Professional Documents

Culture Documents

CV Tecno

Uploaded by

prashantghodkeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV Tecno

Uploaded by

prashantghodkeCopyright:

Available Formats

Curriculum Vitae

PRASHANT GHODKE

E-mail ID: prashantg2012@gmail.com Cell 09594390771

Job Objective

Seeking Challenging assignments in QC, inspection, Production , organization where I

render my services.

Position Summary

A Mechanical Engineering Graduate with 8 year experience in the

area of production & QC , inspection of fabricated Pressure vessel

/heat exchanger/columns, good knowledge of Eng drawing ,welding ,

ASME code /TEMA, inspection & testing . presently working in

Techno Process Equipment pvt ltd. Ambernath MIDC Thane .

An effective communicator with excellent relationship negotiation

skill management skills and strong analytical, problem solving &

organization abilities.

Educational Qualification :-

B.E. (MECH) from Rajiv Gandhi Technical University , M.P. Gotv,Bhopal in June

2005.(65.69%)

PROFESSIONAL SYNOPSIS:

4 Familiar with following Inspection Equipments & Reporting:

UT Thickness Meter – Panametrics – 38DL PLUS

fabricated Pressure vessel /Plant Equipment/ good knowledge of Eng drawing

,welding , ASME code /TEMA inspection & tasting

CERTIFICATIONS & PROFESSIONAL ENHANCEMENTS:

4 ASNT Level II

4 ASNT level II Certificate in RT,UT , MT ,PT

4 Familiar with following Codes, Specification & Procedures:

ASME (Sec. VIII, IX, V, II A & C)

, TEMA

IT Skills :

- Windows 9X / XP / 7

- Well versed with MS Office and Internet Applications.

- Knowledge of Auto-CAD.

PRESENT STATUS: Presently working in Techno Process

Equipment pvt ltd. Ambernath MIDC Thane as QC Engineer

since 2018 Oct to till date now.

Job Handed: REACTORS, COLUMN , HEAT EXCHANGER ,

PRESSURE VESSEL ,

: HPCL, BPCL, MRPL,

Experience Fab 2016 to OCT 2018

Spacetech Equipment & Structural Pvt Ltd Ambernath

QC Engineer.

I was working in Spacetech equipment’s & structural pvt ltd in

under LINDE INDIA LTD as QC Engineer since August 2016 to .

OCT 2018.

Project Status: Oxygen plant in 2200 TPD JSW dolvi.

Job responsibilities.:

See all type of inspection including HORTON SPHERE,

TANK , PIPING

Horton sphere joint fit up and welding

Tank joint fit up and welding.

SS and CS piping inspection and fit up joint.

Erection of all static equipment.

At workshop Inspection of Pressure Vessels , heat exchangers,

columns, agitator, LPG Mounded Bullets, Horton Sphere for oxygen Documentation of material

inspection, inspection of pipe, plate , fitting and tubes & tubes sheet joint ,tube bundle ,

flange ,dished end, welding consumable, review of test certificates, valve inspection ,

witness of NDT test, witness of hydro test , pneumatic test, Witness of Destructive testing

at laboratory, interpretation of RT film

Document required and preparation of WPS, PQR, WPQT, Hand on practice how to prepare

of WPS with code of construction and drawing.

Type of variable, position, Diameter and thickness limitation, familiar with ,

GTAW,SAW,SMAW, knowledge of electrode , inspection of electrode , filler

material , gases, storage of consumables, inspection of painting blasting, surface

preparation, spark testing, Review of painting certificate ,paint data sheet,

Establish of blasting and painting procedure,

Preparation of material identity report, weld map, weld chart , final dimension report, heat

chart, RT chart, review of heat treatment report, review of calibration certificate,

Witness of hydro test, Documentations of hydro test, punch list preparation, preparation of

hydro test report, Preparation of final inspection report,

Experience May 2012 to Jan 2016

Fabtech consultant Pvt Ltd Thane Client L &T workshop

badlapur Thane

QC Engineer

Inspection of Pressure Vessels , heat exchangers, columns,

Documentation of material inspection, inspection of pipe, plate , fitting and tubes & tubes

sheet joint ,tube bundle , flanges ,dished end, welding consumable, review of test

certificates, valve inspection , witness of NDT test, witness of hydro test , pneumatic test,

Witness of Destructive testing at laboratory, interpretation of RT film

Document required and preparation of WPS, PQR, WPQT, Hand on practice how to prepare

of WPS with code of construction and drawing.

