Professional Documents

Culture Documents

Maintenance Process (Breakdown, Preventive Maintenance)

Uploaded by

Safety DeptOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Process (Breakdown, Preventive Maintenance)

Uploaded by

Safety DeptCopyright:

Available Formats

TITLE : Maintenance Process DOCUMENT NO.

-

ISO 9001:2015 Clause Ref. - 8.5 ISSUE -

ISSUE DATE -

PURPOSE : This procedure covers about the maintenance process

SCOPE : This procedure is applicable to all machine and tooling

PROCESS OWNER : Maintenance HOD

By what (Equipment material) Risk Analysis By whom (personal, training, know-how, skills):

1.) Spare Parts Refer Risk Analysis for Maitenance (F/MNT/05) Mechanical / Electrical / Hydraulic / PLC / Knowledge

2.) Tool kit

Inputs: Outputs:

1.) Breakdown Slip / Information 1.) Breakdown Log Book (Updated)

2.) Breadkown log entry / SAP entry 2.) Breakdown Summary Updation / History Card Updated

3.) Machine Manuals/ Warranties (Manufacturers) 3.) Breakdown Analysis Report

4.) PM Planning as per Production Plan 4.) Spare Parts Updated Sheet

Maintenance Process 5.) Machine Handover Sheet

6.) PM Checksheet (Updated)

(Breakdown, Preventive

Maintenance)

How (instructions, procedures, methods, Performance Indicators:

technique): 1.) PM Plan Vs Actual Adherance (%)

(1) Receiving Customer complaint 2.) Breakdown (Hours)

(2) Raising & communication of Customer complaint 3.) MTTR / MTBF

(3) Data collection, root cause analysis and action plan

(4) C/m standardization and communication to customer

for closure

TITLE : CUSTOMER COMPLAINT HANDLING SYSTEM DOCUMENT NO. -

ISO 9001:2015 Clause Ref. - 7.5. 8.5, 8.7, 9.1, 10.3 ISSUE -

ISSUE DATE -

PURPOSE : This procedure covers all non-conforming products / items which are rejected by the customer.

SCOPE : This procedure is applicable to all the rejected products returned from the customer.

PROCESS OWNER : Quality Assurance (QA)

By what (Equipment material) Risks: By whom (personal, training, know-how, skills):

(1) SAP/ MS Excel format (1) Verbal complaint not addressed in QMS/ CAR result in customer (1) Who - Customer Quality Representatives

(2) Phone/Internet/E-Mail/WhatsApp/Customer Portals dissatisfaction (2) Know how trainings - Problem Solving, Why-why

(2) Customer complaint correction / CAR mis-communication within approach/deep analysis, tolerance analysis, Product,

organization result in repeated customer complaint Process Knowledge, Process Audits, Drawing study

(3) Contermeasure are NOT closed as per the timeline

(4) Standardization is not effective for countermeasure (action)

(5) Process owner is NOT competent

Inputs: Outputs:

(1) Customer reported plant rejection, customer portals, (1) Customer Quality Problem Report / Summary

field rejection, returned failed product, Debit claims,etc. (2) Customer analysis/ Corrective Action Report (CAR)

(2) Customer Representative communication formats (wherever applicable)

(3) Past failures know how (3) Communication to customer

(4) Standardized documents - Change Request Notes,

Customer Complaint Control Plan,Process Flow Diagram,OPL (One Point

Handling System Lesson - Before / After) , PFMEA,etc.

(5) Quality Alert communication on assembly & machines

How (instructions, procedures, methods, Performance Indicators:

technique): (1) Customer Plant Rejection - No's/PPM

(1) Receiving Customer complaint (2) Warranty Rejection

(2) Raising & communication of Customer complaint

(3) Data collection, root cause analysis and action plan

(4) Countermeasure standardization and communication

to customer for closure

TITLE : DOCUMENT NO. -

IATF 16949:2016 Clause Ref. - ISSUE -

ISSUE DATE -

PURPOSE :

SCOPE :

PROCESS OWNER :

By what (Equipment material) Risk Analysis By whom (personal, training, know-how, skills):

Inputs: Outputs:

Process Name - ??

