Professional Documents

Culture Documents

Warehouse Design 1

Uploaded by

Truong Diem SuongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warehouse Design 1

Uploaded by

Truong Diem SuongCopyright:

Available Formats

lOMoARcPSD|9691613

Warehouse Design Nguyen Thi Quynh Hoa s3817860

Warehouse Management (Royal Melbourne Institute of Technology University Vietnam)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

RMIT University Vietnam

Lecturer: Scott McDonald

WAREHOUSE DESIGN

PROJECT REPORT

TEAM MEMBERS:

VAN TUE NGHI - S3777212

TRAN PHUONG THAO - S3777217

NGUYEN LE QUYNH MAI - S3756902

NGUYEN THI QUYNH HOA - S3817860

NGUYEN PHAN THUC ANH - S3804800

WORD COUNT: 3120

MAIADO COMPANY

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

"I declare that in submitting all work for this assessment I have read,

understood and agree to the content and expectations of the Assessment

Declaration."

Table of Contents

Executive Summary............................................................................................2

I. Introduction..................................................................................................4

II. General information....................................................................................4

1. Geographic Location:.................................................................................4

2. Features of products...................................................................................5

2.1 Product Assortments................................................................................5

2.2 SKUs........................................................................................................5

2.3 Inventory Management............................................................................6

2.4 Value-added services................................................................................6

III. Warehouse layout & operation:..............................................................7

1. Layout design.............................................................................................7

2. Inbound process..........................................................................................8

3. Outbound process.....................................................................................11

3.1 Order picking.........................................................................................11

3.2 Dispatch.................................................................................................11

3.3 Cross docking........................................................................................12

4. Reverse process........................................................................................13

4.1 Defective products.................................................................................13

4.2 Products of full value.............................................................................15

IV. OHS..........................................................................................................16

V. Equipment..................................................................................................17

VI. Operating system....................................................................................19

VII. Other facilities.........................................................................................21

VIII. Future growth.........................................................................................21

IX. Conclusion...............................................................................................21

X. References...................................................................................................22

XI. Appendices..............................................................................................24

1

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Executive Summary

This report results from the warehouse design by five members, intending to conceptualize

efficient inventory custody and distribution for Maiado, a luxury handbag company, looking

to construct a 20,000m2 warehouse for their Southern Vietnam operation. The facility is

located at the Hiep Phuoc Industrial Park, beside important main roads adjacent to

transportation platforms, while benefiting from utility and service support by the industrial

network and HCMC authorities. The growing market for both production and consumption of

luxury handbag in Vietnam have met with difficulties by these factors:

1. Existence of fake luxury handbags, thinning the market for authentic brands.

2. Lack of automated infrastructure and safety measures for warehousing personals.

3. Order inaccuracy met with across many industries. The above reason contributes

to this disadvantage, along with inefficient operation.

4. Lengthy order cycle time due to non-optimal warehouse layout and operation.

5. Inventory losses and unauthorized distribution (deriving from inventory losses).

6. Damaged and faulty products due to unthorough quality control procedures.

Solutions to be provided by the team will address the majority of these issues, in support of

smooth and seamless operation for Maiado supply chain as well as long-term growth for

downstream supply chain partners:

1. Elaborate reverse logistics procedures - highlighting access to warranties for

authentic retailer purchases.

2. U-shaped warehouse with dock doors on one end, easy to manage in-and-out

inventories and irrelevant resources.

3. Automated system for inventory management and safety concerns: RFID, EDI,

barcode, NEC Warehouse Inspection system, OHS guidelines.

4. Double-deep racking system for space efficiency, with corresponding

locating/retrieval MHEs: deep-reach truck.

5. Powered pallet truck with extended forks, higher capacity and timeliness for order

picking and warehouse transportation in general.

6. Zone picking method for better management of inventories and accurate picking

process.

7. Quality control for both inbound-outbound processes, with RFID portal systems

being final checkpoints for order sufficiency and warehouse security.

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

8. Bulk consolidation by pallet wrapping machines to avoid the collision, damage,

and inventory loss during transportation.

9. Layout is designed according to order cycle time, with dynamic products stored

closest to both inbound-outbound areas.

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

I. Introduction

Maiado is a Vietnamese company specializing in luxury handbags, which targets upper and

high-end customers in the south of Vietnam. As Maiado continues to develop significantly,

the need to expand our business network is essential. Our company anticipates offering our

products to 500,000 customers (end users). Therefore, the requirement of building a 20,000

2

m warehouse to achieve our goal and store more handbags, approximately 200,000

products to meet this need is our priority. Hence, it assigns a Logistics team, including five

members, to find a suitable location and design the warehouse layout. This report will

provide a comparative analysis of Maiado’s area, designs, operations, equipment, operating

system, facilities, occupational health and safety (OHS), and the potential future growth.

II. General information

1. Geographic Location:

The chosen warehouse is located in Hiep Phuoc Industrial Park (HIPC) with 1,686 hectares.