Type of variable, position , Diameter and thickness limitation, familiar with ,

GTAW,SAW,SMAW, knowledge of electrode , inspection of electrode , filler material ,

gases, storage of consumables, inspection of painting blasting, surface preparation,

Review of painting certificate ,paint data sheet, Establish of blasting and painting

procedure,

Preparation of material identity report, weld map ,weld chart , final dimension

report, heat chart, RT chart, review of heat treatment report, review of calibration

certificate,

Witness of hydro test, Documentations of hydro test, punch list preparation, preparation of

hydro test report , Preparation of final inspection report,

Job Handed: REACTORS,COLUMN, TOWER, RESIDENCIAL BRACKET, BOILER

FEED WATER DRUM,CYCLIC GAS COOLER

CLIENT

: KNPC, HPCL,RELIENCE, ONGC

Organization Experience june2009 to may 2012

Elgin Process Equipment Pvt Ltd Navi Mumbai

QC / Production Engineer

Responsibility and Nature of works :

- Checking the drawing, whether it need any correction

- Planning how to make the job more quickly

- Planning how and where to do the jobs as per drawing

- To allocate sufficient skilled and talented worker on jobs

- Arrange proper materials and equipments for the workers

- Checking the Lay out and marking correctly

- Supervising handing of materials by overhead crane without any accident

- Making a safe atmosphere for the workers

- As soon as the job done offering the job to quality control for the approval.

-Raw material identification

Material quality, thickness, size, drawing, verify heat no ,

Plate no & inspection id, Inspection of incoming raw and finishing material at factory,

Look for pitting surface damage, both side Inspection of fabrication, paint,

Visual inspection of welding as per drawing

Hydro testing, in Heat Exchanger, Pressure vessel etc.

Organization Experience

June 2005 to April 2009

Mahanagar gas limited kharghar Navi Mumbai

Designation : TPI

To make rough planning drawing of site and calculation of

consumable pipe, pipe fitting , valves

- Checking the drawing, whether it need any correction

- Planning how to make the job more quickly

- Planning how and where to do the jobs as per drawing

- Arrange proper materials and equipments for the workers

- Checking the Lay out and marking correctly

- Supervising guiding of materials by manually without any

accident

- Making a safe atmosphere for the workers

- As soon as the job done offering the job to quality control for

the approval.

To check depth of trench & length of pipe, witness of pneumatic

pressure testing of pipe.

Personal Details

Address : B 32 Ajanta , Anushkti Nagar , Devnar Mumbai - 94

Father’s name : D.K. Ghodke

Date of Birth : 17TH June 1985

Languages Known : English, Hindi, and Marathi

You might also like

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- VCO and Transparent Soap RevisiDocument16 pagesVCO and Transparent Soap RevisiRikkoNo ratings yet

- Cleaning Workers Training PDFDocument57 pagesCleaning Workers Training PDFOnaFajardo100% (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- CV (Sr. QA QC Engineer)Document5 pagesCV (Sr. QA QC Engineer)mansih457100% (1)

- Praveen Piping Designer ResumeDocument4 pagesPraveen Piping Designer Resumeprvnpg100% (1)

- Acid Rain WorksheetDocument2 pagesAcid Rain Worksheetapi-26422029150% (2)

- Resume An Welding InspectorDocument7 pagesResume An Welding InspectorspearboraNo ratings yet

- Al. Alloy Chemical CompositionDocument9 pagesAl. Alloy Chemical Compositionketan1965No ratings yet

- Aman, Qa-Qc Mechanical EngineerDocument3 pagesAman, Qa-Qc Mechanical Engineeriftekhar ahmedNo ratings yet

