Professional Documents

Culture Documents

Samadhan Navanath Umate: Job Objective

Uploaded by

Sama UmateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Samadhan Navanath Umate: Job Objective

Uploaded by

Sama UmateCopyright:

Available Formats

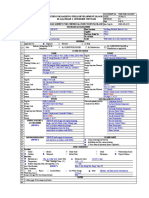

Samadhan Navanath Umate

Mobile: 09604839990

E-Mail: umatesamadhan@gmail.com

JOB OBJECTIVE

Seeking a fulfilling position in the Heat Treatment and Metallurgy field that offers growth

opportunities and allows me to utilize my resourceful experience & leadership skills.

SCHOLASTICS

• Appearing Diploma in Metallurgical Engineering from Government Polytechnic, Pune.

• Bachelor of Mechanical Engineering from SMSMPITR, Akluj (Solapur University) in 2016 with

70.94%

• Diploma in Mechanical Engineering KPJEC, Akkalkot (MSBTE) in 2013 with 70.99%

• Completed SSC from BVM, Anjangoan U, Madha (Pune Board) in 2010 with 73.82%

APERCUE

• A complete 4+ Years in SDE, NPD, Heat treatment- Metallurgy Lab, Production & Quality,

Process improvement in reputed Company.

• To connect with supplier for development of new product.

• Knowledge of various Heat Treatment Processes like as -carburizing, Hardening, Tempering,

Annealing, Stress Relieving, brazing, precipitation hardening, Nitriding and cabo-nidring

process.

• Doing work with design and development department to define material and metallurgical

parameters

WORK EXPERIENCE

Company: ZF (INDIA) STEERING GEAR LTD. PUNE

Position: Trainee Engineer – Heat Treatment Department

Period: Nov. 2016 – Dec. 2018

Company: KALYANI TECHNOFORGE LTD., RANJANGAON

Position: Junior Lab Inspector – Heat Treatment Department

Period: Dec. 2018 – June 2021

Company: EATON FLUID POWER, PUNE

Position: Supplier development Egg. Metallurgist

Period: June 2021 – Aug. 2021

Company: DANFOSS POWER SOLUTION, PUNE

Position: Supplier development Egg. Metallurgist

Period: Aug. 2021 – Till date

SDE & NPD

• Connect with internal & supplier team for new part development

• Daily follow-up related to NPD, design of tolling, P.O., process and product development.

• Supplier development for different materials components for processes such as forging, casting,

process for steel & polymer.

• On time discussion & performing drawing deviation correlation with supplier & engineering

team.

• APQP & PPAP documents for NPD.

Production & Quality Responsibilities: -

• Worked with different teat treatments processes and knowledge of Vacuum hardening, Gas

carburizing, Solution Annealing & Aging, Low pressure carburizing, brazing, plasma and gas

nitriding for tool steel, stainless steel, HSS, Aerospace Materials (17-4 Ph,17-7 ph., cobalt base

alloys etc.), Case and Through hardened steels.

• Monitoring and Performing Heat Treatment cycles according to specifications or work

instructions.

• Verification of the heat treatment cycle for correct temperature and time and maintain the

heating rate and cooling rate.

• Ensuring availability of heat treatment charts, temperature controller, thermocouples.

• Checking overall critical parameters of the components such as surface hardness, core hardness,

case depth, and microstructure before final dispatch.

• Perform daily, weekly, monthly maintenance related activity regarding to the furnace as well as

handle furnace breakdown with maintenance team.

• Maintaining Heat treatment logbook or log sheet, heat treatment charts & further submission

to the department concerned.

• Checking production quality products properties such as incoming material, surface appearance,

distortion surface hardness etc.

Lab Activities Known

• Metallographic preparation of the testing component with etching in lab work.

• Exposure of handling various metallurgical equipment such as Rockwell, Brinell and Vickers,

superficial Hardness testers including Metallurgical Microscope.

• Testing of incoming automobile parts (i.e. raw material casting, forging and Polymer)

• Metallurgical analysis of customer complaints.

• Microstructure analysis of Heat treatment batches of material with Microscope.

• Maintain QMS Documentation related to lab work.

Materials and Standards

• Having knowledge of different types of steel, stainless steel, cast iron, tool steel, aluminum and

polymers grades with aerospace materials and heat treatments.

• Applying IS, ISO, DIN, EN, JIS, GB, ASTM, ASM &AMS standards and used for details of material

grades, processes, testing, microstructure, analysis etc.

• Doing work with design and development department for defining new material, properties and

standards on documentary.

• Connect with customer for developing updates material, failure analysis and defined process.

IT SKILLS

Operating System : Windows XP, Windows 7, Windows 8 Package

MS Office (Word, Excel, Power, PowerPoint)

Other : Internet Applications, SAP & ERP system.

