series Instruction Manual. For inverters with a capacity of 30 kW or above,

close also the keypad enclosure.

-1- -2- -3- -4-

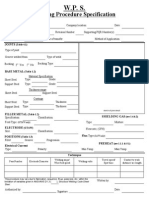

8. Setting 8-3.Output signals of dividing frequency 8-5. Encoder installation and signal 9. Drive Control

8-1. Setting up the switch For OPC-PG3 The input pulse from encoder is divided, and it is possible to output. The division ratio 「n」 is set with dip switch SW1 on the The encoder shall rotate in the direction of Figure8 when terminal FWD is ON. Encoder output pulse is shown the Figure9. For details of PG interface functions available, refer to the FRENIC-series Instruction Manual, "Details of Function Codes" or

option card. Figure 7 shows externals of the ratio of dividing frequency set switch of the pulse output. Connect the encoder directly to the motor using a coupling. If encoder rotation is different from Figure8, change the parameter of the FRENIC-series User's Manual.

Table 4 shows the method of setting SW1. H190.The rotational direction of IEC standard motors is opposite to Figure8.

9-1. Speed control (Vector control with speed sensor)

SW1 Rotational direction when terminal FWD is ON.

The inverter detects the motor's rotational speed from PG feedback signals, decomposes the motor drive current into the exciting and

SW1 torque current components, and controls each of components in vector. The vector control enables speed control with high accuracy

and high response.

For settings and adjustments of the vector control, refer to FRENIC-series Instruction Manual and FRENIC-series User's

Driving side Manual.

SW2

9-2. Connection diagram examples

Figure 7 Ratio of dividing frequency set switch Encoder Figure 10 shows the connection diagram example for speed control.

SW3 Motor

Figure 4 Location of the Switch on OPC-PG3 Figure 5 Switching example and factory default Table 4 Division ratio setting Figure 8 Motor and encoder rotational direction when terminal FWD is ON

SW1 setting n : Division ratio

Change the switch position using a tool with pointed end (end of tweezers, etc.) while taking care to avoid touching 0,8 1(Factory default setting)

other electrical parts and so on. 1,9 2 Forward Signal

If the slider is in the center, this means that it is open. Push the slider in fully. 2 4

3 8

PA

4 16

5 32

6 64

7 128 PB

8-2. Switching between power supplies for PG

Before powering on the inverter, switch between power supplies for the PG using jumper SW2, referring Figure 6. Figure 9 Encoder signals

When changing the dividing frequency output setting, turn the power OFF.

15V 15V 15V If settings are changed with the power ON, pulses will be output from the line driver output even if the inverter is stopped.

There is a possibility that the system will malfunction.

Jumper cap Jumper cap Jumper cap 8-4. Enabling/disabling the wire break detection function with DIP SW3

24V 12V 24V 12V 24V 12V The PG interface card has a wire break detection function that detects wire breaks in the PG cable. It is possible to enable/disable this

SW2 SW2 SW2

detection function in each of the PA, PB, and PZ phases. Please refer to Table 5 when enabling/disabling the detection function for

power supply“12V” power supply“15V” power supply“24V” each phase with the DIP SW3.

Table 5 Enabling/Disabling the Wire Break Detection Function

Figure 6 Configuration of Jumper SW2

Wire Break Detection Function

Selector DIP SW3 Figure 10 Basic Wiring Diagram.

When changing the output setting, set inverter output to OFF. XA phase XB phase XZ phase

ON ON ON ON Use shielding wire for wiring. The shield must be grounded. To prevent malfunction resulting from noise, try as best as possible

to keep the PG interface card wiring separate from the main circuit wiring. Employ such measures as bundling wires together

OFF OFF OFF OFF

inside the inverter to ensure that the PG interface card wiring does not come into direct contact with live parts of the main circuit

Z-OFF ON ON OFF (e.g., main circuit terminal block). If the wiring between the encoder and inverter is long, signal output from the encoder may

malfunction as a result of A phase and B phase interference, possibly resulting in abnormal noise or torque pulsation. In a case

such as this, improvements may be seen by significantly shortening the wiring length (review of wiring route) or using cables

When using an open collector encoder, a disconnection will be mistakenly detected, and therefore DIP SW3 must be

with low stray capacitance may be made. Review the shielding wire if the influence of noise remains significant even after taking

turned OFF.

the above measures.

If using a Z phase with complimentary detector, turn DIP SW3 to Z-OFF.

Fuji Electric Co., Ltd.

