Professional Documents

Culture Documents

Status Code LLC and LLS or Any Other Visual Feedback: Alarm Displayed After Start or Detected by The Self Test

Status Code LLC and LLS or Any Other Visual Feedback: Alarm Displayed After Start or Detected by The Self Test

Uploaded by

Balan OlivianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Status Code LLC and LLS or Any Other Visual Feedback: Alarm Displayed After Start or Detected by The Self Test

Status Code LLC and LLS or Any Other Visual Feedback: Alarm Displayed After Start or Detected by The Self Test

Uploaded by

Balan OlivianCopyright:

Available Formats

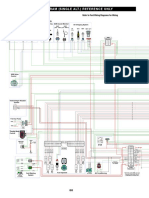

Trouble Shooting Dialog+ EVO Self Test SW 9.

12

Alarm displayed after start or detected by the self test status code LLC and LLS or any other visual feedback Possible causes Test in TSM to do most possible reaso second third

System Error alarm sound from SMPS and loudspeaker no communication TLC to LLC/LLS analysis according separate "System Error trouble shooting" instruction

RAM/ROM Error Error in SW or in the BIOS setting TSM TL Manual Test "File system Check" reload software and check for analysis the LEDs on LLD board / exchanged CF card and motherboard

CRC calibration error Error in the calibration data check the instruction in the LLC and LLS status line confirm setting in production report and calibration recommended Sensor from the Status list

Analog Voltage +-12 out of range fuse / LEDs on SMPS SMPS, Analog or Digital defect TSM low level test 1.1 "+-12V Analog Test" exchanged defective part Analog Board SMPS

Alarm water supply disturbed This alarm occur at any time during the entire operation inlet pressure to low, DMV offset TSM low level test 1.9 “Water Inlet” adjust the pressure reducer valve DMV offset DMV

inlet valve defective TSM low level test 1.9 “Water Inlet” change inlet valve

level sensor defective TSM low level test 1.9 “Water Inlet” change level sensor

power board valve defective TSM low level test 1.9 “Water Inlet” change power board valve

no priming of the system none of the pumps EP/FPE/FPA runs fuse F600 M10A/+24VL blown (SMPS MC) TSM low level test 1.13 / 1.14 / 1.25 Valves replace fuse Fuse F600

for example short circuit 24V at one of the solenoid valves or wire isolate short circuit

Water overflow water runs constant under the machine level sensor or float defective TSM low level test 1.9 “Water Inlet” replace level sensor respective float

via the overflow tube of the up line tank water inlet valve VVBE is stuck open or DMV defective TSM low level test 1.9 “Water Inlet” check inlet valve and DMV on particle

Valve VZ leaking TSM low level test 1.14 Bypass and Disinfection Valves

Service Mode (DIR_ON) LLC 2610x - 2699x LLS 26001 Service jumper X101 is connected TSM low level test 1.30 "SMPS Self test" remove the jumper

Sound and LED test Safety system check: red LEDs, buzzer, loudspeaker and 24 safety relays cable inside the monitor defective / disconnected, Frond Panel Board defecTSM low level test 1.28 front panel board FPB open the monitor and check all connection

LLC 1610x - 1699x LLS 16001 - 16028 SMPS MC safety relays defective TSM low level test 1.1 "24VGB and 24VGD Test" exchange the relays

SMPS-MC EEPROM LLC 2510x - 2599x LLS 25001 SMPS-MC defective TSM low level test 1.30 "SMPS Self test" Test #113 exchange SMPS MC

Battery Test LLC 2710x - 2799x LLS 27001 Battery not loaded or fuse defective TSM low level test 1.30 "SMPS Self test" Test #112 open the Battery sub rack, check the fuse, charge / exchange battery

Buzzer Test via LLS LLC 2810x - 2899x LLS 28001 - 28003 buzzer or main switch defective TSM low level test 1.30 "SMPS Self test" Test #115 check the main switch (second level), exchange main switch or buzzer on SMPS

Monitoring of analog voltage ± 12 V LLC 1710x - 1799x LLS 17001 - 17031 SMPS, Analog or Digital Board defect TSM low level test 1.1 "+-12V Analog Test" exchanged defective part

