Professional Documents

Culture Documents

Propeller Maintenance Manual 132A: Page 7-50 Rev. 22 Dec/20

Uploaded by

Alexis Kidema0 ratings0% found this document useful (0 votes)

42 views3 pagesOriginal Title

hartzell prop blade

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views3 pagesPropeller Maintenance Manual 132A: Page 7-50 Rev. 22 Dec/20

Uploaded by

Alexis KidemaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

PROPELLER MAINTENANCE MANUAL

132A

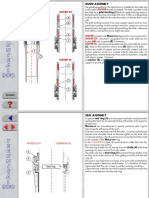

23. Checking for Blade Slippage in Blade Clamp

A. All Propeller Models

(1) With the propeller still mounted on the rotatable fixture of the assembly table,

proceed as follows to provide for visual detection of slippage between the blade

base and the blade clamp.

CAUTION: DO NOT USE A PUNCH OR SCRIBE A LINE ON THE BLADE

BASE. THIS COULD START A CRACK IN THE BLADE.

(a) After you make sure that each blade has the correct pitch, apply a strip

of red plastic tape down the base and across the blade clamp of Blade

Number One as shown in Figure 7-17.

NOTE: If the blade will later be removed to facilitate shipping the

propeller, apply two strips of red tape across each mated blade

base and blade clamp assembly to mark the correct pitch.

(b) Carefully slit the tape along the line where the blade base and blade clamp

meet.

(c) Spray the pieces of tape with lacquer so cleaning solvent will not wash

them off.

(d) Repeat this procedure on the other four blade assemblies.

NOTE 1: After rough flight operations or when the spinner is removed for

maintenance, check the alignment of the pieces of tape on each

blade to detect any slight rotation of a blade base in a blade

clamp.

NOTE 2: Misalignment of the halves of tape on a blade assembly

indicates slippage between the blade base and blade clamp.

Follow the rework procedure in the Blade Clamp Overhaul

chapter of Hartzell Propeller Inc. Standard Practices

Manual 202A (61‑01‑02) to correct blade slippage.

CAUTION: DO NOT PLACE THE PADDED BAR IN THE AREA OF THE

DE-ICE BOOT WHEN APPLYING TORQUE TO A BLADE

ASSEMBLY. PLACE THE BAR IN THE THICKEST AREA OF

THE BLADE, JUST OUTBOARD OF THE DE-ICE BOOT. USE

ONE BLADE PADDLE PER BLADE.

(e) Using a padded blade bar, apply a torque to each blade assembly in

accordance with Torque Values Table 8-1 in the Fits and Clearances

chapter of this manual, as shown in Figure 7-18.

1 Set the propeller to low pitch position and torque the blade toward

low pitch.

(f) If necessary to correct blade slippage, refer to the Blade Clamp Overhaul

chapter of Hartzell Propeller Inc. Standard Practices Manual 202A

(61-01-02).

ASSEMBLY 61-10-32 Page 7-50

Rev. 22 Dec/20

PROPELLER MAINTENANCE MANUAL

132A

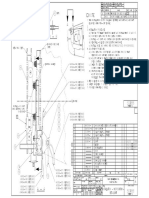

CM93 Sealant

W10348

Sealant CM93 Application

Figure 7-19

ASSEMBLY 61-10-32 Page 7-51

Rev. 22 Dec/20

PROPELLER MAINTENANCE MANUAL

132A

(g) Sealant CM93 Application

1 The application of sealant CM93 to the blade/blade clamp interface is

an optional procedure that may provide additional protection against

corrosion of the blade retention components.

NOTE: Do not apply sealant CM93 to the blade/blade clamp

interface if the blades will be removed to facilitate shipment

of the propeller.

CAUTION 1: TO AVOID PERMANENT DAMAGE TO THE BLADE

RETENTION COMPONENTS CAUSED BY TRAPPED

CHEMICALS, THIS PROCEDURE MUST ONLY BE

PERFORMED FOLLOWING THE ASSEMBLY OF A

PROPELLER AFTER OVERHAUL OR AFTER ANY

OTHER PROCEDURE INVOLVING DISASSEMBLY AND

CLEANING OF THE PROPELLER BLADE RETENTION

COMPONENTS.