PESONAL DETAILS

Name Umate Samadhan Navanath

Date of Birth & Age 10 th July 1994

Father’s Name Navanath

Sex Male

Languages Known English, Marathi and Hindi.

DECLARATION

I hereby declare that, all the details furnished above are true to the best of my knowledge and

understanding

Date:- 31st Aug. 2021 Signature

(Umate Samadhan Navanath )

You might also like

- 1 GTAG Assessing Cybersecurity RiskDocument31 pages1 GTAG Assessing Cybersecurity RiskWrafael Garcia100% (2)

- Resume of A Project CoordinatorDocument3 pagesResume of A Project CoordinatorASHIL PRABHAKARNo ratings yet

- CQM Plan Training Dec2010Document58 pagesCQM Plan Training Dec2010Jessica LuceroNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Dokumen - Pub A Textbook of Production Engineering 11nbsped 9788121901116Document993 pagesDokumen - Pub A Textbook of Production Engineering 11nbsped 9788121901116RahulNo ratings yet

- Astm A500Document6 pagesAstm A500notsofar100% (4)

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- CV of Lead Const EngineerDocument5 pagesCV of Lead Const EngineerChandraSekaranBmNo ratings yet

- Intelligent Building Automation SystemsDocument18 pagesIntelligent Building Automation Systemsnandu shahNo ratings yet

- Canal TurnkeyDocument119 pagesCanal TurnkeyShubhank PariharNo ratings yet

- M.thiruselvam BE Electrical CP ExperienceDocument7 pagesM.thiruselvam BE Electrical CP ExperiencethiruNo ratings yet

- Resume Qa QCDocument3 pagesResume Qa QCMayur KasarNo ratings yet

- BS2789 Grade 500-7 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 500-7 SG Iron: Form of Supplyanu swamiNo ratings yet

- C.V. Roshin CyriascoDocument3 pagesC.V. Roshin CyriascoMatthiew BuckettasNo ratings yet

- Resume Rupesh BorseDocument3 pagesResume Rupesh BorseSagar BhamreNo ratings yet

- DocumentaryDocument3 pagesDocumentarymanoj ranathiiveNo ratings yet

- Curriculum Vitae: Personal DetailsDocument4 pagesCurriculum Vitae: Personal Detailshery fantikaNo ratings yet

- Zeeshan Pathan Mechanical EngineerDocument4 pagesZeeshan Pathan Mechanical EngineerZeeshan PathanNo ratings yet

- CV - Dahlan QA, QC Welding Inspector 2018-1Document8 pagesCV - Dahlan QA, QC Welding Inspector 2018-1Hellgates 1666100% (1)

- Vimal BE MTech Metallurgy 7 Years Experience in HT Metallurgy.Document3 pagesVimal BE MTech Metallurgy 7 Years Experience in HT Metallurgy.Vinoth KumarNo ratings yet

- PRABHAKARAN GANESAN Latest ResumeDocument6 pagesPRABHAKARAN GANESAN Latest ResumesivagnanamNo ratings yet

- CV TecnoDocument4 pagesCV TecnoprashantghodkeNo ratings yet

- Resume of R. Naveen KumarDocument5 pagesResume of R. Naveen Kumarajin ekkishowNo ratings yet

- Naukri RushikeshThorat (7y 0m)Document4 pagesNaukri RushikeshThorat (7y 0m)3asNo ratings yet

- Shaiju - Project EngineerDocument3 pagesShaiju - Project EngineerShaiju Narayanan100% (1)

- Muralidharan.M: No: 62b Mettu Street Sathuma Nagar, Thiruvottiyur, Chennai-600019Document3 pagesMuralidharan.M: No: 62b Mettu Street Sathuma Nagar, Thiruvottiyur, Chennai-600019Murali dharanNo ratings yet

- Jobin Eappen Jose: Career ObjectiveDocument3 pagesJobin Eappen Jose: Career ObjectiveAGNEL V VARKEYNo ratings yet

- Michael Creamer: Materials Testing & Development EngineerDocument2 pagesMichael Creamer: Materials Testing & Development EngineerMichael CreamerNo ratings yet

- Resume Althaf Commisioning New-Converted - RemovedDocument2 pagesResume Althaf Commisioning New-Converted - RemovedWirjono AkbarNo ratings yet

- My ResumeDocument3 pagesMy ResumeRavi Ranjan Kumar BhanuNo ratings yet

- Ankit Singh-QCDocument3 pagesAnkit Singh-QCAnkitNo ratings yet

- Akhilesh CVDocument3 pagesAkhilesh CVUma MaheshwarNo ratings yet

- GoutamYankannavarR 14328994 - 05 02 - 1Document3 pagesGoutamYankannavarR 14328994 - 05 02 - 1Mayur ShindeNo ratings yet