First, HIPC owns a strategic geographic location to approach cities and adjacent areas,

connecting the warehouse to both the domestic region and international market (Hiep Phuoc

n.d.) (Figure 1). It is located rightly on the main roads, National Expressways, and other

water transportation systems. Second, HIPC ensures finding a huge qualified labour source

from universities and colleges nearby (Prosquare n.d.). Next, owning proximity to three

international seaports, including SPCT, Tan Cang - Hiep Phuoc Port, and Saigon - Hiep

Phuoc Port, helping save time and transportation fee (Prosquare n.d.). Regarding utilities, the

priority of 24/24 electricity supply is instructed by Ho Chi Minh City leader; water supply

with the quantity up to 43,000 m3 /day; and industrial gas supply network, clean and

environmentally friendly resources. Moreover, the wastewater treatment capacity is 18.000

m3 /day and night (Prosquare n.d.). Lastly, HIPC supports A to Z, such as tax consultancy

services, investment licenses, construction permits (Bao Tin Real Estate Company n.d.).

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 1. Subdivision Locations of HIPC

2. Features of products

2.1 Product Assortments

The warehouse contains four types of products with different colours. A variety of closures

are typically made with weather-resistant and durable materials.

2.2 SKUs

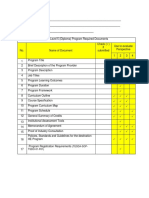

Figure 2. SKUs List

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

For example, the SKU of the first black shoulder bag with push-lock closure inputted into the

computer is S - BK - P - 001, and the second one is S - BK - P - 002. The same processes are

applied to other product categories.

2.3 Inventory Management

The level of product assortment will be classified into three groups which are A, B, and C.

Applying the Pareto Principle to the inventory, it is necessary to keep the big 20 percent of

the products instead of keeping 80 percent in stock because 80 percent of the sales come from

that small 20 percent (Kubasakova, Poliakova & Kubaova 2015). Group A sells 4 bags once a

week, group B sells an average volume of 20 bags weekly, and others that sell well are in

group C. Therefore, the warehouse would store 20 percent of the item in category A,

following those in category B and C - making up about 30 and 50 percent respectively.

Figure 3. ABC categories

2.4 Value-added services

Value-added services help optimize supply chain management, create high value, and deliver

products efficiently to customers (Solistica 2019). In terms of custom labels for a leather

handbag, woven labels can be located outside or inside the internal pocket and large enough

to not miss it. Regarding packaging, each luxury handbag box includes a printed logo with a

ribbon bow.

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

III. Warehouse layout & operation:

1. Layout design

Figure 4. The warehouse layout

With 20,000 m 2 provided to build a warehouse, the main warehouse building will be at the

top-right corner of the layout with a total area is 12,600 m 2 . The rest is 7,300 m 2 for

other purposes such as a 30m for the front yard, parking lot, locker, cafeteria, medical place,

break room, and toilet built on the left side. In the warehouse area, there are three entryways

to go inside the warehouse building. We divide one entrance used for worker-only and the

others used for trucks transporting in and out of the warehouse space.

The warehouse building will have 180m in length, 70m in width, and 12m in height.

Receiving and shipping areas are located right behind the dock doors, followed by staging

areas for sortation and staging. In-between these stations are the cross-docking area, the latter

being closest to dock doors. The down-right corner will be used to build a reverse logistics

area to fix or refurbish handbags and then transfer them to storage areas or move them to

shipping areas to sell them to retail outlets. Additionally, the warehouse building also has a

main office and IT office for the managers' staff and management office. There will be space

for future SKU expansion on the right of the central storage, now used as 3PL services.

There are 216,000 items in storage area (Figure 5).

7

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 5. The number of products stored in each zone

2. Inbound process

Figure 6. Inbound

First, the inbound process starts with handbags and 3PL packages entering the warehouse via

the sawtooth dock area leaning 45 degrees compared to the apron space (Nova Technology

2017), minimizing the required space to 10.6 m from the main entrance for straight trucks.

The unloading process commences with an electric pallet jack carrying around five deliveries

per load through 5 dock doors (Appendix 14) from a straight truck to the receiving area.

Here, 3PL packages are delivered straight to their zone while company packages are put on a

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

U-shape conveyor for quality control conducted by inspection team A unboxing all goods to

check for accessories components including zippers and buckles while the RFID called NEC

examines weight, size, and SKUs following pre-registered images and weight information.

Next, items are individually embedded with SKUs' data, shelf location via an RFID tag,

which can be automatically scanned in batch by remote readers (Qiu, Liang & Huang 2017).

Afterward, cameras and weight scales shoot and weigh handbags according to pre-registered

image recognition technology.

These along with a control terminal and server can act as a platform to exchange data with

the customer's warehouse management system. Therefore, the inspection process becomes

more accurate, owing to automation.

Figure 7. Warehouse Product Inspection System (NEC n.d.)

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 8. Quality Control Specifications

(Adapted from NEC n.d., Stang 2015, SROA n.d.)