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo, 141-0032, Japan

Phone: +81 3 5435 7058 Fax: +81 3 5435 7420

URL http://www.fujielectric.com/

INR-SI47-1955a-E

-5- -6- -7- -8-

You might also like

- Control Op de Puertas MONT20Document67 pagesControl Op de Puertas MONT20Jenssy SayagoNo ratings yet

- User Manual: Elevator Door ControllerDocument20 pagesUser Manual: Elevator Door ControllerHabboula Mourad100% (1)

- Steel W Orks Products (Thailand) : Elevator Controller SystemDocument4 pagesSteel W Orks Products (Thailand) : Elevator Controller Systemtran xobonNo ratings yet

- User'S Manual: GMBH, GermanyDocument167 pagesUser'S Manual: GMBH, GermanyAndres Felipe CaceresNo ratings yet

- TELÉFONO DE EMERGENCIA BÁSICODocument50 pagesTELÉFONO DE EMERGENCIA BÁSICOmisubisi100% (1)

- ML40P Kullanim KilavuzuDocument23 pagesML40P Kullanim KilavuzumuaadhNo ratings yet

- Invt Chv18000 InverterDocument154 pagesInvt Chv18000 InverterAbel CregoNo ratings yet

- LIGHT-CURTAIN-INSTALLATION-GUIDE-peele DoorDocument20 pagesLIGHT-CURTAIN-INSTALLATION-GUIDE-peele DoorRodrigo AntonioNo ratings yet

- Gearless JSA07910E-AA BST BG201 Adjust Manual PDFDocument33 pagesGearless JSA07910E-AA BST BG201 Adjust Manual PDFHamza KefayahNo ratings yet

- Supra Wittur Door Operator ManualDocument3 pagesSupra Wittur Door Operator ManualclaudioNo ratings yet

- Elevator Control Card: User ManualDocument26 pagesElevator Control Card: User ManualГариб Мед100% (1)

- Features Lift Controller MLC-8000 01Document4 pagesFeatures Lift Controller MLC-8000 01Hani KatanaNo ratings yet

- iAstar-AS320 Manual V2.02Document166 pagesiAstar-AS320 Manual V2.02A. PrazNo ratings yet

- Sod IvarDocument41 pagesSod IvarSacha's ChannelNo ratings yet

- Uniscroll 2Document2 pagesUniscroll 2Khaled Zakaria100% (1)

- Microzed-A V Microzed-A V3.1 3.1: User'S ManualDocument38 pagesMicrozed-A V Microzed-A V3.1 3.1: User'S ManualWassim Baccari100% (2)

- Op D4d2ar&op D4b1aDocument3 pagesOp D4d2ar&op D4b1aMed Iliane YahiaNo ratings yet

- Sicor Motor Traction MachineDocument36 pagesSicor Motor Traction MachineSamsudeen SamsudeenNo ratings yet

- Inversors Manual Asc800Document46 pagesInversors Manual Asc800tiextorNo ratings yet

- Manual Agy-Ev GBDocument214 pagesManual Agy-Ev GBstankovukanovicNo ratings yet

- Mlpower: R S T N Pe Outx-P:2-Cr:10ADocument14 pagesMlpower: R S T N Pe Outx-P:2-Cr:10AJavier MartínezNo ratings yet

- Nice 9000Document91 pagesNice 9000Samuel AcevedoNo ratings yet

- Orona 3G X14 EN 1510Document2 pagesOrona 3G X14 EN 1510mohammedalathwaryNo ratings yet

- Soft Start ACS Digistart 3DS30 ManualDocument7 pagesSoft Start ACS Digistart 3DS30 ManualMohamedElsawi100% (1)

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- Gen2 RobustaDocument12 pagesGen2 RobustaKaveenSivasubramaniamNo ratings yet

- Operating Instruction ZETATOP SM160Document38 pagesOperating Instruction ZETATOP SM160yulizardNo ratings yet

- User Manual: Ax Series Lift Control SystemDocument15 pagesUser Manual: Ax Series Lift Control SystemMohd Abu Ajaj100% (1)

- User Manual: Elevator Door ControllerDocument18 pagesUser Manual: Elevator Door Controllerzaki zakiNo ratings yet

- VFD-ED-S Eng Manual 20150204 PDFDocument228 pagesVFD-ED-S Eng Manual 20150204 PDFZomaarNo ratings yet

- FincorElectronics Manuals 2300Document51 pagesFincorElectronics Manuals 2300Angelica GómezNo ratings yet

- MBV191 (N10-VEC01) - Manuel D'installation - GB - Du 13 10 99 (7616) PDFDocument74 pagesMBV191 (N10-VEC01) - Manuel D'installation - GB - Du 13 10 99 (7616) PDFKhaled ZakariaNo ratings yet

