Professional Documents

Culture Documents

EPC Scope of Work OP201670-01-GN-SOW-001 EPC SOW Rev 1

Uploaded by

Ahmed MoharramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPC Scope of Work OP201670-01-GN-SOW-001 EPC SOW Rev 1

Uploaded by

Ahmed MoharramCopyright:

Available Formats

MCC Upgrade Project

Prepared for: Shell Lubricants Egypt

Doc Ref: OP201670-01-GN-SOW-001

Rev: 01

Date: July 2021

EPC Scope of Work

MCC Upgrade Project

EPC Scope of Work

Client

Shell Lubricants Egypt

Document Title

MCC Upgrade Project

Wood Reference Number Client Reference Number (if applicable)

OP201670-01-GN-SOW-001 TBC

Contact

Eoin Burke

Eoin.Burke@woodplc.com

Tel: +353 (0) 91 481219

Wood

Galway Technology Park

Parkmore

Galway

H91 R9YR

Tel +353 91 481210

www.woodplc.com

Revision Date Reason for Issue Prepared Checked Approved

1 09.07.2021 IFR MAR EBU EBU

B 07.07.2021 IDC MAR EBU EBU

0 17.10.2019 Issued for Tender RG/MK/SK/RA RN RI

A 26.09.2019 Issued for Approval RG/MK/SK/RA RN RI

INTELLECTUAL PROPERTY RIGHTS NOTICE AND DISCLAIMER

Wood Group UK Limited, is the owner or the licensee of all intellectual property rights in this document (unless, and to the extent, we have agreed otherwise in a written contract with our client). The content of the

document is protected by confidentiality and copyright laws. All such rights are reserved. You may not modify or copy the document or any part of it unless we (or our client, as the case may be) have given you express

written consent to do so. If we have given such consent, our status (and that of any identified contributors) as the author(s) of the material in the document must always be acknowledged. You must not use any part of

the content of this document for commercial purposes unless we (or our client, in the event that they own intellectual property rights in this document) have given you express written consent for such purposes. This

document has been prepared for our client and not for any other person. Only our client may rely upon the contents of this document and then only for such purposes as are specified in the contract between us, pursuant

to which this document was prepared. Save as set out in our written contract with our client, neither we nor our subsidiaries or affiliates provide any warranties, guarantees or representations in respect of this document

and all liability is expressly disclaimed to the maximum extent permitted by law.

OP201670-01-GN-SOW-001 | July 2021 Page 2 of 86

MCC Upgrade Project

EPC Scope of Work

Signatory Legend

Revision Role Comments

1 Prepared Mostafa Abdelrahman

Checked Eoin Burke

Approved Eoin Burke

OP201670-01-GN-SOW-001 | July 2021 Page 3 of 86

MCC Upgrade Project

EPC Scope of Work

Table of Contents

1.0 Introduction ............................................................................................................................ 9

1.1 Introduction ...................................................................................................................................................................... 9

1.2 Project Description......................................................................................................................................................... 9

1.3 Document Objectives ................................................................................................................................................ 10

1.4 Hold Items ...................................................................................................................................................................... 10

1.5 Definitions ....................................................................................................................................................................... 11

1.6 Acronyms ........................................................................................................................................................................ 12

2.0 Order of Document Precedence .......................................................................................... 14

3.0 Overall Scope of Work ......................................................................................................... 15

3.1 Electrical ........................................................................................................................................................................... 15

3.1.1 Replacement of Existing MCC with New MCC.......................................................................................... 15

3.1.2 Renovation of Electrical Room........................................................................................................................ 15

3.1.3 Modification of Existing LV Switchgear Panels......................................................................................... 16

3.1.4 Replacement of Existing Distribution Boards............................................................................................ 17

3.1.5 Cable Routing in Electrical Room/ Field Area ........................................................................................... 18

3.1.6 Demolition Scope ................................................................................................................................................ 19

3.2 Instrumentation & Control ................................................................................................................................... 19

3.2.1 Replacement of existing IRP with new IRP ................................................................................................. 19

3.2.2 Modification of Existing PLC panel ............................................................................................................... 19

3.2.3 Modification of Existing ESD panel ............................................................................................................... 20

3.2.4 I&C Field Modification ....................................................................................................................................... 20

3.2.5 Demolition Scope ................................................................................................................................................ 21

3.2.6 Miscellaneous Works.......................................................................................................................................... 21

3.3 Civil & Structural ........................................................................................................................................................ 22

3.3.1 Electrical Room structural modification ...................................................................................................... 22

3.3.2 ShellVis Room ....................................................................................................................................................... 23

3.3.3 Miscellaneous Structural Works ..................................................................................................................... 23

3.3.4 Demolition Scope ................................................................................................................................................ 23

3.4 HSE ..................................................................................................................................................................................... 24

OP201670-01-GN-SOW-001 | July 2021 Page 4 of 86

MCC Upgrade Project

EPC Scope of Work

3.5 HVAC ................................................................................................................................................................................ 24

3.6 Piping Demolition...................................................................................................................................................... 25

3.7 Deviations from Scope of Work......................................................................................................................... 26

4.0 Detailed Scope of Work ....................................................................................................... 27

4.1 General Requirements ............................................................................................................................................... 27

4.2 Project Management ................................................................................................................................................. 28

4.3 Mobilization of Key Personnel ............................................................................................................................... 29

4.4 Engineering Office Services ..................................................................................................................................... 30

4.5 Project Control Requirements ................................................................................................................................ 30

4.6 Quality Assurance and Quality Control .............................................................................................................. 31

4.7 Communication Coordination ............................................................................................................................... 31

4.8 Interface Coordination .............................................................................................................................................. 31

4.9 Use and Verification of Information .................................................................................................................... 31

5.0 Engineering & Design Services ........................................................................................... 32

5.1 General ............................................................................................................................................................................. 32

5.2 Units and Measurements ......................................................................................................................................... 33

5.3 Codes, Specifications and Standards .................................................................................................................. 34

5.4 Site Visit and Data Collection ................................................................................................................................. 34

5.5 Engineering Services .................................................................................................................................................. 35

5.6 Design Basis ................................................................................................................................................................... 36

5.7 Electrical Works ............................................................................................................................................................ 36

5.7.1 New MCC ................................................................................................................................................................ 37

5.7.2 Renovation of Existing Electrical Room ....................................................................................................... 37

5.7.3 Modification of Existing LV Switchgear Panels......................................................................................... 38

5.7.4 Replacement of Existing Distribution Boards............................................................................................ 38

5.7.5 Demolition .............................................................................................................................................................. 38

5.8 Instrumentation & Control works ....................................................................................................................... 38

5.9 Civil works ....................................................................................................................................................................... 39

5.9.1 General..................................................................................................................................................................... 39

5.10 HSE works ....................................................................................................................................................................... 40

OP201670-01-GN-SOW-001 | July 2021 Page 5 of 86

MCC Upgrade Project

EPC Scope of Work

5.10.1 Project HSE Plan ................................................................................................................................................... 41

5.10.2 Project HSE Philosophy ........................................................................................................................................ 41

5.10.3 HAZID/ENVID/OHID Reviews .......................................................................................................................... 41

5.10.4 HAZID/ENVID/OHID Close-out Report ....................................................................................................... 41

