Professional Documents

Culture Documents

Form Finished Product Batch Record Surabaya Draft 3

Form Finished Product Batch Record Surabaya Draft 3

Uploaded by

ARSIYANTIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form Finished Product Batch Record Surabaya Draft 3

Form Finished Product Batch Record Surabaya Draft 3

Uploaded by

ARSIYANTICopyright:

Available Formats

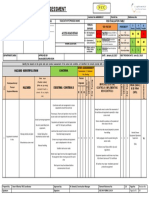

Order No.

001 Finished Product Production Batch Record Page: 1 of 5

S PROCESSING UNIT | SURABAYA

Product Code Product: Wild Borneo Green Batch Lot

GH Mitragyna speciosa GH-001-DS

Name Signature Date

Prepared by Date of Final

QA Officer, Product

Processing Unit, Manufacture

Surabaya 01-Dec-20

Approved by Expiry Date

QA Manager TBA

Head Office

1. PRODUCT DETAILS

Description Finished Product: 5kg units

Form: Milled Powder | 03 screen

Variant: Green

Finished Production 1,000kg (200 x 5kg)

Batch Quantity

Packaging Finished Product Units of 5kg

Storage Conditions Cool, dry and dark

2. FINISHED PRODUCT PRODUCTION BATCH RECORD ISSUANCE

ISSUED BY: Issuer has reviewed the Batch Record to ensure that the copy is complete and

accurate copy of the Master Batch Record and includes records contained within the Production

Batch Tracking Sheet.

QA Officer. S Processing Unit, Surabaya

Print Name: Signature Date

ISSUED TO: Head Office. QA, Manager has reviewed the Batch Record to ensure that the Record

is complete and correct and is now responsible for the Batch Record and coordinating with QA,

Surabaya to ensure the Batch Record is tracked and recorded through to Finished Product Batch

Release and Export.

QA Manager. Head Office

Print Name: Signature Date

3. REFERENCE DOCUMENTS

Standard Operating Procedures (SOPs) 01 through 11.

BATCH NUMBER MANUFACTURING DATE EXPIRY DATE

GH-001-DS–S-0-336-A 1 December 2020 TBA

Order No. 001 Finished Product Production Batch Record Page: 2 of 5

S PROCESSING UNIT | SURABAYA

Product Code Product: Wild Borneo Green Batch Lot

GH Mitragyna speciosa GH-001-DS

Name Signature Date

Prepared by Date of Final

QA Officer, Product

Processing Unit, Manufacture

Surabaya 01-Dec-20

Approved by Expiry Date

QA Manager TBA

Head Office

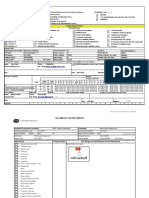

4. RAW MATERIALS

Description Ingredient Milled Leaf Milled Leaf Quantity Verified By/Date

Code Quantity Harvest Lot Staged

Required (kg) Area Codes

Mitragyna MSG 1,010KG

speciosa |

Green

5. PROCESSING EQUIPMENTS

Equipment Description ID No. Machine kg Equipment Performed Verified

Load Size Clean-Down By/Date By/Date

Blending Machine B-01 1,000kg

Filling Machine F-01 100kg

Filling Machine F-02 100kg

Filling Machine F-03 100kg

Filling Machine F-04 100kg

Vacuum Sealer V-01

Vacuum Sealer V-02

Vacuum Sealer V-03

Vacuum Sealer V-04

BATCH NUMBER MANUFACTURING EXPIRY DATE

GH-001-DS–S-0-336-A DATE TBA

1 December 2020

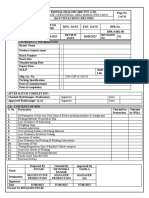

Order No. 001 Finished Product Production Batch Record Page: 3 of 5

S PROCESSING UNIT | SURABAYA

Product Code Product: Wild Borneo Green Batch Lot

GH Mitragyna speciosa GH-001-DS

Name Signature Date

Prepared by Date of Final

QA Officer, Product

Processing Unit, Manufacture

Surabaya 01-Dec-20

Approved by Expiry Date

QA Manager TBA

Head Office

6. PROCESSING CLEARANCE

Step Performed By/Date Verified By/Date

1. Review the Blending (Mixing)

Processing Area and verify that

Cleaning has been performed according

to Facility and Equipment Cleaning

Procedures Policy

2. Verify that the Processing Area does not

contain any items from previous batches

or cleaning activities and that no items

unrelated to the current batch are

present.

3. Processing clearance complete.

QA shall complete the Processing

Clearance Sign and affix it to the

Blending (Mixing) Processing Area

entrance.

