Professional Documents

Culture Documents

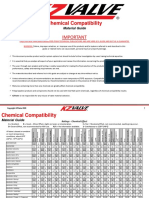

Chemical Compatibility Chart From Ism

Uploaded by

Rozaq Alfan WOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Compatibility Chart From Ism

Uploaded by

Rozaq Alfan WCopyright:

Available Formats

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Acetaldehyde A A D A C B A A D C C D A A B A C C C C N/A A C A A D D A A D D

Acetamide B A A A B A D D A D N/A A A A N/A A A A D B N/A A D A A D C B N/A D B

Acetate Solvents A A N/A A D A A C C D A C A A N/A A A A C D D A N/A B A D A C A D D

Acetic Acid D B D D C B D C C D B C A A A A A A B C A D B B A D C C A D B

Acetic Acid, 20% B A C C C B D C B D B A A A A A A A B A A D A A A D A B A D B

Acetic Acid, 80% D B D D D B D C C D B C A A A A A D C C A D B A A C C B A D B

Acetic Acid, Glacial C A D D D B D C C D B B B A A A A D C D A B B A A D A B A D D

Acetic Anhydride B A C D D A D C D D B D B A C A C D C A D A D B A D B C A D D

Acetone A A D A D A A A D A A D A A B A D B C C D A D A A D D D A D D

Acetylene A A N/A A A A B C B A D C A N/A A A B D B B N/A A D A A A A B N/A A A

Acrylonitrile A A D N/A B B A A D A A A D B N/A N/A A A B C N/A A D A A B A D N/A N/A D

Alcohols: Amyl A A A A C B A A B B A A A A A A A B1 B A C A B B A A A D B D A

Alcohols: Benzyl B B D A D B B A D B B A B A N/A A B D D C D B D A A D A N/A A D A

Alcohols: Butyl A A D A C B A A A N/A B A A B B A B B1 A A A B B A A C A B B B A

Alcohols: Ethyl A A B A C B A A C B A B A A D A A B A A A A B1 A A C A B A C A

Alcohols: Isobutyl A A B A C B B A B C N/A N/A A A N/A A A A A A A A A A A A A A B A A

Alcohols: Isopropyl B B D A A B B A B A B C A A A A A A1 A B A D A1 A1 A A A A B A A

Alcohols: Methyl A A D A C A A A A A B A A A B A A A A A A B B A1 A A A A B A C

Alcohols: Propyl (1-Propanol) A A B A B A A A A A A A A A N/A A B A1 A A A D A A A A A1 A A A A

1

Aluminum Fluoride D D A C C B D D A D D A A B N/A N/A A A B A A A N/A A A A A B A A A

Aluminum Hydroxide A C B A A B B C A A D A A B N/A A A A1 D A A A B A A A A N/A B A A

Aluminum Nitrate A A A1 B B D D N/A A N/A D A A N/A N/A A A A1 A A N/A A A A1 A B A B A B A

Aluminum Sulfate, 10% B B1 A B B B B B A D A A A B B A A A1 A A A A1 A A A A A A A A A

Alums N/A A A1 C B A D N/A A D C A A B D A A A A B N/A A N/A A A N/A N/A A A N/A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Amines A A N/A D D B B D D D N/A D B B A A B C B B D D D B1 A D N/A B B D D

Ammonia, 10% (Ammonium

A A B C A A D D A A D A A A C A A C D A A A D A1 A B A A C B D

Hydroxide)

Ammonia Nitrate A A A1 C A C A D C A D B A B B N/A A A N/A C A D N/A A A B A1 N/A N/A B D

Ammonia, anhydrous A A1 D D A A D D B A D A A B D A A B1 D A B A D A A A A C C A D

Ammonia, liquid B A1 D D A A D D C A D A A B N/A A A C D A N/A B D A1 A A A N/A C A D

Ammonium Acetate B A N/A C A A D D B A N/A A A N/A D N/A A A N/A A N/A A A A A A A N/A N/A A A

Ammonium Bifluoride D B A D N/A B D D B D B A A B N/A N/A A A1 N/A D A N/A N/A A A A A N/A N/A A A

Ammonium Carbonate B B A D D B D D B B D A A B N/A N/A B B1 A A A A C A A A A C A A A

Ammonium Chloride, 10% C B1 A B B B D D B D D A A D A A A A1 A B A B A1 A A A A C B A A

Ammonium Hydroxide (Aqueous

A A B D A B D D D D D A A B C A A A D A A A D A1 A B A A C B D

Ammonia)

Ammonium Nitrate, 10% A A A1 A1 A B D D A B D A A B B A A A C B A A R A A A A C A A A

Ammonium Persulfate A B A D D D D D A D D A B B N/A A A A1 A A A D A A A A A D A A A

Ammonium Phosphate, Dibasic B C A1 B1 A B B D A D D A A B N/A A N/A A1 A A A C A1 A A A A A A A A

Ammonium Phosphate, Monobasic B C A1 B A B A D A D D A A B B N/A N/A A A A A B A A A A N/A A A A A

Ammonium Phosphate, Tribasic B B A1 B A B N/A C A D D A A B N/A N/A N/A C A A A B N/A A A A N/A A A A A

Ammonium Sulfate B B A B B A D D A D D A A B B A A A A A A A A1 A A A A A A A A

Ammonium Thiosulfate N/A A N/A B N/A N/A D D A D D N/A A N/A N/A N/A N/A A N/A A N/A N/A N/A N/A N/A N/A N/A N/A A N/A N/A

Amyl Acetate A A D B C A A A D C A D A A C A N/A C D D D B D B A D A D A D D

Amyl Chloride A A D A A A C A D A A C D A N/A A B D D D D C D D A D A D C C B

Antifreeze A A B D A A B A A A N/A A A A N/A N/A N/A N/A A C A D N/A D A A N/A C N/A B A

Aqua Regia (80% HCl, 20% HNO3) D D D D D D D D D D D C C C N/A A D B D D D D D B A C A1 D A D B

Arsenic Acid A A A D A D D B A D A A A B N/A N/A B B B A A C A A A A A A B B A

Asphalt B A N/A B1 N/A A B A B A A A D N/A B A N/A A D D N/A A D B A A A D N/A N/A A

Barium Carbonate B B A A A D B B A A A A A B N/A A A B N/A N/A A A A A A A A N/A A N/A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Barium Sulfate B B A B1 A B B C A B B B A A D A B B1 A A A A D B A B A A B N/A A

1

Barium Sulfide B B A A C D D D A D D A A N/A N/A N/A A B1 A A A A N/A B A A A A A N/A A

