Professional Documents

Culture Documents

Maintaining and Repairing Rice Cookers

Uploaded by

Leon AtsilegnaveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintaining and Repairing Rice Cookers

Uploaded by

Leon AtsilegnaveCopyright:

Available Formats

Republic of the Philippines

TECHNICAL EDUCATION AND SKILLS DEVELOPMENT AUTHORITY

Regional Manpower Development Center (RMDC)

Sector: ELECTRONICS

Qualification: CONSUMER ELECTRONICS SERVICING NC-II

Unit of Maintain and Repair Electronically-Controlled Domestic Appliances

Competency:

Module Title: Maintaining and Repairing Electronically-Controlled Domestic Appliances

Code No. MAINTAINING AND REPAIRING Developed Date Date Page

RICE COOKER by: Developed Revised No.

TABLE OF CONTENTS

Page

How to Use this Module....................................................................................1

Introduction.....................................................................................................2

Technical Terms...............................................................................................3

Learning Outcome 1.........................................................................................4

Learning Experiences/Activities..............................................................5

Information Sheet 1................................................................................6

Self-Check 1............................................................................................7

Answer key 1...........................................................................................8

Operation Sheet 1...................................................................................9

Operation Sheet 2.................................................................................10

Operation Sheet 3.................................................................................11

Job Sheet 1...........................................................................................12

Learning outcomes 2

Learning Experiences/Activities

Information sheet 2.1

Self check 2.1

Operation sheet 2.1

Job sheet 2.1

Learning Outcomes 3

Learning Experiences/Activities

Information sheet 3.1

Self check 3.1

Operation sheet 3.1

Job sheet 3.1

Learning Outcomes 4

Learning Experiences/Activities

Information sheet 4.1

Self check 4.1

Job sheet 4.1

Assessment Plan

Observation checklist

Observation and Questioning checklist

Demonstration

Written Report

Performance test

Answer key 1.1

Answer key 2.1

Answer key 3.1

Answer key 4.1

Code No. MAINTAINING AND REPAIRING Developed Date Date Page

RICE COOKER by: Developed Revised No.

HOW TO USE THIS MODULE

Welcome to the Module “Maintaining and Repairing a Rice cooker”. This

module contains training materials and activities for you to complete.

The unit of competency “Maintain and Repair Electronically-Controlled

Domestic Appliances” contains the knowledge, skills and attitudes required for

Consumer Electronics Servicing required to obtain the National Certificate

(NC) level II.

You are required to go through a series of learning activities in order to

complete each of the learning outcomes of the module. In each learning

outcome there are Information Sheets, Job Sheets, and Operation Sheets .

Do these activities on your own and answer the Self-Check at the end of each

learning activity.

If you have questions, don’t hesitate to ask your teacher for assistance.

Recognition of Prior Learning (RPL)

You have already some basic knowledge and skills covered in this module

because you have been working for some time; and already completed training

in this area.

If you can demonstrate competence to your teacher in a particular skill, talk

to your teacher so you don’t have to undergo the same training again. If you

have a qualification or Certificate of Competency from previous trainings show it

to him/her. If the skills you acquired are consistent with and relevant to this

module, they become part of the evidence. You can present these for RPL. If you

are not sure about your competence skills, discuss this with your teacher.

After completing this module, ask your teacher to assess your competence.

Result of your assessment will be recorded in your competency profile. All the

learning activities are designed for you to complete at your own pace.

In this module, you will find the activities for you to complete and relevant

information sheets for each learning outcome. Each learning outcome may have

more than one learning activity.

This module is prepared to help you achieve the required competency, in

receiving and relaying information. This will be the source of information that

will enable you to acquire the knowledge and skills in “Maintain and Repair

Electronically-Controlled Domestic Appliances” independently at your own pace

with minimum supervision from your teacher.

Date: ROUGHING-IN ACTIVITIES FOR COMMUNICATION AND DISTRIBUTION SYSTEM Page #

Version No.: USING ELECTRICAL METALLIC CONDUIT 1

Program/Course: CONSUMER ELECTRONIC SERVICING NC II

Unit of Competency: MAINTAIN AND REPAIR ELECTRONICALLY-

CONTROLLED DOMESTIC APPLIANCES

Module Title: Maintaining and Repairing a Rice Cooker

INTRODUCTION:

This module contains information and suggested learning activities on

Maintaining and Repairing a Rice Cooker. It covers the knowledge, skills and

attitudes required to maintain and repair this home appliance.