They are then all transferred to the staging area, which includes sorting, bulk wrapping by

machines, and transiting before being moved accordingly to order, either to the storage space

or cross-docking station. This type of logistics picks up items from a manufacturer to

multiple end clients providing minimal handling, storing, and high security (Luo, Yang &

Wang 2019). Additionally, the staging point provides handbag supporting services, including

adding paddings, foams, and paper boards for shape-keeping, whereas bubble-wrapping and

paper-wrapping avoid discoloration or stains.

After the assortment, on the one hand, all packages are placed on waiting pallets for the

electric power jack to deliver goods to scheduled shelves in storage while others are moved in

bulk on conveyors directly to the staging area on the dispatch side. In terms of storage room,

as the products are all high-end handbags, they are categorized into three sectors relying on

ABC assortment, which comprises zone A, zone B, and zone C.

Generally, the inbound warehouse process is mostly conducted by advanced tracking and

handling technology under human supervision, except for product assortments following their

next destination (storage/cross-docking) in the staging area, where it is done manually

following pre-set orders.

10

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

3. Outbound process

Figure 9. Outbound

3.1 Order picking

The order-picking system we decided to utilize is zone picking. Zone picking allocates

resources in each area, allowing a more accurate picking process (van Gils 2018 et al., p.244).

There are two types of vehicles utilized in this process for mainly different purposes. The

deep-reach forklifts will be used for locating-retrieving items, and the power pallet truck for

outbound transportation and supporting bottom level retrieval, maneuvering sufficiently since

this racking system is space-efficient.

The deep-reach truck drivers will perform retrieval at their respective racking areas so that

inventories are ready for transfer when the powered pallet truck arrives. The deep-reach truck

drivers shall receive notifications to pick the pallets needed, then transfer them onto the

electric pallet truck to be moved to the value-added area before leaving for the dispatching

site.

3.2 Dispatch

This area is the preparation for inventories to leave the warehouse. Inventories will be taken

to the value-added service area and moved onto the quality control department (except for

3PL commodities) before arriving at the sort and staging area for dispatching.

11

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

When arriving at the sort and staging area, the pallets are removed from the vehicle,

depalletized, unwrapped, and await further handling. The handbags' quality control procedure

is similar to that of the receiving process, only with the extra x-ray scanning process

(supervised by the inspection team) for product measurement.

Sortation: First, each labor takes charge of the order, collecting boxes along the conveyor

using RFID readers. As each box flows through, the RFID reader will inform the

corresponding orienting order(s) that it (may) belong to, so workers can pick, palletize, and

confirm back to the system. When the order has been sufficiently collected, the boxes' RFID

labels will be scanned in bulk, re-written with additional destination information, and

palletized.

Consolidation & Packaging: When every order has been palletized, the forklifts will carry

them to the end of the conveyor to be consolidated into bulks by wrapping machines,

avoiding displacement or collision while traveling, then moved to the shipping area. The

pallets will also be labeled with order-embedded RFID tags. Before loading, the forklifts will

drive through the RFID portal system, which picks up the pallets’ order information while

checking every box, automatically confirming the transfer and alerting when false or

insufficient pallets/boxes enter the trucks. This optimizes fulfillment accuracy and increases

security, preventing inventory losses.

3.3 Cross docking

The cross-docking process is just like the warehousing process, only without the storage

function (Cattani, Souza & Ye 2014, p. 893).

Packages will be quality checked and sorted to order using RFID at the receiving area, then

palletized on the powered pallet trucks to be consolidated by wrapping machine and driven

directly to the dispatch area, straight into the trucks. Using vehicles as the primary means of

transportation eliminates the need for time and workforce to load and unload packages from

the conveyors. Since the product quantity does not justify the need for continuous cross-

docking activities, investing in conveyor is also unjustifiable.

12

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

4. Reverse process

The returned products are returned from three primary sources, including manufacturing

returns, distribution returns, and consumer (marketing) returns (Brito & Dekker 2004). The

manufacturing returns are not mentioned in this paper since they relate to components in

manufacturing parts. While distribution returns are mainly due to damage (in transport) or

surplus in stock, consumer returns are guaranteed products or end-of-use products (Talbot,

Lefebvre & Lefebvre 2007). They are classified into two types: defective products and

products of full value.

4.1 Defective products

The defective products in warranty period returned by customers and distributors are scanned

by RFID reader before receiving to ensure authorization. The returned items are stored in the

Reverse Logistics Area for further test on the defects. Those defects are classified based on

the Defect Classification List.

13

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 10. Defect classification list (Adapted from Kohl’s 2008)

14

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

After controlling and sorting the returns, those with minor defects are repaired or refurbished

in the Reverse area and delivered to customers or outlets for reselling. In contrast, those with

significant and critical defects are decided to send back to the manufacturing plant for

remanufacturing, reused, and recycled into raw material or disposal in the landfill.