Beer A A A A A A B A A D B A A A A A A A1 A A A A A1 A A A A A B C A

Benzaldehyde B B B A C B A A D A B D A A B A B A D D B A D D A D A1 D A D D

Benzene B B D A D B A A D A B D D B C B D C D D D A D D A C A1 D A C A

Benzene Sulfonic Acid B B N/A C N/A D B N/A D D N/A D D B B N/A A A A A A D D D A A A D B B A

Benzoic Acid B B D B A B D B D D N/A A D B D A A A D B B D B B A A A B A A A

Benzyl Chloride C B D A D D D D D D D A D C D N/A N/A N/A D D D A1 N/A C A N/A A D N/A N/A A

Borax (Sodium Borate) A A A1 B A B A B B A B A A B A A A A1 A A A A A A1 A A A B B N/A A

Boric Acid, 10% B A A1 A A D B B A D B A A A A A A A1 A D A B A A A A A A A A A

Bromine Gas D D D D D D D D D N/A D D D A D A D D D D A D C D A C A D D B A

Butadiene A A N/A A B A A C D N/A C A C C D A D D D B D C D C A C A D N/A N/A B

Butane Gas A A1 B A A A A C A N/A C C D A A A B C D A D A1 D A A C A D A C A

Butanol (Butyl Alcohol) A A D A D B A A A N/A B A A B B A B B1 A A A B B A A C A B B B A

Butyl Amine A A N/A C D A N/A B C N/A N/A N/A B B D D N/A C D D D A1 D B A D A B B D D

Butyl Ether B A N/A D D A N/A N/A B N/A N/A D D B N/A A N/A N/A D D D A1 N/A D A A A D N/A A D

1

Butyric Acid, 20% B B D A C B A D D D C D B A B A D D D D D C D B A B A D A D B

Calcium Carbonate (Chalk) CaCO3 A B N/A A A D D A A N/A A A A B N/A N/A B B A A A A C1 A A A A A B N/A A

Calcium Chloride, 10% C B B D B D B A A C B A A A A A A B A A A A A A A C A A A N/A A

Calcium Hydroxide (Lye), 10% B B A1 D A C D D A A D A A A B A A A1 A A A A1 D A1 A B A1 A A B A

Calcium Hypochlorite C B N/A D B D D D C D D B B B C B A A D D A D D A A B A B A A A

Calcium Nitrate C B1 A D A B B B A B B A A B N/A A B A A A A A A1 A1 A A A1 B B A A

Calcium Oxide (Unslaked Lime) CaO A A D A A C N/A D A N/A N/A A A A A N/A A B B A A B D A A B A A A C B

Calcium Sulfate, 10% B B C D A C B A A A A A A B N/A A A B B B A D A1 A A B A N/A A N/A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Carbolic Acid (Phenol) B B D D D A D B D D D B B A D B A D D D D D D B A D A D A B A

Carbon Dioxide, dry A A B A A B B A A D A A B A A A B A B B A A N/A A1 A A A B A N/A B

Carbon Dioxide, wet A A B A A A A A A D A A B A A A B A B B A A A A A A A B A N/A B

Carbon Monoxide Gas A A A1 A A A A A A A A A A B A A B A1 D B A A A A A A B A N/A N/A A

Carbonated Water (Carbonic Acid) A A A A A A D A A D B A B A D A A A C A A A A B A A A A B A A

Carbonic Acid (Carbonated Water) A A A B A B D B D D B A B A D A A A C D A A A B A A A A B A A

Chlorine Gas, dry 10% A B D D A C D B B D A D A A D D B D D C B D A D A D A D D A A

Chlorine Dioxide, 8% aqueous

D C B N/A C D D D D D D A D A D N/A C C D D N/A D N/A C A A A B A C B

solution

Chlorine Water (5-10 ppm) C C D D A D D B D N/A D A C A D A C B C D C C N/A D A A B D A N/A A

Chloroacetic Acid B A N/A D C D D C D D D D B A D A A D D D N/A D D C A B A D A A D

Chlorobenzene (mono) A B D D D A B C D B B D D A D A D C D D D D D C B D A D B A A

Chlorobromomethane B B N/A B N/A D N/A N/A D D B N/A B N/A D N/A N/A A D D C C N/A A A D N/A D N/A N/A A

Chloroform A A D A D B B B D B A D D A D B D C D D D A D C A D A D A B A

Chlorosulfonic Acid D B1 N/A D D C B D D D D D D A D A D D D D D D C D A D D D A C D

Chromic Acid, 5% B A B D C C D B D D D A A B D A A D B D A D B D A A A C A B A

Chromic Acid, 10% B B B D C D D D D D D A C A D A A D D D A D B D A A A C B C B

Chromic Acid, 30% B B B D D D D D D D D A B D D A A D D D D D C D A A A C A B A

Chromic Acid, 50% C B D D D D D D D D D D B B D A A D D D D D D D A D A C A B A

Citric Acid, aqueous 10% B A1 D B A C D D A D D B A A A A A D A A A A A A A B A A A N/A A

Citrus Oil or Terpene (d-Limonene) A A C B N/A C A D A D D A B A N/A A C C D D A A C A A C A D A A A

Clorox® Bleach A A B D C A D N/A D D D A B A C D N/A N/A D B A A A D A A A N/A N/A B A

Coffee A A N/A A A A D A A N/A A A A A N/A N/A A N/A A A A A C A A N/A N/A A A N/A A

Copper Chloride D D A A A N/A D D A N/A D A A N/A A A B N/A C A A D N/A A A A A A D A A

Copper Sulfate, 5% B B A1 D A D D B A D B A A A A A A A1 C A A D A A A A A A A N/A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Cresols A A D D D A C A D C A D D B D A D C D D D D D D A D A1 D B D A

Cyclohexane A A D A C A A B B B B D D B A A D B D D D A B D A D A D A D A

Cyclohexanone A A1 D A D A B B D B B D B A D A B D D D D A D D A D D D N/A D D

Detergents A A B A A B A B A N/A A A A B B A A D B B A A A A A A A A A A A

Diacetone Alcohol B B N/A A D A A B D A A D A A C B A A D D A A D A A D D D A B D

Dichlorobenzene N/A B D B D B N/A B D N/A N/A D D A D N/A D D D D N/A D D C A D A D N/A N/A C

Dichloroethane B B D A D B B D D N/A A D N/A A N/A A C C D D A A D D A D A N/A B D C

Diesel Fuel A A N/A A B A A A A A A A D B B A D C D B D A A1 A A A A D B N/A A

Diethyl Ether B B1 D A D B B A D N/A A D D B C C D N/A D D N/A A D A A D A D A N/A D

Diethylamine A A D B B B A A C B A D B A N/A A D D A A N/A A D A D D D B A C A

Dimethylformamide (N,N-

A B D C D B C B C B A D B A B A A A C D D A D A A D D C A D D

Dimethylformamide)