Completion of this module will help you better understand the succeeding

module on maintaining and repairing electronically-controlled domestic

appliances.

This module consists of two (2) learning outcomes. Each learning outcome

contains learning activities supported by instructional sheets. Before you

perform the instructions, read the information sheets and answer the self-check

and activities provided to ascertain to yourself and your teacher that you have

acquired the knowledge necessary to perform the skill portion of the particular

learning outcome.

Upon completing this module, report to your teacher for assessment to check

your achievement of knowledge and skills requirements of this module. If you

pass the assessment, you will be given a certificate of completion.

SUMMARY OF LEARNING OUTCOMES:

Upon completion of the module the students should be able to:

LO1 Identify the functions of the parts of a rice cooker.

LO2 Diagnose a rice cooker and troubleshoot defects found

LO3 maintain and repair a rice cooker.

ASSESSMENT CRITERIA:

Refer to assessment criteria of learning outcomes 1-3 of this module.

PREREQUISITES:

None

Date: ROUGHING-IN ACTIVITIES FOR COMMUNICATION AND DISTRIBUTION SYSTEM Page #

Version No.: USING ELECTRICAL METALLIC CONDUIT 2

TECHNICAL TERMS

Cathode - The negative terminal electrode of a device. The “N” terminal

in a junction diode.

AC Voltage - A voltage in which the polarity alternates.

Alternating - An electric current that rises to a maximum in one

Current direction, falls back to zero and then rises to a maximum in

the opposite direction and then repeats.

Anode - The positive electrode or terminal of a device. The “P”

material of a diode.

Bridge - A circuit using four diodes to provide full wave rectification.

Rectifier Converts AC voltage to a pulsating DC voltage.

Calibration - To adjust the correct value of a reading by comparison to a

standard.

Capacitor - An electronic component having capacitive reactance.

AC/DC - Equipment that will operate on either an AC or DC power

source.

Color Code - Set of colors used to indicate value of a component.

DC Power - Any source of DC power for electrical equipment.

Supply

Diode - A two terminal device that conducts in only one direction.

Electrolytic - It is used to filter the current flowing in the circuit.

Cap.

Full Wave - The rectifier that makes use of the full ac wave in both

Rectifier positive and negative half cycles.

Fuse - A protective device in the current path that melts or breaks

when current exceeds a predetermined maximum value.

Half Wave - A diode rectifier that converts AC to pulsating DC by

Rectifier eliminating either the negative or positive alternation of

each input AC cycle.

Leakage - Small undesirable flow of current through an insulator or

dielectric.

Light Emitting - A semiconductor diode that converts electric energy into

Diode electromagnetic radiation at a visible and near infrared

frequencies when its pn junction is forward bias.

Output - Terminal at which a component, circuit or piece of

equipment delivers current, voltage or power.

Power Supply - Electrical equipment used to deliver either AC or DC

voltage.

Primary - First winding of a transformer. Winding that is connected to

the source as opposed to secondary which is a winding

connected to a load.

Printed Circuit - Insulating board containing conductive tracks for circuit

Board connections.

Rectification - Process that converts alternating current to direct current.

Rectifier - Diode circuit that converts AC to pulsating DC.

Regulated - Power supply that maintains a constant output voltage

Date: ROUGHING-IN ACTIVITIES FOR COMMUNICATION AND DISTRIBUTION SYSTEM Page #

Version No.: USING ELECTRICAL METALLIC CONDUIT 3

Power Supply under changing load condition.

Resistor - Component made of material that opposes the flow of

current and therefore has some value of resistance.

Rotary Switch - Electromechanical device that has a rotating shaft

connected to one terminal capable of making, breaking a

connection to one or more other terminals.

Schematic - Illustration of an electrical or electronic circuit with the

Diagram components represented by their symbol.

Secondary - Output winding of a transformer. Winding that is connected

to a load.

Short Circuit - Also called a short. Low resistance connection between two

points in a circuit typically causing excessive current.

Solder - Metallic alloy used to join two metal surfaces.

Soldering - Process of joining two metallic surfaces to make an

electrical contact by melting solder (tin and lead) across

them.

Soldering Iron - Tool with an internal heating element used to heat surfaces

being soldered to the point where the solder becomes

molten.

Substrate - Mechanical insulating support upon which a device is

fabricated.

Switch - Electrical device having two states, ON (closed) or OFF

(open).