How (instructions, procedures, methods, Performance Indicators:

technique):

You might also like

- Day 1Document3 pagesDay 1Sandeep kulkarniNo ratings yet

- Exercise OhsmsDocument5 pagesExercise OhsmsHR CONSULTING JobNo ratings yet

- TS QuestionsDocument2 pagesTS QuestionsImran AhamedNo ratings yet

- Training Flyer - IsO 9001 Public Trainings Rev2Document1 pageTraining Flyer - IsO 9001 Public Trainings Rev2lewgne08No ratings yet

- 4M ManagementDocument5 pages4M ManagementSachin YadavNo ratings yet

- PM 02 03 Management ReviewDocument4 pagesPM 02 03 Management ReviewAllison SontowinggoloNo ratings yet

- Internal Audit Checklist Q1 - ISO 2015Document29 pagesInternal Audit Checklist Q1 - ISO 2015ayşe çavdar100% (1)

- APG External Providers 2015Document3 pagesAPG External Providers 2015John Rajesh0% (1)

- Form IA-010NC (Audit Notification Letter) (3!28!2012)Document1 pageForm IA-010NC (Audit Notification Letter) (3!28!2012)granburyjohnstevensNo ratings yet

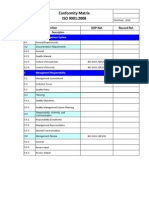

- ISO 9001 Conformity MatrixDocument3 pagesISO 9001 Conformity Matrixkashifbutty2kNo ratings yet

- 1.4 Evidance ISO 9001-2015 On ProcessDocument6 pages1.4 Evidance ISO 9001-2015 On ProcessRaharjo YakinNo ratings yet

- Project Proposal For Iso 9001:2015 Implementation: (Organization Name)Document5 pagesProject Proposal For Iso 9001:2015 Implementation: (Organization Name)RajasekharChimiralaNo ratings yet

- Leaving AfghanistanDocument7 pagesLeaving AfghanistanMahdi Loman50% (2)

- IMS Audit - Version 1Document11 pagesIMS Audit - Version 1arobNo ratings yet

- EMS APG Risks and OpportunitiesDocument3 pagesEMS APG Risks and Opportunitiesdio39saiNo ratings yet

- EMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefDocument13 pagesEMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefBharath K GNo ratings yet

- Preventative Maintenance Plan Template SampleDocument7 pagesPreventative Maintenance Plan Template SamplePankaj KatariyaNo ratings yet

- Management System Auditing by David HoyleDocument35 pagesManagement System Auditing by David HoylesonicefuNo ratings yet

- Contract checklist for Chennai customerDocument1 pageContract checklist for Chennai customerIsaiah100% (1)

- Preview - Iso9001-2015.checklist For ISO 9001-2015Document6 pagesPreview - Iso9001-2015.checklist For ISO 9001-2015Jones RNo ratings yet

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- Operating Procedure for Internal & External CommunicationDocument4 pagesOperating Procedure for Internal & External CommunicationnomanNo ratings yet

- QMS Audit Check-HR R2-ControlledDocument3 pagesQMS Audit Check-HR R2-Controlledkumarkk1969No ratings yet

- Factory Wastewater Test Report SummaryDocument19 pagesFactory Wastewater Test Report SummaryAzrof AhmedNo ratings yet

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoNo ratings yet

- Management Review: ISO 9001:2015 GuidanceDocument3 pagesManagement Review: ISO 9001:2015 GuidanceMadan R HonnalagereNo ratings yet

- Second Test HomeDocument7 pagesSecond Test HomePam MshweshweNo ratings yet

- Logo Perusahaan CAR ISO 9001Document2 pagesLogo Perusahaan CAR ISO 9001Yoepy WijayaNo ratings yet

- SLCP Verification ProtocolDocument62 pagesSLCP Verification ProtocolWILFREDO SSOCONSULTORESNo ratings yet

- ISO Procedures For Maintenance DepartmentDocument1 pageISO Procedures For Maintenance Departmentjfelix_arana0% (1)