- Zahid Mirani CVDocument5 pagesZahid Mirani CVmiranizahidNo ratings yet

- Farukh Rehan ResumeDocument3 pagesFarukh Rehan ResumeEngr Farrukh RehanNo ratings yet

- P Rama Krishna: SummaryDocument5 pagesP Rama Krishna: SummaryKrishna RamaNo ratings yet

- CV - Sakthi.pDocument3 pagesCV - Sakthi.pVenkatesh KumarNo ratings yet

- Winson Lim Hui Wah - Mechanical Engineer (Static Equipment)Document4 pagesWinson Lim Hui Wah - Mechanical Engineer (Static Equipment)WinsonLimHuiWahNo ratings yet

- Shantilal Aher - CVDocument3 pagesShantilal Aher - CVEr Prem AaherNo ratings yet

- MaheshAnandraoPawar (8 0)Document3 pagesMaheshAnandraoPawar (8 0)Samraat MagajiNo ratings yet

- Membuat CVDocument11 pagesMembuat CVPanji WismansyahNo ratings yet

- Althaf Esastra, S.T: Mechanical EngineeringDocument2 pagesAlthaf Esastra, S.T: Mechanical EngineeringAlthaf EsastraNo ratings yet

- Jayakumarank (6 0)Document4 pagesJayakumarank (6 0)Uttisht TNo ratings yet

- Resume FormateDocument5 pagesResume FormateVijayshanker GuptaNo ratings yet

- Sai Charan Majji CVDocument2 pagesSai Charan Majji CVcharan saiNo ratings yet

- Resume: 3/866, Ram Puri Colony Shabad Pratap Ashram Lashkar, Gwalior (M.P.) Mobile: 09993097669, 08905095093Document4 pagesResume: 3/866, Ram Puri Colony Shabad Pratap Ashram Lashkar, Gwalior (M.P.) Mobile: 09993097669, 08905095093VIJETA YADAVNo ratings yet

- A. Deepak Kumar Contact No: +91 - 8110841611Document3 pagesA. Deepak Kumar Contact No: +91 - 8110841611Design V-Tork ControlsNo ratings yet

- Chandhru 2Document4 pagesChandhru 2MoonNo ratings yet

- Curriculum Vitae Ashish KaushikDocument3 pagesCurriculum Vitae Ashish KaushikTourist GuideNo ratings yet

- K.Praveen KumarDocument3 pagesK.Praveen Kumark_parveen33No ratings yet

- Riyas CVDocument4 pagesRiyas CVThehzeb JalalNo ratings yet

- CV - Tran Van DangDocument2 pagesCV - Tran Van Dangvohuu1102No ratings yet

- Mymoonson CVDocument5 pagesMymoonson CVMahmoud shawkyNo ratings yet

- Abdus Salam, 202101, Rohtak, B.Tech Mech, 6 YrsDocument5 pagesAbdus Salam, 202101, Rohtak, B.Tech Mech, 6 YrsPeter SamuelNo ratings yet

- Resume: S.SomasundaramDocument6 pagesResume: S.SomasundaramShankker KumarNo ratings yet

- DipakDocument4 pagesDipakDipak SatapathyNo ratings yet

- Mirza Resume ExperienceDocument5 pagesMirza Resume ExperienceMirza Raziullah BaigNo ratings yet

- Curriculum Vatae: Ponnapalli Satyanarayana Contact No: +91-9989905070, 8610535068Document3 pagesCurriculum Vatae: Ponnapalli Satyanarayana Contact No: +91-9989905070, 8610535068satyanarayanaNo ratings yet

- 33 Subburam A Ramalingam - OriginalDocument3 pages33 Subburam A Ramalingam - OriginalRajaNo ratings yet

- Total Year of Experience: 5 Years': Sasikumar.DDocument3 pagesTotal Year of Experience: 5 Years': Sasikumar.DRameshNo ratings yet

- Resume Narendra SOntakkeDocument3 pagesResume Narendra SOntakkeMd AkhtarNo ratings yet

- Resume: Worked As A Works Manager in JR ForgingsDocument4 pagesResume: Worked As A Works Manager in JR ForgingsMahendar PaladuguNo ratings yet

- SHAHBAZ Updated CVDocument4 pagesSHAHBAZ Updated CVShahbazNo ratings yet

- Mani ResumeDocument3 pagesMani ResumemanikandanNo ratings yet

- Carrier Goal:: ST STDocument3 pagesCarrier Goal:: ST STAsis SahooNo ratings yet

- Curriculum Vitae-Nguyen Ngoc KhaiDocument7 pagesCurriculum Vitae-Nguyen Ngoc KhaiBùi Văn TấnNo ratings yet

- Reducing Cutting Force Induced Bore Cylindricity Errors by Learning Control and Variable Depth of Cut MachiningDocument8 pagesReducing Cutting Force Induced Bore Cylindricity Errors by Learning Control and Variable Depth of Cut MachiningSama UmateNo ratings yet

