Professional Documents

Culture Documents

059 Laporan Test Durability HDP AIRLAID Final

Uploaded by

Bersama Membangun BangsaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

059 Laporan Test Durability HDP AIRLAID Final

Uploaded by

Bersama Membangun BangsaCopyright:

Available Formats

PT URECEL INDONESIA

TANGERANG - INDONESIA

Jl. Industri Raya Kav.2 Kp. Cibadak KM. 21

Bojong Cikupa Kab. Tangerang Banten 15710

No. : 059/URC.RND/XI/2020

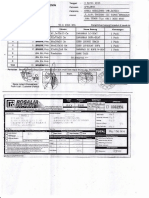

TEST REPORT

I. Test conducted

ASTM D 3574 Tests I3: Dynamic Fatigue Test by Constant Force Pounding (Durability Test)

for HDP AIRLAID Sample

II. Sample details

a. HDP AIRLAID 1800 GSM 80 MM c. UNF 24 YELLOW

b. QDF FIRM

III. Date

02-Nov-20

IV. Procedure

Dimensions : 380 x 380 mm

Compression Force : 750 N similar person's weight of 75 kg

Cycles : 80000 cycles similar with 3 years duration

Process test : Pound repeatedly with constant force using Durability Machine

V. Test Result

Loss of Thickness

Nr Identification L (mm) W (mm) T0 (mm) T1 (mm) Remarks

(%)

1 HDP 380 380 82 64 22

2 HDP + QDF Firm 2 cm 380 380 102.01 87.96 13.8 HDP Diatas

3 HDP + QDF Firm 4 cm 380 380 120.53 114.31 5.2 HDP Diatas

4 HDP + QDF Firm 7 cm 380 380 152.87 147.9 3.3 HDP Diatas

5 HDP + UNF 24 Y 2 cm 380 380 106.68 94.8 11.1 HDP Diatas

6 HDP + UNF 24 Y 4 cm 380 380 124.47 114.67 7.9 HDP Diatas

7 HDP + UNF 24 Y 7 cm 380 380 154.97 147.47 4.8 HDP Diatas

VI. Conclusion

a. Sample HDP AIRLAID dengan ketebalan kurang lebih 80 mm, setelah proses durability ketebalan yang hilang

kurang lebih 22%

b. Sample HDP AIRLAID dengan ketebalan kurang lebih 8 cm dan yang ditambahkan QDF Foam 2 cm, setelah

proses durability ketebalan yang hilang kurang lebih 13.8%

Made by, Checked by, Approved by,

REYNALDI IRWAN AGUSTA

RND Staff RND Manager

Attachment

Photo product

You might also like

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationBetto ToerNo ratings yet

- Extreme Surveillance & It SolutionsDocument2 pagesExtreme Surveillance & It SolutionsPrAsad ThanageNo ratings yet

- A1 Reco Spares 100217Document3 pagesA1 Reco Spares 100217Eidrish ShaikhNo ratings yet

- GWEIKE Quotation of 4020CRDocument18 pagesGWEIKE Quotation of 4020CRFY BaylonNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Masterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutDocument5 pagesMasterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutMuhammad Fadhil ImansyahNo ratings yet

- Continuity/Insulation Resistance Test FormDocument1 pageContinuity/Insulation Resistance Test FormVictor BiacoloNo ratings yet

- Toggle-Injection-Moulding-Machines 2Document16 pagesToggle-Injection-Moulding-Machines 2Vimal AathithanNo ratings yet

- IMDAAD Quote 3231 IMD-AUH Data Quote KUDocument2 pagesIMDAAD Quote 3231 IMD-AUH Data Quote KUविजय भाशकारNo ratings yet

- 120A-3015 Working Table Type CNC Plasma Cutting MachineDocument15 pages120A-3015 Working Table Type CNC Plasma Cutting MachineLardys RodrìguezNo ratings yet

- TOKICO - Presentation of Fuel DispenserDocument45 pagesTOKICO - Presentation of Fuel DispenserbangladetNo ratings yet

