Professional Documents

Culture Documents

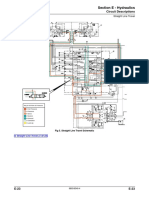

Lampiran 3. Flow Chart PKS PTPN II Pagar Merbau

Uploaded by

Ira SinagaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lampiran 3. Flow Chart PKS PTPN II Pagar Merbau

Uploaded by

Ira SinagaCopyright:

Available Formats

60

Lampiran 3. Flow chart PKS PTPN II Pagar Merbau

FLOW SHEET PABRIK KELAPA SAWIT

PKS.PAGAR MARBAU PTPN - II

S.O.P. H.Crane

Kap. 5 ton TBS

Siklus = 5 Menit/Lori

5

P-221 S.O.P Sterillizer

P-247

P = ( 2,5 s/d 3 ) Kg/Cm² 17 Gas 54

T = ( 120 s/d 130 ) °C

Siklus Merebus = ( 110 s/d 120 ) Menit Uap Bekas 11 18

Kap Timbangan Max 40 Ton Kap. L.Ramp Max

800 Ton TBS

Uap rebus S.O.P Digester

6 12 T = ( 80 s/d 90 ) °C

1 Put = 23 Rpm 19

2 P-290

P-196

13

Kap Lori = 2,5 Ton TBS 7

Keterangan : 3 Bahan bakar

Air kondensat

1. Stasiun Timbangan S.O.P Pressan Boiler

9 8 P = ( 40 s/d 60 ) Bar

2. Loading Ramp 4 S.O.P Thresser Putaran = ± 12 Rpm

3. Transfer Carriage Putaran Drum = ± 23 Rpm

44. Foot tank 14 16

4. Stasiun Sterilizer

5. Hoisting Crane 45. Desanding cyclone 15

38

6. Automatic Feeder 46. Desanding tank 10 37 20

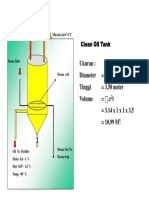

7. Stripper 47. Sludge separator 39 S.O.P Crude Oil Tank

48. Reclaimed tank T = ( 95 s/d 100 ) °C

21 22

8. Under Tresher Conveyor

9. Empty Bunch Conveyor 49. Oil tank 25 28 29

10. Truk Tandan Kosong 50. Oil Purifier

P-519

11. Fruit Elevator 51. Vacum dryer

12. Fruit Distributing Conveyor 52. Transfer tank 24 55

13. Digester 53. Storage tank 30 31

26

14. Screw Press 54. Boiler S.O.P Ripplle Mill

Cracked Effeck

55. Turbin Minimal = 95 % 32

15. Cake Breaker Conveyor

16. Defericarper 56. Back Pressure Vessel ( BPV ) 56

P-520

34 23

17. Fiber Cyclon Fan

S.O.P Kernel silo

18. Separating Coloum 27 33 T3 T1,T2,T3 = ( 40 ,60, 80 ) °C

19. Fiber Cyclon K.Air Max = 7 %

K.Kot Max = 6 % 36

20. Polishing Drum T2 Bahan

Bakar

21. Wet nut elevator Boiler

Fan T1 Distribusi steam ke

22. Nut Silo Drier

setiap stasiun :