Test - Sequence of operations intended to verify the correct

operation or malfunctioning of a piece of equipment or

system.

Transformer - Inductor with two or more windings.

Troubleshootin - Systematic approach to locate the cause of a fault in an

g electronic circuit or system.

Volt-Ohm- - Known as a multitester. A test equipment used to check AC,

Meter DC voltages, current in a circuit and resistance of any

components out of the circuit.

Date: ROUGHING-IN ACTIVITIES FOR COMMUNICATION AND DISTRIBUTION SYSTEM Page #

Version No.: USING ELECTRICAL METALLIC CONDUIT 4

Program/Course: CONSUMER ELECTRONIC SERVICING NC II

Unit of Competency: MAINTAIN AND REPAIR ELECTRONICALLY

CONTROLLED DOMESTIC APPLIANCES

Module Title: MAINTAINING AND REPAIRING A RICE COOKER

Learning Outcome: Identify the functions of the parts of a rice cooker.

Assessment Criteria

1. Operation of a rice cooker is explained.

2. The parts of a rice cooker are identified based on the

manufacturer’s manual.

3. Functions of its parts are explained.

Resources

1. Tan, Michael Q., Gantalao, Fred T., Lasala, Rommel M. Simple Electronics;

Andes Mountain Printers: 2004

2. Enriquez, Marcelo T. Electronics Technology IV; Souvenir Publications, Inc.:

2003

3. www.google.com

4. www.yahoo.com

Date: ROUGHING-IN ACTIVITIES FOR COMMUNICATION AND DISTRIBUTION SYSTEM Page #

Version No.: USING ELECTRICAL METALLIC CONDUIT 5

LEARNING EXPERIENCES/ACTIVITIES

Learning Outcome 1: Identify the function of the parts of a microwave

oven.

Learning Activities Special Instructions

1. Read the attached Information

Sheet #8-B-1-1 on microwave

oven:

Try to answer the Self-Check

2. Answer self check 8-B-1-1

without looking at the

3. Compare your answer to the information sheet.

model answer

4. If you missed some of the

question, go back again to

information sheet#8-B-1-1

5. If you have answered the

question, you are ready to

proceed to learning outcome #2

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 4

INFORMATION SHEET # 8-B-1-1

RICE COOKER

Rice Cooker

Is a self contained kitchen appliance, used primarily for cooking rice. Rice

cookers are used to prepare steamed rice and keep them warm after cooking. It

consist of an insulated case containing a removable cooking pot. A heating

element is located between the two containers, usually controlled by a thermostat

The cooking pot is usually calibrated to ensure proper proportions of the rice and

water.

How the rice cooker operates?

In most rice cookers, the rice and the water are poured in at the start of cooking.

The heater then brings the water to boiling point, during which the rice absorbs the

water and expands. After the present time, the rest of the water is boiled away and

the machine either shuts off or switches to ‘ keep warm” mode. Some models allow

users to add flavorings before or during the cooking.

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 5

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 6

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 7

Major Parts and its Function

Power Cord - is a cord that temporarily connects an

electrical appliance to an electrical

power source. The term is generally used

for cables using a power plug to connect

to a single-phase.

Cast Heater - A part of a rice cooker that produced heat

to the aluminum pan.

Mica heater- consist of an etched-foil sandwiched between

layers of mica. Installed by clamping to heat

sinks, mica heater provide the ultimate

temperature and wattage capability for fast

warmup.

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 8

Thermal fuse – is a cutoff which uses a one-time fusible

link. Unlike the thermostat which

automatically resets itself when

temperature drops, the thermal fuse is

more like an electrical fuse.

Thermostat assembly- a device, as in a home heating

system that automatically responds

to temperature changes and activates

switches controlling the equipment.

Aluminum pan- A part of a rice cooker which the rice is

placed.

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 9

Part name Description Picture

A part of rice cooker which

1.__________________ the rice is placed

2.__________________ Consist of an etched-

foil sandwiched between

Layer of mica

A device as in a home

heating system that

automatically responds

3._________________

to temperature changes

and activates switches

controlling the equipment

Is a cutoff switch uses a

one-time fusible link.

unlike the thermostat

which automatically

resets itself when tempe-

4.__________________

Date:

rature drops.

LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 10

Key to Correction to Self Check #8B-1-1

1. Aluminum pan

2. Mica heater

3. Thermostat assembly

4. Thermal fuse

5. Cast heater assembly

6 Power cord

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 11

Program/Course: CONSUMER ELECTRONIC SERVICING NC II

Unit of Competency: MAINTAIN AND REPAIR ELECTRONICALLY

CONTROLLED DOMESTIC APPLIANCES

Module Title: MAINTAINING AND REPAIRING A RICE COOKER

Learning Outcome 2: Diagnose and troubleshoot a microwave oven.

Assessment Criteria

1. Pre-testing procedure is perform in accordance with manufacturer’s

instruction.

2. System defects/fault symptoms are identified using appropriate tools and

equipment.

3. Identified defects and faults are explained to the responsible person.

4. Results of diagnosis and testing are documented.

5. Troubleshooting is performed in accordance with the service manual.

Resources

5. Tan, Michael Q., Gantalao, Fred T., Lasala, Rommel M. Simple Electronics;

Andes Mountain Printers: 2004

6. Enriquez, Marcelo T. Electronics Technology IV; Souvenir Publications, Inc.: 2003

7. www.google.com

8. www.yahoo.com

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 12

INFORMATION SHEET NO. 8B-2-1

Faults and Trouble of a Rice Cooker

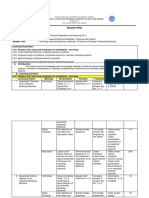

Trouble Cause Inspection Remedy

No power Overload Using multitasked Refer to

Rice cooker is check continuity of component

continuously the ff. parts testing

operated for a.) fuse Replace

more than 3 b.) power cord defective parts,

hrs. with out Refer next

rest Learning

outcome

repairing

procedure

Doesn’t light Rice cooker Check rice cooker Replaced busted

lamp is lamp lamp

continuously

operated for

more than

3hrs.

W/power won’t Foreign Visual check Replaced

heat materials Using multitester switch assy.

short to the check continuity

circuit board

W/power doesn’t Defective Using multitester Refer

heat Cast heater check continuity component

of cast heater testing

filament procedure

Explain to

customer the

cast heater is

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 13

defective

Tools Used in pre-testing a microwave oven

VOM (multitester)

Instructional/Operational Manual

Screw Driver

Pliers

Side cutting pliers

Long nose pliers

Pre-testing procedure of a rice cooker

If………. Possible cause How to fix

Unit cannot be is Ac power cord Visual check ac

turn on property plug in? power cord if

there is loose in

the power plug

Unit does not Is the plug connected Plug-in properly

operate when turn properly?

on Is the front cover Push front

properly close cover/ front lid

properly

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 14

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 15

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 16

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 17

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 18

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 19

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 20

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 21

JOB SHEET#

Results of Diagnosis and Testing

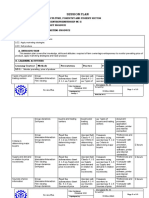

Fill-up the following table:

Brand: ___________________

Model #:__________________

Serial#:___________________

Possible trouble Possible cause of Possible affected Possible remedy

trouble components/parts

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 22

Program/Course: CONSUMER ELECTRONIC SERVICING NC II

Unit of Competency: MAINTAIN AND REPAIR ELECTRONICALLY

CONTROLLED DOMESTIC APPLIANCES

Module Title: MAINTAINING AND REPAIRING A RICE COOKER

Learning Outcome3: Maintain and Repair a rice cooker.

Assessment Criteria

1. Personal Protective Equipment is used in accordance with occupational health

and safety practices.

2. Defective parts/components are placed with identical or recommended

appropriate equivalent ratings..

3. Repaired or replaced parts/components are soldered and mounted at the

specified location.

4. Control setting/adjustments are performed in conformity with service-manual

specifications.

5. Repair activity is performed within the required time.

6. The unit is cleaned after the maintenance and repair activity.

Resources

9. Tan, Michael Q., Gantalao, Fred T., Lasala, Rommel M. Simple Electronics;

Andes Mountain Printers: 2004

10. Enriquez, Marcelo T. Electronics Technology IV; Souvenir Publications, Inc.:

2003

11. www.google.com

12. www.yahoo.com

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 23

INFORMATION SHEET

Specification of Replacement Parts

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 24

Date: LO 1. INSTALL ELECTRICAL METALLIC TUBING Page #

PERFORMING ROUGHING IN ACTIVITIES FOR COMMUNICATION AND

Version No.: DISTRIBUTION SYSTEM USING METALLIC CONDUIT 25

You might also like

- Cblm-Electric FanDocument48 pagesCblm-Electric FanLeon AtsilegnaveNo ratings yet