4.2 Products of full value

While the decision on the inclusion of defective products into the reverse flows is positive,

the products of full value have negative decisions on inclusion (Starostka-Patyk 2017). Those

handbags are first-quality products, which means they are received in identical conditions

that they were sold. If any handbag cannot meet the ongoing standards, it is considered a

defective product. Therefore, those full-value products are redirected for resell in forwarding

logistics. To ensure no full-value handbag is mistakenly classified as defective ones, they are

inspected stringently during the collecting process.

Figure 11. Reverse Logistics flow

15

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

IV. OHS

Figure 12. Risk management in warehouse (Adapted from HSE 2019, IHSN 2018, Paoletta 2020,

Adams 2020)

16

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 13. Safety equipment (Adapted from TNT 2017, Warehouse1 2015, Complete Storage &

Interiors n.d., CSI n.d.)

V. Equipment

These equipment below are installed and used in our warehouse. All equipment will have

preventive maintenance, the maintenance time is based on types of equipment.

Equipment Description Quantity Price

(units)

Storage system Double deep - Accomplish higher stocking density, 10 $109,038

racking system whereas access to the pallets is still

(Figure 18) quick and easy.

- An extremely effective and strong

system with simple construction and

adjustment of load levels.

- Alterable pallet racking and racking

thoroughly tailored with products of

17

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

various weight or quantity

(Ar Racking 2021)

Material handling Raymond Deep - Used for loading and unloading pallets 3 $155,769

equipment (MHE) Reach Forklift in the racking system in both inbound

Truck 7500 (Figure and outbound.

19) - Reach within the racks due to

expandable forks

- Enable double-deep pallet storage in the

racks, reducing two aisles out of every

five, for expanded storage density

(Raymond 2020)

- Works alongside the powered pallet

truck to retrieve pallets in our

warehouse

Electric pallet truck - Used for unloading and loading cargoes 5 $71,394

(Figure 20) from containers to the docking area and

from the docking area to the storage

system and vice versa for outbound.

- Sufficiently flexible to do it all from

dock work and horizontal transport to

low-level order picking, whilst meeting

high throughput and the most

demanding utilization, bringing energy

proficiency, downtime reduction, and

fewer maintenance expenses (Raymond

2020)

Automated pallet - Maximize workforce’s efficiency and 1 $86,538

truck (Figure 21) decrease repeatable horizontal transport

tasks

- Utilized for Inbound such as Staging to

Pick & Drop location and Crossdock

(staging to staging), material transfer

including Pallet from Pick & Drop to

Outbound staging and Outbound

comprising order pallets

(Raymond 2020)

Counterbalanced - Suitable for tasks in trailers, ramps and 1 $17307

Lift Truck (Figure stacking areas (Raymond 2020).

22) - Used for servicing, managing, storing

the empty pallets in our warehouse’s

pallet station. (see Figure )

Other equipments Pallets (Figure 23) - 15 boxes/ pallet 1440 $20,063

18

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

“U” Shaped Belt - Utilized at the sorting and staging areas 2 $3461

Conveyor Line for concentrated sortation and

(Figure 24) consolidation, moving products to be

scanned and picked along the line.

- Assist quality control

Pallet Wrapping - Customize the wrapping type and wrap 2 $339

Machine (Figure 15 boxes/ pallet

25) - Allow to stack 15 boxes/pallet on the

racks, retrieve pallets from the racking

system and transfer pallets to the next

destination without collapse

RF Handheld - Give confirmation of receipts against 8 $2547

Scanner (Figure 26) buy orders, advanced shipping notices

(ASNs) and blind receipts

- Check stock counts by product, area, or

cycle count orders via system

- Furnish movement of commodities

from receiving to storage areas

(Bastian solutions n.d.)

Handheld barcode - Used to support RFID when the codes 2 $238

reader (Figure 27) are outwidth the RFID’s range of reader

Automated - Used for strapping boxes tightly 2 $1797

strapping machine

(Figure 28)

Total $468,491

Figure 14. Equipment used in warehouse

VI. Operating system

There are over 2,400 companies in 58 countries worldwide applying pc/MRP. Pc/MRP is a

cost-effective MRP system with fully integrated modules designing for manufacturing,

distribution, and retail operations (PCMRP n.d.a). By using the standard 13 modules, it offers

a number of potential benefits, for example, the software works flexibly from inventory

functions to purchasing to customer sales and invoicing (DMS Company, Inc n.d.). With the

low-price system (Figure 12), the team can enhance the warehouse performance efficiently

and be able to keep the individual processes and flows of resources at the lowest possible

cost.

19

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 15. Price List (PCMRP n.d.b).

20

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

VII. Other facilities

Figure 16. Other facilities in the warehouse (Adapted from Generatorwarehouse n.d., LinKa n.d.,

Parks 2017, Stanpro 2017)

VIII. Future growth

As for now, the storage area to the right will be dedicated to third-party services. Storage

facilities and warehousing activities will also be provided to ensure proper storage conditions

for the handbags and avoid misconduct from irrelevant resources. Depending on the rate of

consumption, the warehousing service will be charged correspondingly. Fast-moving

consumer goods will require the long-term commitment and be charged $2-3/ton - profiting

by service frequency, while slow-moving products will be charged $30-40/cbm/month. For

future expansion, this area, totaling 450 square meters, will be assembled to expand SKU.