23. Dry nut conveyor S.O.P Bulking Silo 1. Sterilizer

24. Dry nut elevator T = ( 40 s/d 60 ) °C

K.Air Max = 7 % 2. Pressan

25. Nut Grading Screen K.Kot Max = 6 % 3. Klarifikasi

Over Flow Ke 4. Kernel Plant

26. Ripple Mill

Reclaimed Tank 5. Utilities

27.Cracked mixture Conveyor

40 S.O.P Vertical Continius S.O.P Oil Tank

28. Dust cyclon blower - I Tank ( VCT )

T = ( 90 s/d 95 ) °C

T = ( 80 s/d 90 ) °C

ALB = ( 3 s/d 3,5 ) % S.O.P Vacum Drier

29. Dust cyclon- I K.Air Max = 0.6 % 35 51 K.Air Max = 0.15 %

K.Kot Max = 0,030 % K.Kot Max = 0,015 %

S.O.P Sludge Tank

30. Dust cyclon blower - II T = ( 90 s/d 95 ) °C 41 Fan

Kadar Minyak Max = 9 %

31. Dust cyclon- II 45 42 49

32. Air Lock 46 Steam

Inlet Steam

33. Clay Bath Air Inlet

34. Kernel silo drier Panas 52

43

35. Bulking

36. Shell bin Kondensat S.O.P Oil Purifier

Mobil Truck Kernel

37. Crude oil gutter 47

K.Air Max = 0.35 %

K.Kot Max = 0,015 %

38. Vibro separator

39. Crude Oil Tank 48 50 S.O.P Storage Tank

44 T = ( 50 s/d 55 ) °C

40. Balance tank ALB Max = 4,5 %

S.O.P Sludge Separator K.Air Max = 0,35 %

53

41. Continous tank Losis Minyak/Cth Max = 0.60 % K.Kot Max = 0,018 %

Blow Down to Sludge Pit Foot Tank

42. Sludge tank Drap Sentifusi ke Sludge Pit Mobil Tanki CPO

43. Brush strainer Drap Sentrifusi ke Sludge Pit Design by Mechanical Enggeneering

PTP NUSANTARA - II ( PERSERO )

PKS PAGAR MARBAU

Tahun 2009

60

Lampiran 3. Flow chart PKS PTPN II Pagar Merbau

You might also like

- Prarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunDocument49 pagesPrarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunGhina Fatikah SalimNo ratings yet

- Rahmanda Luthfia - Tugas 1Document9 pagesRahmanda Luthfia - Tugas 1Rahmanda LuthfiaNo ratings yet

- Tugas Strategi Rencana ProsesDocument3 pagesTugas Strategi Rencana ProsesgeafitriaNo ratings yet

- Pabrik Baturaja III PT. Semen Baturaja (Persero) TBKDocument3 pagesPabrik Baturaja III PT. Semen Baturaja (Persero) TBKIzzy Rss Outsiders100% (1)

- Kelompok 4 TRK 2Document5 pagesKelompok 4 TRK 2Katharina AjengNo ratings yet

- Neraca Massa Dan Neraca Panas Ball Mill (Revisi FIXED)Document18 pagesNeraca Massa Dan Neraca Panas Ball Mill (Revisi FIXED)astrianyNo ratings yet

- Standard Sizes of Pipes (After Changing)Document45 pagesStandard Sizes of Pipes (After Changing)Muhammad AliNo ratings yet

- Chapter 11 Example 11.2 and 11.3: Multiple Units without and with ReactionsDocument27 pagesChapter 11 Example 11.2 and 11.3: Multiple Units without and with ReactionsNoraiz Fozan KambohNo ratings yet

- Something Related To Catalysts.Document2 pagesSomething Related To Catalysts.Deepro BhattacharyaNo ratings yet

- Lampiran PerhitunganDocument15 pagesLampiran PerhitunganAchmadJa'farShodiqShahabNo ratings yet

- Tabel Antoine 1Document3 pagesTabel Antoine 1atikaindrnNo ratings yet

- MutuDocument5 pagesMutudhitadhitNo ratings yet

- Data Bps Asam AkrilatDocument8 pagesData Bps Asam AkrilatAdePuspitaSariNo ratings yet

- PFD Pemilihan Reaktor Pada Proses Mixed Acid Route Di Pabrik Pupuk NPKDocument1 pagePFD Pemilihan Reaktor Pada Proses Mixed Acid Route Di Pabrik Pupuk NPKAghin AsrofiNo ratings yet

- Hargreaves ProcessDocument7 pagesHargreaves ProcessMuhammad BilalNo ratings yet

- Tugas 1 Perancangan Alat ProsesDocument6 pagesTugas 1 Perancangan Alat ProsesAldo HoseaNo ratings yet

- Satuan SiDocument40 pagesSatuan Siaisyah sri lestari100% (1)

- AfdhalDocument11 pagesAfdhalRiky Mario YuluciNo ratings yet

- MIXER DESIGN FOR BIODIESEL AND TOCOPHEROL MIXTUREDocument13 pagesMIXER DESIGN FOR BIODIESEL AND TOCOPHEROL MIXTUREkurniawanNo ratings yet