CAUTION 2: TO MAKE SURE OF CORRECT ADHESION OF

SEALANT CM93, BLADE AND BLADE CLAMP

SURFACES MUST BE FREE OF GREASE AND DIRT.

2 After performing the check for blade slippage in the clamp, fill the

external void at the blade/blade clamp interface with a

0.25 inch (6.3 mm) maximum bead of sealant CM93, around the

entire circumference of the blade, as shown in Figure 7-19.

3 Permit the sealant to cure for a minimum of two hours, before

returning the propeller to service.

NOTE: Do not permit the CM93 to extend onto the surface of the

clamp, where balance weights and de-ice hardware are

installed.

ASSEMBLY 61-10-32 Page 7-52

Rev. 22 Dec/20

You might also like

- Checking for Blade SlippageDocument3 pagesChecking for Blade SlippageAlexis KidemaNo ratings yet

- Propeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Document7 pagesPropeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Alexis Kidema0% (1)

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Transfluid Montage Och SkotselinstruktionDocument16 pagesTransfluid Montage Och SkotselinstruktionRinto SilalahiNo ratings yet

- Connecting Rod Bearings - Install PDFDocument3 pagesConnecting Rod Bearings - Install PDFGeorge GuerreroNo ratings yet

- Corrections To Repair Manual RM1E: Prado 10Document3 pagesCorrections To Repair Manual RM1E: Prado 10Master XeotoNo ratings yet

- Con Rod TorqueDocument3 pagesCon Rod TorqueJerson T. AltovarNo ratings yet

- Maintaining Flowline EquipmentDocument23 pagesMaintaining Flowline Equipmentralph100% (1)

- Shiver DCDocument12 pagesShiver DCAndreas P.No ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsandres castroNo ratings yet

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5ADocument7 pagesRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungNo ratings yet

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- Sensenich Ground Adjustable Propeller Log BookDocument12 pagesSensenich Ground Adjustable Propeller Log BookFaisNo ratings yet

- Mccauley Propeller Systems Owner Operator Information ManualDocument6 pagesMccauley Propeller Systems Owner Operator Information ManualElLoko MartinesNo ratings yet

- Assembly Manual: SpecificationsDocument19 pagesAssembly Manual: SpecificationsParpala BogdanNo ratings yet

- IOM Manual C132355.SflbDocument14 pagesIOM Manual C132355.SflbVenkat SubramanianNo ratings yet

- AC 665-39005, 665-1180-038 - en (Main Boom Extension)Document94 pagesAC 665-39005, 665-1180-038 - en (Main Boom Extension)arslanahmedkhawajaNo ratings yet

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- Thruster 140-300TT - B500100 Iss 6Document28 pagesThruster 140-300TT - B500100 Iss 6Heriberto TorresNo ratings yet

- 72 50 02Document6 pages72 50 02alvaro lemosNo ratings yet

- Maintaining Aircraft Adapter Safety with the Model 61657-2 Wear GaugeDocument4 pagesMaintaining Aircraft Adapter Safety with the Model 61657-2 Wear GaugeHenryNo ratings yet

- SEA2560 ManualDocument21 pagesSEA2560 ManualPablo MartorellNo ratings yet

- Service Manual Chamber 5011-16Document8 pagesService Manual Chamber 5011-16AwanNo ratings yet

- Petter Marine Diesel Engines Setup GuideDocument33 pagesPetter Marine Diesel Engines Setup Guidesergiozed0% (1)

- F 90Document35 pagesF 90ulises100% (1)

- 19d Impeller SpacingDocument9 pages19d Impeller Spacingbtgottlieb100% (1)

- Temporary Revision Number 7: © Textron Aviation IncDocument62 pagesTemporary Revision Number 7: © Textron Aviation IncJean Mark SilvestreNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument106 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Cap562 999Document213 pagesCap562 999DavidGarcíaNo ratings yet

- Cylinder Blok c4Document7 pagesCylinder Blok c4lilikNo ratings yet

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 pagesJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunNo ratings yet

- BR3 007 ManualDocument5 pagesBR3 007 ManualRodrigo Jechéla BarriosNo ratings yet

- C11 2Document44 pagesC11 2Digambar JadhavNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- 78 36 00 410 040 BDocument5 pages78 36 00 410 040 BRohan SinghNo ratings yet