- RESUME CV Tabeti Abdelkader English 2017Document11 pagesRESUME CV Tabeti Abdelkader English 2017Habib TabetiNo ratings yet

- Tools ISO 9001Document3 pagesTools ISO 9001Miftakhul Nurdianto100% (1)

- ISO 9001 2008 Awareness Training QuestionnaireDocument2 pagesISO 9001 2008 Awareness Training Questionnaireezal2100% (3)

- KEY-QMS-05 - F-01 Document Change Request FormDocument1 pageKEY-QMS-05 - F-01 Document Change Request FormMenuka SiwaNo ratings yet

- Communication MatrixDocument2 pagesCommunication MatrixabimanyubawonoNo ratings yet

- Summary of Iso 90091Document3 pagesSummary of Iso 90091Ihuhwa Marta TauNo ratings yet

- ISO 9001 - Google BooksDocument2 pagesISO 9001 - Google Bookssreenath100% (1)

- All ExercisesDocument13 pagesAll ExercisesMeenal Dutt100% (1)

- PUR-F-SEF - Supplier Evaluation FormDocument1 pagePUR-F-SEF - Supplier Evaluation FormRajkumar PrajapatiNo ratings yet

- PRE Test Question: Iso 9001 Quality Management SystemDocument4 pagesPRE Test Question: Iso 9001 Quality Management SystemAna Hidayah SyuhadaNo ratings yet

- Siemens' Motor HandbookDocument20 pagesSiemens' Motor HandbookJerome BaesNo ratings yet

- Auditing BCPS Quality ManagementDocument6 pagesAuditing BCPS Quality Managementsengcyan100% (1)

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Required Procedures and Records For 2015Document1 pageRequired Procedures and Records For 2015Jeff DrewNo ratings yet

- FMEA Checklist for Supplier EvaluationDocument7 pagesFMEA Checklist for Supplier EvaluationNavnath TamhaneNo ratings yet

- White Belt PPT Slides - Six Sigma PH - 13SEP2020Document18 pagesWhite Belt PPT Slides - Six Sigma PH - 13SEP2020Dos LimNo ratings yet

- Non Conformance ProcedureDocument3 pagesNon Conformance ProcedureAjay G GopalNo ratings yet

- ISO 9001 2015 Mock AuditDocument15 pagesISO 9001 2015 Mock AuditMadan R HonnalagereNo ratings yet

- IntergrafDocument6 pagesIntergrafripac100% (1)

- Mini Quality ManualDocument7 pagesMini Quality Manualwici2915No ratings yet

- QCC+Application Registration+FormDocument4 pagesQCC+Application Registration+FormrajaabidNo ratings yet

- Certified ISO 14001 Lead Auditor - Four Page BrochureDocument4 pagesCertified ISO 14001 Lead Auditor - Four Page BrochurePECBCERTIFICATIONNo ratings yet

- 8.19 Poster Unusual SituationsDocument1 page8.19 Poster Unusual Situationsedumm001No ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Module Wise Deliverables and Project Plan - IsO 17025Document2 pagesModule Wise Deliverables and Project Plan - IsO 17025Vinay YadavNo ratings yet

- Core ObjectiveDocument1 pageCore ObjectiveMatthew LeeNo ratings yet

- ISO 9001:2015 CS 6 Desktop Audit - 2017Document4 pagesISO 9001:2015 CS 6 Desktop Audit - 2017YasirdzNo ratings yet

- Electronic Open Assessment FAQsDocument2 pagesElectronic Open Assessment FAQsshiyas M.MNo ratings yet

- 4.4.1 Turtle Diagram ADocument3 pages4.4.1 Turtle Diagram ArohitNo ratings yet

- Communication Matrix - Quality Updates for All DepartmentsDocument1 pageCommunication Matrix - Quality Updates for All DepartmentsSafety Dept100% (2)

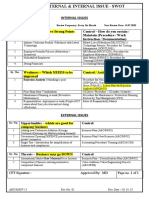

- List of External & Internal Issue - SwotDocument2 pagesList of External & Internal Issue - SwotSafety DeptNo ratings yet