5.10.5 Fire and Gas Detection ...................................................................................................................................... 41

5.10.6 Fire Protection ....................................................................................................................................................... 42

5.10.7 Fire and Gas Detector Layout .......................................................................................................................... 42

5.10.8 Fire and Gas Cause & Effect Chart ................................................................................................................ 42

5.10.9 Fire Fighting & Safety Equipment Layout .................................................................................................. 43

5.10.10 Fire Fighting & Safety Equipment Datasheet............................................................................................ 43

5.10.11 Simultaneous Operations (SIMOPS) Study ................................................................................................ 43

5.10.12 HSE Action Tracking Register .......................................................................................................................... 43

5.10.13 Technical Design Reviews ................................................................................................................................. 44

5.11 HVAC ................................................................................................................................................................................. 44

6.0 Procurement ......................................................................................................................... 45

6.1 Material Scope of Supply ......................................................................................................................................... 45

6.2 Inspection and Testing during Procurement Phase...................................................................................... 45

6.3 Materials Control Scope .......................................................................................................................................... 46

6.4 Transportation............................................................................................................................................................... 46

6.4.1 General..................................................................................................................................................................... 46

6.4.2 Local Transportation ........................................................................................................................................... 47

6.4.3 International Transportation and Customs ................................................................................................ 47

6.4.4 Documents ............................................................................................................................................................. 47

6.4.5 Damaged Goods .................................................................................................................................................. 47

6.5 Storage ............................................................................................................................................................................. 48

6.6 Construction Material ................................................................................................................................................ 48

6.7 Construction Material Inspection ......................................................................................................................... 48

6.8 Spares ............................................................................................................................................................................... 48

6.9 Spare Parts Interchangeability Record (SPIR) Requirement ...................................................................... 48

7.0 Construction Services ........................................................................................................... 50

7.1 General ............................................................................................................................................................................. 50

OP201670-01-GN-SOW-001 | July 2021 Page 6 of 86

MCC Upgrade Project

EPC Scope of Work

7.2 Scope of Field Services .............................................................................................................................................. 50

7.3 Field Engineering and Design Services............................................................................................................... 51

7.4 Coordination with Others ........................................................................................................................................ 52

7.4.1 Contractor Interface Requirements .............................................................................................................. 52

7.4.2 Interface with Other Contractors ................................................................................................................... 52

7.5 Permit Requirements .................................................................................................................................................. 53

7.6 Site Temporary Facilities and Other Requirements ...................................................................................... 53

7.7 Construction Methods and Procedures ............................................................................................................. 54

7.8 Health Safety and Environment............................................................................................................................. 54

7.9 Construction HSE Plan ............................................................................................................................................... 55

7.10 Waste Management Plan ......................................................................................................................................... 55

7.11 Emergency Response Plan....................................................................................................................................... 55

7.12 Construction HSE Advisors and HSE Reporting .............................................................................................. 55

7.13 EPC CONTRACTOR Training and Competence Assurance ........................................................................ 55

7.14 Personnel Protective Equipment ............................................................................................................................ 56

7.15 Risk Management and Work Permits ................................................................................................................. 57

7.16 Housekeeping ............................................................................................................................................................... 57

7.17 Testing & Commissioning Activities ................................................................................................................. 58

7.18 Electrical Works ............................................................................................................................................................ 58

7.19 Instrumentation and Control Works.................................................................................................................... 59

7.20 Civil works ....................................................................................................................................................................... 59

7.20.1 Renovation of existing Shellvis production room ................................................................................... 60

7.20.2 Renovation of existing Electrical room ........................................................................................................ 61

7.20.3 Modification of existing pipe rack ................................................................................................................. 62

7.21 HSSD Installation works ............................................................................................................................................ 62

7.22 HVAC works ................................................................................................................................................................... 62

8.0 Testing, Pre-Commissioning and Commissioning ............................................................ 64

8.1 Testing .............................................................................................................................................................................. 64

8.2 Pre-Commissioning .................................................................................................................................................... 64

8.3 Commissioning ............................................................................................................................................................. 65

OP201670-01-GN-SOW-001 | July 2021 Page 7 of 86

MCC Upgrade Project

EPC Scope of Work

9.0 Documentation .................................................................................................................... 67

9.1 List of Deliverables/Documents ............................................................................................................................ 67

9.2 “As-Built” Documents ................................................................................................................................................ 67

9.3 Dossier and End of Job Report .............................................................................................................................. 67

Appendix A Basic Engineering Documents / Drawings List .................................................... A-1

Appendix B EPC Deliverable List ................................................................................................ B-3

Appendix C EPC As-Built Document List ................................................................................. C-14

Appendix D Company Specifications and Standards ............................................................ D-16

OP201670-01-GN-SOW-001 | July 2021 Page 8 of 86

MCC Upgrade Project

EPC Scope of Work

1.0 Introduction

1.1 Introduction

LOBP was built in 6th of October City, 1994. The plant is consisting of several units to produce lubricants such as

but not limited to tank farm, blending & filling areas. The motor control centre (MCC) is used to operate and

control various fluid transfer process in plant areas. The condition of existing MCC has been degraded over the

years with various undocumented modifications which were implemented in the past. Most of the cables

connected to the MCC are not tagged and As-Built electrical drawings are not available in site. Thus, causing

difficulty in maintaining the system and also pose a serious electrical risk to personnel in site.

Additionally, the existing MCC is located next to hose exchange area and only separated by chain-link fence. There

is a risk of lubricant splash over to the MCC should any of hoses decouple unintentionally due to process upset.

1.2 Project Description

COMPANY initiated MCC upgrade project, as the existing MCC has to be replaced due to following reasons.

• Over the years, MCC has undergone many modifications including some extensions, which do not comply

with COMPANY standards or IEC standards.

• There is no proper drawings/ documents available for existing MCC. Also, there is no cable tag numbers

available for the cables connected to the existing MCC. This is causing difficulty in maintaining the system

as well as electrical hazard risk exposure to the personnel during maintenance.

• The existing MCC is located next to the hose exchange area and only separated by chain- link fence.

There is a risk of lubricant splash over to the MCC should any of the hoses are decoupled unintentionally

due to process upset.

• The breakers and contactors of the existing MCC are damaged and pose serious risk of electrocution or

fire. It is also observed that there is no proper separation provided between the breaker units and wiring

terminals.

• Three nos. of Distribution boards (FIL-MCC-ELEC-PNL07), (FIL-MCC-ELEC-PNL09), (FIL- MCC-ELEC-

PNL10) are connected to the busbar of the Existing MCC. The outgoing loads of these distribution board

are not known, hence the power consumed by these distribution board and the total load on the MCC

are not known.

EPC CONTRCATOR scope for the MCC upgrade project includes;

• Replacement of existing MCC/ LCS in the field with new MCC/ LCS respectively,

• Integration of existing VSD module from the field VSD panels to the new MCC,

• Renovation of existing Electrical Room as per Shell standard,

• Interface new MCC signal to existing PLC/ ESD system,

• Decommissioning/ demolition of existing MCC/ LCS/ VSD panel and its connected cables/ accessories,

• Installation of cabling system, lighting system, earthing and lightning protection system for the new

electrical installations,

OP201670-01-GN-SOW-001 | July 2021 Page 9 of 86

MCC Upgrade Project

EPC Scope of Work

• Installation of structural supports for cable tray, LCS, DB, JB etc.