- Rashid CV (Equipment Inspector-SEP-2017)Document3 pagesRashid CV (Equipment Inspector-SEP-2017)vajidqcNo ratings yet

- Application For The Post of Suitable Position For Mechanical QA/QC INSPECTORDocument4 pagesApplication For The Post of Suitable Position For Mechanical QA/QC INSPECTORAhmed Imtiaz RaoNo ratings yet

- Resume For The Position of Qa-Qc Welding Inspector or Qa-Qc Mechanical EngineerDocument4 pagesResume For The Position of Qa-Qc Welding Inspector or Qa-Qc Mechanical EngineerBucek Buddy100% (1)

- Seawater and Marine Structure CorrosionDocument11 pagesSeawater and Marine Structure CorrosioniraprobotNo ratings yet

- L 1 Asad Ahmad Qaqc Piping Welding Ins PDFDocument9 pagesL 1 Asad Ahmad Qaqc Piping Welding Ins PDFyasiriftikharNo ratings yet

- QC/ Welding InspectorDocument6 pagesQC/ Welding Inspectorapi-78450733No ratings yet

- Determination of Density LabDocument4 pagesDetermination of Density LabKarim BiswasNo ratings yet

- Mechanical Supervisor ResumeDocument4 pagesMechanical Supervisor ResumeAnwar Rahman100% (4)

- CV - Sagar Sharma Mechanical EngineerDocument5 pagesCV - Sagar Sharma Mechanical Engineersagar sharmaNo ratings yet

- Mechanical Engineer with 3+ years experience seeking challenging positionDocument6 pagesMechanical Engineer with 3+ years experience seeking challenging positiondavidgeorge143No ratings yet

- NDT Level 2 Technician resumeDocument5 pagesNDT Level 2 Technician resumeqatar kingNo ratings yet

- CV 1 - Cswip 3.1weldnig &NDT InspectorDocument7 pagesCV 1 - Cswip 3.1weldnig &NDT Inspectorzahid liaqatNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Mohammad Rijwan: Aramco, Sabic, Sadara, SatorpDocument5 pagesMohammad Rijwan: Aramco, Sabic, Sadara, SatorpMohammad RizwanNo ratings yet

- Prashant Ghodke: Curriculum VitaeDocument4 pagesPrashant Ghodke: Curriculum VitaeSharmila Laxman DakeNo ratings yet

- Naukri_RushikeshThorat[7y_0m]Document4 pagesNaukri_RushikeshThorat[7y_0m]3asNo ratings yet

- Resume Sample PDFDocument4 pagesResume Sample PDFamitrdttecNo ratings yet

- Open To Relocation Overseas & Anywhere in IndiaDocument4 pagesOpen To Relocation Overseas & Anywhere in IndiaamitrdttecNo ratings yet

- Barath Kumar - CV 2016Document5 pagesBarath Kumar - CV 2016barathNo ratings yet

- Shadman Zeya c.v5Document5 pagesShadman Zeya c.v5Raj AryanNo ratings yet

- Curriculum Vitae for QA/QC Engineer PositionDocument4 pagesCurriculum Vitae for QA/QC Engineer Position1dzrbtcom ProfessionalprogramminglanguageNo ratings yet

- Experienced QA/QC Engineer ResumeDocument6 pagesExperienced QA/QC Engineer ResumeJanardhan SuryaNo ratings yet

- Iftekhar 14Document2 pagesIftekhar 14Iftekhar AhmedNo ratings yet

- Mechanical Engineer ..Document4 pagesMechanical Engineer ..Saswat Kumar RoutNo ratings yet

- AswaDocument4 pagesAswaaswaeNo ratings yet

- INSpECTION ENGINEER PDFDocument4 pagesINSpECTION ENGINEER PDFKaranDinaNo ratings yet

- QC Inspector Piping CVDocument4 pagesQC Inspector Piping CVSathishkumar DNo ratings yet

- Knowledge in Autocad Plant3DDocument5 pagesKnowledge in Autocad Plant3DrajNo ratings yet

- CV Prashant Peso 2022-1Document3 pagesCV Prashant Peso 2022-1Neeta TawadeNo ratings yet

