Professional Documents

Culture Documents

Two-Separator System Simulation Using HYSYS

Uploaded by

berhatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two-Separator System Simulation Using HYSYS

Uploaded by

berhatCopyright:

Available Formats

Problem Statement

100 kmol/h of a mixture consisting of the following three components and their respective mole

fractions:

Ethyl Benzene 0.3

Is fed at a temperature of 50 °C into the first of two separators operating at a pressure of 150

kPa absolute and temperature 125 °C. The liquid from the first separator is then fed to the

second separator operating at the same pressure, but a temperature of 130 °C. A fraction 0.3 of

the liquid from the second separator is recycled to the first separator.

Using HYSYS:

1. Calculate the vapour and liquid streams and the heat load if the above mixture is fed into the

first of two separators operating at a given temperatures and pressures. The liquid outlet from

the first separator is fed to the second separator and part of liquid from that is recycled.

Problem Background

Phase transfers in chemical processes occur in virtually all commercial chemical

processes (Felder, 2005). Aspen HYSYS can be used to simulate an environment which the

chemical process can take place by the sensitivity analysis which is done by producing

interactive models. This means concepts of designs can be designed in detail which in effect will

reduce costs and allow improved operating decisions. This is why Aspen HYSYS will be an ideal

software to use to produce in depth knowledge of what systems will behave like.

The system obeys Rault’s and Dalton’s Laws. Where Dalton’s law suggests that the total

vapour pressure of a mixture is equivalent to the sum of the vapour pressures of the

components. In contrast Rault’s law suggests the volatility in the mixture is equivalent to the

vapour pressure of each component in their pure states. At a certain pressure all mixtures will

have a single boiling point The total vapour pressure which is contributed from all the

components will boil at this point. The contribution of each component to the vapour pressure

will have an effect on the quantity of boiling. So we can state that the components which arise in

the vapour phase will be more volatile relative to the less volatile components (Petlyuk, 2004)

Fluid Package

The SRK equation of state is the most accurate equation derived from the Redlich-

Kwong (RK) equation. The RK equation gave a good degree of accuracy however when it

came to multi component equilibriums calculations are often poor. SRK is more

accurate than the van der Waals equation and ideal gas equation making it the most

common method used for vapour-liquid phase equation (Felder, 2005).

RT aα

P= −

V m−b V m ( V m +b )

Computer Simulation using HYSYS (PFD)

In this problem statement the simulation of the process flow was generated by the

HYSYS software to find the problem given. On the opening of HYSYS the simulation basis

windows is opened and an equation of state is required in our experiment the SRK equation of

state was selected as the fluid package. The components added where Benzene, Toluene and

Ethyl Benzene. After everything has been successfully achieved in the Simulation Bases Manager

we are able to enter the Simulation Environment. Here we can construct our system. Using the

‘Workbook’ tool we can define; Material Streams, Compositions and Energy Streams. Inserting

certain information and not ‘over-defining’ the process HYSYS is able to calculate the data

required.

The PFD of the two-separator system can be seen in Figure 1. Continuing the first separator

system and modifying the stream names so we are able to refer to our system systematically. In

this system we add a second separator (V-101), a mixer (MIX-100), recycler (RCY-1) and a

splitter (TEE-100). We utilise the second separator by having a different temperature in this

case 403K. A mixer is used mix the recycle and feed stream which is put through to the first

separator. Using the splitter the ‘liquid 2’ stream can be fragmented where 30% is recycled and

the rest is liquid product. The 30% of which is divided is sent to the recycler and then the

stream is sent to the mixer. In this system the pressure, temperature, molar flow and

compositions of the components in the feed are defined. However the temperatures change at

both separators; V-100 and V-101, 398K and 403K respectively. A change in temperature can be

achieved with an energy stream at both separators. Inputting this data, we can calculate other

Material Streams, Compositions and Energy Streams.