• Installation of firefighting system for the renovated Electrical Room.

• Modification of existing LV Switchgear panels listed in this document, as per the recommendations

provided in Basic Design & Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002),

• Replacement of existing Distribution Boards listed in this document, as per the recommendations

provided in Basic Design & Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002),

• Verify and rearrange the new heat tracing, lighting, Minebea’s panel and battery room panels recently

installed in the exiting room within the new MCC room arrangement.

1.3 Document Objectives

This document defines the Scope of Work for the EPC CONTRACTOR to be appointed by COMPANY, who shall be

responsible for performing the Detailed Design & Engineering, Procurement, Supply, Inspection, Transportation

to Site, Construction, Installation, Testing, Pre-commissioning, Commissioning and hand over the facilities to

COMPANY.

The Scope of Work document, whilst being detailed is not intended to define each individual piece of equipment

or material but provide an overview to the EPC CONTRACTOR of the Scope of Work and the main components.

This document is to be read in conjunction with the Basic Design & Engineering Package Report, Shell DEP and

BASIC ENGINEERING documents/ drawings included in the EPC dossier.

1.4 Hold Items

A list of HOLDs for this document are presented below.

HOLD No. Description

1.

OP201670-01-GN-SOW-001 | July 2021 Page 10 of 86

MCC Upgrade Project

EPC Scope of Work

1.5 Definitions

COMPANY Shell Lubricants Egypt

PROJECT MCC Upgrade Project- Basic Engineering

AGREEMENT Contract between COMPANY and EPC CONTRACTOR for

implementation of PROJECT

Shall is to be understood as mandatory in relation to the requirements of this

document.

Should is to be understood as recommended in relation to the requirements of this

document.

EPC CONTRACTOR The party which carries out all or part of the design, engineering, procurement,

construction, commissioning or management of the PROJECT. CONTRACTOR

includes its approved MANUFACTURER(s), VENDOR(s), SUPPLIER(s) and SUB-

CONTRACTOR(s).

VENDOR/ The Party (Parties) which manufactures and/or supplies materials, equipment,

MANUFACTURER/ technical documents or drawings and/or services to perform the duties specified

SUPPLIER by the COMPANY/ EPC CONTRACTOR. Here after called as VENDOR.

SUB-CONTRACTOR/ The party(s) which carry(s) out all or part of the design, procurement, installation

SUB-VENDOR and testing of the system(s) as specified by the CONTRACTOR.

OEM is the Party (Parties), who has manufactured & supplied original Equipment

(Original Equipment Manufacturer).

SITE Area where PROJECT is being built and includes the areas affected by the

PROJECT.

OP201670-01-GN-SOW-001 | July 2021 Page 11 of 86

MCC Upgrade Project

EPC Scope of Work

1.6 Acronyms

AC Alternating Current

CIF Cost, Insurance, Freight

CPT Carriage Paid To

DB Distribution Board

DCP Dry Chemical Powder

DCS Distributed Control System

EMDB Emergency Distribution Board

ENVID Environmental Impact Identification

EPC Engineering, Procurement, Construction

ESD Emergency Shut Down

EXW Ex Works

FAT Factory Acceptance Test

F&G Fire and Gas

FOB Free On Board

GA General Arrangement

HAC Hazardous Area Classification

HAZID Hazard Identification

HC Hydrocarbon

HSE Health, Safety, Environment

HSSD High sensitive smoke detection

HVAC Heating, Ventilation, Air Conditioning

I&C Instrumentation and Control

I/O Input/ Output

IRP Interposing Relay Panel

JB Junction Box

OP201670-01-GN-SOW-001 | July 2021 Page 12 of 86

MCC Upgrade Project

EPC Scope of Work

LCS Local Control Station

LOBP Lube Oil Blending Plant

LV Low Voltage

MCC Motor Control Center

MDB Main Distribution Board

MTO Material Take-Off

QA/ QC Quality Assurance/ Quality Control

OEM Original Equipment Manufacturer

O/G Outgoing

OHID Occupational Health Identification

PHA Preliminary Hazard Analysis

PLC Programmable Logic Controller

PPE Personal Protective Equipment

PTW Permit to work

PVC Poly Vinyl Chloride

SAT Site Acceptance Test

SIMOP Simultaneous Operation

SLD Single Line Diagram

SPIR Spare Parts Interchangeability Record

TBT Tool Box Talk

VSD Variable Speed Drive

OP201670-01-GN-SOW-001 | July 2021 Page 13 of 86

MCC Upgrade Project

EPC Scope of Work

2.0 Order of Document Precedence

Any conflicts between the referenced documents/ drawings (Codes/ Standards, Specifications and COMPANY

supplied documents/ drawing) shall be brought to COMPANY notice in writing prior to offer submission for

clarification/ resolution. The COMPANY interpretation shall then be final and binding on EPC CONTRACTOR. The

most stringent requirements as stipulated in the documents listed hereunder shall govern and the following

general order of precedence shall apply to conflict resolution.

• Level 1 National Standards and Regulations (Egypt Electricity standards)

• Level 2 COMPANY Standards (PRS 30.09.00.01 and DEP)

• Level 3 Standards as referred to in the Shell DEP related to subject matter

• Level 4 Any other National/ International Codes/ Standards to define the work involved not in

contradiction with the above listed Standards.

• Level 5 Project Documents and Drawings

OP201670-01-GN-SOW-001 | July 2021 Page 14 of 86

MCC Upgrade Project

EPC Scope of Work

3.0 Overall Scope of Work

This section describes the overall scope of work which covers the engineering, design, modifications, demolishment,

manufacturing, supply, transportation, installation, testing, commissioning and handing over in satisfactory operating

condition of the new Electrical/ instrumentation & control/ HVAC/ Fire Protection system including the related civil

/structural works.

This scope shall be read in conjunction with Basic Design & Engineering Package Report (Doc No. EGLOBP-00-GN-REP-

002) and the documents/ drawings listed in Appendix-A.

All the installation works shall be carried out in line with Shell DEP requirements and as per the details provided in

below sections.

3.1 Electrical

Brief Electrical works for the replacement of existing MCC with new MCC, renovation of Electrical Room,

modification of existing LV Switchgear panels, replacement of existing LV Distribution Boards, installation of cabling,

earthing, lightning, lighting system for new installations, demolition of existing MCC, field LCS/ VSD and related

cabling system for the PROJECT are listed in below sections.

3.1.1 Replacement of Existing MCC with New MCC

EPC CONTRACTOR shall replace the existing MCC near hose exchange area (inside factory building) with new MCC as

per the details provided in Basic Design & Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002). The new

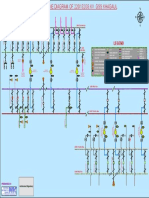

MCC shall be designed based on new MCC single line diagram (Drg no. EGLOBP -00-EL-SLD-002), with necessary

intelligent motor protection, control and monitoring system as per Shell Standard Protection drawing - LV Motor

Protection-S66.229-0 and as per Shell DEP 33.67.01.31. The new MCC shall be installed in the renovated electrical room.