- Nilesh Kumar Resume.2021Document4 pagesNilesh Kumar Resume.2021NILESH KUMAR PANKAJ100% (1)

- Lijo Johnson - Api Inspector - 510 - CVDocument5 pagesLijo Johnson - Api Inspector - 510 - CVonline M100% (1)

- Ravishekh CVDocument3 pagesRavishekh CVraj kumar SinghNo ratings yet

- Piping SupervisorDocument4 pagesPiping SupervisorEr AkhlaqueNo ratings yet

- Vinoth Kumar P CV QC Qa WiwDocument13 pagesVinoth Kumar P CV QC Qa Wiwvignesh0tNo ratings yet

- Shahbaz Ahmad CVDocument8 pagesShahbaz Ahmad CVShahbaz AhmadNo ratings yet

- Joel e Jose - CV - 2023 05Document3 pagesJoel e Jose - CV - 2023 05joelNo ratings yet

- CV of Raj (Dec'23)Document3 pagesCV of Raj (Dec'23)ahiadarshNo ratings yet

- Curriculum Vitae: M. Kranthi Nadh, Darmareddy Colony, Near Anil Diabetic Center Kukatpalli, Hyderabad - TelanganaDocument5 pagesCurriculum Vitae: M. Kranthi Nadh, Darmareddy Colony, Near Anil Diabetic Center Kukatpalli, Hyderabad - TelanganaL KISHORE REDDYNo ratings yet

- CSWIP 3.1 Welding Inspector resumeDocument4 pagesCSWIP 3.1 Welding Inspector resumeGokulPrasadNo ratings yet

- Curriculum Vitae for Mechanical QA/QC Engineer with 6+ Years ExperienceDocument5 pagesCurriculum Vitae for Mechanical QA/QC Engineer with 6+ Years ExperienceVIVEKANANDANNo ratings yet

- Bui Van Diep Bui Van Diep: Thông Tin ChungDocument7 pagesBui Van Diep Bui Van Diep: Thông Tin Chunganon_33553517No ratings yet

- Dhinesh Suman Prasath Cswip3.1, ASNT Level II Certified Inspection EngineerDocument4 pagesDhinesh Suman Prasath Cswip3.1, ASNT Level II Certified Inspection Engineersahaya freedonNo ratings yet

- Mr. Sontaya Pojid: Personal InformationDocument7 pagesMr. Sontaya Pojid: Personal InformationNatthawut KentharaphakNo ratings yet

- Tenveer Hussain CV 29124Document7 pagesTenveer Hussain CV 29124Tanveerhussain Q.ANo ratings yet

- Chandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979Document13 pagesChandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979kbpatel123No ratings yet

- Résumé: 120 "Shri Ram Kutir", Udhna, Pandesara, Surat-394210Document4 pagesRésumé: 120 "Shri Ram Kutir", Udhna, Pandesara, Surat-394210Raj AryanNo ratings yet

- Naukri_VISHALRAJARAMINGALE[6y_9m]Document4 pagesNaukri_VISHALRAJARAMINGALE[6y_9m]3asNo ratings yet

- Name Bijinlal AT: Current Position Engineer-Inspection QC Call +91 9497109600 MailDocument4 pagesName Bijinlal AT: Current Position Engineer-Inspection QC Call +91 9497109600 MailUdayan JadavNo ratings yet

- Resume 10201Document14 pagesResume 10201nicko.arya.dharmaNo ratings yet

- Rahul P R's ResumeDocument6 pagesRahul P R's ResumeGuna RajNo ratings yet

- Shailendra Rao CV and Documents 08.04.2024_compressed_compressed_compressedDocument32 pagesShailendra Rao CV and Documents 08.04.2024_compressed_compressed_compressedshailendrarao333No ratings yet

- QC Inspection CV UpdatedDocument7 pagesQC Inspection CV UpdatedEr AkhlaqueNo ratings yet

- Mymoonson CVDocument5 pagesMymoonson CVMahmoud shawkyNo ratings yet

- New Updated Haider CVDocument5 pagesNew Updated Haider CVFarhan haiderNo ratings yet