You might also like

- Differential DistillationDocument36 pagesDifferential DistillationShruti100% (1)

- Recycling Effect on Steady State SystemDocument31 pagesRecycling Effect on Steady State SystemJim100% (2)

- Modelling & Simulation of Binary Distillation ColumnDocument53 pagesModelling & Simulation of Binary Distillation Columnpriyankthada100% (6)

- MMT 4Document4 pagesMMT 4api-425256110No ratings yet

- Lecture 14Document17 pagesLecture 14Pranav ShreyasNo ratings yet

- 10390001-2-3 h1748 As Built DocumentsDocument768 pages10390001-2-3 h1748 As Built Documentsbatizap batizapNo ratings yet

- AP PHYSICS B 1988 MC + AnswersDocument17 pagesAP PHYSICS B 1988 MC + AnswersbastardNo ratings yet

- PDFDocument10 pagesPDFAnonymous 20VAruNo ratings yet

- Vapor-Liquid Equilibrium Calculation of Multi-Components System With Estimation of Pre-Heat TemperatureDocument16 pagesVapor-Liquid Equilibrium Calculation of Multi-Components System With Estimation of Pre-Heat TemperatureDimitar PartenovNo ratings yet

- Mass BalanceDocument9 pagesMass Balancerr1819No ratings yet

- Plant DesignDocument9 pagesPlant DesignPashew PirotNo ratings yet

- Process Modeling Using HYSYS With Chemical Industry Focus (TQN)Document5 pagesProcess Modeling Using HYSYS With Chemical Industry Focus (TQN)Cesar Augusto Vanegas MurilloNo ratings yet

- A Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsDocument6 pagesA Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsAbdul SamadNo ratings yet

- Comprehensive Investigation On High Pressure Ldpe Manufacturing - Dynamic Modeling of Compressor, Reactor, SeparatorDocument10 pagesComprehensive Investigation On High Pressure Ldpe Manufacturing - Dynamic Modeling of Compressor, Reactor, Separatorsswoo8245No ratings yet

- Muhammad H. GhaniDocument18 pagesMuhammad H. GhaniKhalid Al-RawiNo ratings yet

- ChemSep Thermodynamic Property Model SelectionDocument6 pagesChemSep Thermodynamic Property Model SelectionJohn WilliamsNo ratings yet

- Uncovering The Realities of Simulation, Part 1 (Of 1)Document11 pagesUncovering The Realities of Simulation, Part 1 (Of 1)bjsatola100% (2)

- Httpcpe Czasopisma Pan Plimagesdatacpewydaniano3201211calculationofvapourliquidliquidequilDocument15 pagesHttpcpe Czasopisma Pan Plimagesdatacpewydaniano3201211calculationofvapourliquidliquidequilLeonardoNo ratings yet

- Fluid Phase EquilibriaDocument19 pagesFluid Phase EquilibriaYli S'cNo ratings yet

- PRO-II Thermodynamic Model SelectionDocument79 pagesPRO-II Thermodynamic Model Selectionchemsac2100% (1)

- Flash Separation Flash DistillationDocument15 pagesFlash Separation Flash DistillationmanishNo ratings yet

- Mass Balance Analysis TechniquesDocument8 pagesMass Balance Analysis TechniquesJef PerezNo ratings yet

- Distillation Lecture Note-2Document20 pagesDistillation Lecture Note-2BasseyNo ratings yet

- A Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDocument22 pagesA Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDaniel MedeirosNo ratings yet

- Theory of DistillationDocument18 pagesTheory of DistillationjaviercdeaeNo ratings yet

- Artigo - Calculating and Applying K-ValuesDocument15 pagesArtigo - Calculating and Applying K-Valuesh_agurtoNo ratings yet

- Midterm CaeDocument17 pagesMidterm CaeDianne AlarconNo ratings yet

- Working Guide to Vapor-Liquid Phase Equilibria CalculationsFrom EverandWorking Guide to Vapor-Liquid Phase Equilibria CalculationsRating: 5 out of 5 stars5/5 (1)

- Isothermal Vapor-Liquid Equilibria For Mixtures of Ethanol, Acetone, and Diisopropyl EtherDocument16 pagesIsothermal Vapor-Liquid Equilibria For Mixtures of Ethanol, Acetone, and Diisopropyl EtherAngie AyusawaNo ratings yet

- Hysys Course 2012Document71 pagesHysys Course 2012Mohamad Ibrahim100% (1)

- Selecting Chemical Property MethodDocument31 pagesSelecting Chemical Property MethodAdilaAnbreenNo ratings yet

- Len ZingDocument5 pagesLen Zingkhali54No ratings yet

- Simulation of Catalytic ProcessesDocument33 pagesSimulation of Catalytic ProcessesAkhi Sofi100% (4)

- Table of Content: Vapour Liquid Equilibrium Lab ReportDocument37 pagesTable of Content: Vapour Liquid Equilibrium Lab ReportLouie Shaolin Lungao0% (1)