The signal from new MCC shall be interfaced with existing PLC and ESD system through new Interposing Relay Panel (IRP)

to be installed in the Electrical Room.

Existing VSD modules currently located inside each VSD panels in the field shall be integrated into the new MCC. EPC

CONTRACTOR shall carry out interaction with OEM of existing VSDs and VENDOR of the new MCC for the VSD

module integration works.

New Local Control Station (LCS) with Start/Stop/ Emergency Stop buttons and with H-O-A selector switch shall be

placed in the field, next to the motor. New power/ control cables shall be laid from new MCC to field motors/ LCS as

part of this PROJECT.

3.1.2 Renovation of Electrical Room

Existing Electrical Room shall be renovated in accordance with Shell Standard Drawing S68.040, Shell DEP

33.64.10.10-Gen. and Shell DEP 34.17.00.32-Gen. in order to accommodate new MCC, IRP, HVAC Control Panel, future

DCS and Control System, Junction boxes etc. required for the MCC upgrade PROJECT.

The current Electrical Room is inadequate to accommodate the above panels and future DCS/ Control system. Therefore,

existing ShellVis equipment, the wall between ShellVis and Electrical room shall be demolished to extend the

Electrical room. Standard safety/ maintenance distance between LV panels/ Instrumentation panels/ from walls

OP201670-01-GN-SOW-001 | July 2021 Page 15 of 86

MCC Upgrade Project

EPC Scope of Work

shall be maintained inside the renovated Electrical Room as per Shell DEP 33.64.10.10-Gen.

Following are the minimum modifications required for the Electrical room, to meet the requirements of Shell DEP’s:

• Air conditioning shall be provided in the electrical room to cool and dry the air. The Heating and air-

conditioning requirements shall be designed in accordance to Shell DEP 31.76.10.10-Gen.

• All new doors shall be fitted with internal panic bolt for emergency exit. Doors shall be placed at each

end of the Electrical Room.

• Safety and instrumentation earthing system shall be provided for earthing of all equipment inside the

electrical room. The earthing system shall be designed as per Shell standard drawings S680.030 and

Shell DEP 33.64.10.33-Gen.

• Lightning protection system shall be provided for electrical room in accordance with local regulations/

IEC 62305. The lightning protection system shall be designed and installed in accordance with Shell DEP

33.64.10.33-Gen.

• The floor mounted electrical panels shall be installed on raised floor (false floor). The raised floor shall be

with smooth level to permit the handling of equipment on rollers during installation and maintenance.

Insulated rubber mat shall be provided in the electrical room as per IEC 61111.

• Lighting system and power sockets for the new Electrical room shall be provided as per Shell DEP-

33.64.10.10-Gen.

• Firefighting system shall be provided in Electrical Room as per Shell DEP 80.47.10.30-Gen. A common alarm shall

be routed from electrical room direct to LOBP’s central fire alarm system.

• Existing LV switchgear panel (MPBP & MPBL) shall be moved 100mm to the front side to comply with Shell

Standard drawing S680.030.

• Existing ventilation openings of electrical room shall be closed after installation of HVAC system.

• A new ramp shall be provided in one access door of the electrical room to bring electrical equipment inside the

electrical room. New staircase shall be provided in the other access door for entry into the electrical room.

• All cable entry holes in the electrical room floor or walls shall be suitably sealed.

Refer Basic Design & Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002) and Updation – Equipment

Layout for Electrical Room (Drg no. EGLOBP -00-EL-LAY-001) for more details.

3.1.3 Modification of Existing LV Switchgear Panels

Following LV Switchgear panels shall be modified, based on the recommendations provided in Basic Design &

Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002), in order to improve the operability and

maintainability of these panels:

• Main Distribution Board (MDB) in Electrical Transformer Room

• Emergency Distribution Board (EMDB) near to Boiler Room

OP201670-01-GN-SOW-001 | July 2021 Page 16 of 86

MCC Upgrade Project

EPC Scope of Work

• LV Switchgear Panel (MPBP) in Electrical Room

• LV Switchgear Panel (MPBL) in Electrical Room

EPC CONTRACTOR shall develop a modification scope of work for the OEM of above panels, detailing the modification

requirements. OEM shall carry out all the modification works, in presence of EPC CONTRACTOR/ COMPANY

personnel.

OEM shall perform following tasks with support from EPC CONTRACTOR during panel modification;

• Perform site survey to understand scope of works.

• Assess the duration (any shutdown) required for the modification of LV switchgear panel.

• Provide sufficient information and documentation for modification related works to permit a successful

installation during the construction stage.

• Develop detailed execution methodology, including individual feeder shutdown duration and get prior

approval from COMPANY.

• Provide all modification materials, new materials, procurement and supply to jobsite as part of his scope.

• Mobilize an experienced site installation team for modification related works.

• Provide necessary installation, construction, pre-commissioning and commissioning items and services

for modification job.

• Provide all personnel, supervision, professional and technical services, materials, equipment and support

services to perform the work in accordance with this scope of work.

• Follow work procedures that ensure no damage is caused to existing facilities and equipment.

Further to the above, for the Emergency Distribution Board (EMDB) near to Boiler Room, outdoor area lighting shall be

provided by the EPC CONTRACTOR to have proper illumination in this area.

The modification for Electrical Transformer Room (where the Main Distribution Board is located) based on the

recommendations mentioned in section 7.1.1 of Basic Design & Engineering Package Report (Doc No. EGLOBP -00-

GN-REP-002), are not part of this project.

3.1.4 Replacement of Existing Distribution Boards

Following LV Distribution Boards shall be replaced, based on the recommendation provided in Basic Design &

Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002):

• Distribution board for PU-Utilities

• Distribution board for Compressor and boiler

• Distribution board for Plastic area lighting

• Distribution board for TFF panel

• Distribution board for M/C panel

OP201670-01-GN-SOW-001 | July 2021 Page 17 of 86

MCC Upgrade Project

EPC Scope of Work

• Distribution board for MZ lighting panel

• Distribution board for OCME System (FIL-MCC-ELEC-PNL10)

• Distribution board for CFT System (FIL-MCC-ELEC-PNL09)

• Distribution board (FIL-MCC-ELEC-PNL07)

EPC CONTRACTOR shall demolish and replace the identified existing Distribution Boards. The new Distribution Boards shall

be designed in accordance with Shell DEP 33.64.10.10-Gen. and as per the recommendations mentioned in Basic Design

& Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002).

As part of early works during EPC stage, EPC CONTRACTOR shall conduct a site visit to identify the outgoing loads and

cables of the existing Distribution Boards. Individual breakers shall be switched off and continuity test for the cable shall

be performed to identity each loads. The outgoing breaker ratings of new Distribution Boards shall be designed,

based on the identified loads during site visit.

Further to the above, based on the integrity of the existing cables, EPC CONTRACTOR shall replace the damaged cables

(if any). The replacement of cables for Distribution Boards (which is not covered in BASIC ENGINEERING report) shall be

carried out by EPC CONTRACTOR based on reimbursable basis to COMPANY during EPC, as per the quantity of

cable to be replaced. Cable size shall be re-checked based on the load connected to each feeders.