- Y3 - Module 6 - Maintaining and Repairing Flat IronDocument37 pagesY3 - Module 6 - Maintaining and Repairing Flat IronAlberto A. FugenNo ratings yet

- Y3 - Module 4 - Maintaining and Repairing A BlenderDocument48 pagesY3 - Module 4 - Maintaining and Repairing A BlenderAlberto A. FugenNo ratings yet

- CBLM - Rice Cooker OkDocument34 pagesCBLM - Rice Cooker OkROJANE F. BERNAS, PhD.No ratings yet

- Terminate and Connect Electrical CircuitsDocument39 pagesTerminate and Connect Electrical CircuitsDivina LayaNo ratings yet

- Basic Electricity ExploratoryDocument89 pagesBasic Electricity ExploratoryLLOYD ARENASNo ratings yet

- 6 Yoyoy 2 - Common CBLM TERMINATE AND CONNECT ELECTRICAL WIRING AND ELECTRONIC CIRCUIT 1Document47 pages6 Yoyoy 2 - Common CBLM TERMINATE AND CONNECT ELECTRICAL WIRING AND ELECTRONIC CIRCUIT 1Glaiza Magistrado MonteNo ratings yet

- CBLM Testing1Document126 pagesCBLM Testing1Donabel NoveroNo ratings yet

- Grade 8 Perform Mensuration CBLM SLM LASDocument62 pagesGrade 8 Perform Mensuration CBLM SLM LASMat Domdom SansanoNo ratings yet

- Hand Tools for Electronics ServicingDocument15 pagesHand Tools for Electronics ServicingRoxanne RodrigoNo ratings yet

- Washing Machine Module GuideDocument51 pagesWashing Machine Module GuideSer TakeshiNo ratings yet

- EPAS Q2 CES-Module Washing-MachineDocument23 pagesEPAS Q2 CES-Module Washing-MachineMeranie MelocotonesNo ratings yet

- Electronics-Cblm 2019 Lesson SessionDocument98 pagesElectronics-Cblm 2019 Lesson SessionCastor Jr Javier100% (1)

- ELECTRONIC PRODUCTS ASSEMBLY AND SERVICING NCII COMPETENCY-BASED LEARNING MATERIALSDocument33 pagesELECTRONIC PRODUCTS ASSEMBLY AND SERVICING NCII COMPETENCY-BASED LEARNING MATERIALSneil jovert ortosteNo ratings yet

- TR-Electronic Products Assembly and Servicing NC IIDocument74 pagesTR-Electronic Products Assembly and Servicing NC IIMicah Alexene JeilNo ratings yet

- Consumer Electronics ServicingDocument2 pagesConsumer Electronics ServicinglorenzchNo ratings yet

- CBLM Eim Module 1Document49 pagesCBLM Eim Module 1John B. BataraNo ratings yet

- EPAS G11 Quarter 2 Week 5 7Document20 pagesEPAS G11 Quarter 2 Week 5 7Chiarnie LopezNo ratings yet

- Core 2 CBLM (New)Document114 pagesCore 2 CBLM (New)Joel MilanNo ratings yet

- ELECTRONIC PRODUCTS ASSEMBLY AND SERVICING NCII COMPETENCY-BASED LEARNING MATERIALSDocument35 pagesELECTRONIC PRODUCTS ASSEMBLY AND SERVICING NCII COMPETENCY-BASED LEARNING MATERIALSPaul Senen Didulo50% (2)

- 5 Yoyoy 2 - CBLM COMMON USING HAND TOOLSfinalDocument35 pages5 Yoyoy 2 - CBLM COMMON USING HAND TOOLSfinalGlaiza Magistrado MonteNo ratings yet

- CBLM Core 3Document216 pagesCBLM Core 3International Technology Center Inc0% (2)

- TVL - Ia: Quarter 3 - Module 5Document14 pagesTVL - Ia: Quarter 3 - Module 5Chiarnie LopezNo ratings yet

- Module 1 - EIM Prepare Electrical Power and HydraulicDocument58 pagesModule 1 - EIM Prepare Electrical Power and HydraulicNoel Bua-ay100% (1)

- CBLM Competency Elect Install and Maint NC IIDocument51 pagesCBLM Competency Elect Install and Maint NC IIRoderick Rosanes100% (1)