- Frame and Underbody: Section 9NDocument6 pagesFrame and Underbody: Section 9NJarry PotterNo ratings yet

- Qa-Lhb-Draft Gear & CouplingDocument4 pagesQa-Lhb-Draft Gear & CouplingSriram SubramanianNo ratings yet

- Osn 407-19-23Document22 pagesOsn 407-19-23ferbmdNo ratings yet

- 09 10 00 SeDocument18 pages09 10 00 SeAdrian LauNo ratings yet

- Static Discharger Maintenance PracticesDocument3 pagesStatic Discharger Maintenance PracticesSahil SodhiNo ratings yet

- McFarlane Shimmy Dampner ManualDocument6 pagesMcFarlane Shimmy Dampner ManualmidunNo ratings yet

- Super DecathlonDocument22 pagesSuper DecathlonIwan MaspaitellaNo ratings yet

- Assembly Instructions: Folding MarkersDocument6 pagesAssembly Instructions: Folding MarkersPetrNo ratings yet

- Bromma Telescopic Spreader EH5U PDFDocument418 pagesBromma Telescopic Spreader EH5U PDFsubhan.ubaedillah100% (3)

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- Steering Spherical Bearing Wear LimitsDocument2 pagesSteering Spherical Bearing Wear LimitsJose A. Basanta H.No ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Fis190 en A5Document8 pagesFis190 en A5andhucaosNo ratings yet

- Installation Procedure: NoticeDocument3 pagesInstallation Procedure: NoticeGlaidsonNo ratings yet

- John Deere CT322 Compact Track Loader Service Repair Manual (TM2152)Document17 pagesJohn Deere CT322 Compact Track Loader Service Repair Manual (TM2152)laopaodunNo ratings yet

- 206-19-42 July 2019Document9 pages206-19-42 July 2019turboshaftNo ratings yet

- Modification Instruction: Truck, Medium, Mc2, Unimog - All TypesDocument3 pagesModification Instruction: Truck, Medium, Mc2, Unimog - All TypesmichaelNo ratings yet

- Replacement: - Front Brake PadDocument2 pagesReplacement: - Front Brake PadMiguel AngelNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Er 82Document2 pagesEr 82Dibyendu ChakrabortyNo ratings yet

- Bastidor D10T (Radiador)Document10 pagesBastidor D10T (Radiador)Israel MirandaNo ratings yet

- Sec 1-AirOperatedBacksaverDocument16 pagesSec 1-AirOperatedBacksaverRuben CondeNo ratings yet

- Manual de La Bop 3.06 15M PDFDocument28 pagesManual de La Bop 3.06 15M PDFJack FosterNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Propeller Maintenance Manual 132A: Page 7-46 Rev. 22 Dec/20Document1 pagePropeller Maintenance Manual 132A: Page 7-46 Rev. 22 Dec/20Alexis KidemaNo ratings yet

- Propeller manual beta system assemblyDocument2 pagesPropeller manual beta system assemblyAlexis KidemaNo ratings yet

- Fits and Clearances - Contents: Propeller Maintenance Manual 132ADocument8 pagesFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaNo ratings yet

- Ipc Cleveland Wheels & BrakesDocument295 pagesIpc Cleveland Wheels & Brakesjarrison50% (2)

- Propeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Document46 pagesPropeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Alexis KidemaNo ratings yet

- 5 0324 RG ManualDocument21 pages5 0324 RG ManualT/ROXNo ratings yet

- Testing and Troubleshooting - Contents: Propeller Owner's Manual 139Document10 pagesTesting and Troubleshooting - Contents: Propeller Owner's Manual 139Alexis KidemaNo ratings yet

- SL Hartzell 2016Document36 pagesSL Hartzell 2016Alexis KidemaNo ratings yet

- Propeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Document46 pagesPropeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Alexis KidemaNo ratings yet

- 206 - Concorde Battry CMM-24-30-71Document39 pages206 - Concorde Battry CMM-24-30-71irakgonzalezNo ratings yet

- Propeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Document46 pagesPropeller Maintenance Manual 132A: Page 5-5 Rev. 22 Dec/20Alexis KidemaNo ratings yet

- Micro Smith Beta Light 67 FDocument1 pageMicro Smith Beta Light 67 FAlexis KidemaNo ratings yet