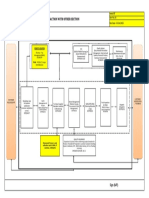

- Process Interaction With Other Section: Remote LocationDocument1 pageProcess Interaction With Other Section: Remote LocationSafety DeptNo ratings yet

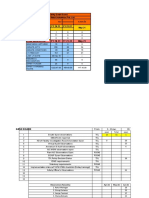

- Master list of special part characteristicsDocument2 pagesMaster list of special part characteristicsSafety DeptNo ratings yet

- 8.3.3.2 - Process Design Input & Verification SheetDocument3 pages8.3.3.2 - Process Design Input & Verification SheetSafety DeptNo ratings yet

- Master List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoDocument6 pagesMaster List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoSafety DeptNo ratings yet

- A Prepration Sheet - 16062020Document5 pagesA Prepration Sheet - 16062020Safety DeptNo ratings yet

- 4.3.1 - F - Determine The Scope of QMSDocument1 page4.3.1 - F - Determine The Scope of QMSSafety DeptNo ratings yet

- Communication Matrix - Quality Updates for All DepartmentsDocument1 pageCommunication Matrix - Quality Updates for All DepartmentsSafety Dept100% (2)

- POSHS METAL INDUSTRIES PVT FIRE PAINT SCHADULEDocument16 pagesPOSHS METAL INDUSTRIES PVT FIRE PAINT SCHADULESafety DeptNo ratings yet

- 6.1 Risk - Opportunity AnalysisDocument4 pages6.1 Risk - Opportunity AnalysisSafety DeptNo ratings yet

- List of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Document1 pageList of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Safety DeptNo ratings yet

- POSHS Metal Industries PVT - LTDDocument12 pagesPOSHS Metal Industries PVT - LTDSafety DeptNo ratings yet

- 4.2 - Needs and Expectation With Risk AnalysisDocument3 pages4.2 - Needs and Expectation With Risk AnalysisSafety Dept50% (2)

- Employee List For LOTO ProcedureDocument7 pagesEmployee List For LOTO ProcedureSafety DeptNo ratings yet

- Job Safety Analysis Power Transformer TestingDocument8 pagesJob Safety Analysis Power Transformer TestingAnilPagoluNo ratings yet

- Monthwise EHS theme planDocument6 pagesMonthwise EHS theme planSafety DeptNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- Observation No Observation Detail Visit Date Observation TypeDocument6 pagesObservation No Observation Detail Visit Date Observation TypeSafety DeptNo ratings yet

- POSHS Metal Industries PVT - LTDDocument11 pagesPOSHS Metal Industries PVT - LTDSafety DeptNo ratings yet

- DASH BOARD For PendingsDocument3 pagesDASH BOARD For PendingsSafety DeptNo ratings yet

- Checklist of Gas Cutting SetDocument3 pagesChecklist of Gas Cutting SetSafety DeptNo ratings yet

- Office Safety ChecklistDocument4 pagesOffice Safety ChecklistMuse TaqimNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Manual Metal Arc WelderDocument1 page(Your Business Name Here) - Safe Work Procedure Manual Metal Arc WelderSafety DeptNo ratings yet

- POSHS Metal Industries PVT - LTD: Checklist of Gas Cutting SetDocument1 pagePOSHS Metal Industries PVT - LTD: Checklist of Gas Cutting SetSafety DeptNo ratings yet

- List of Barricades:: Sr. No. Section Line No DescriptionDocument4 pagesList of Barricades:: Sr. No. Section Line No DescriptionSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Metal LatheDocument1 page(Your Business Name Here) - Safe Work Procedure Metal LatheSafety DeptNo ratings yet

- Checklist For Full Body Safety HarnessDocument1 pageChecklist For Full Body Safety HarnessSafety DeptNo ratings yet

- Vendor Details Plant Details External Audit Details: Vendor /factory Reg NoDocument18 pagesVendor Details Plant Details External Audit Details: Vendor /factory Reg NoSafety DeptNo ratings yet

- People V Estrada Case DigestDocument2 pagesPeople V Estrada Case DigestKim V100% (1)