Dyes A A N/A C D B A N/A D N/A A N/A A N/A D N/A N/A N/A C C A A D N/A A B N/A N/A N/A C A

Ethane A A N/A A N/A A N/A N/A A A A A D A N/A N/A N/A N/A D B N/A D N/A D A A A D N/A A A

Ethanol (Ethyl Alcohol) A A B A D B A A C B A B A A D A A B A A A A C A A C A B A C A

Ethanolamine A A N/A D C B N/A B B B D N/A B B N/A D N/A N/A B B A A N/A D A D C B B N/A D

Ether A A D A D B B A D C A D C B N/A B D D D D D A D D A D B D A C C

Ethyl Acetate B B D A D A B A D A A D B A B A A A C D A A1 D A A D D B A D D

Ethyl Benzoate A A D A D A N/A N/A D A A D A A C N/A B C1 D D A D D B A D D D N/A D A

Ethyl Chloride A A D A D B A A A C B D A B C B C C B C D A D D A D A D A D A

Ethyl Ether B B D A D B B A D C A D D B N/A A D D D D D A N/A D A D A1 D A N/A D

Ethylene Glycol B B A B A A B A A A A A A B A A A A1 A A A A B A A A A A A B A

Ethylene Oxide Gas (EtO), dry 3% B B D D A D D C D D D C C A A A B A D D A A C D A D A D N/A N/A D

Fatty Acids B A A A A A C A B C D A D A B A A D C C A A B A A A A C B B A

Ferric Chloride, 10% D D A D A D D D A D D A A B C A D A A B A A A1 A A A A B A B A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Ferric Nitrate B B A D A D D C A D D A A B D A B A1 A A A A A A A A A C A N/A A

Ferric Sulfate B A A D B D D C A D D A A A A A A A1 A A A A A A A A A B A B A

Ferrous Sulfate B B A D A B B B A D B A A B A A B A1 B A A D A A A A A N/A A B B

Fluosilicic Acid, 20% C B D B B D N/A B A B B A A B N/A A B B1 A B B D N/A A A A A D D A A

Fluosilicic Acid, 100% D D D A C D N/A B B D D N/A A B N/A B C B A B B D N/A A A B A D D D A

Formaldehyde, 40% A A A A1 B B A A B B B A A B C A A D B B A A A A A A A N/A B N/A A

Formaldehyde, 100% C A B A D A N/A B C C A A A A D A A B C C A D A1 C A A A B A B D

Formic Acid (Methanoic Acid), 10% B A D A1 B A D C C D C A A A B A A D C A A D A A A A A B C B C

Fruit Juices A A B D A A D N/A A D A A A A B A A A D A B A A B A A A N/A A B A

Fuel Oils A A D A B C B A A A A N/A D A B A C B D B B A B A B A B D A A A

Furfural (Ant Oil ) C5H4O2 A B D A D A A B D B A D D B B D A D D D D B D D A D B1 D A D D

Gallic Acid, 5% A B N/A N/A A D C B B D D C B B D A A A A B A A A A B B A D B A A

Gasoline (high-aromatic) A A D B D D N/A A A A N/A C D A A A B A D A B A A A B A A D B A A

Gasoline, leaded, ref. A A D A D A A A A A B D D A A A B N/A D B B A A B A B A D A C A

Gasoline, unleaded A A1 D A D A A A A A B C D A N/A A B N/A D B D A1 A1 C A C A D A C A

Glucose A A B A A A A N/A A A A A A A A N/A A A1 A A A A A A A A A A A A A

Glue, PVA (Polyvinyl Acetate) A A1 N/A A D A N/A A A A B A A A A N/A A A A A N/A A N/A N/A A C A A A C B

Glycerin A A C A A A B A A A A A A A A A A A A A A A A1 A A A A A A A A

Glycolic Acid A A B A C N/A N/A N/A A N/A N/A A A A N/A B B A D A N/A N/A N/A A A B B A A A A

Grease N/A A N/A D A N/A A A A A A N/A D A A N/A N/A N/A D D N/A N/A A N/A A A A D N/A A A

Heptane A A D A C A A A A A A A D A B A B B D B B A B C1 A C A D A B A

Hexane A A D A C A A A A A A B D A A A C D D B B B D B A B A D A D A

Honey A A N/A A A A N/A A A A N/A N/A A A N/A N/A N/A B A A N/A A A A A A A A N/A A A

Hydraulic Oil (Petro) A A N/A B D A A A A A A N/A D A D N/A A C D A N/A A N/A D A A A B N/A A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Hydraulic Oil (Synthetic) A A N/A B D A A A D A A N/A A A A N/A A A D A N/A A N/A D A A A B N/A A A

Hydrazine (Diamine) H2NNH2 A A N/A B C N/A D N/A B D A D A N/A C N/A D N/A C B N/A N/A D C A N/A A B N/A N/A A

Hydrobromic Acid, 20% D D N/A C D D D N/A D D D A A A N/A A D B A D B D N/A A N/A B A D A B A

Hydrobromic Acid, 100% D D B D D D D N/A D D D A A C N/A A D B A D B D N/A C A A A D A B A

Hydrochloric Acid, 20% D D A C C D D D D D D A A A B A A A1 A C A D B B1 A A A D D A A

Hydrochloric Acid, 37% D D A C C D D D B D D A C B C A A B A B A D D C A B A B D A A

Hydrochloric Acid, 100% D D A C D D D D D D D A D A D A D N/A D D A D D B A D A D D A A

Hydrochloric Acid, dry gas D D N/A N/A N/A D D A N/A N/A D A N/A A N/A A D A N/A N/A A A N/A B A A A N/A C N/A N/A

Hydrofluoric Acid, 20% D D C D C D D B D D B C D B D B A A B B C C D A1 A B A D D C A

Hydrofluoric Acid, 50% D D C D C D D B D D B C D B D B A A B D D D D A A B A D D C B

Hydrofluoric Acid, 75% D D C D D D D B D D B C C B D B B C D D D D D C A C A D D C B

Hydrofluoric Acid, 100% B B D D D D D B D D B C D B D A D N/A D D D D D C A C A D D D B

Hydrogen Gas A A A1 N/A N/A A A A A A A A A A A B A A1 B A A A1 A1 A A A A C A A A

Hydrogen Peroxide, 10% B B A D C A D B D C D A A A D A A A B D A C A A A A A A A B A

Hydrogen Peroxide, 30% B B N/A D C A D B D B D A B A D B A C1 C D A D A1 B A A A B B B A

Hydrogen Peroxide, 50% B A1 N/A D D A D B D N/A D A B A D A A C1 C D N/A D A1 B A A A B A B A

Hydrogen Peroxide, 100% B A1 A D D A D B D B D A D A D B A C1 C D A D A B A A A B B B A