Blood Leak Detector LLC 1102x - 1199x LLS 11000 - 11012 air in the system, calcification, blood leak defective TSM low level test 1.18 "Blood Leak" check the system for air, calibrate the blood leak, exchanged the module

DFS Pressure Test required MSBK1/2 = 16000 LLC 1220x LLS 12000 - 12019 air in the system, MSBK1/2 position sensor or membrane defective TSM low level test 1.15 balance chamber check the feedback value MSBK1/2 (15000 - 30000), check with syringe and manometer at FBK1

required pressure PDA > 425 mmHg LLC 1221x LLS 12020 PDA defective TSM low level test 1.16 pressure sensors water side check PDA Sensor

air in the system, leakage (liquid exit/air entry) O-ring defective, rinsing bridge need maintenance TSM low level test 1.27 DFS pressure test of therapy bypass the rinsing bridge, check where the air is comming from, maintenance of rinsing bridge

no pressure build-up on PDA FPE or RVFPE defectiv, VDABK1/2 leaking TSM low level test 1.20 overview water part check FPE and RVFPE

no pressure build-up on PDA leak at VDABK1/2 TSM Low Level test 1.19 Automatic Leakage Test check with clamping scissors VDABK1/2

requiment pressure PDA <= 380 mmHg LLC 1230x LLS 12021 Valve VDEBK1/2 leaking TSM Low Level test 1.19 Automatic Leakage Test check with clamping scissors VDEBK1/2

no pressure reduction on PDA UF pump defectiv, drain tube snapped off check UF pump and drain tube

feedback signal valves LLC 1235x LLS 12021 - 12026 power board valves defective, connector or cable defective TSM low level test 1.13 / 1.14 / 1.25 Valves isolate defectiv part

PDA out of range 300 mmHg < PDA < +450 mmHg LLC 1235x LLS 12027 - 12038 valve VDE/VBP permanent open TSM low level test 1.27 DFS pressure test of therapy

Max. deviation PDA > 25 mmHg Pressure increase on PDA Leakage of a valve VDE/VBP TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VDE / VBP

Max. deviation PDA > 25 mmHg Pressure reduction on PDA Leakage of a valve VDABK1/2 or on UF pump TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VDABK1/2 repective on UF pump during pump stop UF pump

feedback signal valves LLC 1240x LLS 12061 - 12066 power board valves defective, connector or cable defective TSM low level test 1.13 / 1.14 / 1.25 Valves isolate defectiv part

PDA out of range 300 mmHg < PDA < +380 mmHg LLC 1240x LLS 12067 - 12078 Leakage of a valve VDA TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VDA

requiment pressure PDA > 425 mmHg LLC 1245x LLS 12101 no failer known

requiment pressure PDA < 380 mmHg LLC 1250x LLS 12101 no pressure decrease, valve VDEBK1/2 leaking TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VDEBK1/2

feedback signal valves LLC 1255x LLS 12101 -12121 power board valves defective, connector or cable defective TSM low level test 1.13 / 1.14 / 1.25 Valves isolate defectiv part

Max. deviation PDA 25 mmHg LLC 1255x LLS 12122 -12133

Pressure increase on PDA Leakage of the membrane TSM low level test 1.13 valves and 1.15 balance chamber check with syringe and manometer at FBK1 the membrane

Pressure reduction on PDA Leakage of a valve VABK1/2 TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VABK1/2

requiment pressure PDA > 425 mmHg LLC 1260x LLS 12151 no failer known

requiment stable value MSBK1/2 LLC 1265x LLS 12151 membrane defectiv TSM low level test 1.15 balance chamber maintenance balancing chamber, exchange of membrane

requiment pressure PDA <= 380 mmHg LLC 1270x LLS 12151 no failer known

feedback signal valves LLC 1275x LLS 12151 - 12161 power board valves defective, connector or cable defective TSM low level test 1.13 / 1.14 / 1.25 Valves isolate defectiv part

Max. deviation PDA 25 mmHg LLC 1275x LLS 12162 - 12183

Pressure increase on PDA Leakage of the membrane VEBK1/2 TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VEBK1/2

