Professional Documents

Culture Documents

Steel Column Base Plate Analysis

Uploaded by

Vega DesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Column Base Plate Analysis

Uploaded by

Vega DesCopyright:

Available Formats

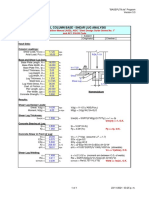

"BASEPLT9.

xls" Program

Version 3.3

STEEL COLUMN BASE PLATE ANALYSIS

Per AISC 9th Edition Manual (ASD) and "Design of Welded Structures" (O. Blodgett) Assumptions: 1. Program follows the procedures and guidelines of the AISC 9th Edition Allowable Stress (ASD) Manual (2nd Revision, 1995) pages 3-106 to 3-110 for wide

For Axial Load with or without Moment flange column base plates subjected to concentric axial compressive load only.

Job Name: Subject: 2. Program uses a "cubic equation" method of solution for column base plates subjected to axial compression or tension load with major axis column bending

Job Number: Originator: Checker: e = M*12/P as presented in "Design of Welded Structures" - by Omer W. Blodgett (James F. Lincoln Arc Welding Foundation), pages 3.3-6 to 3.3-10.

3. The total number of anchor bolts on both sides of the column flanges is 'Nb'. Anchor bolts MUST be in only 2 rows, one row outside of each column flange.

Input Data: ED1 4. Permitted anchor bolt diameters are: 5/8", 3/4", 7/8", 1", 1-1/8", 1-1/4", 1-3/8", 1-1/2", 1-3/4", 2", 2-1/4", 2, 1/2", 2-3/4", and 3".

P 5. For case of concentric axial compression load without moment:

Base Plate Yield Stress, Fy = 36.00 ksi ED2 n (-down) P = -P (which was input) for use in equations below

be fp = P/(N*B) , m = (N-0.95*d)/2 , n = (B-0.8*bf)/2 , n' = SQRT(d*bf)/4 , q = 4*fp*d*bf/((d+bf)^2*Fp) < 1.0 , l = 2*(1-SQRT(1-q))/SQRT(q) <= 1.0

Concrete Compressive Strength, f'c = 3.000 ksi

Anchor Bolt/Rod Material = F1554 (36) Col. tp = 2*c*SQRT(fp/Fy) , where: c = maximum of: m, n, or l*n'

Shear Coefficient, C = 1.85 B 0.80*bf 6. For case of axial load (compression or tension) plus moment resulting in anchor bolt tension, with eccentricites (e) as shown below:

P = -P (which was input) for use in equations below

tp ABS(e) = M*12/P > N/2-Xc/3 (for P = compression) , ABS(e) = M*12/P > N/2-ED1 (for P = tension) Page breaks may be placed

n MR = Es/Ec = 29000/(57*SQRT(f'c*1000)) , As = (Nb/2)*p*db^2/4 increments of 76 rows for

fp(max) Xc^3 + 3*(e-N/2)*Xc^2 + 6*MR*As/B*((N/2-ED1)+e)*Xc - 6*MR*As/B*(N/2+(N/2-ED1))*((N/2-ED1)+e) = 0 , and solve cubic equation for Xc

m 0.95*d m T= Xc T = -P*(N/2-Xc/3-e)/(N/2-Xc/3+(N/2-ED1)) , Tb = T/(Nb/2) , fp(max) = 2*(P+T)/(Xc*B)

Tb*(Nb/2) 7. Plate bending is calculated due to both plate bearing stress and anchor bolt tension, where effective plate width used for anchor bolt tension is as follows:

N N be = Minimum of: (m-ED1) or (B-2*ED2)/(2*(Nb/2-1)) + Minimum of: (m-ED1) or (B-2*ED2)/(2*(Nb/2-1)) or ED2

8. For interaction of anchor bolt tension and shear, this program follows the article: "Design Aid: Anchor Bolt Interaction of Shear and Tension Loads",

Plan Elevation by Mario N. Scacco, AISC Engineering Journal, 4th Quarter - 1992. Anchor bolt interaction formula is as follows: Tb/Ta + (C*Vb)/Va <= 1.0.