IX. Conclusion

In conclusion, the complete design of Maiado’s warehouse has been illustrated throughout

this report. The main goal of Maiado is to provide not only effective logistics but also value-

added services to increase profitability and enhance the customer experience.

21

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

X. References

Alibaba n.d., Automated strapping machine, Alibaba, viewed 4 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=Automated+strapping+machine+&viewtype=&

tab=>.

Alibaba n.d., Double deep racking system, Alibaba, viewed 6 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=double+deep+racking+system>.

Alibaba n.d., Handheld barcode reader, Alibaba, viewed 30 December 2020,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=barcode+handle+reader>.

Alibaba n.d., Pallets, Alibaba, Alibaba, viewed 5 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=Pallet&viewtype=&tab=>.

Alibaba n.d., Pallet wrapping machine, Alibaba, viewed 3 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=pallet+wrapping+machine>.

Alibaba n.d., RF Handheld Scanner, Alibaba, viewed 5 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=RF+Handheld+Scanner+&viewtype=&tab=>.

Alibaba n.d., U Shaped Belt Conveyor Line, Alibaba, viewed 4 January 2021,

<https://www.alibaba.com/trade/search?

fsb=y&IndexArea=product_en&CatId=&SearchText=U+Shaped+Belt+Conveyor+Line&viewtype=&

tab=>.

Ar Racking storage solutions (Ar Racking) 2021, Double Deep Pallet Racking, Ar Racking storage

solutions, viewed 4 January 2021, <https://www.ar-racking.com/en/storage-systems/industrial-

racking/pallet-racking/double-deep-pallet-racking>.

Bao Tin Real Estate Company n.d., To attract investors, industrial zones need to enhance their quality,

Chothuexuong, viewed 24 December 2020, <http://www.chothuexuong.com.vn/en/News/to-attract-

investors-industrial-zones-need-to-enhance-their-quality/>.

Bastian Solutions n.d., RF Handheld Scanners, Bastian Solutions, viewed 26 December 2020,

<https://www.bastiansolutions.com/solutions/service/supply-chain-software/warehouse-management-

system/rf-handheld-scanners/>.

Cattani, K, Souza, G & Ye, S 2014, ‘Shelf Loathing: Cross Docking at an Online Retailer’,

Productions and Operations Management Society, vol. 23, no. 5, pp. 893-906, viewed 30 December

2020, Wiley database.

22

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

DMS Company, Inc n.d., pcMRP - DMS Company, DMS Company, Inc, viewed 2 January 2021,

<https://www.dmscoinc.com/manufacturing-software/pcmrp/>.

Hiep Phuoc n.d., Overall and subdivision, Hiep Phuoc, viewed 2 January 2021,

<https://www.hiepphuoc.com/en/vitri/Overall-and-subdivision.html>.

ISHN 2018, ‘Reinventing fire detection in industrial warehouses’, Industrial Safety & Hygiene News,

20 December, viewed 10 January 2021, <https://www.ishn.com/articles/109985-reinventing-fire-

detection-in-industrial-warehouses>

Kubasakova, I, Poliakova, B & Kubaova, J 2015, ‘ABC Analysis in the Manufacturing Company’,

Applied Mechanics and Materials, vol. 803, pp. 33-39.

Luo, H, Yang, X & Wang, K 2019, ‘Synchronized Scheduling of Make to Order Plant and Cross-

docking Warehouse’, Computers & Industrial Engineering, vol. 138, pp. 106-108.

Raymond 2020, Automated pallet truck, Raymond, viewed 26 December

2020,<https://www.raymondcorp.com/forklifts/automated-lift-trucks/3010-raymond-courier-

automated-pallet-truck>.

Raymond 2020, Counterbalanced lift truck, Raymond, viewed 28 December 2020,

<https://www.raymondcorp.com/forklifts/counterbalanced-trucks/4460-sit-down-forklift>.

Raymond 2020, Deep-Reach Truck, Raymond, viewed 27 December 2020,

<https://www.raymondcorp.com/forklifts/reach-fork-trucks/7000-deep-reach>.

Machines4u n.d., Electric pallet truck, Machines4u, viewed 6 January 2021,

<https://www.machines4u.com.au/search/electric+pallet+truck/>.

Raymond 2020, Electric pallet truck, Raymond, viewed 26 December 2020,

<https://www.raymondcorp.com/forklifts/pallet-trucks/8410-pallet-truck>.

Machines4u n.d., Automated pallet truck, Machines4u, viewed 6 January 2021,

<https://www.machines4u.com.au/search/Automated+pallet+truck/>.