Hydrogen Sulfide, aqueous C A B C A B D A D D D A B A A A A A C A A C A A A B A C B A D

Hydrogen Sulfide, dry C A N/A A A B D B D D D A B A A B A A C A N/A C N/A A A A A C A D D

Isopropyl Alcohol (IPA, isopropanol) B B D A A B B A B A B C A A A A A A1 A B A D A1 A1 A A A A B A A

Ketones A A A D D B N/A A D A A N/A D A D B D C A D D A1 D C A D C N/A A D D

Lacquer Thinners A A A D D A A A D C A N/A D A D N/A D A D D D A B D A D N/A D C D D

Lacquers A A A D N/A A D A D C A A D A D A D A D D D A D D A D D D A A D

Lactic Acid B B D B A B D B A D B A A B D A A A A A A B B B A B B A A A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Latex A A1 B B N/A A A A A A N/A N/A A A N/A N/A N/A N/A N/A B N/A A N/A A1 A N/A A A N/A A A

1 1

Ligroin A A N/A B N/A D N/A N/A A A N/A N/A D N/A N/A N/A N/A A D B N/A D A A1 A N/A A D N/A A A

Lime (CaO) A A A1 B A A N/A N/A A A N/A N/A D N/A C A A A N/A A N/A A D D A B A N/A A A A

Linoleic Acid B A A B N/A A D C B D D A D A N/A N/A B A D D N/A N/A N/A B A A A1 B N/A A B

Lithium Hydroxide C C N/A N/A N/A D D B C B N/A N/A A B N/A N/A D N/A A D N/A N/A D A A N/A N/A N/A N/A N/A A

Lubricants A A1 N/A A A A A A A A A N/A D A A N/A B D D D C A A A A B A D A B A

Lye (KOH, Potassium Hydroxide) B A A A B D D D B B B A A B D B B A B B A C D A A B A C D B B

Lye (NaOH, Sodium Hydroxide) B B C C A D D D A D B A B C C B B D A B A A D A A A D A B B B

Magnesium Bisulfate A A N/A N/A N/A D N/A A B N/A N/A N/A N/A N/A N/A N/A A N/A B B N/A A A A1 A A N/A N/A N/A A N/A

Magnesium Chloride, 10% D D B B A D D B A D A A A A C A A A A A A A A1 A1 A B A A A A A

1

Magnesium Hydroxide, 10% B A B A A C D B A A B A A A C A B A A A A B A A A A A A A C A

Malic Acid (Apple Acid) C4H6O5 A A1 N/A A N/A B B B A D D A D B N/A N/A N/A B1 B D N/A A D A A A A B A A A

Mercury A A B A A D D A A A D A A A B A A A A A A A D B A A A N/A A D A

Methane Gas A A A A A A A A A N/A A N/A D A B N/A A N/A D B N/A A A A A B A D N/A N/A A

Methanol (Methyl Alcohol) A A D A C A A A A A B A A A B A A A A A A B B A1 A A A A B A C

Methyl Acetate A B D B D A N/A A D A B N/A B A C A C B D B N/A A D D A D B D N/A A D

Methyl Acetone (mixture) A A N/A D N/A A A A D A N/A N/A A A N/A N/A N/A N/A A D N/A A N/A D A D D N/A N/A A D

Methyl Alcohol, 10% A A D A C A A A A A A A A A B A A A A A A B B A1 A A A A B A C

Methyl Butyl Ketone A A N/A D D A N/A D D N/A N/A N/A A N/A N/A N/A N/A N/A D D N/A D D D A A D D N/A N/A D

Methyl Cellosolve B B A D A B A A A C B D B N/A N/A N/A N/A N/A D B N/A C D B A D A D N/A C D

Methyl Chloride A A D B D D A B D D N/A D D B D A N/A C D D D B D D A D A D A D A

Methyl Ethyl Ketone (MEK, Butanone) A A D C D B A A D A A D A A B A D B D D D A D B1 A D D D A D D

Methyl Ethyl Ketone Peroxide

N/A A D D N/A D D D D D D D D N/A N/A N/A N/A N/A D D N/A N/A N/A N/A A N/A N/A B N/A N/A D

(MEKP)

Methyl Isobutyl Ketone B B D D D B N/A A D C B D B A B A D C D D D B1 D A A D D D A N/A D

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Methyl Isopropyl Ketone A A N/A A D A N/A A D C A N/A C A D N/A D D D D D A D N/A A D A C N/A N/A D

Methylamine A A D D D A D A B A N/A N/A A B N/A A N/A A B A N/A N/A D A1 A D C N/A N/A D D

Methylene Chloride B B D B D C A B D B B D C B D A D D B D D C D B A D B D B D B

Milk A A B A A A D A A D D A A A B A B A A A A A A B A A A1 A A B A

Mineral Spirits A A D A B A A A A B N/A A D B N/A A D B D C A A C B A A N/A D B B A

Monochloroacetic Acid A A N/A D D D B B D D D N/A C A D B D N/A N/A A N/A D D N/A A N/A B N/A A N/A C

Monoethanol Amine A A N/A D N/A B N/A A D A D N/A B N/A D N/A N/A C B D A A N/A B A D C B B N/A D

Morpholine N/A A C N/A D A N/A B D B N/A N/A D A N/A N/A B N/A A D D A1 D B1 A N/A B N/A N/A N/A N/A

Motor Oil A A1 C B B A A A A N/A A A D N/A B A A C D B A A1 A A A B B N/A A A N/A

Mustard A A B C N/A B N/A A B D N/A A A A B N/A A A B A A A A A A B A N/A A B D

Naphtha A A D A D A A A A B A A D B B A D A D D D A B B B A A D B C A

Natural Gas A A B B A A A A A A A N/A D N/A B N/A A A C A N/A N/A D A A A N/A A N/A A A

Nitric Acid, 5-10% A A B D A A D A D D D A A A C A A B D B A D A A A A A C A D A

Nitric Acid, 20% A A B D A D D A D D D A A A D A B C D D B D B A1 A A A D A D A

Nitric Acid, 50% A A C D C D D A D D D B D A D A D B D D B D B B A B A D A D A

Nitric Acid (Concentrated) A A D D D D D A D D D D D B D A D C D D B D C D A B A D A D A

Nitrobenzene B B D C D B C A D C B D B D D A D C D D D B D B A D A D A D B

Nitromethane A A D A D A N/A N/A D N/A A N/A B A C A D A B D D B D B1 A B A1 D N/A B D