- 1.3 Boiler OperationDocument23 pages1.3 Boiler OperationLydia RupidaraNo ratings yet

- Presentasi TRK Topik 3 - Kelompok 8Document19 pagesPresentasi TRK Topik 3 - Kelompok 8Martha IvanaNo ratings yet

- DestilasiDocument11 pagesDestilasiDwiky DarmawanNo ratings yet

- Data BPS NitroselulosaDocument36 pagesData BPS Nitroselulosawilly dwinovNo ratings yet

- Impor Dimethyl Ether (DME)Document3 pagesImpor Dimethyl Ether (DME)Savannah Yonita CNo ratings yet

- Reaktor Trickle BedDocument8 pagesReaktor Trickle BedAgaNo ratings yet

- Ocw Chapter 4Document48 pagesOcw Chapter 4Agam HanasichulaNo ratings yet

- Faktor Konversi Satuan Ke Si: A. PanjangDocument1 pageFaktor Konversi Satuan Ke Si: A. PanjangFahmiNo ratings yet

- Perhitungan Neraca Panas Di Clinker CoolerDocument3 pagesPerhitungan Neraca Panas Di Clinker CoolerPutri Hanifah SNo ratings yet

- Block Diagram Alir Proses Produksi Asam Nitrat: Filter Compresor UdaraDocument1 pageBlock Diagram Alir Proses Produksi Asam Nitrat: Filter Compresor UdaraevinNo ratings yet

- AmineeeeeeeeeeeeeeeeeeeeDocument50 pagesAmineeeeeeeeeeeeeeeeeeeeAchmadJa'farShodiqShahabNo ratings yet

- GasLiquid Reactions - First Order - Hatta NumberDocument4 pagesGasLiquid Reactions - First Order - Hatta NumberShivahari GopalakrishnanNo ratings yet

- Kopp Rules Heat Capacity Solid PDFDocument134 pagesKopp Rules Heat Capacity Solid PDFMouad ArradNo ratings yet

- Hitungan Neraca MassaDocument19 pagesHitungan Neraca MassaAchmadJa'farShodiqShahabNo ratings yet

- Parameter Menghitung Temperatur Kalorik (Caloric Temperatur, TDocument4 pagesParameter Menghitung Temperatur Kalorik (Caloric Temperatur, TRiski Maulana100% (1)

- Tugas Terjemah Kern 98-100Document3 pagesTugas Terjemah Kern 98-100Diiah 'bubull' LestariiNo ratings yet

- Rustic Wood Toy Manufacturing Cash Flow AnalysisDocument2 pagesRustic Wood Toy Manufacturing Cash Flow AnalysispratitatriasalinNo ratings yet

- Soal Dan Pembahasan Termodinamika Teknik PDFDocument32 pagesSoal Dan Pembahasan Termodinamika Teknik PDFTri WidayatnoNo ratings yet

- Optimally Economic Design of Flare Systems PDFDocument5 pagesOptimally Economic Design of Flare Systems PDFMedaculoNo ratings yet

- Thermo1 AssignentDocument6 pagesThermo1 AssignentmasmashitahNo ratings yet

- MATLAB ProjectsDocument2 pagesMATLAB ProjectsNidhi ChauhanNo ratings yet

- 03Document1 page03Pipit Aditia Listiyani100% (1)

- Perrys Handbook ViscosityDocument3 pagesPerrys Handbook ViscosityAlexis Cieza Bailon0% (2)

- Teknik Penambangan BatubaraDocument21 pagesTeknik Penambangan BatubaraInda LamersNo ratings yet

- Solid Gas FluidizationDocument9 pagesSolid Gas FluidizationHaris PratamaNo ratings yet

- Flash DrumDocument14 pagesFlash DrumFajar AgumNo ratings yet

- Analisa Ekonomi (Ekotek, Teknik Kimia)Document13 pagesAnalisa Ekonomi (Ekotek, Teknik Kimia)Beta PertiwiNo ratings yet