- JIGUO Quotation of TMY-1060H Automatic Hot Foil Stamping Machine-5Document24 pagesJIGUO Quotation of TMY-1060H Automatic Hot Foil Stamping Machine-5MuhammadIsmail Engr.No ratings yet

- KR2PG2402 enDocument1 pageKR2PG2402 enCustomer ServiceNo ratings yet

- Erection Manual For Granulator 10.6.16 PDFDocument100 pagesErection Manual For Granulator 10.6.16 PDFdang2172014No ratings yet

- Catalog Icanclave Serie DDocument8 pagesCatalog Icanclave Serie DSung Soon ChangNo ratings yet

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- KR3PG3804 enDocument1 pageKR3PG3804 enCustomer ServiceNo ratings yet

- GT-KB48 Slip Resistance TesterDocument3 pagesGT-KB48 Slip Resistance Testernishad saifiNo ratings yet

- Top Hammer Drill - Productos - Furukawa Rock DrillDocument1 pageTop Hammer Drill - Productos - Furukawa Rock DrillMiguel FiallosNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- Labelmanager 420P: High-Performance Portable Label Maker With PC or Mac ConnectionDocument2 pagesLabelmanager 420P: High-Performance Portable Label Maker With PC or Mac ConnectionBiswajeet DasNo ratings yet

- LG Digital X-Ray Detector A-Si DXD17-14-10HQ701G - Datasheet v2.0Document2 pagesLG Digital X-Ray Detector A-Si DXD17-14-10HQ701G - Datasheet v2.0bassem besbesNo ratings yet

- Sales Quote: Bpak Frans TurisnoDocument2 pagesSales Quote: Bpak Frans TurisnoRonald GunawanNo ratings yet

- Revise Audio CCTV Camera OfferDocument1 pageRevise Audio CCTV Camera OfferashokNo ratings yet

- Integrapac™ Ultrafiltration Skid: Product Data SheetDocument4 pagesIntegrapac™ Ultrafiltration Skid: Product Data SheetMOhamedNo ratings yet

- Productivity Improvement High Pressure Die Casting: Presentation byDocument26 pagesProductivity Improvement High Pressure Die Casting: Presentation byNIMISHNo ratings yet

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 pagesThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeNo ratings yet

- Mip Get View BoqdripsystemDocument6 pagesMip Get View BoqdripsystemGonamakalaPalli XavierNo ratings yet

- Sales Quote: Bpak Frans TurisnoDocument2 pagesSales Quote: Bpak Frans TurisnoRonald GunawanNo ratings yet

- Test 123Document11 pagesTest 123herlinaNo ratings yet

- CAT Primary PulveriserDocument2 pagesCAT Primary PulverisertwrwtrtrNo ratings yet

- Drywall Screw, Bugle Head Cross Recessed Drive, Drill Point, Black PhosphateDocument2 pagesDrywall Screw, Bugle Head Cross Recessed Drive, Drill Point, Black PhosphateMIGUELONo ratings yet

- Drywall ScrewDocument2 pagesDrywall ScrewMIGUELONo ratings yet

- 1 - 32T C LS DZ32C LS Operating Manual 2019.5Document49 pages1 - 32T C LS DZ32C LS Operating Manual 2019.5Ashley Apil100% (1)

- Практична 2Document2 pagesПрактична 2Іван РоднойNo ratings yet

- 330 Square Bottom Paper Bag Making Machine and Handle Machine PDFDocument22 pages330 Square Bottom Paper Bag Making Machine and Handle Machine PDFGrecia Valeria Ugarte ArchondoNo ratings yet

- SDLG E660Fl Quotation: Attn: Mrs. FransiskaDocument2 pagesSDLG E660Fl Quotation: Attn: Mrs. FransiskaAnggaNo ratings yet

- Fully Enclosed Exchange Table Fiber Laser Cutting MachineDocument3 pagesFully Enclosed Exchange Table Fiber Laser Cutting MachinevfqhwqmgsdNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Gandhi Automation - Auto TypeDocument17 pagesGandhi Automation - Auto Typec prakashNo ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- X-Ray Pipeline CrawlerDocument4 pagesX-Ray Pipeline CrawlerBala SingamNo ratings yet