- ProblemsDocument4 pagesProblemsmarslanjameelmalikNo ratings yet

- Distillation & BPDocument12 pagesDistillation & BPAmirahKamaruddinNo ratings yet

- Thermodynamic Models & Physical Properties: Property Method SelectionDocument24 pagesThermodynamic Models & Physical Properties: Property Method SelectiondoufethiNo ratings yet

- The Solvent-Solute Interaction in Supercritical Solution at Equilibrium: Modeling and Related Industrial ApplicationsDocument10 pagesThe Solvent-Solute Interaction in Supercritical Solution at Equilibrium: Modeling and Related Industrial ApplicationsImranzo HsnNo ratings yet

- Lab Report 2 (Thermo) - UTSDocument8 pagesLab Report 2 (Thermo) - UTSsiddhant dhimanNo ratings yet

- Report1 Draft2 27-9Document36 pagesReport1 Draft2 27-9Arvind RavichandranNo ratings yet

- Distillation Separation TechniquesDocument12 pagesDistillation Separation TechniquesAbhishek SardaNo ratings yet

- Equilibrium Stage Processes Flash VaporizationDocument30 pagesEquilibrium Stage Processes Flash Vaporizationj0haNN3sNo ratings yet

- Buoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeDocument8 pagesBuoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeSajjad AhmedNo ratings yet

- Model and Optimisation of A Multi-Effect Evaporator of Sugarcane Juice: Energy Consumption and Inversion LossesDocument6 pagesModel and Optimisation of A Multi-Effect Evaporator of Sugarcane Juice: Energy Consumption and Inversion LossesakarczNo ratings yet

- 052 KaraleDocument22 pages052 KaraleyahyaNo ratings yet

- Aspen Homework #1, Due Tuesday, November 1st, 2016Document2 pagesAspen Homework #1, Due Tuesday, November 1st, 2016Michael Taylor WarrenNo ratings yet

- Lab Cheat Sheet, Distill and ArtificalDocument5 pagesLab Cheat Sheet, Distill and ArtificalFarhan M JafrINo ratings yet

- Transcript - Multicomponent Flash Calculations VideoDocument3 pagesTranscript - Multicomponent Flash Calculations VideoChristopher RileyNo ratings yet

- Lecture 3Document12 pagesLecture 3Supriya KadamNo ratings yet

- Distillation TheoryDocument40 pagesDistillation TheoryIrvin HernandezNo ratings yet

- Vapor-Liquid Equl. K - ValueDocument49 pagesVapor-Liquid Equl. K - ValueZivko Dimic100% (1)

- Introduction to Vapor/Liquid Equilibrium ModelsDocument10 pagesIntroduction to Vapor/Liquid Equilibrium ModelsdawitNo ratings yet

- Lab Report 1 PDF FormatDocument14 pagesLab Report 1 PDF FormatSapna RanaNo ratings yet

- Two Phase Flow Safety ValveDocument7 pagesTwo Phase Flow Safety Valversingle81No ratings yet

- Ie9706424 PDFDocument6 pagesIe9706424 PDFIsrael HernándezNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Thermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeFrom EverandThermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeNo ratings yet

- Property 20package 20descriptionsDocument23 pagesProperty 20package 20descriptionsGonnartNo ratings yet

- Heat Exchanger Simulation to Determine Cold Stream Flow RateDocument3 pagesHeat Exchanger Simulation to Determine Cold Stream Flow RateberhatNo ratings yet

- Heat Exchanger Simulation to Determine Cold Stream Flow RateDocument3 pagesHeat Exchanger Simulation to Determine Cold Stream Flow RateberhatNo ratings yet

- Dist 001H C2SplitterDocument12 pagesDist 001H C2SplitterudokasNo ratings yet

- HW - PL - Tce 02Document1 pageHW - PL - Tce 02berhatNo ratings yet

- Separating Vapor and Liquid Mixture Using Distillation ColumnDocument2 pagesSeparating Vapor and Liquid Mixture Using Distillation ColumnberhatNo ratings yet

- Dist 001H C2SplitterDocument12 pagesDist 001H C2SplitterudokasNo ratings yet

- Rx-003h CSTR CistotransDocument13 pagesRx-003h CSTR CistotransudokasNo ratings yet