- G.raju Reddy Resume (PDF1) PDFDocument3 pagesG.raju Reddy Resume (PDF1) PDFanon_708469687No ratings yet

- Resume Abdul Hafiza: Work ExperienceDocument4 pagesResume Abdul Hafiza: Work ExperienceShashwat PandeyNo ratings yet

- Contact Details for QA/QC ProfessionalDocument5 pagesContact Details for QA/QC ProfessionalibrahimNo ratings yet

- The Health-Illness ContinuumDocument2 pagesThe Health-Illness ContinuumprashantghodkeNo ratings yet

- Rajiv Gandhi University of Health Sciences, Bangalore, KarnatakaDocument18 pagesRajiv Gandhi University of Health Sciences, Bangalore, KarnatakaprashantghodkeNo ratings yet

- Rajiv Gandhi University of Health Sciences, Bangalore, KarnatakaDocument18 pagesRajiv Gandhi University of Health Sciences, Bangalore, KarnatakaprashantghodkeNo ratings yet

- 3006 - December 2019 - EJVD0M45LBNZ1ERWMHRSYBY35038939175474846469113845Document1 page3006 - December 2019 - EJVD0M45LBNZ1ERWMHRSYBY35038939175474846469113845prashantghodkeNo ratings yet

- #NAME? Claim For Reimbursement of ExpensesDocument1 page#NAME? Claim For Reimbursement of ExpensesprashantghodkeNo ratings yet

- Inspection Report - 60001Document9 pagesInspection Report - 60001prashantghodkeNo ratings yet

- Normal Medical FormatDocument1 pageNormal Medical FormatprashantghodkeNo ratings yet

- #NAME? Claim For Reimbursement of ExpensesDocument1 page#NAME? Claim For Reimbursement of ExpensesprashantghodkeNo ratings yet

- Invoice OD308762441464523000Document1 pageInvoice OD308762441464523000prashantghodkeNo ratings yet

- New Schedule Till June 2013 PDFDocument2 pagesNew Schedule Till June 2013 PDFprashantghodkeNo ratings yet

- New Schedule Till June 2013 PDFDocument2 pagesNew Schedule Till June 2013 PDFprashantghodkeNo ratings yet

- ReportDocument5 pagesReportprashantghodkeNo ratings yet

- CV TecnoDocument4 pagesCV TecnoprashantghodkeNo ratings yet

- CV TecnoDocument4 pagesCV TecnoprashantghodkeNo ratings yet

- Inspection Report - 40001Document6 pagesInspection Report - 40001prashantghodkeNo ratings yet

- New Schedule Till June 2013 PDFDocument2 pagesNew Schedule Till June 2013 PDFprashantghodkeNo ratings yet

- New Schedule Till June 2013 PDFDocument2 pagesNew Schedule Till June 2013 PDFprashantghodkeNo ratings yet

- Work ExpDocument1 pageWork ExpprashantghodkeNo ratings yet

- Dish Fit Up With ShellDocument2 pagesDish Fit Up With ShellPrashantNo ratings yet

- Curriculum Vitae CV for Project EngineerDocument5 pagesCurriculum Vitae CV for Project EngineerprashantghodkeNo ratings yet

- Cardiac ArrestDocument8 pagesCardiac ArrestprashantghodkeNo ratings yet

- How To Play SudokuDocument34 pagesHow To Play SudokujitnikhilNo ratings yet

- Inspection Report - 100001Document6 pagesInspection Report - 100001prashantghodkeNo ratings yet

- Mformat Arch PDFDocument11 pagesMformat Arch PDFMary Grace ManiponNo ratings yet

- Antibiotics Classification and MechanismsDocument20 pagesAntibiotics Classification and MechanismsSalmanNo ratings yet

- Dong Zhang Quan 2020Document13 pagesDong Zhang Quan 2020Samanta Sin HacheNo ratings yet