Pressure reduction on PDA Leakage of a valve VABK1/2 or UF pump TSM low level test 1.27 DFS pressure test of therapy check with clamping scissors VABK1/2 repective on UF pump during pump stop UF pump

pressure PDA Trouble-Shooting

DFS Pressure Test between - 200 mmHg and 200 mmHg

at intermittent faultsLLC 1280x LLS 12162 - 12000 unknown

minor leak at any valve, UF pump,… TSM low level test 1.19 Leak Test check with two clamping scissors, start from PDA

Integrity Test HDF Onlin reqiuments feedback ports and BP cover LLC 1502x no feedback from PSAUS, PSABF or BPV TSM low level test 1.3 BP Venous and 1.25 HDF online Detecheck feedback sensors

feedback signal valves LLC 1510x LLS 15001 - 15010 power board online defective, connector or cable defective TSM low level test 1.13 / 1.14 / 1.25 Valves isolate defectiv part

first negative test PDA <-300mmHg / Max. deviation PDA 50 mmHg LLC 1515x LLS 15011 - 15018 minor leak from FPE to RVDA anywhere TSM low level test 1.19 Leak Test check for air intake and with two clamping scissors , start from PDA

LLC 1520x VSAA / Port O-ring defectiv TSM low level test 1.19 Leak Test check visual for air intake at the port connectors, maintain O-ring and adjust port doors

feedback signal valves LLC 1525x LLS 15021 - 15030 power board online defective, connector or cable defective TSM low level test 1.25 HDF online Valves isolate defectiv part, power board HDF online

Max. deviation PDA 50 mmHg LLC 1525x LLS 15031 - 15032 VSAE Valve or port connection leaking TSM low level test 1.19 Leak Test check with clamping scissors at VSAE

Test Online Substitution Pump LLC 1525x LLS 15033 - 15039 Blood pump roller or pump venous defectiv TSM low level test 1.3 Blood Pump Venous check the feedback signals speed and direction

feedback signal valves LLC 1530x LLS 15041 - 15050 power board online defective, connector or cable defective TSM low level test 1.25 HDF online Valves isolate defectiv part, power board HDF online

Max. deviation PDA 50 mmHg LLC 1535x LLS 15051 - 15058 VSAA Valve or port connection leaking TSM low level test 1.19 Leak Test check with clamping scissors at VSAA

feedback signal valves LLC 1540x - 1560x LLS 15101 - 15110 power board online defective, connector or cable defective TSM low level test 1.25 HDF online Valves isolate defective part, power board HDF online

pressure reduction with UF pump, PDA < -250 mmHg LLC 1540x - 1560x LLS 15110 - 15111 DF Filter problem TSM low level test 1.24 HDF online troubleshooting as described in the training document DF Filter (the lower one)

DDE or RVDA offset > 50 mmHg TSM low level test 1.20 overview water part check RVDA and DDE throttle adjustment

pressure increase to - 100 mmHg LLC 1565x LLS 15121 - 15127 HFB Filter blocked or tube to the filter kinked TSM low level test 1.24 HDF online troubleshooting as described in the training document

Integrity Test HDF Online Trouble-Shooting at intermittent faults minor leak at any valve, UF pump,… TSM low level test 1.19 Leak Test check with two clamping scissors, start from PDA (only negative test required)

UF Pump test LLC 2002x LLS 20000 - 20012 feedback sensor LLS defective TSM low level test 1.17 UF pump check the supervisor feedback status reed or hall sensor defective

Conductivity Test LLC 2110x - 2199x LLS 20000 - 21012 Analog board or conductivity sensor defective TSM low level test 1.12 Concentrate Pumps and Conductivit check the conductivity values of all sensors visual and with a instrument, check all connectors calcification Analog Board Conductivity cell leaking

Temperature Test LLC 2202x - 2299x LLS 22000 - 22012 Temperature sensor or Analog Board defective TSM low level test 1.11 Concentrate Pumps and Conductivit check temperature sensor about leaking and correct flow direction sensor wet wrong direction assembled

SAD Level Test LLC 3002x - 3099x LLS 30000 - 30009 SAD defective, calibration out of range TSM low level test 1.7 Air Sensor, Red Sensor calibrate the SAD SAD