- Installation Session Plan for Lighting Fixtures and OutletsDocument4 pagesInstallation Session Plan for Lighting Fixtures and OutletsJeprie L. Gultia100% (1)

- Electrician's Knife 2. This is used to drill holes in walls or woodDocument174 pagesElectrician's Knife 2. This is used to drill holes in walls or woodbhadz SabellaNo ratings yet

- Servicing Industrial Electronics ModulesDocument11 pagesServicing Industrial Electronics ModulesBaltazar Midred100% (2)

- TRB EIM NCIIDocument10 pagesTRB EIM NCIIDonnie Ray Lucio100% (1)

- Edited CBLM EpasDocument36 pagesEdited CBLM EpasCeleste Licuanan Ching86% (14)

- Preparing/making Printed Circuit Board (PCB) ModulesDocument9 pagesPreparing/making Printed Circuit Board (PCB) ModulesShaira Claire CorreNo ratings yet

- Competency-Based Learning Materials: Electronic Products Assembly and ServicingDocument40 pagesCompetency-Based Learning Materials: Electronic Products Assembly and Servicingmichael sto domingo100% (1)

- PTS TemplateDocument52 pagesPTS TemplateRhony BayocbocNo ratings yet

- Forms 1.1-1.4 (Mohamad Zuharie S. Dimalanas)Document13 pagesForms 1.1-1.4 (Mohamad Zuharie S. Dimalanas)Ladymae Barneso Samal100% (1)

- Competency-Based Curriculum for Electrical Installation and MaintenanceDocument95 pagesCompetency-Based Curriculum for Electrical Installation and MaintenanceIch Khay100% (1)

- Epas Modules of InsDocument74 pagesEpas Modules of InsMelba33% (3)

- Core 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsDocument81 pagesCore 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsSuigen JM MontejoNo ratings yet

- Apply Quality StandardsDocument44 pagesApply Quality StandardsSario CabanogNo ratings yet

- 4 Final Competency Based Learning MaterialsDocument34 pages4 Final Competency Based Learning MaterialsAnn NadiahanNo ratings yet

- CBLM Eim Module 2Document148 pagesCBLM Eim Module 2John B. Batara100% (1)

- Electronic Product Assembly and ServicingDocument16 pagesElectronic Product Assembly and ServicingCHESTER ALLAN MENDEZ100% (2)

- Electric Flat Iron Parts and OperationDocument12 pagesElectric Flat Iron Parts and OperationArvin Paul A. Soriano100% (1)

- Installing Wiring Devices Session PlanDocument12 pagesInstalling Wiring Devices Session Planangelo naquitaNo ratings yet

- Session Plan Electric FanDocument6 pagesSession Plan Electric FanEdenezer Rosario100% (1)

- G9-Epas-Q1-Slem 5 Maintain Measuring InstrumentsDocument9 pagesG9-Epas-Q1-Slem 5 Maintain Measuring InstrumentsCRISTINA TAGUILIDNo ratings yet

- Competency Based Learning Materials for Electronics AssemblyDocument37 pagesCompetency Based Learning Materials for Electronics AssemblyInternational Technology Center Inc100% (3)

- Quarter 2 Week 1Document112 pagesQuarter 2 Week 1CHESTER ALLAN MENDEZNo ratings yet

- Competency-Based Learning Materials for Applying Quality StandardsDocument32 pagesCompetency-Based Learning Materials for Applying Quality StandardsSSVTC LRCNo ratings yet

- Updated Session Plan Install Electrical Protective DevicesdocxDocument5 pagesUpdated Session Plan Install Electrical Protective DevicesdocxYna Kaye Balboa100% (1)

- TRB EIM NCIIDocument10 pagesTRB EIM NCIIOwie MendozaNo ratings yet

- Learning Competencies Code Days Topics: First WeekDocument3 pagesLearning Competencies Code Days Topics: First WeekZeen DeeNo ratings yet

- EIM Module For New NormalDocument23 pagesEIM Module For New NormalJohn B. BataraNo ratings yet

- EPAS Module 2 Q1Document20 pagesEPAS Module 2 Q1KAGIG TVNo ratings yet

- LEARNING OUTCOME NO. 1 Prepare To AssembDocument21 pagesLEARNING OUTCOME NO. 1 Prepare To AssembAldrin TaghapNo ratings yet

- TESDA Self-Assessment Guide for Electronics Assembly and ServicingDocument9 pagesTESDA Self-Assessment Guide for Electronics Assembly and ServicingAra CNo ratings yet