- ABIR ProfileDocument30 pagesABIR ProfileMohamad NasserNo ratings yet

- Characteristics of Atomic Layer Deposited Tio 2 Films and Their Photocatalytic ActivityDocument6 pagesCharacteristics of Atomic Layer Deposited Tio 2 Films and Their Photocatalytic ActivityShenawarAliNo ratings yet

- Karakteristik Dan Pola Penggunaan Obat Analgesik Nsaid Pada Pasien Pasca Operasi Di Rsud Abdul Wahab Sjahranie SamarindaDocument11 pagesKarakteristik Dan Pola Penggunaan Obat Analgesik Nsaid Pada Pasien Pasca Operasi Di Rsud Abdul Wahab Sjahranie SamarindaAgung WsbNo ratings yet

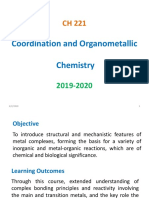

- Coordination and Organometallic ChemistryDocument42 pagesCoordination and Organometallic Chemistryfrank samndomiNo ratings yet

- The Following Text Is For Questions Number 1 and 2Document8 pagesThe Following Text Is For Questions Number 1 and 2ayip7miftahNo ratings yet

- SEMINAR PERDANA KESELAMATAN & KESIHATAN PEKERJAANDocument18 pagesSEMINAR PERDANA KESELAMATAN & KESIHATAN PEKERJAANjhj01No ratings yet

- Merck Anaerocult A (Generador de Anaerobiosis P Jarra)Document1 pageMerck Anaerocult A (Generador de Anaerobiosis P Jarra)linamas14No ratings yet

- Waterproofing System To Submerge Structure (Lift Pit) General RequirementsDocument3 pagesWaterproofing System To Submerge Structure (Lift Pit) General Requirementsaldeto71No ratings yet

- Measuring Control Sensor Technology ProMinent Product Catalogue 2014 Volume 2Document216 pagesMeasuring Control Sensor Technology ProMinent Product Catalogue 2014 Volume 2PUIA DANIELNo ratings yet

- Inhaled Anesthetics No. 9Document4 pagesInhaled Anesthetics No. 9mhma44490No ratings yet

- Pedel Powered Zeolite (Vacuum) RefrigeratorDocument7 pagesPedel Powered Zeolite (Vacuum) RefrigeratorAvikantNo ratings yet

- A. 2003. Grimsky, G. R. Spectrophotometric Determinaion of Protein ConcentrationDocument9 pagesA. 2003. Grimsky, G. R. Spectrophotometric Determinaion of Protein ConcentrationJorge Luis RomeroNo ratings yet

- Aromatic Hydrocarbons and ReactionsDocument13 pagesAromatic Hydrocarbons and ReactionsCCNo ratings yet

- Ground Floor Sanitary & Storm Drainage Isometric Ground Floor Waterline IsometricDocument1 pageGround Floor Sanitary & Storm Drainage Isometric Ground Floor Waterline IsometricroiNo ratings yet

- Kid para Valvula FlowtekDocument1 pageKid para Valvula FlowtekshenNo ratings yet

- Cable Cleats R2Document13 pagesCable Cleats R2Vishal RanjanNo ratings yet

- Begg Cousland Envirotec - Mist Elimination Equipment - 2018Document12 pagesBegg Cousland Envirotec - Mist Elimination Equipment - 2018Dũng LêNo ratings yet

- St5001 Maintenance and Rehablitation of Structures Question Bank Unit 1Document10 pagesSt5001 Maintenance and Rehablitation of Structures Question Bank Unit 1Suman.SNo ratings yet

- Critical Review On The Analytical Methods For The Determination of Sulfur and Trace Elements in Crude OilDocument20 pagesCritical Review On The Analytical Methods For The Determination of Sulfur and Trace Elements in Crude OilLindaNo ratings yet

![Naukri_RushikeshThorat[7y_0m]](https://imgv2-1-f.scribdassets.com/img/document/724574723/149x198/150b98bc2a/1713515908?v=1)

![Naukri_VISHALRAJARAMINGALE[6y_9m]](https://imgv2-1-f.scribdassets.com/img/document/726474322/149x198/fd5b3bd353/1714022160?v=1)