Nitrous Acid B B D N/A C D D B D D C A A D N/A B D N/A C D N/A N/A N/A A A A B N/A N/A A B

Nitrous Oxide B B N/A N/A D B B D A B B N/A A B N/A N/A N/A C A A N/A C D D A A D N/A N/A A B

Oils: Citric A A D A N/A A B N/A D D N/A N/A B A N/A N/A B A N/A D A A A A A B A N/A A D A

Oils: Cod Liver A A A B A A D N/A A D N/A A A A N/A A A N/A D B N/A N/A A A A A A B N/A N/A A

Oils: Corn A A B A A A B N/A D A B N/A C A A A A A D A A A N/A A1 A B A A N/A B B

Oils: Cottonseed A A A A A A A N/A A A A A D A A A A A D C A B N/A A A B A A A B A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Oils: Diesel Fuel (20, 30, 40, 50) A A N/A D B A A A A A A N/A D B A A D A D B D A A A A B A D B A A

Oils: Fuel (1, 2, 3, 5A, 5B, 6) A A D D B C B A B A A N/A D A A A C B D D A A B B A A B C B A B

Oils: Hydraulic Oil (Petro) A A N/A B N/A A A A A A A N/A D A A N/A A C D A N/A A N/A D A A A B N/A A A

Oils: Hydraulic Oil (Synthetic) A A N/A B N/A A A A D A A N/A A A A N/A A A D A N/A A N/A D A A A B N/A A A

Oils: Mineral A A A A A A A A A N/A B A D A A A A B D B A A B A A B A C A B A

Oils: Silicone A A A A B A A A A A A A A A A N/A A A D D A A A A A A A C N/A A A

Oils: Soybean A A A A N/A A N/A A A A N/A A C A B A A A D C N/A A N/A A A A A A A B A

Oils: Turbine A A N/A A N/A A N/A A B A A A A N/A N/A N/A N/A C D D N/A A N/A B A A A D A A A

Oleic Acid A A D A C A D B B N/A A A B A A B C C1 D C A A A B A C A D B C B

Oxalic Acid, cold 10% B A A B A A D B D C B A A B D D A A1 B D A B1 N/A A1 A B B B A B A

Ozone Gas B A B C A B B B D C A A A A C A C1 C D C N/A D A B A B A A A B A

Palmitic Acid B A A A D B D A A N/A B A B B A N/A A N/A B D N/A A A B A B A1 D N/A B A

Paraffin A A A A A A A A B N/A B A D B N/A A B B B B A A A A A B A N/A A B B

Pentane (Amyl Hydride) C5H12 C C A B N/A B A C A N/A A N/A D A B N/A N/A D D B N/A A A D A A A D N/A A A

Peracetic Acid (Peroxyacetic Acid) B A B D D C D D C D D D B A N/A N/A A D D D N/A D A A A C A C N/A D A

Perchloric Acid C C N/A C C D N/A B D N/A D A B B D B D B D A N/A D D C A C A D D D A

Peroxyacetic Acid (Peracetic Acid) B A B D D C D D C D D D B A N/A N/A A D D D N/A D A A A C A C N/A D A

Petroleum A A B B N/A D N/A A A N/A B A D N/A B N/A D C D B D A C B A N/A A D A N/A A

Phenol, 10% B B D B D A N/A B D D B A B B D B D B A D D D B B A C A D B C A

Phenol (Carbolic Acid) B B D D D A D B D D D B B A D B D D D D D D D B A D A D A B A

Phosphoric Acid, >40% D D C D C C D B D D D A B A D A A B B B A B A A1 A B B D C D A

Phosphoric Acid, crude D B C D D C D B D D D N/A B A N/A A B B D D A B A B A B A D C D A

Phosphoric Acid, S40% D C B D D C D B D D D A B A N/A A A A B B A B A A A B B C C D A

Phosphorus A A N/A B D B N/A A N/A N/A B B N/A A N/A N/A D B N/A N/A N/A N/A D A A A A N/A N/A B N/A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Photographic Developer A A B D B N/A N/A A A D D A B B D N/A A A A A A N/A A A A A N/A B A N/A A

Photographic Solutions D N/A N/A D B N/A N/A A B N/A D A A B B A A A B B A A A A A A B A A A B

Potassium Bicarbonate B B A C A D N/A B A A B A A B N/A A B A A A A A N/A A A A B A A A A

Potassium Bromide B B A A A C N/A B A D B A A B N/A A B A A A A A A A A A A A A B A

Potassium Chloride, up to 30% B A A A A D D B A A B A A A B A A A A A A A A A A A A A A A A

Potassium Dichromate B B B A B B D B A A B A A B C A B A B A A B A A A A A A A C A

Potassium Ferrocyanide B B A1 B C B N/A B D C B B A B N/A A B A1 A A A B D A1 A A A1 N/A A B A

Potassium Hydroxide (Caustic

B A A A B D D D B B B A A B D B A A B B A C D A A A A C D B B

Potash)

Potassium Iodide A A B N/A A B N/A A A A A A A A N/A N/A B B B A N/A A A A1 A A A1 N/A A B A

Potassium Nitrate, 10% B B B A A B B B A A A A A B B N/A B A A A A B A A A A A A A A A

Potassium Nitrite B B B A N/A B B B A A A A A B B N/A N/A A A A A B A A A A A A A A A

Potassium Permanganate B B B A B B C A C A A A A A D N/A A A A A A D A1 A A A A N/A A B A

Propane (liquefied) A A A A N/A A A A A A A A D A A A D C D C A A C A A A A D N/A N/A A

Propylene (C3H6, Propene, Methyl

B A B A B A N/A N/A D A A N/A D A N/A N/A N/A N/A D D N/A N/A A A A B A D N/A B A

Ethylene)

1 1

Propylene Glycol B B B B B B B A A A A C A B N/A N/A A B A C N/A A B A A C A A A N/A A

Pyridine (C₅H₅N) A A A B D B B B D A B D B B C A D B D D B C D A1 A D D D B D D

Resorcinol (C6H6O2) N/A N/A A N/A C N/A N/A N/A N/A N/A N/A N/A B N/A D N/A A B1 N/A D N/A D B A1 A C N/A N/A N/A C A

Rosins A A N/A B N/A B C B A D B C A A N/A A B B N/A A N/A A N/A A1 A C N/A A N/A N/A A

Salicylic Acid B B1 A D B B C A B A A N/A A A N/A A A B1 A D N/A A A A A B A N/A A B A

Salt Brine (NaCl saturated) B A A1 A A B A B A D B A A A A N/A A A A A A A A A A A A A A N/A A

Sea Water C C A1 A A B D A A D B A A A D A A A1 A B A A1 A1 A A A A A A N/A A

Shellac (Bleached) A A N/A A N/A A B A A A A N/A A N/A N/A N/A N/A A A B N/A A N/A A A N/A N/A N/A N/A N/A A