3.1.5 Cable Routing in Electrical Room/ Field Area

New power and control cables for the new MCC shall be laid on new aboveground cable trays installed on existing pipe

racks, new cable trays inside factory building and renovated electrical room as shown in the Cable routing layout (Drg

no. EGLOBP-00-EL-CRL-001). New branch cable trays shall be used to lay cables to the individual field motors/ LCS’s

from the main cable tray installed on the pipe rack. These new branch cable trays shall be installed on new metallic

support from ground level.

Single pair cables from individual pressure switches shall be routed to a new junction box installed in the field. A new

multi-pair cable from the field junction box shall be routed through existing instrumentation trays to a new junction

box in the electrical room. Single pair cables from new junction box in the electrical room shall be connected to individual

VSDs inside the new MCC.

Instrumentation cables from the new IRP shall be routed to the new MCC and to the existing PLC in the control room

through new aboveground cable trays shown in the Cable routing layout (Drg no. EGLOBP -00-EL-CRL-001). Cable

laying, terminations (both power and control) etc. at the source and load ends including fabrication of cable trays/ racks,

supply of required cable trays and junction boxes, bulk materials shall be part of the EPC CONTRACTOR’s scope.

New Junction boxes, LCSs and new trays in the field area shall be connected to existing plant earthing system as per Shell

DEP 33.64.10.33-Gen.

For power connection to Distribution Board for OCME System, Distribution Board for CFT System and Distribution

Board (FIL-MCC-ELECPNL07) from existing LV Switchgear Panels (MPBP and MBPL) in electrical room, the new cable

shall be laid in existing cable trays inside the factory building and new cable trays in the pipe rack/ electrical room.

OP201670-01-GN-SOW-001 | July 2021 Page 18 of 86

MCC Upgrade Project

EPC Scope of Work

3.1.6 Demolition Scope

EPC CONTRACTOR’s scope shall include the demolition of existing MCC near hose exchange area, existing IRP in Control

Room, existing LCS/ VSD panels near the motor in the field and its associated cables/ connection accessories. The

existing cables connected to MCC/ IRP/ LCS/ VSD shall be disconnected prior to demolition works.

Further to the above, EPC CONTRACTOR shall also demolish the following existing Distribution Boards as per the

recommendations mentioned in Basic Design & Engineering Package Report (Doc No. EGLOBP -00-GN-REP-002): -

• Distribution board for PU-Utilities

• Distribution board for Compressor and boiler

• Distribution board for Plastic area lighting

• Distribution board for TFF panel

• Distribution board for M/C panel

• Distribution board for MZ lighting panel

• Distribution board for OCME System (FIL-MCC-ELEC-PNL10)

• Distribution board for CFT System (FIL-MCC-ELEC-PNL09)

• Distribution board (FIL-MCC-ELEC-PNL07)

3.2 Instrumentation & Control

Brief Instrumentation works for the modification of existing PLC panel, ESD panel, replacement of local control panel

near Base Oil Unloading and Additive tank area, installation of new JB/ Alarm panels, new cabling system, demolition of

existing IRP and related cabling system between existing MCC and IRP for the PROJECT are listed in below sections.

3.2.1 Replacement of existing IRP with new IRP

New IRP shall be installed in Electrical Room to interface the signal between new MCC and existing PLC/ ESD panels.

The new MCC panel shall also have interfaces to all the new and existing pumps/motors in the field. All control,

monitoring and safeguarding signals from the new MCC as defined in Shell DEP 33.67.01.31 ‘Low-Voltage Switchgear

and Control gear Assemblies’ shall be interfaced to the existing PLC. ESD trip commands from ESD panel shall also be

connected to new MCC through new Interposing Relay Panel.

3.2.2 Modification of Existing PLC panel

The existing PLC Panel shall be modified to interface the status signals and commands to the new MCC panel.

EPC CONTRACTOR shall mobilize the OEM’s immediately after PROJECT award to carry out adequacy check of existing

PLC being affected as part of this PROJECT. The adequacy report shall be submitted to COMPANY/ EPC CONTRACTOR

for review and approval.

• The spare I/O’s have been identified in BASIC ENGINEERING site visit report. However, the OEM as part of the

adequacy report shall submit detailed information for the use of the existing I/O’s. The adequacy report shall

encompass all the details so that the existing PLC performance is not deteriorated in any way while these

OP201670-01-GN-SOW-001 | July 2021 Page 19 of 86

MCC Upgrade Project

EPC Scope of Work

modifications are being carried out. All necessary hardware/ software modifications in the existing PLC

to accommodate the PROJECT requirement shall be considered as part of the scope and performed only by

the respective OEM. All necessary software licenses in the existing PLC shall be procured and considered for

the PROJECT requirement.

• EPC CONTRACTOR shall consider new I/O cards to be installed in spare slots of the existing PLC, in case

spare I/O’s cannot be used or are unavailable at the execution stage of the PROJECT. All associated cost related

to engineering/ panel internal modifications, hardware/ software modifications shall be considered by EPC

CONTRACTOR.

The major scope of modification in existing PLC shall be as the following:

• Due to replacement of existing IRP with a new IRP, all cable wiring shall be re-wired from the new IRP located

at the renovated Electrical Room to the PLC panel in the Control Room.

• The newly added pumps and motors shall also be interfaced. All new IO’s as part of these additions shall

be provided with new terminals inside the PLC panel to interface with the IRP panel.

• All existing pump/motor signal tags shall be verified in the PLC by loop check and functionality checks

during the pre-commissioning/commissioning activities.

• All the new IO signals as part of added pumps and motors shall be newly configured in the PLC system and

shall be verified in the PLC through loop checks and functionality checks during the pre-

commissioning/commissioning activities.

• The base oil unloading tank control panel and additive tank control panel shall be replaced with new

PLC based control panels in the field. These panels shall have provisions to interface to the future DCS. The

cabling from alarm panels to the electrical building shall utilize the existing field cable trays.

3.2.3 Modification of Existing ESD panel

The existing ESD panel shall be modified to interface the trip commands to the new MCC.

EPC CONTRACTOR shall mobilize the OEM’s immediately after PROJECT award to carry out adequacy check of existing

ESD being affected as part of this PROJECT. The adequacy report shall be submitted to COMPANY/ EPC CONTRACTOR

for review and approval. If existing ESD panel is not adequate, the spare space inside the existing PLC panel shall be

utilized to accommodate ESD hardware components.

The major scope of modification in existing ESD panel shall be as the following:

• The newly added pumps and motors shall also be interfaced to ESD panel. If required new terminals shall

be provided inside the ESD panel to accommodate new signals.

• All existing pump/motor signal tags shall be verified in the ESD by loop check and functionality checks

during the pre-commissioning/commissioning activities.

3.2.4 I&C Field Modification

EPC CONTRACTOR shall install new field control panels for additive tank and base oil unloading pumps and replace

OP201670-01-GN-SOW-001 | July 2021 Page 20 of 86

MCC Upgrade Project

EPC Scope of Work

the existing control panels in these locations. New instrument cables shall be provided for these panels if existing cables

are not reusable.

EPC CONTRACTOR shall install new field Alarm panel for finished product tanks including the related power and control

cabling.

The major I&C field modification works are listed below:

• All pressure switch signals shall be wired through existing cable trays to a new junction box to be

provided in the field. Cable routing layout (Drg no. EGLOBP -00-EL-CRL-001) shall be referred, for cable

routing details and for the location of new junction box in the field.