SAD Counter Test LLC 3102x - 3199x LLS 31000 - 31008 SAD, Digital or Analog Board defective TSM low level test 1.7 Air Sensor, Red Sensor isolate the defective part SAD Analog Board Digital Board

Pressure sensors blood side feedback signal valves LLC 3202x - 3240x LLS 32000 - 32002 level regulation Board defective TSM low level test 1.31 Level Regulation check feedback signals of the valves level regulation board

pressure Test LLC 3250x - 3260x LLS 32004 - 32010 sensor defective, Filter are blocked, wrong connected blood line TSM low level test 1.6 Pressure Sensor (Blood Side) check user setup, internal or external Filter are maybe blocked, pressure comparing user setup blocked Filter LR Board leaking

all trend code > 32768 are negative at the trend file calculate 65536 to the negative value and you get the real test code example 65536 -32534 = 32002

Pressure Test Substitution Line PA >270 mmHg LLC 4002x - 4020x LLS 40000 - 40011 clamp on tubing system still closed / DF filter problem TSM low level test 1.24 HDF online troubleshooting as described in the training document

LLC 4030x - 4099x LLS 40012 - 40019 Throttle DDE has an offset TSM low level test 1.20 overview water part check RVDA and DDE throttle adjustment

Blood Side Pressure Retention blood pump arterial speed test LLC 3302x - 3310x LLS 33000 - 33014 blood pump drive or roller defective, feedback signal missing TSM low level test 1.2 Blood Pump Arterial check the tork and the roller feedback signal roller / bearing defec blood pump drive

pressure test LLC 3330x LLS 33015 - 33023 tubing system not correct connected, leaking, SAKV oversized gap TSM low level test 1.5 Tubing Clamps check bloodline setup, check gap at SAKV (1.4 / 1.5mm), check blood pump roller SAKV gap

LLC 3340x LLS 33024 - 33038 filter on PBE or PBS blocked TSM low level test 1.6 Pressure Sensor (Blood Side) wrong bloodline connection, filter blocked, tube kinked

online tubing test LLC 3350x - 3399x LLS 33039 - 33041 online tubing not correct connected TSM low level test 1.3 Blood Pump Venous check connection and online kit, tubing clamps, check BP venous user setup

DF Filter problem TSM low level test 1.24 HDF online troubleshooting as described in the training document decalcification DF Filter

Disinfection Valve VD LLC 3710x - 3799x LLS 37000 - 37010 feedback signal VD , particle inside the valve TSM low level test 1.14 Bypass and Disinfection Valves clean with hot water and a syringe, adjust the position of switching flag particle adjustment

Adimea Self Test Adimea defect, air in the system TSM Top Level Test ADIMEA Self Test check the inlet tube on air, feedback blood leak sensor and Temperature sensor TSD on 25°C air Adimea

You might also like

- Fault Code 431 (Iss) Accelerator Pedal or Lever Idle Validation Circuit - Data Erratic, Intermittent, or IncorrectDocument15 pagesFault Code 431 (Iss) Accelerator Pedal or Lever Idle Validation Circuit - Data Erratic, Intermittent, or IncorrectAhmedmahNo ratings yet

- Tecu PDFDocument6 pagesTecu PDFAngu Chamy100% (3)

- FORD 6.4l4diesel PDFDocument14 pagesFORD 6.4l4diesel PDFJesus Vega Hummer100% (1)

- Samsung Plasma TV Type PN60E8000GFXZA - Fast Track Troubleshooting Guide - Service ManualDocument7 pagesSamsung Plasma TV Type PN60E8000GFXZA - Fast Track Troubleshooting Guide - Service ManualNorlec HiFi75% (4)

- Troubleshooting Guide Ingersol Rand CompressorDocument3 pagesTroubleshooting Guide Ingersol Rand Compressorahilsergey100% (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Perkins 2506-15Document144 pagesPerkins 2506-15namvinh100% (2)

- Technical Support International: Module 11: Self Test Part 2 HydraulicsDocument26 pagesTechnical Support International: Module 11: Self Test Part 2 HydraulicsBrayan RamírezNo ratings yet

- Sepam s40 Oc Ef RelayDocument12 pagesSepam s40 Oc Ef Relaymuhamad solehNo ratings yet