- HYSYS Course Level 1: November 2018Document53 pagesHYSYS Course Level 1: November 2018berhatNo ratings yet

- HYSYS Simulation of Chemical Process Equipments: September 2015Document8 pagesHYSYS Simulation of Chemical Process Equipments: September 2015Viet ThieuNo ratings yet

- Effect of Deep Breathing on Blood Pressure in Hypertensive PatientsDocument10 pagesEffect of Deep Breathing on Blood Pressure in Hypertensive PatientssendyNo ratings yet

- Tes VCB PG en 031215Document80 pagesTes VCB PG en 031215Anthony BarbachanNo ratings yet

- 1 Soalan 1Document7 pages1 Soalan 1Radziah MohamedNo ratings yet

- Section UpdatedDocument12 pagesSection UpdatedrsduarteNo ratings yet

- Hyundai AcbDocument72 pagesHyundai AcbASRUL HELMINo ratings yet

- Saddle - Analysis by PV-EliteDocument17 pagesSaddle - Analysis by PV-EliteSunilNo ratings yet

- Basic Thermodynamics ConceptsDocument27 pagesBasic Thermodynamics ConceptsLorielle OlivaNo ratings yet

- Iron Horse PM DCDocument6 pagesIron Horse PM DCAmir Hooshang Ghadymi MahaniNo ratings yet

- Electrical Load List - Rev. 00Document7 pagesElectrical Load List - Rev. 00swarupananda mohantyNo ratings yet

- GW 3 Water Potential BSCDocument18 pagesGW 3 Water Potential BSCLiaqat ZaibNo ratings yet

- Non Newtonian FluidsDocument3 pagesNon Newtonian Fluidsvladimir3oNo ratings yet

- Indian Standard: Specification For Electric Ceiling Type Fans and RegulatorsDocument25 pagesIndian Standard: Specification For Electric Ceiling Type Fans and RegulatorsJai KaranNo ratings yet

- SCX-DCX SXM-DXM NT Eng 50hz 60hzDocument28 pagesSCX-DCX SXM-DXM NT Eng 50hz 60hzAndré Marcelo DiasNo ratings yet

- Calculation of Enthalpy ChangesDocument18 pagesCalculation of Enthalpy ChangesYulia T RahkadimaNo ratings yet

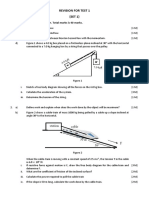

- Revision For Test 1 (SET 1) : Answer All Question Within 1 Hour. Total Marks Is 40 MarksDocument3 pagesRevision For Test 1 (SET 1) : Answer All Question Within 1 Hour. Total Marks Is 40 MarkshadassahhadidNo ratings yet

- CapacitanceDocument71 pagesCapacitanceTharaj ThajNo ratings yet

- ISC Series: Signal ConvertersDocument8 pagesISC Series: Signal ConvertersMohammad HosseinNo ratings yet

- Transformer and Induction Motor Concepts Explained in DetailDocument2 pagesTransformer and Induction Motor Concepts Explained in Detailshiny_vikram6365No ratings yet

- Marsh Funnel Method for Measuring Drilling Mud ViscosityDocument1 pageMarsh Funnel Method for Measuring Drilling Mud Viscositylamosy78No ratings yet

- Insulation Thickness Calculation for Steam PipesDocument29 pagesInsulation Thickness Calculation for Steam Pipesrajachem100% (2)

- Seriola K 3120Document2 pagesSeriola K 3120WWTP SerafoodNo ratings yet

- EPA Test Procedure For EVs-PHEVs-11-14-2017Document2 pagesEPA Test Procedure For EVs-PHEVs-11-14-2017Free LoaderNo ratings yet

- MTS63 4Document1 pageMTS63 4Kevim Guillen RodriguezNo ratings yet

- How Is The Working Principle of Load Shedding in Power Plants, and What Are The Terms of The InstallationDocument6 pagesHow Is The Working Principle of Load Shedding in Power Plants, and What Are The Terms of The InstallationAbdulyunus AmirNo ratings yet

- Ic Op-Amp Ha 17741Document19 pagesIc Op-Amp Ha 17741evhyajahNo ratings yet

- Electric Machine: Induction MotorDocument32 pagesElectric Machine: Induction MotorOkezaki TemoyoNo ratings yet

- Wave PropagationDocument580 pagesWave Propagationtinixx100% (4)