- Tle g9 Epas Adm Quarter 1Document47 pagesTle g9 Epas Adm Quarter 1Jan Carlo CozoNo ratings yet

- Mount and Solder Electronic Components: Information Sheet 1.3.1 Learning Outcome No. 3Document22 pagesMount and Solder Electronic Components: Information Sheet 1.3.1 Learning Outcome No. 3Shaira Claire CorreNo ratings yet

- TVL - Ia (Electronic Product Assembly and Servicing) Activity Sheet-Quarter 2 - Week 5Document8 pagesTVL - Ia (Electronic Product Assembly and Servicing) Activity Sheet-Quarter 2 - Week 5Paul Senen DiduloNo ratings yet

- Using and Maintaining Hand ToolsDocument28 pagesUsing and Maintaining Hand ToolsMarfe MontelibanoNo ratings yet

- Y3 - Module 1 - Assembling AC-DC Power SupplyDocument56 pagesY3 - Module 1 - Assembling AC-DC Power SupplyAlberto A. FugenNo ratings yet

- Supervise Work-Based Training TemplateDocument120 pagesSupervise Work-Based Training Templatechingferdie_111No ratings yet

- Technical Education and Skills Development Authority: Surallah National Agricultural SchoolDocument4 pagesTechnical Education and Skills Development Authority: Surallah National Agricultural SchoolLeon AtsilegnaveNo ratings yet

- Assemble Information SheetDocument18 pagesAssemble Information SheetLeon AtsilegnaveNo ratings yet

- Epas Revised CBLMDocument74 pagesEpas Revised CBLMLeon Atsilegnave100% (1)

- Converter PCBDocument6 pagesConverter PCBLeon AtsilegnaveNo ratings yet

- Core 1 - Install and Configure Computer SystemDocument6 pagesCore 1 - Install and Configure Computer SystemLeon AtsilegnaveNo ratings yet

- NCIII Basic Comp 04-CBLM Ver1Document73 pagesNCIII Basic Comp 04-CBLM Ver1Leon AtsilegnaveNo ratings yet

- Philippines Technical Education Guide on Servicing Audio EquipmentDocument52 pagesPhilippines Technical Education Guide on Servicing Audio EquipmentLeon Atsilegnave100% (1)

- Information Sheet 1.1-1: Learning ObjectivesDocument66 pagesInformation Sheet 1.1-1: Learning ObjectivesLeon AtsilegnaveNo ratings yet

- Session Plan Core AgroEntrepreneurship NC IIDocument10 pagesSession Plan Core AgroEntrepreneurship NC IILeon Atsilegnave89% (9)

- Technical Education Authority Philippines - Trainer Evaluation of Competency-Based Learning MaterialsDocument19 pagesTechnical Education Authority Philippines - Trainer Evaluation of Competency-Based Learning MaterialsLeon Atsilegnave100% (1)

- Contextual LearningDocument30 pagesContextual LearningLeon Atsilegnave100% (4)

- RAC Servicing NC III Competency Guide - Using Relevant TechDocument47 pagesRAC Servicing NC III Competency Guide - Using Relevant TechLeon AtsilegnaveNo ratings yet

- CBC - Agroentrep NC IIDocument84 pagesCBC - Agroentrep NC IILeon Atsilegnave100% (1)

- Assessment FeeDocument1 pageAssessment FeeLeon AtsilegnaveNo ratings yet

- PA 212 Knowledge Management & ICTDocument2 pagesPA 212 Knowledge Management & ICTLeon Atsilegnave93% (14)

- Action Plan (Regional) Regional Training of Trainers On Agroentrepreneurship NciiDocument3 pagesAction Plan (Regional) Regional Training of Trainers On Agroentrepreneurship NciiLeon AtsilegnaveNo ratings yet

- Assessment FeeDocument1 pageAssessment FeeLeon AtsilegnaveNo ratings yet

- November 20 ContractDocument1 pageNovember 20 ContractLeon AtsilegnaveNo ratings yet

- PA211 - Public Administrative Thoughts and InstitutionsDocument7 pagesPA211 - Public Administrative Thoughts and InstitutionsLeon AtsilegnaveNo ratings yet

- An5346 Stm32g4 Adc Use Tips and Recommendations StmicroelectronicsDocument15 pagesAn5346 Stm32g4 Adc Use Tips and Recommendations StmicroelectronicsPaulo PecegueiroNo ratings yet