7. PRODUCTION PROCEDURE

Processing Step Performed By/Date Verified By/Date

1. Load the Blender with the Batch Lots

noted to be staged in Point (4): Raw

Materials.

2. Blend (mix) the milled Mitragyna

speciosa leaf powder into a

homogeneous batch lot in accordance

with the Blender/Mixer Operations

Procedure

BATCH NUMBER MANUFACTURING EXPIRY DATE

GH-001-DS–S-0-336-A DATE TBA

1 December 2020

Order No. 001 Finished Product Production Batch Record Page: 4 of 5

S PROCESSING UNIT | SURABAYA

Product Code Product: Wild Borneo Green Batch Lot

GH Mitragyna speciosa GH-001-DS

Name Signature Date

Prepared by Date of Final

QA Officer, Product

Processing Unit, Manufacture

Surabaya 01-Dec-20

Approved by Expiry Date

QA Manager TBA

Head Office

8. FINISHED PRODUCT FILLING AND PACKING PROCEDURE

Step Performed By/Date Verified By/Date

1. Transfer the Blended Finished

Production Batch into the Filling

Machines (F01; F02; F03;F04) and fill

and seal in accordance with SOP 09:

Filling and Packing

2. Filling and sealing should be followed

as quickly as possible by labelling.

3. Affix Finished Product Batch Number

(#) labels to the final product packs in

the Clean Room.

4. Finish all product labelling in

accordance with the SOP 10: Packaging

and Labelling

9. STANDARD OPERATING PROCEDURES (SOP) COMPLIANCE

This confirms the supporting Standard Operating Procedures (SOPs) have been followed:

SOP#05; SOP#06; SOP07; SOP08; SOP09; SOP10; SOP11

Name Signature Date

Production

Quality Assurance

10. YIELD CALCULATION

Yield = 100 % x Bulk Milled Product + Rejects + Samples ÷ Weight of Milled Leaf Raw

Materials

= _______ (Specification: XX – YY %)

BATCH NUMBER MANUFACTURING EXPIRY DATE

GH-001-DS–S-0-336-A DATE TBA

1 December 2020

Order No. 001 Finished Product Production Batch Record Page: 5 of 5

S PROCESSING UNIT | SURABAYA

Product Code Product: Wild Borneo Green Batch Lot

GH Mitragyna speciosa GH-001-DS

Name Signature Date Date of Final

Prepared by Product

QA Officer, Manufacture

Processing Unit, 01-Dec-20

Surabaya Expiry Date

Approved by TBA

QA Manager

Head Office

11. POST-PRODUCTION BATCH REVIEW

The complete Post-Production Batch Record has been reviewed for completeness and accuracy.

All pages are complete and all entries conform to Good Production Documentation Practices.

Name Signature Date

Operations Manager

QA Officer

QA Manager

12. FINISHED PRODUCT BATCH RELEASE

The material produced through the execution of this Batch Record is hereby verified and released by

QA according to Product Release Procedure.

The product conforms to Finished Product Specification: Wild Borneo Green (BG)

Certificate of Authenticity (COA) No: ___________ Date: ____________

Name Signature Date

Operations Manager,

Surabaya

Quality Assurance Officer,

Surabaya

Quality Assurance, Manager.

Head Office

BATCH NUMBER MANUFACTURING DATE EXPIRY DATE

GH-001-DS–S-0-336-A 1 December 2020 TBA

You might also like

- SOP For Change OverDocument6 pagesSOP For Change OverJayesh Meharwal100% (3)

- Area Qualification ProtocolDocument19 pagesArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- PVPRDocument47 pagesPVPRBRIJENDRA KUMAR SINGH100% (2)

- ASEAN TMHS GMP Training Chapter 5 Annex 5 Sample Batch Manufacturing RecordDocument8 pagesASEAN TMHS GMP Training Chapter 5 Annex 5 Sample Batch Manufacturing RecordSakinah Muhamad50% (2)

- SOP of Handling of Packaging MaterialDocument3 pagesSOP of Handling of Packaging Materialanoushia alviNo ratings yet

- Batch Manufacturing RecordDocument7 pagesBatch Manufacturing RecordAnu Joshi100% (1)

- High Speed Multi Function GrinderDocument4 pagesHigh Speed Multi Function GrinderOth ManNo ratings yet

- Format For MFRDocument13 pagesFormat For MFRSUNILA DEVI100% (3)

- Batch Release ChecklistDocument4 pagesBatch Release Checklistmarkandey gupta100% (1)

- 023-SOP For Conducting Hold Time StudyDocument3 pages023-SOP For Conducting Hold Time StudyAshok Lenka100% (2)