• The new instrument cable tray as shown in the cable routing drawing shall be utilised for cable laying between

the electrical and the control room.

• New Alarm panel shall be provided for indication of high and low level alarms for all tanks in the field.

For High High alarm, a beacon with a siren and for high and low level, alarm indications with lamp shall

be provided as a minimum in these alarm panels.

• If existing cable trays are not available from the tank to the new alarm panel to be provided as part of

this PROJECT, new instrument cable trays shall be provided to extend the cabling till every tank in the

field.

• All tank alarm panels shall have provisions for interfacing to the future DCS. The cabling from alarm panels to

electrical building shall utilize the existing field cable trays.

3.2.5 Demolition Scope

Existing IRP and its associated cables/ connection accessories in Control Room shall be demolished after the

commissioning of new IRP in renovated Electrical Room.

In addition, existing Control Panels for Base Oil Unloading and Additive tank area shall be demolished after the

commissioning of new Control Panels in these locations.

3.2.6 Miscellaneous Works

• Provide start up and COMMISSIONING assistance, including scheduling, planning and coordination activities

with COMPANY personnel. Additionally, sufficient instrumentation control personnel shall be continuously

available to commission all loops. Effect any necessary configuration or programming changes. Trouble

shoot any problems relating to instrumentation devices or control systems and maintain all control

systems and instrumentation documentation in an "as-built" status.

• Perform SITE acceptance testing with VENDOR assistance.

• Develop and obtain approval for all systems logging and reporting requirements.

• Prepare, review and obtain approval of all graphics layouts of PLC SCADA.

• Perform all system configuration, required protocol development, interface database development,

control and sequence programming as required for the PROJECT implemented functionalities.

OP201670-01-GN-SOW-001 | July 2021 Page 21 of 86

MCC Upgrade Project

EPC Scope of Work

• Provide software and hardware factory acceptance test, site installation and Site Acceptance

• Test procedure documents for review and approval of COMPANY, for all systems.

• Mobilize VENDORS to install all system hardware and final software at site. Facilitate SITE integration

testing with VENDOR assistance.

• Approval for panel & instrument tagging (Tagging Philosophy) shall be obtained from company and

revised the existing drawing accordingly.

3.3 Civil & Structural

Brief civil & structural works for the Electrical/ShellVis modification/ demolition and structural supports for cable trays, LCS,

Control Panels, JBs, Distribution Boards etc. are listed in below sections.

3.3.1 Electrical Room structural modification

Following are the structural modifications required in the existing electrical room. Refer to attached Sketch-1 in Basic

Design and Engineering Report (Doc no. EGLOBP -00-GN-REP- 002):

• Raised floor shall be provided in the electrical room to install new panels. The raised floors shall follow the

requirements of ICC-ES AC175 in those regions where applicable.

For regions where ICC-ES AC175 is not applicable, then the following shall apply:

• The height of the floor should be 500 mm (1ft 8 in) minimum. It is better to provide the false floor for a height

of 8000mm to accommodate the cables under the electrical equipment/panels

• The panels shall have a factory-applied, anti-static, wearing surface.

• The floor panels shall rest on adjustable pedestals manufactured of mild steel with mild steel foot and

top plates.

o The pedestals shall be glued to the concrete floor, adjustable in height.

o The height adjustment shall incorporate an automatic positive locking device.

o Bracing shall be installed to prevent lateral movement of the flooring system.

• Separate steel structures should be provided to support electrical equipment.

• The load bearing capacity of the floor shall meet the local standards and testing requirements (static,

impact and dynamic loading) and meet or exceed the design floor loads for the room.

• Electrical requirements for the Electrical Room shall be in accordance with DEP 33.64.10.10-Gen. or DEP

34.64.20.10-Gen.

• The entire flooring system shall be electrically grounded.

• False floor shall be a rigid frame type with hinged or fixed column bases. The structural framework shall

be rolled structural shapes.

• Steel sheeting with insulation shall be provided on the top of false floor steel frame which will cater as

OP201670-01-GN-SOW-001 | July 2021 Page 22 of 86

MCC Upgrade Project

EPC Scope of Work

a deck for the electrical equipment.

• The double panel steel door shall be modified to accommodate as per the false floor level.

• Internal wall between existing electrical room and ShellVis room shall be demolished to combine the both

rooms into a modified single electrical room.

• The surface of all floors, including the space under the cavity floor, where dust is liable to accumulate shall be

sealed with epoxy paint or PVC coating.

3.3.2 ShellVis Room

Following are the structural modifications required in the existing ShellVis room:

• ShellVis equipment shall be shifted to the new location as recommended by COMPANY and the room shall

be made free to accommodate new MCC, MPBP/MPBL, HVAC panel, IRP, JB, future DCS and Control

System Cabinets etc.

• All the foundations & connecting piping related to the ShellVis equipment shall be demolished.

• Same false floor as mentioned above for Electrical Room shall be installed to combine both rooms into

a modified single electrical room

• The double panel steel door shall be demolished, and that open space shall be closed by block masonry

or as like existing walls.

• The sliding steel door covering the full length of wall shall be demolished; open space created by the

demolition shall be closed with block work or as like existing walls and a new double leaf steel door shall be

installed.

• Waterproofing shall be done on the roof as per Shell DEP recommendation.

• The ventilation ducts shall be left as it is, that can be further utilized to accommodate the HVAC ducts

coming from the roof slab.

• Post demolition of ShellVis equipment/piping, any wall opening for the ShellVis equipment in ShellVis/

Electrical Room walls to be closed properly with like material of the parent structure.

3.3.3 Miscellaneous Structural Works

• Construct T-Supports along with foundations as per approved for construction drawing.

• Cantilever extension for the existing pipe rack to accommodate cable tray support.

• Construct supporting arrangement for new DB’s and provide shelters if required.

• Supporting arrangement for the new junction boxes, control panels, LCS, distribution boards and new

high-level alarm panels.

3.3.4 Demolition Scope

EPC CONTRACTOR’s scope shall include the demolition of existing ShellVis equipment/ piping/ structures and

OP201670-01-GN-SOW-001 | July 2021 Page 23 of 86

MCC Upgrade Project

EPC Scope of Work

structural supports for existing VSD, LCS, Control Panel in the field.

• EPC CONTRACTOR shall demolish, remove, dispose of materials and reinstate disturbed or damaged

pavement/ ground surface where redundant foundations have been identified.

• EPC CONTRACTOR shall demolish abandoned/ unused structures and facilities interfering with the

construction of new facilities subject to COMPANY approval for demolition or new facilities shall be

designed suitably to avoid the demolition of existing structures/ facilities.

• All demolished materials shall be removed from site and disposed of in a manner approved by

COMPANY. Disposal of excavated/ surplus material to COMPANY designated location/ suitable dump.

All costs associated with the disposal of materials shall be included in the EPC CONTRACTOR scope of work.

Disposal of material shall be carried out as per COMPANY regulation.