- At - 802 Rigging Procedures 2015Document15 pagesAt - 802 Rigging Procedures 2015Alexis KidemaNo ratings yet

- Fire Boss ManualDocument91 pagesFire Boss ManualAlexis KidemaNo ratings yet

- Fire Boss ManualDocument91 pagesFire Boss ManualAlexis KidemaNo ratings yet

- Hubungan Derajat Merokok Dengan Nilai Arus Puncak Ekspirasi Pada Pria Dewasa Awal (20-40 Tahun) Di Desa Tampaksiring, Kecamatan TampaksiringDocument8 pagesHubungan Derajat Merokok Dengan Nilai Arus Puncak Ekspirasi Pada Pria Dewasa Awal (20-40 Tahun) Di Desa Tampaksiring, Kecamatan TampaksiringBima SorayaNo ratings yet

- 20-1-16 LS Dyna - SHPB Analysis FinalDocument7 pages20-1-16 LS Dyna - SHPB Analysis FinalJayDeep KhajureNo ratings yet

- Boq ChandigarhDocument2 pagesBoq ChandigarhVinay PantNo ratings yet

- Cold Seal Plain Paper 55mm-SpecDocument1 pageCold Seal Plain Paper 55mm-Specilyas khan100% (1)

- Manual de Instrucciones GA 11-22 - AII 229653 PDFDocument38 pagesManual de Instrucciones GA 11-22 - AII 229653 PDFJ Angel Martinez C100% (1)

- Jedec 22B112A 1Document30 pagesJedec 22B112A 1Shih Chien ChenNo ratings yet

- FP Diesel New Numbers Announcement Aug 17Document3 pagesFP Diesel New Numbers Announcement Aug 17Hebert MedinaNo ratings yet

- FLLTDocument34 pagesFLLTShyam SNo ratings yet

- HES2125 10S2 Revision01Document4 pagesHES2125 10S2 Revision01Roberto RizzoNo ratings yet

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Inversor Min Growatt 8000 TL XDocument2 pagesInversor Min Growatt 8000 TL XIngenieria 2No ratings yet

- Government of Chhattisgarh: Ublic Orks EpartmentDocument19 pagesGovernment of Chhattisgarh: Ublic Orks EpartmentLucky ChopraNo ratings yet

- CG Notes Unit5Document24 pagesCG Notes Unit5Rahul PatilNo ratings yet

- Compaction Factor TestDocument3 pagesCompaction Factor TestNitisha Rathore100% (5)

- IEEE STD'sDocument7 pagesIEEE STD'sRajmohanNo ratings yet

- TM 9-1651 Data Transmission System m3, January 1942Document78 pagesTM 9-1651 Data Transmission System m3, January 1942Advocate100% (1)

- Engine Control Module (ECM) X2 (LXV)Document2 pagesEngine Control Module (ECM) X2 (LXV)carloNo ratings yet

- 5WMNT 01CDocument2 pages5WMNT 01CSaraiNo ratings yet

- Oxmetrics ManualDocument238 pagesOxmetrics ManualRómulo Tomé AlvesNo ratings yet

- Flash Anf Fire PointDocument8 pagesFlash Anf Fire PointMUHAMMAD AKRAM100% (2)

- Concrete Bridges in GermanyDocument12 pagesConcrete Bridges in GermanydelujaNo ratings yet

- Rate Analysis for South Tripura District construction projectsDocument3 pagesRate Analysis for South Tripura District construction projectsSushanta DasNo ratings yet

- API 5L Grade X52 Pipe SpecificationDocument4 pagesAPI 5L Grade X52 Pipe SpecificationEngr ÄiSeraj AlamNo ratings yet

- Shotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Document26 pagesShotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Đông Nguyễn100% (1)

- Comparative Study of Bioethanol and Commercial EthanolDocument21 pagesComparative Study of Bioethanol and Commercial Ethanolanna sophia isabelaNo ratings yet

- Trade Secret Complaint Against GoogleDocument24 pagesTrade Secret Complaint Against GoogleNitasha TikuNo ratings yet

- CHEMICAL BONDING typesDocument68 pagesCHEMICAL BONDING typesHarsh Tyagi100% (2)

- CUPRA TCR SEQ Technical Form - Final-1Document109 pagesCUPRA TCR SEQ Technical Form - Final-1jaime cid monzoNo ratings yet