- Lecture # 4: Communication SystemsDocument17 pagesLecture # 4: Communication SystemsKhalid MajeedNo ratings yet

- Diferencias Entre STVF7 y WBVFDocument14 pagesDiferencias Entre STVF7 y WBVFFranklin Palacios100% (1)

- Fuji Igbt Application ManualDocument95 pagesFuji Igbt Application Manualramon navaNo ratings yet

- Ingenia 3T Omega HPDocument24 pagesIngenia 3T Omega HPUlises NavarreteNo ratings yet

- Simple AM Receiver and Transmitter CircuitsDocument4 pagesSimple AM Receiver and Transmitter CircuitsGokulk2011100% (2)

- B550 PG VelocitaDocument99 pagesB550 PG VelocitaEduardo RigueraNo ratings yet

- 07 - LTE Physical Channels and Procedures - v04Document197 pages07 - LTE Physical Channels and Procedures - v04Deepak PatniNo ratings yet

- TDA1555QDocument11 pagesTDA1555QНикифор СтанојоскиNo ratings yet

- FP1500 Installation ManualDocument57 pagesFP1500 Installation ManualMihai Iavorschi100% (1)

- DS18B20Document2 pagesDS18B20Leonardo MouraNo ratings yet

- 240pin Unbuffered DIMM Based On 4Gb Q-Die: DatasheetDocument42 pages240pin Unbuffered DIMM Based On 4Gb Q-Die: DatasheetAnonymous CMS3dL1TNo ratings yet

- Arduino Modules L298N Dual H Bridge Motor ControllDocument7 pagesArduino Modules L298N Dual H Bridge Motor ControllMarius DanilaNo ratings yet

- CMC 256plus: 6-Phase Current + 4-Phase Voltage Test SetDocument3 pagesCMC 256plus: 6-Phase Current + 4-Phase Voltage Test SetDuško TovilovićNo ratings yet

- ColorduinoV1.3 DSDocument3 pagesColorduinoV1.3 DSMarco OBNo ratings yet

- Parker Installationsanleitung PCM Modul Ep2 Ep3 MSG30 2902 INST EN 2019Document66 pagesParker Installationsanleitung PCM Modul Ep2 Ep3 MSG30 2902 INST EN 2019nime fuziNo ratings yet

- Data Sheet: HCPL-3120/J312 HCNW3120Document27 pagesData Sheet: HCPL-3120/J312 HCNW3120onafetsNo ratings yet

- How To Speed Up UTorrent For Faster DownloadsDocument3 pagesHow To Speed Up UTorrent For Faster Downloadsalex danielNo ratings yet

- TEA1523PDocument20 pagesTEA1523PRoberto SantosNo ratings yet

- LIPS Board Block Diagram: Primary SecondaryDocument3 pagesLIPS Board Block Diagram: Primary SecondaryListenNo ratings yet

- Ie0if32023001028 Rev01Document92 pagesIe0if32023001028 Rev01fernando choqueNo ratings yet

- Introduction To Computer NetworksDocument118 pagesIntroduction To Computer Networkskaynaan YareNo ratings yet

- Communication Systems Lab 3Document4 pagesCommunication Systems Lab 3Naima YaqubNo ratings yet

- PVS-16 - 20 - 24mh-Sungrow CombinerDocument1 pagePVS-16 - 20 - 24mh-Sungrow CombinerRafaelNo ratings yet

- Fiber Optic Sensor Technology: An Overview: Sensors and Actuators A Physical May 2000Document23 pagesFiber Optic Sensor Technology: An Overview: Sensors and Actuators A Physical May 2000Anonymous eW303jNo ratings yet

- Network Monitoring Metrics and Applications in SecurityDocument22 pagesNetwork Monitoring Metrics and Applications in SecurityArdi SyahNo ratings yet

- Specification Sheet - BDS 770 (English EU)Document2 pagesSpecification Sheet - BDS 770 (English EU)Jegan NathNo ratings yet

- Mettler Toledo LinxsDocument36 pagesMettler Toledo LinxsSandro MunizNo ratings yet

- EN-eng 3A2 I-O - Configuration Analogue-In-3861600585790624Document21 pagesEN-eng 3A2 I-O - Configuration Analogue-In-3861600585790624yousufNo ratings yet

- DBTV1301: Service ManualDocument69 pagesDBTV1301: Service Manualgeps2010No ratings yet