Shellac (Orange) A A N/A A N/A A B A A A A N/A A N/A N/A N/A N/A A D D N/A A N/A A A N/A N/A N/A N/A N/A A

Silicone A A D A N/A A A A A A A A A A A A A N/A C A A A A1 A A A A C N/A N/A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Silver Bromide D D N/A C A D N/A D N/A D N/A N/A N/A B N/A A N/A A N/A N/A A N/A N/A N/A A N/A N/A N/A N/A N/A N/A

Silver Nitrate B B B A A D D B B C D A A A D A A A A A A A A1 A A A A A A B A

Soap Solutions A A A A A C B B A A A A A A A N/A B D B B A A A A A A A A A B A

Sodium Acetate B B B B B B B B B B A A A A N/A A A A A B A B A A A B A D A N/A D

Sodium Benzoate N/A N/A A N/A A A N/A A B N/A N/A A A A N/A N/A B A1 A A N/A B A1 A1 A B A1 N/A A B A

1 1

Sodium Bicarbonate (Baking Soda) A A A A A D D A A C B A A B B A A A A A A A A A A A A A A B A

Sodium Bisulfate, 10% D C A B A D D A1 B D B A1 A B C A1 B A1 A A A A A A A A1 A A A B A

Sodium Bisulfite B B A C A D D B A D B A1 A B B N/A B A1 A A A C A A A A1 A A A B A

Sodium Bromide C C B A A D N/A A N/A C D A1 A B N/A A A A1 A A A1 B A A A B1 A1 N/A A B1 A

Sodium Carbonate A A B A B D B A1 A B A A1 A A B A A B1 A A A B A1 A A A1 A A A B A

Sodium Chlorate A B A A A C B B B B B A A B N/A N/A B B1 A A A D A A A A A C A B A

Sodium Chloride B B A A A C D B A D B A1 A A A A A A1 A A A A A1 A A A1 A A A B A

Sodium Hydroxide, 80% C B A D A D D C D D D A B A D A C D A B A C D A A A A A D A D

Sodium Hypochlorite, <20% C C B D A D D C B D D A B A A A A A C C A D C A A A A B C C A

Sodium Hypochlorite, 100% D D D D N/A D D C D D D C B B D A C B1 C C A D D B A B A B C N/A A

Sodium Hydrosulfite (Sodium

N/A N/A N/A N/A A A N/A N/A C N/A N/A C B A N/A N/A N/A N/A C B N/A A N/A N/A A C N/A C N/A A B

Dithionite)

Sodium Nitrate B B A1 A A B B B A B D A A B B A B A1 B B A A D A A A A D A B A

Sodium Perborate B B A B A C D B B C B A A B B A A A B B A B A A A A N/A B N/A N/A A

Sodium Peroxide A A A1 D C C D A B C B A A B B A B A B B N/A A A B A B A D N/A N/A A

Sodium Polyphosphate B B N/A B N/A D D B A D A A A A N/A A B A C B A A N/A A A A A D A N/A A

Sodium Silicate (Water Glass) A B A1 C A A D B A B B A A B A A A A1 A A A A A A A A A A A B A

Sodium Sulfate (Salt Cake,

B B A1 B A A B B A B B A A B A A A A1 B A A A A1 A A A A A A N/A A

Thenardite)

1

Sodium Sulfide B D A B A D D B A C D A A B A A B A B A A A D A A A A A A B A

Sodium Sulfite B A A1 A A C D B A A D A A B A A B B B A A D A A1 A A A A A A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Sodium Thiosulfate (hypo) A B A1 C B A D A B C D A A A N/A A A A B A A B D A1 A A A A A N/A A

1

Starch A A A A A A A B A C N/A A A N/A B A A B A A A A A A A A A N/A N/A N/A A

Stearic Acid B A A1 A A B D B B C D B B B C N/A A B C B A A1 A A1 A B A B A B A

Stoddard's Solvent A A B A A A A A A A A C D A A A N/A C1 D C D A A1 C A C A D A C A

Styrene (Vinylbenzene) C6H5CHCH2 A A N/A A D A A A D A B D D D D N/A N/A N/A D D A A D N/A A D A D N/A N/A B

Sulfite Liquors B B N/A D N/A D D B A C D B A B N/A N/A A A1 B B N/A B N/A A A B A B N/A N/A A

Sulfur Dioxide D A D B D B D B D N/A B A A C C A D B N/A B A C B A A A A B A C A

Sulfur Dioxide Gas, dry D A A B B B D B D A A A A B C A A A C D A B A A A A A B A C A

Sulfur Dioxide Gas, wet A C A B D A D C D B D A C B X N/A D A C D D D A C A A A B N/A A A

Sulfur Trioxide, dry D A N/A D N/A A A B D A B A C B X N/A A C C D D A N/A D A A C B D B A

Sulfuric Acid, <10% D B B D A D D B A C D A A B A A A A A B A C A A1 A A A C D B A

Sulfuric Acid, 10-75% D D B D D D D B B D D A B B X A A A C B A D B A A A A D D N/A A

Sulfuric Acid, 75-100% C D A D D D D B C D D C B B C A B B D D A D D C A D A D D D A

Sulfuric Acid, cold concentrated C B D D D B D B D D D D C A B A B C D D A D N/A A1 A D A D D D B

Sulfurous Acid, 10% B B N/A C A B D B B D D A B B C A B B1 B C A D D A A A A D A B A

Tannic Acid, 10% B A A B A C B B A C A A A B A A A B1 A A A C C A A A B B A B A

Tetrachloroethane B A D A D C C N/A D A A C D A N/A A D N/A D D D C D C A C A D A N/A A

Toluene (Toluol) A A D C D A A A D A A D D A B B D C D D D A D C A D A D A D C

Trichloroacetic Acid D C N/A N/A C D N/A N/A C D D N/A B B D A C A C D N/A C D A A B B D D C C

Trichloroethylene B B D D D D N/A B D C A D D A C A D D D D D C D C A D B D A N/A A

Triethylamine A A N/A D A N/A N/A C C A A A A N/A N/A A N/A N/A B A B A D D A B A1 N/A N/A A D

Trisodium Phosphate B B B A B D A A A N/A B A A A A N/A A A A A A A A A A A A A N/A A A

Turpentine (C0H16) A A D A1 B A D A A N/A B A D B B A B D D D D B D D A D A D B B A

Urea B B B A A B N/A B B N/A D A A B B N/A A A N/A B A A D A A D A B A B A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

ver 26-Jun-2020

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. N/A = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

ISM

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Noryl® (PPO)

Viton® (FKM)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

Brass

HDPE

CPVC

LDPE

PTFE

PVC

Varnish A A N/A A N/A A A B B C B D D A N/A A B A D D D A D A A D A D N/A D A

Vegetable Juice A A B A N/A D A A A D A N/A A N/A N/A N/A N/A N/A N/A N/A A A A N/A A N/A N/A B N/A A A