3.4 HSE

The renovated Electrical Room shall be provided with additional 5kg CO2 extinguisher by EPC CONTRACTOR while

retaining the existing 2 x 5kg CO2 along with ceiling mounted DCP extinguisher as per the recommendations in Basic

design and engineering package report (Doc no. EGLOBP -00-GN-REP-002). Since an early warning aspirating system will

be installed (HSSD) to detect the presence of smoke particles much earlier than by a normal smoke detector, clean

agent system as a fire suppression system (FM 200, Novec, Inergen) is not

required in Electrical Room. EPC CONTRACTOR shall utilize a specialist VENDOR to install the HSSD Panel. The HSSD shall

have connection to the F&G/ESD Panel to set alarm. Power for new HSSD panel shall be fed from new PU DB in Electrical

Room. Existing F&G detectors shall be retained and relocated as per NFPA 72 & applicable COMPANY DEP standards.

EPC CONTRACTOR shall carry out following studies during detailed engineering.

• Study the feasibility of including H2S detectors in the renovated Electrical Room to comply with Shell DEP

(31.76.10.10 -Gen.).

• Study the requirement to provide HC detectors in the renovated Electrical Room HVAC system to comply

with applicable Shell DEP 31.76.10.10- Gen. and study the HC detector trigger action on the new HVAC

system.

3.5 HVAC

EPC CONTRACTOR shall include design, engineering, procurement, supply, inspection & testing, installation,

erection, field supervision, pre-commissioning, testing and commissioning, of HVAC system for the renovated

Electrical Room in the scope.

HVAC system shall be provided with the following:

• DX cooling and condenser coils made from refrigerant grade copper in accordance with EN 14276-2 or ANSI

equivalent shall be tested to 36 barg (520 psig) minimum.

• DX cooling coils shall be sized to minimize moisture carry-over.

• On completion of satisfactory testing, DX coils shall be dehydrated, charged with an inert gas and sealed

OP201670-01-GN-SOW-001 | July 2021 Page 24 of 86

MCC Upgrade Project

EPC Scope of Work

• DX units shall have a common fault alarm per unit.

• Refrigerant systems shall be strength-tested to 1.3 times the maximum allowable pressure in accordance with

EN 378 and Pressure testing shall be performed prior to painting, installation of insulation.

Instrumentation, pressure relief valves and any items of equipment, having lower pressure limits than the test

pressures specified, shall be isolated during the tests.

• The HVAC system of the Electrical/ ShellVis room shall be controlled by a single HVAC control panel and

interfacing with existing PLC in the control room for alarm indications.

• Air supply to the indoor spaces in the building through a supply duct and the return shall bed ducted from

room.

• Provision of interfacing signals from PLC/ ESD panels to HVAC control panel.

• The requirement of the flow will finalized after finalization of detailed engineering prior to procurement

commencement (ie, relevant for installation of F&G detector which is to be provided by others)

o Flammable gas detector in HVAC air intake

o Smoke detector in air intake duct

• EPC CONTRACTOR shall provide the following interfacing signals from the HVAC control panel to PLC and

ESD panels as minimum but not limited to

o Trip main circuit breaker of HVAC panel

o HVAC system running indication

o HVAC system fault indication

o AC Unit trip status alarm

o High Temperature Alarm

3.6 Piping Demolition

EPC CONTRACTOR shall be responsible for demolition of ShellVis equipment, associated foundation and connecting

piping of the ShellVis equipment to the nearest flange connection after isolation and decommissioning of the ShellVis

equipment. COMPANY to provide marked-up copies of the ShellVis schematic for EPC CONTRACTOR before

demolition. EPC CONTRACTOR in consultation and with approval from COMPANY shall finalize all the piping materials

required for mechanical isolation, identify all energy sources and other hazards, and shall identify all the isolation point

(i.e isolation boundaries).

COMPANY to confirm the correct methodology for flushing prior to demolishing activity/ handover to EPC

CONTRACTOR.

COMPANY to supervise the assessment of disassembling operation and to confirm the methodology of the

assembly post submission of EPC CONTRACTOR proposal.

OP201670-01-GN-SOW-001 | July 2021 Page 25 of 86

MCC Upgrade Project

EPC Scope of Work

3.7 Deviations from Scope of Work

EPC CONTRACTOR shall obtain agreement/ formal acceptance from COMPANY prior to implementing any deviation

from the agreed Scope of Work. Requests for deviations shall be documented in a query system to formalize the question

and response. It is the responsibility of the EPC CONTRACTOR to clarify all the site queries.

OP201670-01-GN-SOW-001 | July 2021 Page 26 of 86

MCC Upgrade Project

EPC Scope of Work

4.0 Detailed Scope of Work

4.1 General Requirements

EPC CONTRACTOR shall be responsible for detailed design & engineering, procurement, supply of material,

inspection, transportation to site, installation, modification, demolishment, pre-commissioning & commissioning,

Project Management and support services in accordance with EPC tender package including the following:

• Review the documents that are defined in the Tender Package, which includes EPC Scope of Work, Shell DEP’s,

BASIC ENGINEERING Dossier etc.

• Provide Project Management Services, Planning, Controls, and Administration services.

o Document Management including provision of electronic documents and drawings compatible with

COMPANY format.

o Overall Project Schedule in accordance with COMPANY requirement.

• Ensure that all the new documents are developed from BASIC ENGINEERING/ COMPANY provided as-built

documents to avoid duplication.

• Carryout site visits, site survey, site measurements, free space verification, site data collection.

• On completion of the Site Surveys, discuss key findings with respect to interface details, testing methodology

and constructability issues with concerned site personnel prior to departure from site.

• Submit site visit report with site findings for COMPANY review/ approval.

• Liaison with COMPANY to ensure synergy with on-going/ future projects.

• Carry out all the WORKS in a safe manner without creating disruption, obstruction or risk to other personnel

working in that area in accordance with COMPANY requirement.

• Perform detailed design in accordance with BASIC ENGINEERING Dossier, Shell DEP’s and latest International

Codes & Standards. However, in absence of these, Industry Best Practice shall be followed.

• Preparation and submission of all Design, Engineering, modifications, demolishment, Procurement,

Construction, pre-commissioning, commissioning, start-up, Material Control and Quality Control

documentation (including procedures, method statements and execution plans) for COMPANY review and

approval.

• Implementation of actions arising out of COMPANY PROJECT Technical / Safety Review(s).

• Provide Scribe/ Secretaries for all Technical/ HSE reviews and prepare the respective reports and close-

outs.

• CONTRACTOR shall dispose or sell the construction surplus and scrap generated during execution of the

PROJECT as approved by COMPANY, COMPANY to confirm the disposal means.

• Provide mobile sanitary facility and disposal through approved Contractors.

OP201670-01-GN-SOW-001 | July 2021 Page 27 of 86

MCC Upgrade Project

EPC Scope of Work

• Develop Project Quality Plan and Procedures in line with COMPANY Procedures.

• Prepare all PROJECT procedures, inclusive of coordination/ communication/ electronic transport of

documents/ control/ monitor/ management/ change orders/ invoicing/ design documents, etc. and

obtain COMPANY approval.

• Provide two years maintenance spare for all equipment.

• Provide, the recommended “Spare Parts Interchangeability Record” (SPIR) for the two- year operating spares,

for all supplied and installed items.

• Submit all as built drawings and final documents including final VENDOR documents to COMPANY. Native

files shall be provided for all documents, drawings and software files.

• COMPANY will assist EPC CONTRACTOR with the following

• COMPANY will provide a plot plan showing assembly points/escape route.