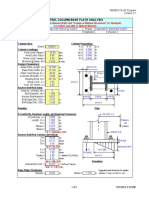

COLUMN LOADS DESIGN DATA RESULTS

COLUMN COLUMN Case 1: Maximum Load Condition Case 2: Minimum Load Condition Base Plate Data Pier Data Anchor Bolt Data Eccentricities and Bearing Lengths Bearing Pressure Check Plate Thk. Check Bolt Tension Check Bolt Shear Check Interaction

LOCATION SIZE Axial Shear Moment Axial Shear Moment Length Width Thickness Length Width Total No. Diameter Edge Dist. Edge Dist. Eccentricity Brg. Length Eccentricity Brg. Length fp(max) Fp S.R. = tp S.R. = Tb Ta S.R. = Vb Va S.R. = S.R. =

P V M P V M N B tp Lpx Lpy Nb db ED1 ED2 e(case 1) Xc(case 1) e(case 2) Xc(case 2) (actual) (allowable) fp(max)/Fp (req'd) tp(req'd)/tp (actual) (allowable) Tb/Ta (actual) (allowable) Vb/Va Tb/Ta +

(kips) (kips) (ft-kips) (kips) (kips) (ft-kips) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (ksi) (ksi) (in.) (kips) (kips) (kips) (kips) C*Vb/Va

A-1 W10x100 -525.00 0.00 0.00 -525.00 0.00 0.00 19.000 17.000 2.000 28.000 28.000 4 1.000 1.500 1.500 0.000 19.000 0.000 19.000 1.625 1.636 0.994 1.861 0.931 0.00 15.00 0.000 0.00 7.78 0.000 ---

A-2 W12x106 -600.00 0.00 0.00 -600.00 0.00 0.00 19.000 16.000 1.750 34.000 34.000 4 1.000 1.500 1.500 0.000 19.000 0.000 19.000 1.974 2.048 0.964 1.579 0.902 0.00 15.00 0.000 0.00 7.78 0.000 ---

A-3 W10x100 -360.00 20.00 60.00 -360.00 20.00 60.00 19.000 17.000 2.000 36.000 36.000 4 1.250 2.000 2.000 2.000 19.000 2.000 19.000 1.818 2.100 0.866 1.845 0.922 0.00 23.44 0.000 5.00 12.15 0.412 ---

A-4 W14x90 -130.00 20.00 59.58 -130.00 20.00 59.58 28.750 24.000 1.750 36.000 36.000 4 1.250 2.000 2.000 5.500 26.641 5.500 26.641 0.407 1.439 0.283 1.561 0.892 0.02 23.44 0.001 5.00 12.15 0.412 0.762

A-5 W14x90 -130.00 20.00 175.00 -130.00 20.00 175.00 28.750 24.000 2.500 36.000 36.000 6 1.750 2.500 2.500 16.154 15.532 16.154 15.532 0.928 1.439 0.645 2.265 0.906 14.30 45.94 0.311 3.33 23.81 0.140 0.570

A-6 W14x90 0.00 20.00 175.00 0.00 20.00 175.00 28.750 24.000 2.250 36.000 36.000 6 2.000 2.750 2.750 (Infinite) 10.602 (Infinite) 10.602 0.735 1.439 0.511 2.161 0.961 31.16 60.00 0.519 3.33 31.10 0.107 0.718

A-7 W14x90 150.00 0.00 0.00 150.00 0.00 0.00 28.750 24.000 2.250 36.000 36.000 6 1.375 2.000 2.000 0.000 0.000 0.000 0.000 0.000 1.439 0.000 2.132 0.947 25.00 28.36 0.881 0.00 14.70 0.000 ---

A-8 W14x90 150.00 5.00 50.00 150.00 5.00 50.00 28.750 24.000 2.500 36.000 36.000 6 1.750 2.500 2.500 4.000 0.000 4.000 0.000 0.000 1.439 0.000 2.314 0.925 33.42 45.94 0.727 0.83 23.81 0.035 0.792

A-9 W14x90 130.00 20.00 175.00 130.00 20.00 175.00 28.750 24.000 2.750 36.000 36.000 6 2.250 3.500 3.500 16.154 5.762 16.154 5.762 0.425 1.439 0.296 2.541 0.924 53.14 75.94 0.700 3.33 39.36 0.085 0.856

1 of 1 23/11/2021 03:25 p. m.