- Ra DewateringGGDocument8 pagesRa DewateringGGloveson709100% (1)

- Distribution Transformer Manufacturing Process ManualDocument64 pagesDistribution Transformer Manufacturing Process ManualGaurav Sagar100% (2)

- Gibbs Cam Wrong ChoiceDocument4 pagesGibbs Cam Wrong ChoicercaletaNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument4 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Section A Organizational Chart: DirectorDocument10 pagesSection A Organizational Chart: DirectorTrivesh SharmaNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- BMR - Reference - Moisturizing CreamDocument6 pagesBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- BPR TABLET JarDocument16 pagesBPR TABLET JarBIONIAL HEALTHCARENo ratings yet

- 1 SMF 2023Document37 pages1 SMF 2023Tareq Al MahmudNo ratings yet

- Page 1 of 8Document8 pagesPage 1 of 8israel afolayan mayomiNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

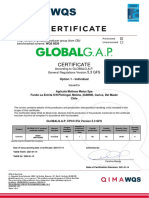

- Wqs9420 Certificado Globalgap 2021Document2 pagesWqs9420 Certificado Globalgap 2021Oscar perezNo ratings yet

- Emiset - BPRDocument25 pagesEmiset - BPRjordan7half7donNo ratings yet

- JV-P13 Production and Process Management (OK)Document24 pagesJV-P13 Production and Process Management (OK)BÍCH NGUYỄNNo ratings yet

- Market Complaint Amlotus 10 2021-01Document2 pagesMarket Complaint Amlotus 10 2021-01opd pharmacyNo ratings yet

- Iq-Oq-Pq - Wet Granulator (GH-1)Document13 pagesIq-Oq-Pq - Wet Granulator (GH-1)Carlos OrtizNo ratings yet

- Check List of Batch RecordDocument2 pagesCheck List of Batch RecordShagorShagor50% (2)

- FLAMC - SOP - 04 Traceability ProcedureDocument3 pagesFLAMC - SOP - 04 Traceability ProcedureVine CelestialNo ratings yet

- BPR Warm AmberDocument10 pagesBPR Warm AmberAnakaya IRANo ratings yet

- Change Control Alaxan FR Capsule 2020Document6 pagesChange Control Alaxan FR Capsule 2020Rio FebriansyahNo ratings yet

- Rework ProcedureDocument2 pagesRework ProcedurekingopsyNo ratings yet

- Batch ReleaseDocument12 pagesBatch Releasemarkandey gupta50% (2)

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair50% (2)

- Vendor Rating Shroud Supplier 2022-23Document12 pagesVendor Rating Shroud Supplier 2022-23Rajhans PressingNo ratings yet

- Global GAP - SAIC - CapsicumDocument1 pageGlobal GAP - SAIC - CapsicummkmikmiNo ratings yet

- Moisture Balance Verification DPCDocument1 pageMoisture Balance Verification DPCRecca DeocampoNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alviNo ratings yet

- Control Plan Ingersol RandDocument2 pagesControl Plan Ingersol Randrgrao85No ratings yet

- Reference Format No.: SOP/QA/001-F01-00Document4 pagesReference Format No.: SOP/QA/001-F01-00Rahul67% (3)

- Storage and Handling of Finished ProductsDocument2 pagesStorage and Handling of Finished Productsreflectprakash3610100% (3)

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- GPE-16 Refractory Concrete Installation Procedure R. 1pdfDocument12 pagesGPE-16 Refractory Concrete Installation Procedure R. 1pdfmaupatas100% (1)

- 18 Rabiprazole Capsule.Document15 pages18 Rabiprazole Capsule.negishivam679No ratings yet

- Qag047 F02 01Document1 pageQag047 F02 01rahul kumarNo ratings yet

- Flow Diagram HSE New FormatDocument3 pagesFlow Diagram HSE New Formatnumantabassum3No ratings yet

- Isir001 Pcba Light Guide LHDocument11 pagesIsir001 Pcba Light Guide LHAnkurNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- Poultry Antigen BMRs Template - AG-H5-dDocument24 pagesPoultry Antigen BMRs Template - AG-H5-dIslam AlshaerNo ratings yet

- Manufacturing Formula: Product: Ctzine SyrupDocument6 pagesManufacturing Formula: Product: Ctzine SyrupMohammed Zubair100% (1)

- Work Instruction For GRC Production: S.No ActivityDocument2 pagesWork Instruction For GRC Production: S.No ActivityEngr Primus ChinonyeNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- Audit Office ACDocument1 pageAudit Office ACWaqasNo ratings yet

- EU Approved Units EIA - MaharashtraDocument7 pagesEU Approved Units EIA - MaharashtragibinkumarNo ratings yet