Machines4u n.d., Counterbalanced Lift Truck, Machines4u, viewed 6 January 2021,

<https://www.machines4u.com.au/search/Counterbalanced+Lift+Truck/>.

Machines4u n.d., Deep Reach Forklift Truck, Machines4u, viewed 6 January 2021,

<https://www.machines4u.com.au/search/Deep+Reach+Forklift+Truck/>.

Nova Technology 2017, Dock Planning Standards, Nova Technology, viewed 27 December 2020,

<https://pdf4pro.com/fullscreen/dock-planning-standards-home-nova-2ed8.html>.

PCMRP n.d.a, FAQ, PCMRP, viewed 2 January 2021, <https://pcmrp.com/faq.htm#q_5>.

PCMRP n.d.b, Price List, PCMRP, viewed 2 January 2021, <https://pcmrp.com/pricing.htm>.

23

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Prosquare n.d., Hiep Phuoc Industrial Park, Prosquare, viewed 24 December 2020,

<http://www.prosquare.com.vn/en/hiep-phuoc-industrial-park>.

Qiu, L, Liang, X & Huang, Z 2017, ‘PATL: A RFID Tag Localization Based on Phased Array

Antenna’, Scientific Reports, vol. 7, no. 1, pp. 44183.

Solistica 2019, ‘Value-Added Services that improve your competitiveness’, Solistica, 3 January,

viewed 24 December 2021,

<https://blog.solistica.com/en/value-added-services-that-improve-your-competitiveness>.

SROA n.d., ‘How to Prepare Leather for Long Term Storage’, Storage Rentals of America, viewed 10

January 2021, <https://www.shdlogistics.com/workplace-wellbeing/avoiding-falls-height-warehouse

https://sroa.com/blog/storage-tips/how-to-prepare-leather-for-long-term-storage/#:~:text=Desirable

%20Temperature%20and%20Humidity%20for,the%20humidity%20is%20too%20high>

Van Gils, T,; Ramaekers, K., Braekers, K., Depaire, B. & Caris, A 2018, ‘Increasing order picking

efficiency by integrating storage, batching, zone picking, and routing policy decisions’, International

Journal of Production Economics, vol. 197, p.243-261.

XI. Appendices

Figure 17. 5 boxes per pallet in the receiving area

24

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 18. The double deep racking system

Figure 19. Raymond deep reach truck 7500

25

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 20. Raymond Pallet Jack 8410

26

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 21. Raymond courier 3010

Figure 22. Raymond Sit Down forklift 4460

27

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 23. The empty pallets in the warehouse

Figure 24. The U-shaped belt conveyor

28

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 25. The pallet wrapping machine

29

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 26. Radio Frequency Scanner

Figure 27. Handheld Barcode Reader

30

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Figure 28. The automated strapping machine (Alibaba n.d.)

Figure 29. The 2D Warehouse Layout

31

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

lOMoARcPSD|9691613

Contribution Form

Student name Student number Percentage of Student Signature

Contribution

out of 100%

Van Tue Nghi s3777212 20%

Tran Phuong Thao s3777217 20%

Nguyen Le Quynh Mai s3756902 20%

Nguyen Thi Quynh Hoa s3817860 20%

Nguyen Phan Thuc Anh s3804800 20%

32

Downloaded by Truong Diem Suong (suongsky2605@gmail.com)

You might also like

- Review and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Thailand Country ReportFrom EverandReview and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Thailand Country ReportNo ratings yet

- Report Internship1 TranThiBichNgoc IELSIU19051Document25 pagesReport Internship1 TranThiBichNgoc IELSIU19051hong thaoNo ratings yet

- OMGT2222 Transportation and Freight Logistic Final ReportDocument34 pagesOMGT2222 Transportation and Freight Logistic Final ReportJosh lamNo ratings yet

- MaxDocument205 pagesMaxKanpicha ChanngamNo ratings yet

- Intership ReportDocument81 pagesIntership ReportsunnyNo ratings yet

- Bibica Final Report Supply Chain ManagementDocument35 pagesBibica Final Report Supply Chain Managementkhanhhuyen1007No ratings yet

- 1.1 Problem Statement:: 1.2 Scope of The StudyDocument19 pages1.1 Problem Statement:: 1.2 Scope of The StudyKAWSER RAFINo ratings yet

- Business Economics Report: Foreign Trade University School of Economics and International BusinessDocument50 pagesBusiness Economics Report: Foreign Trade University School of Economics and International BusinessNam NguyenNo ratings yet

- Case Study On Logistics PerformanceDocument5 pagesCase Study On Logistics PerformanceJay DanielNo ratings yet

- Capstone Project 2 PDFDocument28 pagesCapstone Project 2 PDFBinder GrewalNo ratings yet

- Final Report MIS - Group 3 - A03EDocument63 pagesFinal Report MIS - Group 3 - A03ETB VlogsNo ratings yet

- Qualitative Evaluation of RFID Implementation On Warehouse Management SystemDocument7 pagesQualitative Evaluation of RFID Implementation On Warehouse Management Systemblackwidow23No ratings yet