- 10.3.01 Service Code List - Lindiag Software V2.62A: 1 Overview of Service Codes Cep14 Travel ElectronicDocument12 pages10.3.01 Service Code List - Lindiag Software V2.62A: 1 Overview of Service Codes Cep14 Travel Electronicjabrik bobelNo ratings yet

- Altanova Ebook How To Test A Power TransformerDocument39 pagesAltanova Ebook How To Test A Power TransformerMustapha Aljameel100% (1)

- TT204 Identifying Television SMPS ProblemsDocument4 pagesTT204 Identifying Television SMPS Problemsadrianocpoli4090No ratings yet

- POX-100BT Error Trouble Shooting 20170927Document7 pagesPOX-100BT Error Trouble Shooting 20170927GirayNo ratings yet

- Chery S11 PDFDocument91 pagesChery S11 PDFtiffany0% (1)

- 《TPS-1607-ARD Technical user manual》 -English versionDocument16 pages《TPS-1607-ARD Technical user manual》 -English versionadi waluyoNo ratings yet

- ISA SymbologyDocument41 pagesISA SymbologyBagus AtmajaNo ratings yet

- TI 2018 - 04 Software Version 9.1B (EN)Document56 pagesTI 2018 - 04 Software Version 9.1B (EN)Balan Olivian100% (6)

- TI 2018 - 01 Software Version 9.1A (EN)Document50 pagesTI 2018 - 01 Software Version 9.1A (EN)Balan Olivian100% (2)

- Inst263 - Question 68BDocument1 pageInst263 - Question 68BNGASSAKI ATONGUI Christ HubertNo ratings yet

- SAT 110V 25A DC ChargerDocument9 pagesSAT 110V 25A DC ChargerAzhar RimaNo ratings yet

- Fault Codes: Adm2 Fault Codes (J1939) Spn/Fmi Adm2 Fault Codes (K-Line) Description Remedial Action PinDocument5 pagesFault Codes: Adm2 Fault Codes (J1939) Spn/Fmi Adm2 Fault Codes (K-Line) Description Remedial Action PinivanzlxNo ratings yet

- ClimateMaster Troubleshooting Info Revised 10-04-11Document5 pagesClimateMaster Troubleshooting Info Revised 10-04-11Daniel VeraNo ratings yet

- 220 JBT Info TestreportsDocument5 pages220 JBT Info TestreportsC.H. WEENo ratings yet

- IR145YDocument3 pagesIR145YAndy Kong KingNo ratings yet

- DSAFRAZ0020366Document3 pagesDSAFRAZ0020366amitNo ratings yet

- EMM Codes-InlineDocument2 pagesEMM Codes-Inlineramavtal99No ratings yet

- Rocess Ower UPS System: Three Phase 10-125 kVADocument4 pagesRocess Ower UPS System: Three Phase 10-125 kVAFlorentino PonceNo ratings yet

- ASC Charge Controller ManualDocument24 pagesASC Charge Controller ManualNikolai TuretskyNo ratings yet

- Site Acceptance Test SAT Supervisory Control and Data Acquisition ScadaDocument1 pageSite Acceptance Test SAT Supervisory Control and Data Acquisition ScadaSaeedNo ratings yet

- FordDocument5 pagesFordmiguelNo ratings yet

- LAPD Link Congestion AlarmDocument3 pagesLAPD Link Congestion AlarmanandkusNo ratings yet

- DTC P2769 Torque Converter Clutch Solenoid Circuit Low (Shift Solenoid Valve DSL) Torque Converter Clutch Solenoid Circuit High (Shift Solenoid Valve DSL)Document3 pagesDTC P2769 Torque Converter Clutch Solenoid Circuit Low (Shift Solenoid Valve DSL) Torque Converter Clutch Solenoid Circuit High (Shift Solenoid Valve DSL)Nofiu SodeeqNo ratings yet

- AEG Electrolux Washing Machine EWM100Document6 pagesAEG Electrolux Washing Machine EWM100HelitonNo ratings yet

- Test 330Document5 pagesTest 330Achmad Nanda NidzamNo ratings yet

- Measuring and Monitoring Relay CM-PSS: Three-Phase Monitor For Over-And Undervoltage Data SheetDocument6 pagesMeasuring and Monitoring Relay CM-PSS: Three-Phase Monitor For Over-And Undervoltage Data SheetMinh ToanNo ratings yet