- Module 1 Personal Development - PH Learner's Handbook - FINALDocument21 pagesModule 1 Personal Development - PH Learner's Handbook - FINALLJames Sacueza100% (1)

- SHS Core Komunikasyon at Pananaliksik SaDocument2 pagesSHS Core Komunikasyon at Pananaliksik SaPaghuta Lanta PaakaNo ratings yet

- Cambridge Library Collection: ClassicsDocument10 pagesCambridge Library Collection: ClassicsCarlos AugustoNo ratings yet

- SEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingDocument3 pagesSEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingSn AhsanNo ratings yet

- Sgsy Paper: June 2021Document7 pagesSgsy Paper: June 2021ima doucheNo ratings yet

- A2 Flyers Listening Part 4Document9 pagesA2 Flyers Listening Part 4MahekNo ratings yet

- Web-Based Procurement SystemDocument29 pagesWeb-Based Procurement SystemMish Lei Franxh100% (1)

- Self Tower InstallDocument88 pagesSelf Tower InstallBoris BravoNo ratings yet

- Lesson Plan Counting 1-100 Naldo Tricia Mae v. Beed 2aDocument6 pagesLesson Plan Counting 1-100 Naldo Tricia Mae v. Beed 2aRico BongonNo ratings yet

- Diamond ModelDocument15 pagesDiamond Modelcherry d.bandolaNo ratings yet

- Managing People in Global Markets-The Asia Pacific PerspectiveDocument4 pagesManaging People in Global Markets-The Asia Pacific PerspectiveHaniyah NadhiraNo ratings yet

- Forgetting Music - Duration Space and Remembrance in The LateDocument95 pagesForgetting Music - Duration Space and Remembrance in The LatelourencobrNo ratings yet

- Antonio J MolinaDocument4 pagesAntonio J MolinaLeira Salazar100% (2)

- 4th Grade Answer KeyDocument43 pages4th Grade Answer KeyJustine Chmelko StoltzNo ratings yet

- Pig Calculation Tables: Date Batch Nr. Number of PigletsDocument7 pagesPig Calculation Tables: Date Batch Nr. Number of PigletsUrs SchaffnerNo ratings yet

- High Court of H.PDocument5 pagesHigh Court of H.PAnshul SharmaNo ratings yet

- Nurse CPD Requirements for Resuscitation Council CoursesDocument2 pagesNurse CPD Requirements for Resuscitation Council CoursesEdy Syahputra HarahapNo ratings yet

- Task Performance Rizal WorksDocument2 pagesTask Performance Rizal WorksMikel Angelo ManansalaNo ratings yet

- 6 Leadership Lessons From Kevin Johnson, Starbucks CEO - Perspectives LTDDocument4 pages6 Leadership Lessons From Kevin Johnson, Starbucks CEO - Perspectives LTDnarenNo ratings yet

- IHL Partial SyllabusDocument4 pagesIHL Partial Syllabusjstn libyNo ratings yet

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- Practice TestDocument6 pagesPractice TestTớ Là GuangNo ratings yet

- Reflection Paper BSCSDocument3 pagesReflection Paper BSCSSeignir TVNo ratings yet

- Reuben Sanders CV 11 19Document1 pageReuben Sanders CV 11 19Anonymous Y0cxALSNo ratings yet

- Secondary Syllabus Form 3Document18 pagesSecondary Syllabus Form 3Syazwani Abu Bakar100% (1)

- Extension of Time Standard LettersDocument41 pagesExtension of Time Standard LettersFrancis Aw Soon Lee96% (46)

- 2016-17 Google Classroom Codes - ITDocument2 pages2016-17 Google Classroom Codes - ITSubin Chitrakar100% (1)

- Don't Overload Students - Assigning Too Much Work Discourages Learning - InformED PDFDocument5 pagesDon't Overload Students - Assigning Too Much Work Discourages Learning - InformED PDFClayton BrásNo ratings yet

- TPM - Bill N MaggardDocument107 pagesTPM - Bill N MaggardAnghelo AlcaldeNo ratings yet