- Business Research MethodDocument11 pagesBusiness Research MethodSamuel Lau 刘恩得No ratings yet

- Work 1Document100 pagesWork 1ScribdTranslationsNo ratings yet

- Tiểu Luận Lớn MGT 403 AcDocument20 pagesTiểu Luận Lớn MGT 403 AcvonhoailienNo ratings yet

- Value Stream Mapping Case StudyDocument12 pagesValue Stream Mapping Case StudySaikat GhoshNo ratings yet

- Warehouse Design 2Document33 pagesWarehouse Design 2Truong Diem SuongNo ratings yet

- Lean KaizenDocument55 pagesLean KaizenNadeem NaseemNo ratings yet

- Internship T EllerDocument40 pagesInternship T EllerELiNo ratings yet

- Export Procedure & Documentation in An Apparel Export HouseDocument62 pagesExport Procedure & Documentation in An Apparel Export HousePrashant Rampuria85% (20)

- SDM Part 1Document33 pagesSDM Part 1SushmitaNo ratings yet

- Report Warehouse ManagementDocument37 pagesReport Warehouse ManagementChau AnhNo ratings yet

- Badm - What Is AoaDocument11 pagesBadm - What Is AoaPramget KaurNo ratings yet

- C2X Chain To Excellence: KonseputoDocument26 pagesC2X Chain To Excellence: KonseputoRishabh AgrawalNo ratings yet

- MS 1064-10-2018-PrepdfDocument5 pagesMS 1064-10-2018-Prepdfyang tanNo ratings yet

- LDSD - Mulugeta & SirgutDocument30 pagesLDSD - Mulugeta & SirgutSirgut TesfayeNo ratings yet

- Project TDTCDocument49 pagesProject TDTCEvans Mzumbwe50% (2)

- Global Supply Chain Managemt Group 12Document35 pagesGlobal Supply Chain Managemt Group 12Hương LýNo ratings yet

- Java AssignmentDocument36 pagesJava Assignmentjames smithNo ratings yet

- Last Inventory Management System FinalDocument58 pagesLast Inventory Management System Finaltsbaye WaNo ratings yet

- An Application of Lean and Agile Concepts in A Distribution Center of An Automobile Industry in ThailandDocument10 pagesAn Application of Lean and Agile Concepts in A Distribution Center of An Automobile Industry in ThailandmohanpusNo ratings yet

- Logistics ProjectDocument68 pagesLogistics ProjectGuru60% (5)

- GR 10 - Ms. Ngo Thi Thao UyenDocument61 pagesGR 10 - Ms. Ngo Thi Thao UyenQuynh Chau TranNo ratings yet

- Project Report: Rics Schoolofbuilt EnvironmentDocument29 pagesProject Report: Rics Schoolofbuilt Environmentkumar AbhishekNo ratings yet

- Nikhar Final ReportDocument66 pagesNikhar Final ReportGundeep SinGhNo ratings yet

- Square Textiles Ltd.Document35 pagesSquare Textiles Ltd.Al Amin100% (1)

- Report NewDocument22 pagesReport NewYNo ratings yet

- Group09 DuongVoNhiAnh Supermarket-SimulationDocument27 pagesGroup09 DuongVoNhiAnh Supermarket-SimulationPhạm VĩnhNo ratings yet

- GITAM School of International Business GITAM University Visakhapatnam-45Document11 pagesGITAM School of International Business GITAM University Visakhapatnam-45vashyanth dubbalaNo ratings yet

- Financail Report VadilalDocument105 pagesFinancail Report VadilalAshutoshSharmaNo ratings yet

- Woring Capital Group 7 Nike FinalDocument64 pagesWoring Capital Group 7 Nike FinalTran An KhanhNo ratings yet

- Final ReportDocument15 pagesFinal Reportshindidtamim2000No ratings yet

- Rmit Yarraville Terminal Assign 1Document14 pagesRmit Yarraville Terminal Assign 1s3924517No ratings yet

- Business Project Summative AssignmentDocument26 pagesBusiness Project Summative AssignmentZoya zafar100% (1)

- Reducing Risks and Costs When Working With Incoterms in Purchasing Within The Asia-Pacific RegionDocument60 pagesReducing Risks and Costs When Working With Incoterms in Purchasing Within The Asia-Pacific RegionDominique DIAKITENo ratings yet

- Lucky Textile Mills Limited: Production & Operation Management - Project ReportDocument16 pagesLucky Textile Mills Limited: Production & Operation Management - Project ReportMuhammad TalhaNo ratings yet

- Group 2.1 - Industry 4.0 - Development - in - ContainerizationDocument12 pagesGroup 2.1 - Industry 4.0 - Development - in - ContainerizationBhushan PawarNo ratings yet

- Internship 1 Report ModelDocument19 pagesInternship 1 Report ModelTài Nguyễn PhanNo ratings yet