- 1.03-012.06 Potential Supplier Assessment - Technical Manufacturing SurveyDocument37 pages1.03-012.06 Potential Supplier Assessment - Technical Manufacturing SurveySama UmateNo ratings yet

- Materials Evaluation and Corrosion Test Needs For A Direct-Fired SCO Oxy-Combustion PlantDocument14 pagesMaterials Evaluation and Corrosion Test Needs For A Direct-Fired SCO Oxy-Combustion PlantSama UmateNo ratings yet

- Ndustries. 14 Nos, 108 Kg.Document10 pagesNdustries. 14 Nos, 108 Kg.Sama UmateNo ratings yet

- Metallurgy Laboratory Inspection ReportDocument2 pagesMetallurgy Laboratory Inspection ReportSama UmateNo ratings yet

- Jurnal C-8 SulardjakaDocument6 pagesJurnal C-8 SulardjakaSama UmateNo ratings yet

- BS2789 Grade 600-3 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 600-3 SG Iron: Form of SupplySama UmateNo ratings yet

- BS2789 Grade 700-2 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 700-2 SG Iron: Form of SupplySama UmateNo ratings yet

- BS2789 Grade 420-12 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 420-12 SG Iron: Form of SupplySama UmateNo ratings yet

- BS2789 Grade 400-15 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 400-15 SG Iron: Form of SupplySama UmateNo ratings yet

- Physical Property: Language Watch EditDocument2 pagesPhysical Property: Language Watch EditSama UmateNo ratings yet

- Indian Two-Wheeler Industry: Building The Nation, ResponsiblyDocument17 pagesIndian Two-Wheeler Industry: Building The Nation, ResponsiblySai RishikNo ratings yet

- It's Still A: Big WorldDocument10 pagesIt's Still A: Big Worldh1saysNo ratings yet

- Interpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionDocument10 pagesInterpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionJesus ZilchNo ratings yet

- BC Hydro, 6911 Southpoint Drive, Burnaby, BC V3N 4X8Document1 pageBC Hydro, 6911 Southpoint Drive, Burnaby, BC V3N 4X8dgretchenNo ratings yet

- APM - 9.5 - APM For Oracle WebLogic Server GuideDocument39 pagesAPM - 9.5 - APM For Oracle WebLogic Server Guideggen_mail.ruNo ratings yet

- MoTaI 3-4.4Document68 pagesMoTaI 3-4.4ali resulNo ratings yet

- Tugas Inggris AzDocument7 pagesTugas Inggris AzsetiawatiNo ratings yet

- Report On Self Driving CarDocument23 pagesReport On Self Driving CarAnonymous 8zeEYkNo ratings yet

- BIT Sindri Placement StatisticsDocument15 pagesBIT Sindri Placement StatisticsSaurabh YadavNo ratings yet

- Primary Crushing Plant 2 Substation: LegendDocument1 pagePrimary Crushing Plant 2 Substation: LegendAngel Lazarte DueñasNo ratings yet

- Timesheet Management SystemDocument2 pagesTimesheet Management Systemrahulsisodia9409No ratings yet

- Computer Terminology and Software TestingDocument99 pagesComputer Terminology and Software TestingoluninjaaNo ratings yet

- Before You Read The Passage, Talk About These QuestionsDocument2 pagesBefore You Read The Passage, Talk About These Questionsjohan amaraNo ratings yet

- Diaphram Part and Lists Drawing Page 37 39Document3 pagesDiaphram Part and Lists Drawing Page 37 39Bara BarackNo ratings yet

- Recruitment Process in ACC CEMENTDocument83 pagesRecruitment Process in ACC CEMENTAmit PasiNo ratings yet

- Productattachments Files e X Exc-GtDocument53 pagesProductattachments Files e X Exc-GtAmadou Fall100% (1)

- SCC Configuration GuideDocument17 pagesSCC Configuration GuideMv IrinelNo ratings yet

- Quality ProgressDocument68 pagesQuality Progressمحمد يسرNo ratings yet

- The State University of Zanzibar (Suza) .: Department of Computer Science and Information TechnologyDocument26 pagesThe State University of Zanzibar (Suza) .: Department of Computer Science and Information TechnologyMasoud MachanoNo ratings yet

- 2.01.005 Hard Elastic Coating143R 680FM VP1351NFHDocument2 pages2.01.005 Hard Elastic Coating143R 680FM VP1351NFHMOHAMEDNo ratings yet

- Aj Plast PDFDocument24 pagesAj Plast PDFSanjay Kumar ShahiNo ratings yet

- Materials ManagementDocument12 pagesMaterials ManagementrasgeetsinghNo ratings yet

- ST 3Document1 pageST 3Pooja KulkarniNo ratings yet