- Global GAP - SAIC - CucumberDocument1 pageGlobal GAP - SAIC - CucumbermkmikmiNo ratings yet

- UTM - Packaging Process ValidationDocument14 pagesUTM - Packaging Process Validation김소정No ratings yet

- IAC-HC-HCPR23 Product TracebilityDocument4 pagesIAC-HC-HCPR23 Product TracebilityFaisal RehmanNo ratings yet

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- Asml SustainabilityDocument53 pagesAsml SustainabilityAnthony VenerosNo ratings yet

- GIRT7020 Gb-Requirements-For-Platform-Height-PlatformDocument19 pagesGIRT7020 Gb-Requirements-For-Platform-Height-PlatformGabriel BroascaNo ratings yet

- 4350 - 9-06 - Approval Standard For Windstorm Resistant Fenestrations PDFDocument34 pages4350 - 9-06 - Approval Standard For Windstorm Resistant Fenestrations PDFramoruso100% (1)

- Cross Bracing Slotted Strut Channel 41x41x2x2256mm PDFDocument1 pageCross Bracing Slotted Strut Channel 41x41x2x2256mm PDFYaseen PathanNo ratings yet

- Lowrider - September 2018 PDFDocument92 pagesLowrider - September 2018 PDFBig FloresNo ratings yet

- Develop Profitable New Products With Target CostingDocument15 pagesDevelop Profitable New Products With Target CostingRavindra SinghNo ratings yet

- 3.5.1 EngineeringDocument29 pages3.5.1 EngineeringashrafkamilNo ratings yet

- Certification of Engine Usage Monitoring SystemsDocument12 pagesCertification of Engine Usage Monitoring SystemsRamprasad SrinivasanNo ratings yet

- DPT FormatDocument1 pageDPT FormatTanver AliNo ratings yet

- AN-1525 Single Supply Operation of The DAC0800 and DAC0802: Application ReportDocument7 pagesAN-1525 Single Supply Operation of The DAC0800 and DAC0802: Application Reporttidjani86No ratings yet

- Model PIM 08 PDFDocument5 pagesModel PIM 08 PDFRaja Pappireddy100% (1)

- GESITS Business Meeting For AsbumpiDocument18 pagesGESITS Business Meeting For AsbumpiDon Mintapraja100% (1)

- IE 307 Work Systems Analysis & Design Makeup Homework Due Date: 27/12/2021Document4 pagesIE 307 Work Systems Analysis & Design Makeup Homework Due Date: 27/12/2021Dana AltheebNo ratings yet

- Ism ChecklistDocument16 pagesIsm Checklistjonas casimeroNo ratings yet

- Story Biz HandbookDocument408 pagesStory Biz HandbookUjjal BastakotiNo ratings yet

- Vehicle LTK Study For WebDocument25 pagesVehicle LTK Study For Webmkeit123No ratings yet

- ASQ Magazine Issue Six Sigma Forum Volume 15 Issue 3Document28 pagesASQ Magazine Issue Six Sigma Forum Volume 15 Issue 3naacha457No ratings yet

- Sec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanDocument1 pageSec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanSn AhsanNo ratings yet

- Group - 9 - Sec - B - IQDM - Merton - Truck - CompanyDocument8 pagesGroup - 9 - Sec - B - IQDM - Merton - Truck - CompanyMANVENDRA SINGH PGP 2019-21 BatchNo ratings yet

- 2002 Maintenance FocusDocument63 pages2002 Maintenance FocusIonut NaeNo ratings yet

- Construction Today MagazineDocument1 pageConstruction Today MagazineSchofield MediaNo ratings yet

- Literature Review of Online Payment SystemDocument5 pagesLiterature Review of Online Payment Systemrobin75% (4)

- RPG Enterprises Group Strategy: Team Name: Case-A-Novas Members: Keerthan G Abhishek Pai Pradeep KDocument11 pagesRPG Enterprises Group Strategy: Team Name: Case-A-Novas Members: Keerthan G Abhishek Pai Pradeep KSuman MandalNo ratings yet

- Butadiene Unit 101 - ModelDocument5 pagesButadiene Unit 101 - ModelWaleed EL-sheshtawyNo ratings yet

- Etl Innoket 89400691 000801 en K1Document91 pagesEtl Innoket 89400691 000801 en K1Eren akarsuNo ratings yet

- Inspection Procedure: 00-SAIP-10 21 December 2005 Non-Conformance Reports Document Responsibility: Inspection DepartmentDocument8 pagesInspection Procedure: 00-SAIP-10 21 December 2005 Non-Conformance Reports Document Responsibility: Inspection Departmentaamirtec301100% (1)