- Flowsheet Sistem Utilitas Water Treatment KEL 1Document1 pageFlowsheet Sistem Utilitas Water Treatment KEL 1Febri5awalsyahNo ratings yet

- Tangki DegummingDocument6 pagesTangki DegummingApriadiNo ratings yet

- 4 2020 Pap Menara DistilasiDocument48 pages4 2020 Pap Menara DistilasiAlwan Al AzharNo ratings yet

- Pengolahan Limbah Cair Tapioka Dengan TeknologiDocument9 pagesPengolahan Limbah Cair Tapioka Dengan TeknologiSudaryanto WidarNo ratings yet

- Tugas Kelas A Termodinamika Industri KimiaDocument1 pageTugas Kelas A Termodinamika Industri KimiaayatbimaNo ratings yet

- Lamp. B - Neraca PanasDocument38 pagesLamp. B - Neraca PanasAhmad Herman100% (1)

- EKOTEKDocument6 pagesEKOTEKDHILA AYUNINGTYASNo ratings yet

- Data Konstanta AntoineDocument32 pagesData Konstanta AntoineSurya NingrumNo ratings yet

- Single Line Diagam Area Tembilahan: PLTD Parit 4Document1 pageSingle Line Diagam Area Tembilahan: PLTD Parit 4Joni EfwanNo ratings yet

- D222 Hydraulic Schematic 4072461R3Document3 pagesD222 Hydraulic Schematic 4072461R3Rômulo MagalhãesNo ratings yet

- Devoir 1Document3 pagesDevoir 1aminata.1dNo ratings yet

- Section - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas LimitedDocument1 pageSection - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas Limitedsumit kumarNo ratings yet

- Circuit Descriptions: Section E - HydraulicsDocument1 pageCircuit Descriptions: Section E - HydraulicsNikNo ratings yet

- 1990 APA PDS Supplement 3 Design and Fabrication of Plywood StressedDocument28 pages1990 APA PDS Supplement 3 Design and Fabrication of Plywood StressedVinícius Da Cunha FerreiraNo ratings yet

- Presentation Nanomaterial USU 2021 - Karna WijayaDocument119 pagesPresentation Nanomaterial USU 2021 - Karna WijayaIra SinagaNo ratings yet

- Analisa Melalui Pengendapan (Gravimetri)Document14 pagesAnalisa Melalui Pengendapan (Gravimetri)Ira SinagaNo ratings yet

- 985 118246 1 10 20190726Document9 pages985 118246 1 10 20190726Muhamad Julian PriansyahNo ratings yet

- Extraction of Silica From Bengkulu Beach Sand Using Alkali Fusion MethodDocument5 pagesExtraction of Silica From Bengkulu Beach Sand Using Alkali Fusion MethodEcikkNo ratings yet

- Production of Biodiesel From Fish Waste and Characterization of Produced BiodieselDocument7 pagesProduction of Biodiesel From Fish Waste and Characterization of Produced BiodieselGagan BNo ratings yet

- The Photochemical Reaction of Tris (Ethylenediamine) Cobalt (III) Ion With FerrocyanideDocument6 pagesThe Photochemical Reaction of Tris (Ethylenediamine) Cobalt (III) Ion With FerrocyanideIra SinagaNo ratings yet

- South African Journal of Chemical Engineering: L.B. Moyo, S.E. Iyuke, R.F. Muvhiiwa, G.S. Simate, N. HlabanganaDocument7 pagesSouth African Journal of Chemical Engineering: L.B. Moyo, S.E. Iyuke, R.F. Muvhiiwa, G.S. Simate, N. HlabanganaIra SinagaNo ratings yet

- Waste Can Alum Synthesis for Water TreatmentDocument6 pagesWaste Can Alum Synthesis for Water TreatmentIra SinagaNo ratings yet

- Addition of Olein From Milk Fat Positively Affects The Firmness of ButterDocument8 pagesAddition of Olein From Milk Fat Positively Affects The Firmness of ButterIra SinagaNo ratings yet

- !!! Data Blanding FFA 24.02.19...Document3 pages!!! Data Blanding FFA 24.02.19...Ira SinagaNo ratings yet