- Explanation of SymbolsDocument26 pagesExplanation of SymbolsRaja Durai100% (1)

- Ml40P Control Panel Connection, Pit and Floor Wiring SchemesDocument62 pagesMl40P Control Panel Connection, Pit and Floor Wiring Schemeskoceila HAMMADNo ratings yet

- CX User ManuelDocument26 pagesCX User ManuelSafi100% (3)

- Konel Evo Pro +a3 CeDocument1 pageKonel Evo Pro +a3 CeSENER AKSOYNo ratings yet

- MicroZed v35 CatalogDocument32 pagesMicroZed v35 CataloghabibullaNo ratings yet

- 01 SNP PCBs r0Document28 pages01 SNP PCBs r0Renee CarranzaNo ratings yet

- Fältcom ECII Flex: ManualDocument41 pagesFältcom ECII Flex: ManualMohamed HajjiNo ratings yet

- CX/ELF Series Lift Control System: User ManualDocument26 pagesCX/ELF Series Lift Control System: User ManualMohamed Saad100% (2)

- Axial Motor Machine Mx06: Spare Parts ManualDocument13 pagesAxial Motor Machine Mx06: Spare Parts ManualMarta Silva VenturaNo ratings yet

- Yaskawa L100A Pasarela PDFDocument502 pagesYaskawa L100A Pasarela PDFCarlos Eduardo Price Muñoz100% (1)

- Flex 2: Electric Screw Driven Platform LiftDocument24 pagesFlex 2: Electric Screw Driven Platform LiftCatur Putra SuadnyanaNo ratings yet

- ATV LIFT Programming Manual EN BBV19478 04 PDFDocument345 pagesATV LIFT Programming Manual EN BBV19478 04 PDFApexBD01No ratings yet

- Ethan Frome Quick Guide for Kollmorgen Control SystemDocument31 pagesEthan Frome Quick Guide for Kollmorgen Control SystemJibjab7No ratings yet

- QCM-320 Rev-B1 - NBDZDocument19 pagesQCM-320 Rev-B1 - NBDZبن يامة حسام الدينNo ratings yet

- AS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFDocument296 pagesAS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFRogério da Silva de OliveiraNo ratings yet

- A2000 Door Operator Controller: QMA (Shanghai) Electric Co., LTDDocument85 pagesA2000 Door Operator Controller: QMA (Shanghai) Electric Co., LTDJesús David Diaz MontesNo ratings yet

- ENG Icaro Seriale V1.9 PDFDocument4 pagesENG Icaro Seriale V1.9 PDFMohamad NawloNo ratings yet

- Controller: Installation & CommissioningDocument100 pagesController: Installation & CommissioningGanesh Kotian100% (1)

- Spare Part ListDocument8 pagesSpare Part ListUmer FarooqNo ratings yet

- Plano Mikrolift Ml50sDocument61 pagesPlano Mikrolift Ml50sJavier MartínezNo ratings yet

- Arcode Geared Sp-16 Cpc-T.enDocument38 pagesArcode Geared Sp-16 Cpc-T.enAbdallh YassenNo ratings yet

- Rescue V Rescue V1.4 1.4: User'S ManualDocument36 pagesRescue V Rescue V1.4 1.4: User'S Manualbouabdallah badisNo ratings yet

- Door Drive Operating Instructions ID Unique PM.2.000186ENDocument15 pagesDoor Drive Operating Instructions ID Unique PM.2.000186ENHugo SoaresNo ratings yet

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocument7 pagesTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaNo ratings yet

- AU6860B Datasheet v01Document14 pagesAU6860B Datasheet v01david29xNo ratings yet

- SB 2 003229 en 01Document2 pagesSB 2 003229 en 01gustavo sanchezNo ratings yet

- g400 en PDFDocument13 pagesg400 en PDFReynold SuarezNo ratings yet

- Combivert: Instruction ManualDocument36 pagesCombivert: Instruction Manualruisengo100% (1)

- 1103A 33TG2 ElectropaK NOV14Document2 pages1103A 33TG2 ElectropaK NOV14Ursula Dina PratiwiNo ratings yet

- Manual Power Wizard 1.0Document80 pagesManual Power Wizard 1.0Eduard Machado100% (5)

- Features Lift Controller MLC-8000 01Document4 pagesFeatures Lift Controller MLC-8000 01Hani KatanaNo ratings yet

- Mégalift Quote Request - Load Lift: Commercial Manager Estimate Ref. N°Document2 pagesMégalift Quote Request - Load Lift: Commercial Manager Estimate Ref. N°Hani KatanaNo ratings yet