- Kana - Bfc-10-Ch-Std-Ga-Ec-110 VacDocument6 pagesKana - Bfc-10-Ch-Std-Ga-Ec-110 VacJiyaul HaqueNo ratings yet

- Troubleshooting Pulse Width ModulatedDocument3 pagesTroubleshooting Pulse Width ModulatedYuri Condori huamanNo ratings yet

- 373elr GFR PDFDocument5 pages373elr GFR PDFputrasejahtraNo ratings yet

- Q & A of InstrumentsDocument86 pagesQ & A of InstrumentsAbdelrahman Mohamed Elshafei100% (1)

- Is Now Part ofDocument19 pagesIs Now Part ofWadeck DiegoNo ratings yet

- Controls and IndicatorsDocument74 pagesControls and IndicatorsMohd Muzakir Mat LazinNo ratings yet

- Gear Box ErrorDocument6 pagesGear Box ErrorFilmon TesfayNo ratings yet

- Technical Support Notification - PLLD - Periodic Line Failure (576047-380)Document2 pagesTechnical Support Notification - PLLD - Periodic Line Failure (576047-380)pvelascokNo ratings yet

- LCA110 ClareInc.Document6 pagesLCA110 ClareInc.Tomi OzzyNo ratings yet

- Mid187 Ppid1180 Se9102Document2 pagesMid187 Ppid1180 Se9102AwanNo ratings yet

- Warrick Series 26 Control Installation and Operation BulletinDocument2 pagesWarrick Series 26 Control Installation and Operation BulletinwpertuzpantojaNo ratings yet

- Multilayer Transient VoltageDocument10 pagesMultilayer Transient Voltagegotcha75No ratings yet

- Dmt400 Samsung DishwasherDocument6 pagesDmt400 Samsung DishwasherZeigtNo ratings yet

- Mantto y ProbledddmrasDocument24 pagesMantto y ProbledddmrasSandra AristaNo ratings yet

- Critical Failure: Modes and PreventionDocument7 pagesCritical Failure: Modes and PreventionSandro CuetoNo ratings yet

- TS PHIIR Part2Document186 pagesTS PHIIR Part2Soumya SahooNo ratings yet

- APC200 ECM-ECI Full Flow Error Codes Ver2 9Document17 pagesAPC200 ECM-ECI Full Flow Error Codes Ver2 9Samuel Jorge SelbachNo ratings yet

- Megger DLRO200 ManualDocument15 pagesMegger DLRO200 Manualtriyan saefudinNo ratings yet

- Troubleshooting Pulse Meters Part 2Document8 pagesTroubleshooting Pulse Meters Part 2bauro mikaereNo ratings yet

- Phase Sequence Relay PFN Mecotron: OperationDocument1 pagePhase Sequence Relay PFN Mecotron: Operationhonafa- R.O.N.ONo ratings yet

- Transformer Loss Measurement Systems: W W W W W W W W WDocument4 pagesTransformer Loss Measurement Systems: W W W W W W W W WVinzoKeiNo ratings yet

- S. No. Description Make Qty.: Client: Vensa Infrastructure Ltd. Project: Siddarth Nagar Project, UPDocument1 pageS. No. Description Make Qty.: Client: Vensa Infrastructure Ltd. Project: Siddarth Nagar Project, UPaayushNo ratings yet

- ΕΠΕΞΗΓΗΣΗ ΣΦΑΛΜΑΤΩΝ INVERTER VACON DANFOSSDocument9 pagesΕΠΕΞΗΓΗΣΗ ΣΦΑΛΜΑΤΩΝ INVERTER VACON DANFOSSAurangzaib JahangirNo ratings yet

- Day 5 ESP Troubleshooting During Operation - LastDocument12 pagesDay 5 ESP Troubleshooting During Operation - LastomerkhalidhameedNo ratings yet

- Mardsen DP-3810 Service ManualDocument12 pagesMardsen DP-3810 Service ManualBalan Olivian0% (1)