- Analisis Asam Lemak BebasDocument1 pageAnalisis Asam Lemak BebasIra SinagaNo ratings yet

- Ansi C29 6Document16 pagesAnsi C29 6AlbertoNo ratings yet

- Mechanical & Electrical Reasoning Study GuideDocument24 pagesMechanical & Electrical Reasoning Study GuideAbdu AbdoulayeNo ratings yet

- ReportDocument54 pagesReportVinayKumar100% (1)

- SOP For Diesel Generator Set (DG)Document2 pagesSOP For Diesel Generator Set (DG)PADCL100% (4)

- SRU Reaction Furnace Waste Heat Boiler Tube Failure Causing Unscheduled Shutdown (Rev. 1) (FINAL)Document11 pagesSRU Reaction Furnace Waste Heat Boiler Tube Failure Causing Unscheduled Shutdown (Rev. 1) (FINAL)MubeenNo ratings yet

- AirbusDocument52 pagesAirbusKyriakos TousNo ratings yet

- Work Centre M15 Service ManualDocument380 pagesWork Centre M15 Service ManualMarcos GarciaNo ratings yet

- SESB Certified ContractorsDocument10 pagesSESB Certified Contractorsarvind raj100% (1)

- Study Simple Steam Engine ModelDocument3 pagesStudy Simple Steam Engine ModelPradyot DeoliaNo ratings yet

- De Longhi Heating Radiators Provide Quality, Practicality and Environmental BenefitsDocument16 pagesDe Longhi Heating Radiators Provide Quality, Practicality and Environmental BenefitsVladimirNo ratings yet

- cs830 A4rdDocument10 pagescs830 A4rdprimero marnezNo ratings yet

- Place, Space, and Theories of Economic ValueDocument19 pagesPlace, Space, and Theories of Economic ValueMatt TenneyNo ratings yet

- ChE 122 LE1 NotesDocument4 pagesChE 122 LE1 Notesgoogley71No ratings yet

- CISP Harar M & E Framework For RRLH Through IFSA Fedis & GGDocument79 pagesCISP Harar M & E Framework For RRLH Through IFSA Fedis & GGaberra100% (1)

- Hamworthy Topping Up GeneratorDocument2 pagesHamworthy Topping Up GeneratorHARISHNo ratings yet

- Nobels Ab1 Switcher PDFDocument1 pageNobels Ab1 Switcher PDFChristian BrasselNo ratings yet

- FTJ November 2010Document6 pagesFTJ November 2010Sharan Kumar GNo ratings yet

- Arduino Control Relay - Tutorial #5Document6 pagesArduino Control Relay - Tutorial #5Denaiya Watton LeehNo ratings yet

- President SpeechDocument14 pagesPresident SpeechManish JaiswalNo ratings yet

- E C S PDFDocument412 pagesE C S PDFRájDèép TrìpâţhíNo ratings yet

- SFP Catalog 1 Metal BellowsDocument92 pagesSFP Catalog 1 Metal BellowshalongvanNo ratings yet

- Instruction Manual for Wine Chiller Models EWC801 and EWC1201Document16 pagesInstruction Manual for Wine Chiller Models EWC801 and EWC1201josue1965No ratings yet

- Chapter 8 Internal Forced ConvectionDocument26 pagesChapter 8 Internal Forced ConvectionDazuky UkyNo ratings yet

- Manual Book Mov Auma PDFDocument44 pagesManual Book Mov Auma PDFDidi Gunawan100% (1)

- Induced Polarization Survey TechniquesDocument7 pagesInduced Polarization Survey TechniquesJavedkhanaNo ratings yet

- SW-F2.1 500 Service ManualDocument15 pagesSW-F2.1 500 Service ManualEzequiel CopettiNo ratings yet

- NCERT Physics Class 6-10 CompilationDocument119 pagesNCERT Physics Class 6-10 Compilationvishal tiwari100% (1)

- Presentation - Fire Protection Regulations - EnGDocument19 pagesPresentation - Fire Protection Regulations - EnGoctyabrovaNo ratings yet

- IEC Earthing Types TN, TT, ITDocument5 pagesIEC Earthing Types TN, TT, ITNavneet Singh100% (1)