- Bidi-Switch: Power Switch Bidirectional InterfaceDocument9 pagesBidi-Switch: Power Switch Bidirectional InterfaceSupuran RichardoNo ratings yet

- Switching Behavior Improvement of Insulated Gate Controlled DevicesDocument9 pagesSwitching Behavior Improvement of Insulated Gate Controlled DevicesOsman T.No ratings yet

- El2.e - 001Document2 pagesEl2.e - 001kamalNo ratings yet

- nRF52 DK User Guide v1.2 PDFDocument30 pagesnRF52 DK User Guide v1.2 PDFMylena ReisNo ratings yet

- CPDprogram ELECTRICALENG-32919 PDFDocument102 pagesCPDprogram ELECTRICALENG-32919 PDFJurgen Robert TumlosNo ratings yet

- Device Properties Manual For Programming Cards - DPD00705V004Document34 pagesDevice Properties Manual For Programming Cards - DPD00705V004KyleNo ratings yet

- Cons Trucci On TelmexDocument68 pagesCons Trucci On TelmexGjurinovic Enriquez GotNo ratings yet

- Generator Protection RelayDocument195 pagesGenerator Protection Relayvaksreedharan100% (1)

- 9K688NDocument7 pages9K688NHelar Armejo VasquezNo ratings yet

- WPS D1.3-2012 BlankDocument1 pageWPS D1.3-2012 BlankpjbedelNo ratings yet

- Catalogue 2023Document70 pagesCatalogue 2023amirul adikaNo ratings yet

- Pinza Prova 5601Document2 pagesPinza Prova 5601Sublimec San RafaelNo ratings yet

- Inovance Err Trouble Shooting GuideDocument23 pagesInovance Err Trouble Shooting GuideSohag Walle UllahNo ratings yet

- Data Sheet 6ES7323-1BL00-0AA0: Supply VoltageDocument3 pagesData Sheet 6ES7323-1BL00-0AA0: Supply VoltageQuy HoangNo ratings yet

- S8VM Power Supplies Will Be Discontinued February 2019: Overview SummaryDocument27 pagesS8VM Power Supplies Will Be Discontinued February 2019: Overview Summaryrizky nurmansyahNo ratings yet

- LT8570 1Document34 pagesLT8570 1Malik ZainNo ratings yet

- TV Tuner Functions and Front-End ServicingDocument32 pagesTV Tuner Functions and Front-End ServicingAriel BecerraNo ratings yet

- UNITROL Now - 67 - 13Document24 pagesUNITROL Now - 67 - 13nileshNo ratings yet

- GFE-AD analogue addressable detectors data sheetDocument1 pageGFE-AD analogue addressable detectors data sheetAdrian OprisanNo ratings yet

- BOQ for construction of 1x5 MVA 33/11 KV Sub-stationDocument8 pagesBOQ for construction of 1x5 MVA 33/11 KV Sub-stationShadab WaseemNo ratings yet

- Abb Soft StarterDocument120 pagesAbb Soft Starternaaf3350% (1)

- 12 - Control and MonitoringDocument50 pages12 - Control and Monitoringlam266No ratings yet

- How Does A Brushless Electric Motor Work - HowStuffWorks PDFDocument2 pagesHow Does A Brushless Electric Motor Work - HowStuffWorks PDFAnil JobyNo ratings yet

- 2414 IS-ThermalModelCalculations 20210805Document10 pages2414 IS-ThermalModelCalculations 20210805jorge_moralesmNo ratings yet

- D. Intermediate Frequency. 2. Magnetrons Commonly: (Mid RS)Document12 pagesD. Intermediate Frequency. 2. Magnetrons Commonly: (Mid RS)aziz100% (1)

- Universal Circuit BreakerDocument3 pagesUniversal Circuit BreakerMalith DeemanthaNo ratings yet

- Enviromental Effect On Voltage Ac Transmission Lines Audible Noise A. AI-FarajDocument6 pagesEnviromental Effect On Voltage Ac Transmission Lines Audible Noise A. AI-Farajömer InceNo ratings yet

- User'S Manual: Sysdrive 3G3FvDocument401 pagesUser'S Manual: Sysdrive 3G3FvdesmauroNo ratings yet

- Radiant Power Corp. Component Maintenance Manual Part Number Cbs24Document95 pagesRadiant Power Corp. Component Maintenance Manual Part Number Cbs24Philipp Pyro100% (1)

- Time Varying SignalsDocument17 pagesTime Varying SignalsDiego Cancino SilvaNo ratings yet