- Open WellDocument27 pagesOpen WellYbudNo ratings yet

- Review and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Malaysia Country ReportFrom EverandReview and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Malaysia Country ReportNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- Special Economic Zones in the Indonesia–Malaysia–Thailand Growth Triangle: Opportunities for CollaborationFrom EverandSpecial Economic Zones in the Indonesia–Malaysia–Thailand Growth Triangle: Opportunities for CollaborationNo ratings yet

- Review and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Integrative ReportFrom EverandReview and Assessment of the Indonesia–Malaysia–Thailand Growth Triangle Economic Corridors: Integrative ReportNo ratings yet

- Managing Successful Projects with PRINCE2 2009 EditionFrom EverandManaging Successful Projects with PRINCE2 2009 EditionRating: 4 out of 5 stars4/5 (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningFrom EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- PDF Atm Security System Using Fingerprint Project Report CompressDocument2 pagesPDF Atm Security System Using Fingerprint Project Report Compressswathi H ANo ratings yet

- Program Evaluation Documents (Table 1 To 16)Document14 pagesProgram Evaluation Documents (Table 1 To 16)Cristina CarpioNo ratings yet

- Elektor Mag Summer 2023Document33 pagesElektor Mag Summer 2023Ludo Bagman100% (3)

- 900169-001-Ovation 1 Quick Start Guide-Rev00 PDFDocument12 pages900169-001-Ovation 1 Quick Start Guide-Rev00 PDFNorlan JoinerNo ratings yet

- CA-AM Amplifier ManualDocument2 pagesCA-AM Amplifier ManualDewey AndersonNo ratings yet

- NDG Online NDG Linux Essentials Challenge B: Bash ScriptingDocument5 pagesNDG Online NDG Linux Essentials Challenge B: Bash ScriptingOmar OughzalNo ratings yet

- EEE G592 Mobile & Personal Communication: BITS PilaniDocument21 pagesEEE G592 Mobile & Personal Communication: BITS PilaniRoshan JayswalNo ratings yet

- DatabaseDocument18 pagesDatabaseSyed SalmanNo ratings yet

- CAT 928Hz Wheel Loader PDFDocument16 pagesCAT 928Hz Wheel Loader PDFIGNACIONo ratings yet

- 7192 Part D1 Cons enDocument126 pages7192 Part D1 Cons enbenis100% (4)

- Patriot RSL: Installation/Owners ManualDocument60 pagesPatriot RSL: Installation/Owners ManualPete GaetaNo ratings yet

- As ISO 8930-2005 General Principles On Reliability of Structures - List of Equivalent TermsDocument6 pagesAs ISO 8930-2005 General Principles On Reliability of Structures - List of Equivalent TermsSAI Global - APACNo ratings yet

- Gray White Simple Modern Thesis Defense PresentationDocument55 pagesGray White Simple Modern Thesis Defense Presentationjohn lyod de la cruzNo ratings yet

- SPARK Matrix™: Product Lifecycle Management (PLM), 2021Document27 pagesSPARK Matrix™: Product Lifecycle Management (PLM), 2021robinmakNo ratings yet

- Packet Life in LinuxDocument19 pagesPacket Life in LinuxshanbhagdhirajNo ratings yet

- Bahir Dar Chapter TwoDocument62 pagesBahir Dar Chapter Twoblackhat0917No ratings yet

- Ford Ranger Spare PartsDocument2 pagesFord Ranger Spare PartsNgila João AndréNo ratings yet

- Digital Microwave Radio: 1. Introduction To DMRDocument14 pagesDigital Microwave Radio: 1. Introduction To DMRgeraldstar22No ratings yet

- Leaflet Agya 0722Document3 pagesLeaflet Agya 0722Obito UchihaNo ratings yet

- Delivery Cost SAP PDFDocument7 pagesDelivery Cost SAP PDFsappz3545448No ratings yet

- Design of JFET Bias Circuits: ExperimentDocument11 pagesDesign of JFET Bias Circuits: ExperimentShang Divina EbradaNo ratings yet

- iDR-0 Service Manual AP7233 - 1Document9 pagesiDR-0 Service Manual AP7233 - 1zikelabsNo ratings yet

- Base Line: Air. Anytime. AnywhereDocument4 pagesBase Line: Air. Anytime. Anywheremogwai71No ratings yet

- Eaw CatalogDocument20 pagesEaw CatalogalwiNo ratings yet

- Cyberforce Overview PresentationDocument21 pagesCyberforce Overview Presentationandreko11No ratings yet

- Sterfite Tech: January 24, 2019Document36 pagesSterfite Tech: January 24, 2019mgn_mca943No ratings yet

- Analysis of @darealbubu - Whotwi Graphical Twitter AnalysisDocument1 pageAnalysis of @darealbubu - Whotwi Graphical Twitter Analysisdeer muNo ratings yet

- Mcp3424 - Conversor Adc 18bitsDocument58 pagesMcp3424 - Conversor Adc 18bitsCarlos SanchezNo ratings yet