- Mip Get View BoqdripsystemDocument6 pagesMip Get View BoqdripsystemGonamakalaPalli XavierNo ratings yet

- Jotun ARAMCO SystemsDocument6 pagesJotun ARAMCO SystemsMuneer ShaNo ratings yet

- KR2DB2403 enDocument1 pageKR2DB2403 enCustomer ServiceNo ratings yet

- Mip Get View BoqdripsystemDocument6 pagesMip Get View BoqdripsystemRama Krishna ReddyNo ratings yet

- Metrix Digital Metal Hardness Tester PDFDocument18 pagesMetrix Digital Metal Hardness Tester PDFAJITHNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Mip Get View BoqdripsystemDocument6 pagesMip Get View BoqdripsystemGonamakalaPalli XavierNo ratings yet

- Quotation / Proforma InvoiceDocument1 pageQuotation / Proforma InvoiceSubham DasNo ratings yet

- Spek Dan Brosur Mesin CNC Router Automatik Tool ChangeDocument2 pagesSpek Dan Brosur Mesin CNC Router Automatik Tool Changedarlinginthe thefranxxNo ratings yet

- Rev5 RAB CCTV GMB1Document1 pageRev5 RAB CCTV GMB1CV. PEMUDA MERDEKANo ratings yet

- D5 N8-121727C8 - 80% Wool + 20% Nylon FloatDocument1 pageD5 N8-121727C8 - 80% Wool + 20% Nylon FloatsdhrtwrNo ratings yet

- Sales Quote: Bpak Frans TurisnoDocument2 pagesSales Quote: Bpak Frans TurisnoRonald GunawanNo ratings yet

- TDS TREVA Bioplastic TR6041 NaturalDocument2 pagesTDS TREVA Bioplastic TR6041 NaturalHenry HungNo ratings yet

- Leisuwash Model ListDocument8 pagesLeisuwash Model ListŞansal DikmenerNo ratings yet

- MEITRACK T355 User Guide V1.0-20141222Document13 pagesMEITRACK T355 User Guide V1.0-20141222arturo0diaz_1No ratings yet

- PANDA Instruction ManualDocument16 pagesPANDA Instruction Manualkiru.implantsNo ratings yet

- Getting Started with Tiva ARM Cortex M4 Microcontrollers: A Lab Manual for Tiva LaunchPad Evaluation KitFrom EverandGetting Started with Tiva ARM Cortex M4 Microcontrollers: A Lab Manual for Tiva LaunchPad Evaluation KitNo ratings yet

- Apb - Nov 06,2013 #2038Document1 pageApb - Nov 06,2013 #2038Bersama Membangun BangsaNo ratings yet

- Apb - Dec 26,2013 #2142Document1 pageApb - Dec 26,2013 #2142Bersama Membangun BangsaNo ratings yet

- Apb - April 08, 2013 #SJDocument1 pageApb - April 08, 2013 #SJBersama Membangun BangsaNo ratings yet

- Ank April 02,2013 #SJ & PLDocument2 pagesAnk April 02,2013 #SJ & PLBersama Membangun BangsaNo ratings yet

- Test Report - QDF FR - BS 5852 Part 1 1979 Cig (2018)Document4 pagesTest Report - QDF FR - BS 5852 Part 1 1979 Cig (2018)Bersama Membangun BangsaNo ratings yet

- Test Report: Tested Sample Standard ResultDocument3 pagesTest Report: Tested Sample Standard ResultBersama Membangun BangsaNo ratings yet

- Govt. Pilot High School Rawalakot AJK Pre-Board ExamDocument2 pagesGovt. Pilot High School Rawalakot AJK Pre-Board ExamAbdul qadeerNo ratings yet

- The Set School Computer Class Vii Chapter:Cyber SecurityDocument9 pagesThe Set School Computer Class Vii Chapter:Cyber SecurityAisha Anwar100% (1)