- Dioda Tunel: Universitatea "Politehnica" Bucuresti Departamentul de FizicaDocument9 pagesDioda Tunel: Universitatea "Politehnica" Bucuresti Departamentul de FizicaBalan OlivianNo ratings yet

- Agricultural Robot For Automatic Ploughing and SeedingDocument7 pagesAgricultural Robot For Automatic Ploughing and SeedingMadhusudhan N MNo ratings yet

- Advanced View Arduino Projects List - Use Arduino For Projects-3Document58 pagesAdvanced View Arduino Projects List - Use Arduino For Projects-3Bilal AfzalNo ratings yet

- Bahan Training Infus SpaceDocument20 pagesBahan Training Infus SpaceSanchia JanitaNo ratings yet

- Chapter 1 UpdatedDocument20 pagesChapter 1 Updatedዘረአዳም ዘመንቆረርNo ratings yet

- Control ProjectDocument24 pagesControl ProjectJayyaad ArshadNo ratings yet

- Mechatronics Main ProjectDocument20 pagesMechatronics Main ProjectAbdi YizotawNo ratings yet

- Density Based Traffic Controller With Android OverridingDocument2 pagesDensity Based Traffic Controller With Android Overridingankush belkarNo ratings yet

- Osjetnik Vanjske Temperature QAC22Document5 pagesOsjetnik Vanjske Temperature QAC22Asima NezirevicNo ratings yet

- Std. Options Unit P Adc DDocument2 pagesStd. Options Unit P Adc Drahas kathaNo ratings yet

- Epic AZ Detector Calibration Procedure 9202-0183 RevDocument56 pagesEpic AZ Detector Calibration Procedure 9202-0183 RevJulio Cesar Lugo RuizNo ratings yet

- 42g td001 - en p.pd1Document10 pages42g td001 - en p.pd1soayNo ratings yet

- Multi-Functional Blind Stick For Visually Impaired PeopleDocument5 pagesMulti-Functional Blind Stick For Visually Impaired PeopleRaghu BNo ratings yet

- Pro Drm1800Document8 pagesPro Drm1800Wilber SilesNo ratings yet

- The Seeker Experimental System at MIT Lincoln Laboratory: Keywords: Infrared, Cryogenic, Radiometric, NODDS, SeekerDocument11 pagesThe Seeker Experimental System at MIT Lincoln Laboratory: Keywords: Infrared, Cryogenic, Radiometric, NODDS, SeekerAlex YangNo ratings yet

- 2022 ORVIBO Smart Home CatalogDocument52 pages2022 ORVIBO Smart Home CatalogFuture StoreNo ratings yet

- Consilium PDF Cs4000 07Document6 pagesConsilium PDF Cs4000 07nauta007No ratings yet

- SEM164 Humidity & Temperature Transmitters: 2.2 MechanicalDocument2 pagesSEM164 Humidity & Temperature Transmitters: 2.2 MechanicalElsad HasanliNo ratings yet

- CIBANO 500 Ordering Information ENUDocument17 pagesCIBANO 500 Ordering Information ENUasssasasNo ratings yet

- En - Mga 12 EX - Product InformationDocument2 pagesEn - Mga 12 EX - Product InformationTrung TrinhNo ratings yet

- SeriesDocument8 pagesSeriesMohamad SolehNo ratings yet

- Extra NewsletterDocument8 pagesExtra NewsletterTrịnh Đức HạnhNo ratings yet

- 1.4 - Systems Approach To DesigningDocument23 pages1.4 - Systems Approach To DesigningArchit GuptaNo ratings yet

- FireClass BrochureDocument8 pagesFireClass BrochureStephen Odon FastoNo ratings yet

- MA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001Document28 pagesMA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001michael KetselaNo ratings yet

- Lab 2 SensorDocument9 pagesLab 2 Sensorahmad faizNo ratings yet

- Fire Alarm SystemDocument50 pagesFire Alarm SystemMayada SaadNo ratings yet

- 4 Ts-9101-8222 Temperature SensorDocument10 pages4 Ts-9101-8222 Temperature SensorAbiodun IloriNo ratings yet

- Af 2400 985b1 English CatalogDocument2 pagesAf 2400 985b1 English CatalogThanh Hai StarkNo ratings yet