Vinegar A A A B A D D A B D B A A A C A A A B B A A A1 A A B B A A A A

Water, Deionized A A1 A1 N/A A A A N/A A D B A A A N/A A A N/A A A A A N/A A1 A A A1 N/A A A A

Water, Distilled A A B B A A A A A D B A A A N/A A A A1 A A A A A1 A A A A C A B A

Water, Fresh A A A A1 A B B A A D B A A A A A A A1 A A A A A1 A A B A B A B A

Water, Salt B B A1 A A B D A A D B A A A A A A A1 A A A A1 A1 A A B A B A B A

Weed Killers A A N/A A N/A D N/A N/A B N/A N/A N/A N/A N/A B N/A N/A N/A N/A C N/A A N/A C N/A N/A N/A A N/A N/A A

Whiskey and Wines A A C A A C B A A D B A A N/A B A B C A C A A A A A A A A A C A

Xylene (Xylol, Dimethylbenzene) B B D A D A A A D B A D D A B A D B D D B A1 D B A D A D A D B

Zinc Chloride, 10% B B A C B D D B A D C A A B A A A A A A A A A A A B A B A A A

Zinc Sulfate, 10% B A A C B D B B A D B A A A D A A A1 B A A A A1 A A A A A A A A

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation,

operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or

use of products described herein can cause personal injury or product damage.

*Conditions are based on ambient or room temperature unless otherwise noted, about 64°F (18°C) to 73°F (23°C).

ISM Industrial Specialties Mfg.

4091 S. Eliot St., Englewood, CO 80110-4396

Phone 888-850-4128 I Fax 303-761-7939

industrialspec.com

© Copyright 2020 Industrial Specialties Mfg.

You might also like

- Chemical Compatibility Chart From IsmDocument11 pagesChemical Compatibility Chart From IsmMajid KhanNo ratings yet

- Chemical Compatibility Chart From IsmDocument18 pagesChemical Compatibility Chart From Ismkumar.arunk6784No ratings yet

- Valve Material Selection Guide 2020Document14 pagesValve Material Selection Guide 2020Jan Andre EriksenNo ratings yet

- Elastomers Chemical Compatibility CharDocument12 pagesElastomers Chemical Compatibility CharsubrataNo ratings yet

- Chemical Resistance 71010Document22 pagesChemical Resistance 71010Kevin LinNo ratings yet

- Graco ChemCompGuideEN BDocument54 pagesGraco ChemCompGuideEN BBruno AlbertNo ratings yet

- Chemical Compatibility Guide Ammonia LiqDocument1 pageChemical Compatibility Guide Ammonia LiqدSalem Abd ElghanyNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- Ecce12 ColucciDocument12 pagesEcce12 ColucciparsmessengerNo ratings yet

- KeyPlast Colorants Main Brochure 2021 - Chip BookDocument8 pagesKeyPlast Colorants Main Brochure 2021 - Chip BookHung TranNo ratings yet

- 2SD 2017 PDFDocument1 page2SD 2017 PDFtabassam7801No ratings yet

- TI-Polymer-Periodic TableDocument1 pageTI-Polymer-Periodic TablePiero FranciaNo ratings yet

- Thiết Kế Kỹ Thuật: Typical Distribution BoardDocument1 pageThiết Kế Kỹ Thuật: Typical Distribution BoardAn BuiNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)Document1 pageDarlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)mundomusicalmeriaNo ratings yet

- Chemical Compatibility Chart SMD Fluid ControlsDocument7 pagesChemical Compatibility Chart SMD Fluid Controlsmayur mahajanNo ratings yet

- Chemical Test Instruction (27 Feburary 2017)Document9 pagesChemical Test Instruction (27 Feburary 2017)AmirulNo ratings yet

- Section Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignDocument1 pageSection Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignAbhijeet OundhakarNo ratings yet

- Chemical Resistance GB 0612Document2 pagesChemical Resistance GB 0612Gonza Carnevale0% (1)

- Parker O-Ring Handbook (Modified)Document83 pagesParker O-Ring Handbook (Modified)precillaNo ratings yet

- Yamada Corrosion Guide CR0214Document23 pagesYamada Corrosion Guide CR0214Eddie GuillénNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Pieghevole Icap Sira Woodcoating Settembre 2022Document2 pagesPieghevole Icap Sira Woodcoating Settembre 2022kingkb58No ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2389)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2389)Gilberto DiazNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNo ratings yet

- 2SB1587 PDFDocument1 page2SB1587 PDFisaiasvaNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Migue Rodriguez RamirezNo ratings yet

- FN1016 2SD2390Document1 pageFN1016 2SD2390jcarlos1960No ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistormarcelo giussaniNo ratings yet

- Property Comparison Chart PDFDocument2 pagesProperty Comparison Chart PDFmecano1No ratings yet

- 2sd2560 Ds enDocument1 page2sd2560 Ds enMarius IggyNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1559)Document1 pageDarlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1559)Gilberto DiazNo ratings yet

- VQ20 Tf2z304enDocument2 pagesVQ20 Tf2z304enChin YongkaiNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar TransistorGilberto DiazNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar Transistorroberto carlos martinez narvaezNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument1 pageDarlington: Silicon NPN Triple Diffused Planar TransistorLucas JúniorNo ratings yet

- Technical Information: Chemical Resistance ChartDocument7 pagesTechnical Information: Chemical Resistance ChartCarolina Guthemberg JacomeNo ratings yet

- Tabela de Corrosão Little GiantDocument12 pagesTabela de Corrosão Little GiantAlex Sandro FerreiraNo ratings yet

- Chemical Resistant Chart (Hofland Deltaflex)Document40 pagesChemical Resistant Chart (Hofland Deltaflex)윤병택No ratings yet

- Joa12160 Sup 0002 TableS2 S18Document2 pagesJoa12160 Sup 0002 TableS2 S18Uzairie AnwarNo ratings yet

- SLD MDBDocument1 pageSLD MDBMd. MoniruzzamanNo ratings yet

- Bito Catalog 2018-Komplett English PDFDocument404 pagesBito Catalog 2018-Komplett English PDFKovacs ArnoldNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enaliomairNo ratings yet

- Peta Klausul Ke Dept 9001-2015Document1 pagePeta Klausul Ke Dept 9001-2015martin iluva168No ratings yet

- 2 SB 1626Document1 page2 SB 1626wds657No ratings yet

- Nomad Chem Guide Diaphragm PumpsDocument20 pagesNomad Chem Guide Diaphragm PumpsTahaNo ratings yet

- Plastic Material Properties Table - OpticDocument3 pagesPlastic Material Properties Table - OpticDINAMIKA AVIASINo ratings yet