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Steel Column Base Plate AnalysisDocument1 pageSteel Column Base Plate AnalysisVega DesNo ratings yet

- Steel Column Base Plate AnalysisDocument1 pageSteel Column Base Plate AnalysisVega DesNo ratings yet

- Steel End/Base Plate & Anchor Bolts Analysis & DesignDocument6 pagesSteel End/Base Plate & Anchor Bolts Analysis & DesignRey GonzalesNo ratings yet

- Steel End/Base Plate & Anchor Bolts Analysis & DesignDocument6 pagesSteel End/Base Plate & Anchor Bolts Analysis & DesignRey GonzalesNo ratings yet

- Steel End/Base Plate & Anchor Bolts Analysis & DesignDocument6 pagesSteel End/Base Plate & Anchor Bolts Analysis & DesignRey GonzalesNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- RECTBEAMDocument16 pagesRECTBEAMselva84No ratings yet

- Rectangular Concrete Beam, Column Analysis and DesignDocument17 pagesRectangular Concrete Beam, Column Analysis and DesignRohit Khandelwal100% (3)

- Torsion 9Document7 pagesTorsion 9Cheng Por EngNo ratings yet

- BoefDocument6 pagesBoefmetroroadNo ratings yet

- Pipe Column Base Plate Design-1Document3 pagesPipe Column Base Plate Design-1samehNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcklconNo ratings yet

- BEAMANAL (Metric) CopieDocument19 pagesBEAMANAL (Metric) Copierelu59No ratings yet

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation Analysisbuffyto5377100% (1)

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation AnalysisMagdy BakryNo ratings yet

- DOS - Base Plate - 2 PDFDocument22 pagesDOS - Base Plate - 2 PDFInam UllahNo ratings yet

- Rectangular Concrete Beam, Column Analysis and DesignDocument27 pagesRectangular Concrete Beam, Column Analysis and DesignFernando Sernaqué CalleNo ratings yet

- RECTBEAMDocument23 pagesRECTBEAMHatori Al-HiterNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Lifting LugDocument4 pagesLifting Lugsjkang0226100% (4)

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument19 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionOmar FarukNo ratings yet

- BMREINF13Document50 pagesBMREINF13NEO100% (1)

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument22 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionLee Man HonNo ratings yet

- RECTBEAMDocument20 pagesRECTBEAMsalimanraharjoNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionfuffinoNo ratings yet

- Pile Capacity - BYWGDocument70 pagesPile Capacity - BYWGHamidAffandyNo ratings yet

- Lesson 4 Analysis and Design For Axial Tension (Part 2)Document3 pagesLesson 4 Analysis and Design For Axial Tension (Part 2)EJ Dela CruzNo ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- Slab On Grade Excel Sheet PDF FreeDocument10 pagesSlab On Grade Excel Sheet PDF FreeImaduddin KhajaNo ratings yet

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument25 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionJuan Jose Gutierrez VidalNo ratings yet

- Beam and Column Design - ACI 11 - MOTIURDocument34 pagesBeam and Column Design - ACI 11 - MOTIURmotiur basumNo ratings yet

- DOS - Base Plate - 2Document23 pagesDOS - Base Plate - 2Inam UllahNo ratings yet

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument16 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionAli Syaputra100% (1)

- Base PlateDocument27 pagesBase PlateSabih Hashim AlzuhairyNo ratings yet

- MONORAILDocument7 pagesMONORAILDiego Andres RamosNo ratings yet

- Lug Fatigue Analysis - Engineering LibraryDocument9 pagesLug Fatigue Analysis - Engineering Libraryviki vigneshNo ratings yet

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- "Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramNEONo ratings yet

- Penerapan Fem Untuk Menentukan Material Komponen Propulsi Roket Rkx-10C16Document9 pagesPenerapan Fem Untuk Menentukan Material Komponen Propulsi Roket Rkx-10C16Akbar adiwarsitaNo ratings yet

- Circ BaseDocument8 pagesCirc BaseMario Sajulga Dela Cuadra100% (1)

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignVivek AnandanNo ratings yet

- "Deckslab" - Slab On Metal Deck Analysis / Design: Program DescriptionDocument22 pages"Deckslab" - Slab On Metal Deck Analysis / Design: Program DescriptionRexter UnabiaNo ratings yet

- XXXX-XXX-XX-XX-XXX Base Plate Structural Calculation Report - 1702016 - Rev. ADocument7 pagesXXXX-XXX-XX-XX-XXX Base Plate Structural Calculation Report - 1702016 - Rev. AsridharNo ratings yet

- PT NotesDocument5 pagesPT NotesNiraj ShindeNo ratings yet

- Stress DesignDocument11 pagesStress DesignKarthikeyan SankarrajanNo ratings yet

- Afghan University "Engineering Faculty": Subject: Design of Steel StructuresDocument18 pagesAfghan University "Engineering Faculty": Subject: Design of Steel StructuresHamid ElmyNo ratings yet