- The 108 Star Bearers in The Suikoden TierkiesDocument51 pagesThe 108 Star Bearers in The Suikoden TierkiesEkky Maretha PrathiwiNo ratings yet

- IBM x3850X5 x3950X5 HX5 OverviewDocument118 pagesIBM x3850X5 x3950X5 HX5 OverviewTruong Anh VuNo ratings yet

- DESIDOC Journal of Library & Information Technology, Vol. 31, No. 2, March 2011, Pp. 116-120 © 2011, DESIDOCDocument5 pagesDESIDOC Journal of Library & Information Technology, Vol. 31, No. 2, March 2011, Pp. 116-120 © 2011, DESIDOCanon_69363824No ratings yet

- A Watch by Peter Henlein in LondonDocument13 pagesA Watch by Peter Henlein in LondonbahchovanskiNo ratings yet

- Career Planner WorkbookDocument26 pagesCareer Planner WorkbookMy NguyễnNo ratings yet

- American VitruviusDocument312 pagesAmerican VitruviusEugen IliesiuNo ratings yet

- AS Integration I AssessmentDocument2 pagesAS Integration I AssessmentAbd Elrhman MohamedNo ratings yet

- Formal Essay ExamplesDocument2 pagesFormal Essay Examplesfz6etcq7No ratings yet

- The Application of Scrambled SentencesDocument58 pagesThe Application of Scrambled SentencesDexhaNo ratings yet

- DSP-Lab REC-553Document66 pagesDSP-Lab REC-553PraveenNo ratings yet

- GN Divisions - P Codes: LegendDocument1 pageGN Divisions - P Codes: LegendRavindra KumaraNo ratings yet

- Statistics and ProbabilityDocument20 pagesStatistics and ProbabilityAngel Lorayne SalvacionNo ratings yet

- Dynamic Operation of Chemical Reactors Friend or FoeDocument9 pagesDynamic Operation of Chemical Reactors Friend or FoeSteve Wan100% (1)

- Auntie Annes Allergen Information 2023Document1 pageAuntie Annes Allergen Information 2023BHAVESHNo ratings yet

- Chanelle Assignment 2Document16 pagesChanelle Assignment 2api-535296602No ratings yet

- KNPCC-13 Nit KNPCC 13Document10 pagesKNPCC-13 Nit KNPCC 13Shubh ShuklaNo ratings yet

- Third Year Sixth Semester CS6601 Distributed System 2 Mark With AnswerDocument25 pagesThird Year Sixth Semester CS6601 Distributed System 2 Mark With AnswerPRIYA RAJI86% (7)

- Super Desk Master ManualDocument108 pagesSuper Desk Master Manuals3m3staNo ratings yet

- Cpo 10Document16 pagesCpo 10Vijay SharmaNo ratings yet

- Ic 01Document3 pagesIc 01gsm.nkl6049No ratings yet

- Acid Bases and SaltsDocument6 pagesAcid Bases and Saltsasma asifNo ratings yet

- Turcon V-Stack Seal Assembly: Multi-Element Lip Seal For High Pressure Oil and Gas ApplicationsDocument2 pagesTurcon V-Stack Seal Assembly: Multi-Element Lip Seal For High Pressure Oil and Gas ApplicationsDanialNo ratings yet

- Name: - Grade & Section: - Teacher: - Date: - ScoreDocument11 pagesName: - Grade & Section: - Teacher: - Date: - Scorenicolekate reyNo ratings yet

- Manual of HND Research Project - Final - 0Document44 pagesManual of HND Research Project - Final - 0Anees Ur Rehman100% (3)

- Scentsy Layers Ingrediants ListDocument16 pagesScentsy Layers Ingrediants ListsimonejanesNo ratings yet

- GTP 19 Application FormDocument5 pagesGTP 19 Application FormGaluh Kusuma Kencana Putri0% (1)

- Inked 2011-02Document102 pagesInked 2011-02Herr Panzer40% (5)

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyAM76No ratings yet