- Elemento-Termico-B11.5 3 G000103137Document1 pageElemento-Termico-B11.5 3 G000103137Enrique Espinosa SilvaNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 2SB1647Document1 page2SB1647Julio barriosNo ratings yet

- Mars3 Tech 600-12000 20200805Document6 pagesMars3 Tech 600-12000 20200805Daniel Lack PendásNo ratings yet

- What Does It Mean ? Linear & Circular Economy Concept: Kumpul - Angkut - BuangDocument53 pagesWhat Does It Mean ? Linear & Circular Economy Concept: Kumpul - Angkut - BuangIrvan VerdianNo ratings yet

- Kamber SELFDocument1 pageKamber SELFAbdurrazzaqNo ratings yet

- Tabla de Compatibilidad QuímicaDocument26 pagesTabla de Compatibilidad QuímicaReinaldo UrpinNo ratings yet

- A201 - Building ElevationsDocument1 pageA201 - Building ElevationsØwięs MØhãmmedNo ratings yet

- 0000003221Document3 pages0000003221Ael Ch100% (2)

- Wolfersdorrff Consulting - Tire Technology 2020 - "Tire-To-Tire Recycling - A Global Industry Update"Document13 pagesWolfersdorrff Consulting - Tire Technology 2020 - "Tire-To-Tire Recycling - A Global Industry Update"Martin von WolfersdorffNo ratings yet

- V-41112 Pi PDFDocument1 pageV-41112 Pi PDFVivek VNo ratings yet

- 188 2819 STR DRG RWB 10+455 Sub 02 2Document1 page188 2819 STR DRG RWB 10+455 Sub 02 2ashish kUmarNo ratings yet

- General Specifications: Model CA51/ CA71 HANDY CAL CalibratorDocument6 pagesGeneral Specifications: Model CA51/ CA71 HANDY CAL CalibratorgokulrajeNo ratings yet

- HDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesDocument8 pagesHDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesRozaq Alfan WNo ratings yet

- APT3200 ManualDocument46 pagesAPT3200 ManualRozaq Alfan WNo ratings yet

- Function RGBDocument7 pagesFunction RGBRozaq Alfan WNo ratings yet

- Eas KLS GNP1213 WP PDFDocument8 pagesEas KLS GNP1213 WP PDFRozaq Alfan WNo ratings yet

- NASA: 180557main ETM Rock FactDocument1 pageNASA: 180557main ETM Rock FactNASAdocumentsNo ratings yet

- GenChem2 - Q3 - Mod4 - Rate of ReactionRate of Law and Catalysis - v4Document6 pagesGenChem2 - Q3 - Mod4 - Rate of ReactionRate of Law and Catalysis - v4Артем МонтерейNo ratings yet

- Electrical Properties of SolidsDocument54 pagesElectrical Properties of SolidsAnthonio MJNo ratings yet

- 6th Edi. Plant Physiology by Lincoln Taiz, Eduardo ZeigerDocument888 pages6th Edi. Plant Physiology by Lincoln Taiz, Eduardo ZeigerCherry Einsthyl Arenas71% (14)

- RearrangementsDocument64 pagesRearrangementsBandita Datta50% (2)

- Extension of The Stöber Method To The Preparation of Monodisperse Resorcinol-Formaldehyde Resin Polymer and Carbon Spheres. - Liu Et Al.Document5 pagesExtension of The Stöber Method To The Preparation of Monodisperse Resorcinol-Formaldehyde Resin Polymer and Carbon Spheres. - Liu Et Al.Ion NeagaNo ratings yet

- Supplementary Laboratory Activity - Analysis of ProteinsDocument4 pagesSupplementary Laboratory Activity - Analysis of ProteinsEthel May AlabastroNo ratings yet

- Mind Map MinorDocument43 pagesMind Map MinorAliia HamdanNo ratings yet

- 10 1006@fstl 2001 0820Document6 pages10 1006@fstl 2001 0820SUBHADIP MANIKNo ratings yet

- 0620 s05 QP 6Document12 pages0620 s05 QP 6Varun PanickerNo ratings yet

- 26 TH MRNG Paper by VedanthuDocument34 pages26 TH MRNG Paper by VedanthuSaviiNo ratings yet

- Astm A514 GR SDocument9 pagesAstm A514 GR SMario GaytanNo ratings yet

- Classification Tests For Hydrocarbons Using Solubility, Ignition, Nitration, Baeyer'S Test, Bromine Test and Basic Oxidation TestDocument5 pagesClassification Tests For Hydrocarbons Using Solubility, Ignition, Nitration, Baeyer'S Test, Bromine Test and Basic Oxidation TestKyle Guzman100% (1)

- Hydrolysis 2016Document20 pagesHydrolysis 2016Kashish ParmarNo ratings yet

- Point Defects in SolidsDocument37 pagesPoint Defects in SolidsSachi SinghNo ratings yet

- 214 Lab-Exp 5 2021Document20 pages214 Lab-Exp 5 2021Rahaf ZaitounNo ratings yet

- Technical Circular: 0199 - 99 - 2105 en 4th ExchangeDocument6 pagesTechnical Circular: 0199 - 99 - 2105 en 4th ExchangealexanderNo ratings yet

- Detoxification of Hazardous ChemicalsDocument1 pageDetoxification of Hazardous ChemicalsBalaji Prasanna Kumar100% (2)

- Titration (Chemistry Experiment Report)Document7 pagesTitration (Chemistry Experiment Report)JasgeoNo ratings yet

- Bud162005 Workshop1 WaterlessdyeingtechnolgyDocument61 pagesBud162005 Workshop1 WaterlessdyeingtechnolgyRohan PhelanNo ratings yet

- TDS - Atmer 163Document2 pagesTDS - Atmer 163Aprie SubektiNo ratings yet

- Washing Powder FormulationDocument4 pagesWashing Powder FormulationDeogracious Chawira71% (7)

- Ultrasonic Welding of Platic and Polymeric CompositesDocument21 pagesUltrasonic Welding of Platic and Polymeric CompositesUmesh ManoharNo ratings yet

- Water StopperDocument6 pagesWater StopperMF YousufNo ratings yet

- 14.3 and 14.4 WorksheetsDocument16 pages14.3 and 14.4 Worksheetssam playz08No ratings yet

- Accepted Manuscript: Moringa StenopetalaDocument50 pagesAccepted Manuscript: Moringa Stenopetalaimran shaukatNo ratings yet

- Determination of COD From Supplied Sample.Document3 pagesDetermination of COD From Supplied Sample.Anonymous G304U86No ratings yet

- 214 Lab-Exp 5 2021Document20 pages214 Lab-Exp 5 2021Rahaf ZaitounNo ratings yet

- Lecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsDocument75 pagesLecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsUtsho DasNo ratings yet

- ChemistryDocument7 pagesChemistryUttam RajNo ratings yet