- The Plasma Dispersion Function: The Hilbert Transform of the GaussianFrom EverandThe Plasma Dispersion Function: The Hilbert Transform of the GaussianRating: 5 out of 5 stars5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- Logical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeFrom EverandLogical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeNo ratings yet

- Steel Column Base - Shear Lug AnalysisDocument1 pageSteel Column Base - Shear Lug AnalysisVega DesNo ratings yet

- Steel Column Base Plate AnalysisDocument1 pageSteel Column Base Plate AnalysisNagender Kumar0% (1)

- Steel Column Base - Shear Lug AnalysisDocument1 pageSteel Column Base - Shear Lug AnalysisVega DesNo ratings yet

- Steel Column Base Plate AnalysisDocument1 pageSteel Column Base Plate AnalysisNagender Kumar0% (1)

- Steel Column Base Plate AnalysisDocument1 pageSteel Column Base Plate AnalysisNagender Kumar0% (1)

- Steel Column Base - Shear Lug AnalysisDocument1 pageSteel Column Base - Shear Lug AnalysisVega DesNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Free ConvectionDocument4 pagesFree ConvectionLuthfy AditiarNo ratings yet

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Document8 pagesNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasNo ratings yet

- World of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageDocument11 pagesWorld of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageAin NawwarNo ratings yet

- Brochure - OasisDocument24 pagesBrochure - OasisVivek RNo ratings yet

- The Handmaid's TaleDocument40 pagesThe Handmaid's Taleleher shahNo ratings yet

- General Return Service Agreement (RSA) GuidelinesDocument2 pagesGeneral Return Service Agreement (RSA) GuidelinesJune Francis AngNo ratings yet

- Citrus Information Kit-Update: Reprint - Information Current in 1998Document53 pagesCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNo ratings yet

- RESEARCHDocument5 pagesRESEARCHroseve cabalunaNo ratings yet

- 2023 2024 Syllabus PDFDocument23 pages2023 2024 Syllabus PDFRika DianaNo ratings yet

- XXXX96 01 01 2023to28 08 2023Document18 pagesXXXX96 01 01 2023to28 08 2023dabu choudharyNo ratings yet

- What Is Urban PlanningDocument33 pagesWhat Is Urban PlanningDivine Grace FernandoNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet

- MCFKTP G3 S2 SC Number Pattern PuzzlesDocument5 pagesMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoNo ratings yet

- LAB REPORT - MGCLDocument5 pagesLAB REPORT - MGCLKali stringsNo ratings yet

- Chemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFDocument178 pagesChemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFsogunmola100% (2)

- When SIBO & IBS-Constipation Are Just Unrecognized Thiamine DeficiencyDocument3 pagesWhen SIBO & IBS-Constipation Are Just Unrecognized Thiamine Deficiencyps piasNo ratings yet

- Big Brother Naija and Its Impact On Nigeria University Students 2 PDFDocument30 pagesBig Brother Naija and Its Impact On Nigeria University Students 2 PDFIlufoye Tunde100% (1)

- Chapter 9Document28 pagesChapter 9Aniket BatraNo ratings yet

- Entrepreneurial MotivationDocument18 pagesEntrepreneurial MotivationRagavendra RagsNo ratings yet

- The Philippine GovernmentDocument21 pagesThe Philippine GovernmentChristel ChuchipNo ratings yet

- The Teacher Research Movement: A Decade Later: Cite This PaperDocument13 pagesThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNo ratings yet

- Installation of Submarine PE PipesDocument84 pagesInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- School Activity Calendar - Millsberry SchoolDocument2 pagesSchool Activity Calendar - Millsberry SchoolSushil DahalNo ratings yet

- Technical Rockwell Automation FactoryTalk HistorianDocument6 pagesTechnical Rockwell Automation FactoryTalk HistorianAmit MishraNo ratings yet

- Fellows (Antiques)Document90 pagesFellows (Antiques)messapos100% (1)

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet

- AIP 2020 FINAL JuneDocument5 pagesAIP 2020 FINAL JuneVINA ARIETANo ratings yet

- Pre-Paid Customer Churn Prediction Using SPSSDocument18 pagesPre-Paid Customer Churn Prediction Using SPSSabhi1098No ratings yet

- Arc Hydro - Identifying and Managing SinksDocument35 pagesArc Hydro - Identifying and Managing SinkskbalNo ratings yet