• COMPANY to assign a proper safe footprint acting as a minor workshop for special minor activities e.g.

grinding, small welding activities and notify the EPC CONTRACTOR with the required inspection checklist/

documents for heavy equipment and the required equipment’s certificates.

• COMPANY to highlight to EPC CONTRACTOR the marked-up plot plan to indicate the existing facilities to be

utilized for temporary facility.

• COMPANY to ensure that existing light is adequate and covering all workplaces / Escape routes.

4.2 Project Management

EPC CONTRACTOR shall be responsible for Project Management of this job including but not limited to management,

control and direction of surveys, design and engineering, procurement, subcontracting, construction, mechanical

completion, pre-commissioning, commissioning, test run etc. other major activities & functions are as follows:

• Management of and coordination with SUB-CONTRACTORs/ OEM/ VENDORs, Third Party Inspection Agencies;

including those nominated/ assigned by COMPANY;

• Interface Management related to interfaces with all other affected parties but in particular, with other

Contractors executing related projects of COMPANY or its affiliates, other Contractors working at or near the

SITE, operators of existing facilities, local authorities, COMPANY, etc.;

• All deposits and securities required by local authorities.

• All insurances except insurances arranged by COMPANY. Construction All-risk which shall also include transit

insurance and Third-Party liability.

• Lodging and follow-up of insurance claims including claims under insurances arranged by COMPANY.

• All required information handover, including electronic data, as specified by COMPANY.

• Provision of notices as required to all authorities within jurisdiction.

• Arrangements of all required approvals, permits, visas, etc. from the concerned authorities.

OP201670-01-GN-SOW-001 | July 2021 Page 28 of 86

MCC Upgrade Project

EPC Scope of Work

• Procurement management including, floating enquiries, bid evaluation, coordinating with VENDORs, third

party inspection agencies and material management.

• Quality Assurance and Quality Control throughout the engineering, procurement and construction phase.

• Human resource management.

• Deal expeditiously with Third Party claims such that WORK is not affected;

• Provision of security at PROJECT locations.

• Arrangement of Site Office and Site Workshop with accommodation for construction team in the designated

area.

4.3 Mobilization of Key Personnel

Following AGREEMENT, EPC CONTRACTOR shall commence mobilisation of the PROJECT Team, which will continue

on a dedicated basis commensurate with the requirements of the work. The mobilisation of the principal personnel

including the PROJECT Manager and a team required for PROJECT Control, Procurement, QA/QC, HSE, Construction,

Communication, Document Control, etc. shall be undertaken within the first week from AGREEMENT.

During the mobilisation period, EPC CONTRACTOR shall prepare the PROJECT Plan in line with the COMPANY

Quality and HSE requirements, PROJECT Co-ordination Procedures, Execution Plan including proposed

engineering SUB-CONTRACTOR etc. and submit for COMPANY approval. Within two (2) weeks of the effective

date, EPC CONTRACTOR shall submit detailed Mobilization Plan with the CV’s of Key personnel who will be involved

in PROJECT Management, Engineering, Procurement, Construction, Quality Control, HSE and Commissioning activities

for COMPANY approval.

Following the mobilisation of the EPC CONTRACTOR’s team within two weeks from award of AGREEMENT, a Kick-off

meeting shall be held with COMPANY where the EPC CONTRACTOR’s PROJECT team, execution plans and other PROJECT

specific details and requirements shall be

presented.

EPC CONTRACTOR shall provide suitably qualified and experienced personnel for this PROJECT. As a minimum,

the following key personnel shall be assigned to the PROJECT:

• Project Manager

• Engineering Manager

• Construction Manager

• Lead Discipline Engineers

• Project Control Engineer

• QA/QC Engineer

• HSE Engineer

OP201670-01-GN-SOW-001 | July 2021 Page 29 of 86

MCC Upgrade Project

EPC Scope of Work

4.4 Engineering Office Services

EPC CONTRACTOR shall comply with the following mandatory COMPANY requirements:

The detailed engineering shall be carried out from a single location. This shall be the EPC CONTRACTOR’s or SUB-

CONTRACTOR’s Office unless otherwise agreed by COMPANY in writing.

EPC CONTRACTOR’s Project Management Team shall be organised on a task force basis and located at EPC

CONTRACTOR’s or SUB-CONTRACTOR’s Home Office during the detailed design phase, unless otherwise agreed

by COMPANY in writing.

EPC CONTRACTOR shall provide all Office Services that are required for the implementation of the WORK in

conformance with the agreement. The Office Services include, but are not limited to, the following and shall conform

to the requirements set out in the relevant documents and the remainder of the agreement:

• Detailed Engineering.

• Detailed Design.

• Procurement.

• Project Controls.

• Project Reporting.

• Accounting.

• Project Management.

• Information Technology/Systems Management.

• Construction Planning.

• Pre-Commissioning and Commissioning Planning.

• Pre-Commissioning.

• Commissioning.

• Initial Operation and Test Run.

• Drawings, Documents and Manuals.

• Source Inspection and Testing.

• Quality Assurance.

• Quality Control.

• QA/QC Certification.

4.5 Project Control Requirements

The scope of Project Control Services to be performed by EPC CONTRACTOR during EPC phase shall include, but

not limited to Planning, Scheduling and Monitoring Services.

OP201670-01-GN-SOW-001 | July 2021 Page 30 of 86

MCC Upgrade Project

EPC Scope of Work

4.6 Quality Assurance and Quality Control

The quality system shall provide for the planned and systematic control of all quality-related activities performed during

design, procurement, construction, pre-commissioning and COMMISSIONING up to final acceptance.

Implementation of the system shall be in accordance with CONTRACTOR’S Quality Manual and Project-specific

Quality Plan.

4.7 Communication Coordination

EPC CONTRACTOR shall communicate and coordinate with COMPANY authorities in the event of an emergency.

4.8 Interface Coordination

EPC CONTRACTOR shall manage, control and coordinate all interfaces associated with the PROJECT such as with

sister/ neighbouring companies, security agencies, end user, local authorities, other contractors etc.

EPC CONTRACTOR shall ensure that all interfaces between the PROJECT and existing operating facilities, existing

on-going projects are identified well in advance and relevant hazards and any potential risks are assessed and managed

for smooth implementation and operation of the PROJECT facilities.

4.9 Use and Verification of Information

The Scope of work has been explicitly defined under section 4 & 5 of this document. Any additional work, which does

not, falls under EPC scope of work or any additional requirements

specified during execution phase of PROJECT by COMPANY shall be considered as variation and the same shall be

charged on reimbursable basis. Reimbursable basis rates shall be agreed between EPC CONTRACTOR and

COMPANY before start of PROJECT.

OP201670-01-GN-SOW-001 | July 2021 Page 31 of 86

MCC Upgrade Project

EPC Scope of Work

5.0 Engineering & Design Services

5.1 General

The PROJECT shall be designed and engineered in conformity with this document and the requirements set forth in

the Basic Design & Engineering Package Report (Doc No. EGLOBP-00-GN-REP-002), Shell DEP’s, International codes and

standards, recommended practices, safety design codes, included elsewhere.

The requirements of International codes and standards stated in the Shell DEP, Basic Design & Engineering Package